I have seven months to pull off the daunting task of building an entire World War II Jeep — with a new frame, new body, new engine, and pretty much anything else I can buy new from eBay — in preparation for the off-road trails of the 60th Easter Jeep Safari in Moab, Utah. Here’s my initial plan for how I’m going to pull this off.

So, first things first: I have purchased an entire body and frame from eBay. These (especially the latter) represent the backbone of the World War II Jeep; they are the proverbial Christmas tree that I can now begin decorating.

So let’s go step by step.

Buy Some Literature

Though I’m quite familiar with flat-fender Jeeps (having owned a CJ-2A and CJ-3B), I am going to resist the urge to just jump right in without looking, so to speak. No, a World War II Jeep is a more complex machine than the civilian flat-fender Jeeps I’m used to, and understanding how they go together is something I should spend time on.

I’ve purchased the book “Building a WWII Jeep,” shown above, and I have a few other WWII Jeep books already on my bookshelf (plus some great government-issue ones I’ll be receiving soon); I’m looking forward to seeing step-by-step instructions on how to complete this rather ambitious project.

Get The Chassis Rolling

Step one is: I need to get the frame you see above rolling. That means I need to get a pair of axles, some leaf springs, and some leaf spring shackles. That’s job one: I have to get this thing to the point where I can roll it around. Plus, the axles represent the final part of the drivetrain, and building backwards from them — to the driveshafts, transfer case, transmission, and ultimately the engine — makes tons of sense.

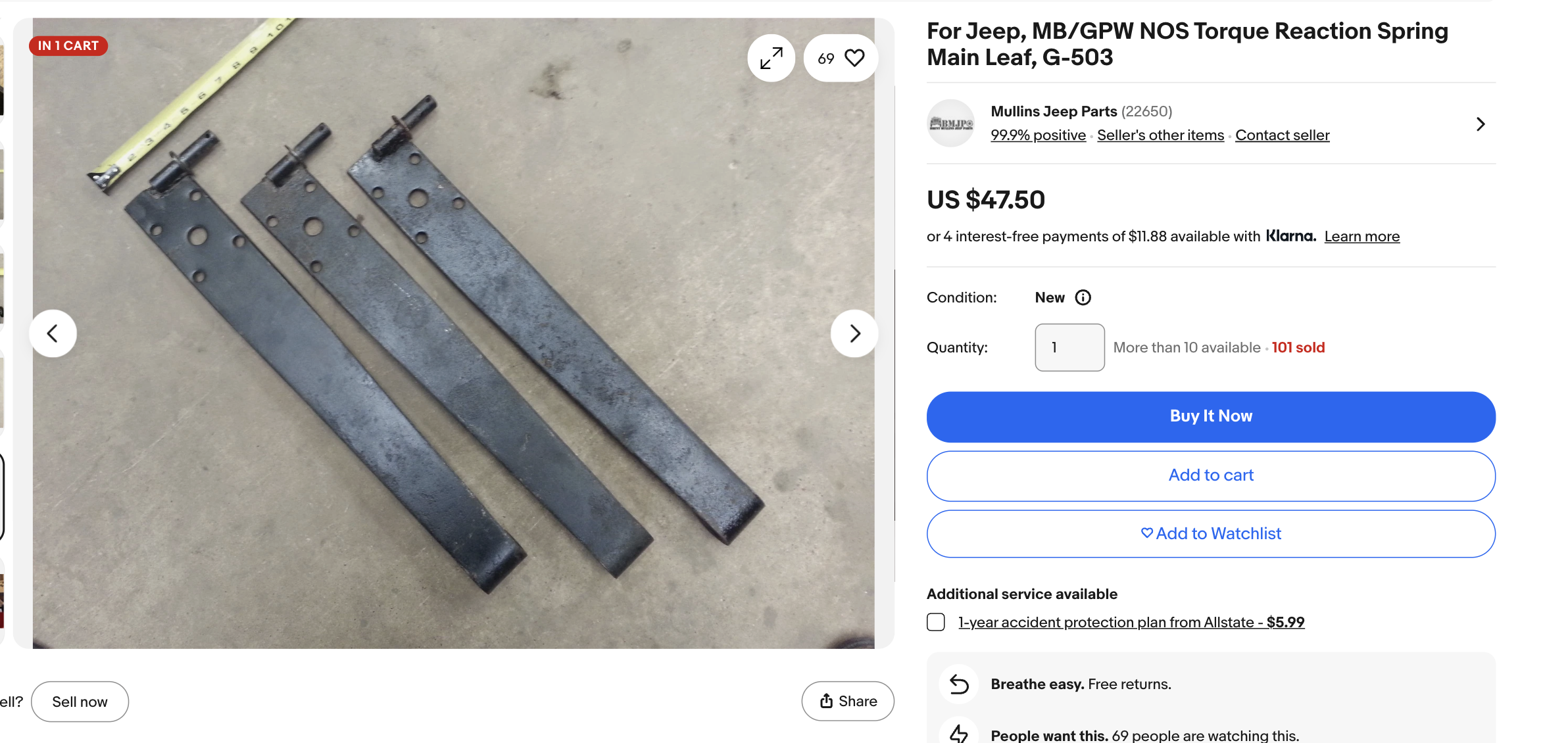

To pull off step one, I need to buy some leaf springs, shackles, shock absorbers, wheels, and tires, all of which are easily purchase-able on eBay. I also have to buy what’s called a “Torque Reaction Spring,” which is just a stiff metal bar that’s meant to mitigate the World War II’s inherent tendency to turn under braking due to the rather funky steering bell crank-on-axle-housing design — something I covered a number of years ago in an article.

Check this out; I can buy a New Old Stock one right here on eBay from a College Station, Texas-based seller named Mullins Jeep Parts:

So the springs and shocks and shackles should be no big deal, but what could be a problem is the axles. Nobody makes new axles for World War II Jeeps, and finding New Old Stock ones isn’t going to happen, since they’re big and bulky and nobody wanted to store them for 80 years. Ditto on transfer cases.

So I need to find a used set of axles and a transfer case somewhere. And that brings me to this…

I Need A Parts Car

While I plan to use as many new parts as possible, I will not be able to find every tiny piece brand new. To have a vehicle that I can reference and snag a small part or two from is going to make this project go much, much faster.

I have a few friends in the Jeep community who are working some magic to put me in touch with someone who might have a rotted-out World War II Jeep they might be able to sell me for cheap. We’ll see how that goes.

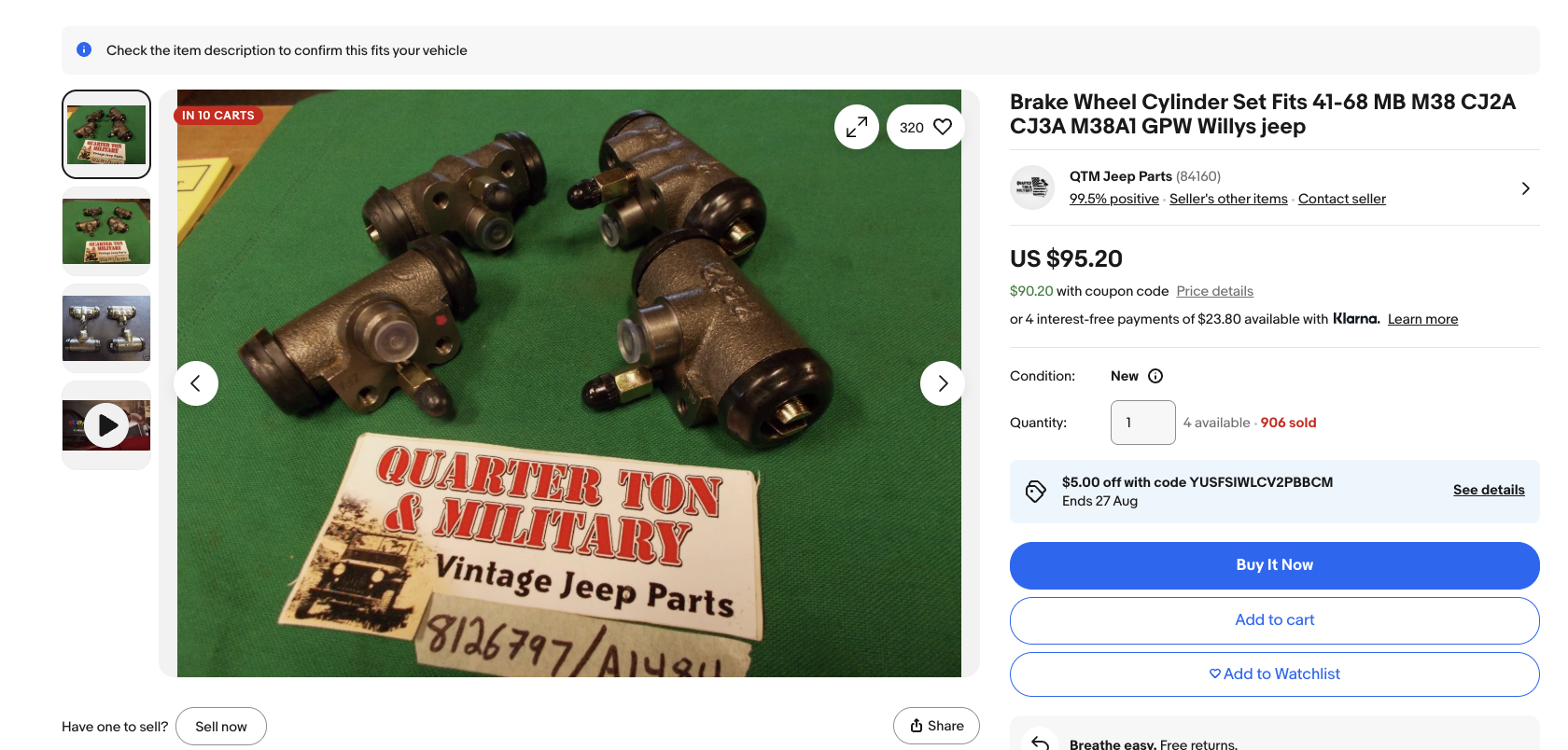

Next I’ll Do The Brakes And Steering

I want to get the chassis to the point where I can easily maneuver it around my driveway or tow it to a friend’s shop (Fred Williams) for some weekend fun, so I’ll install new wheel cylinders (see above), brake shoes, brake hardware, brake lines, a new master cylinder, and a new pedal. Then I’ll bleed the brakes. This is a job I did recently on my 1954 Willys CJ-3B, so it shouldn’t be too challenging, especially with the body out of the way.

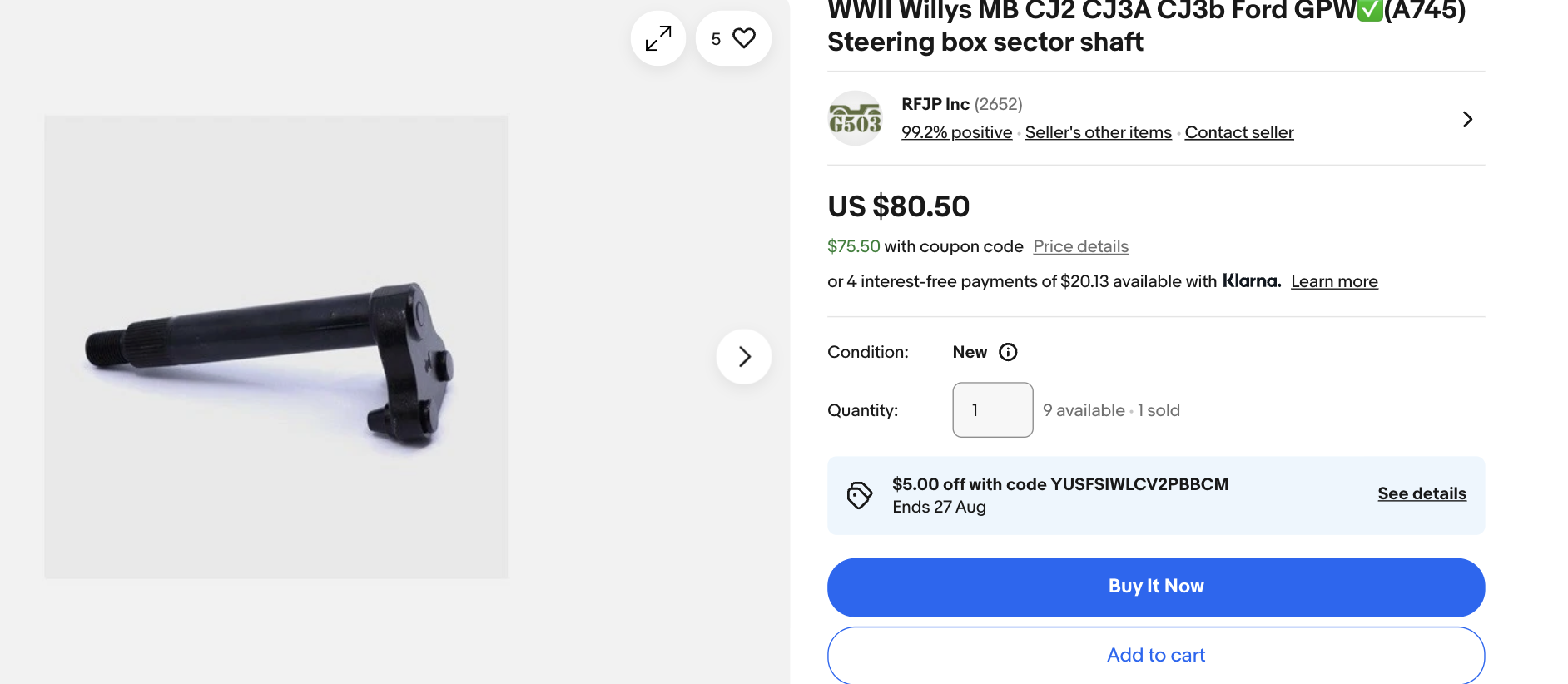

I’m not sure that I can actually buy a new steering box, so I’ll have to rebuild an old one using a new sector shaft and some new bushings. Once the chassis in on a suspension, and it can steer and brake, then it’s time for the drivetrain.

Drivetrain, Then Engine

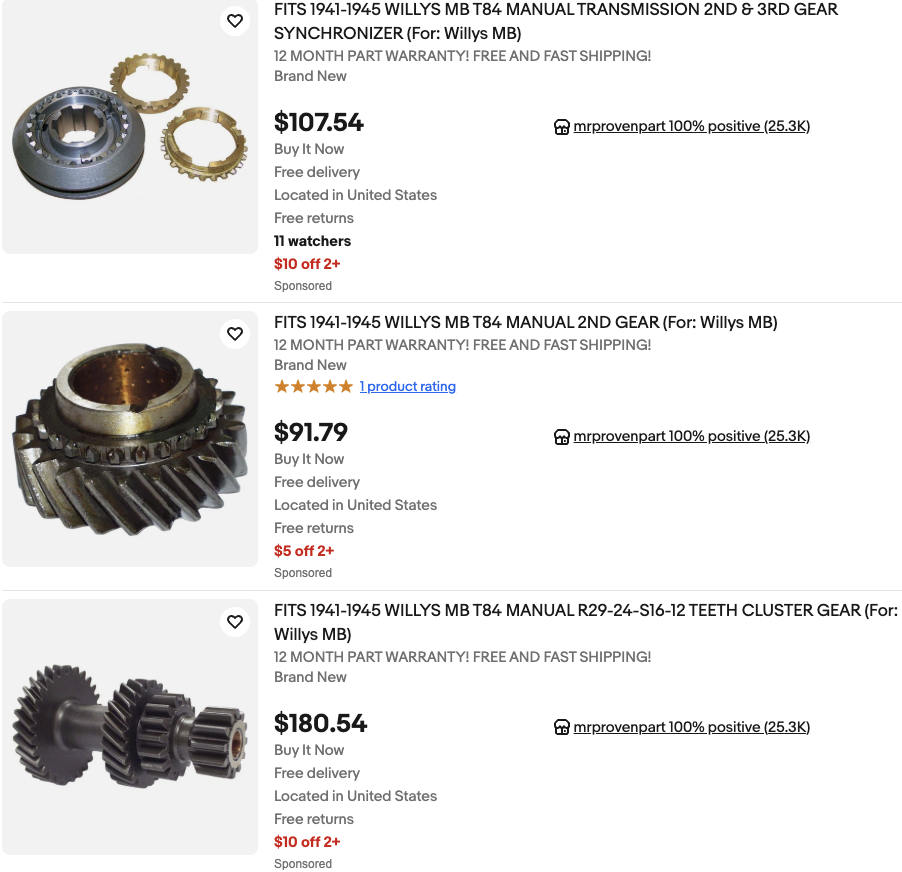

My goal is to bolt up the driveshafts, transfer case, and transmission prior to installing the engine. Of course, I won’t simply be “bolting” anything on; I’ll replace as many guts as I can – gears, bearings, synchronizers, etc. I want the Jeep to be as new as possible. If I can find a new transmission, I’ll see about buying it; if not, I’ll just swap out the guts, as they’re readily available.

When I have the brakes and drivetrain all bolted up to the rolling chassis, then I’ll start on the powertrain. That’s going to be a huge job.

One can purchase a new Go-Devil engine block with pistons, but on top of that, I’ll need a crankshaft, camshaft, lifters, valves, seals, an oil pump, a carburetor, an intake and exhaust manifolds/exhaust pipe, water pump, radiator, timing gears, generator, and on and on — this is not trivial stuff, and it’s going to be very time consuming to put it all together.

I have to make sure all the clearances on the new block are on point, that all the bearings caps are tightened just right, that all the seals are installed properly, that mechanical timing is right, and on and on. I could see the powertrain alone taking an entire month.

Painting

Once I have the engine running, and the vehicle driving quietly via a nicely rebuilt transmission and an exhaust, it’s time to do some painting. While typically I’d never try to paint car on my own — it is an art after all — a friend of mine tells me that Olive Drab paint is quite easy to spray and rather forgiving. So I’ll need to buy a big tent, a spray gun, a compressor, and a bunch of OD Green. I’ll spray the chassis down (blocking the tires off to avoid them getting painted) and I’ll paint the body panels separately so I can get the bottom of the tub before I install it onto the chassis.

It’s Time To Mount The Body Panels

Once I mount the body to the chassis, I’ll permanently install the steering column, throw in the gauges, fasten up the shifters and shift boot, bolt in the fuel tank and seats, put some glass in the windshield before bolting it to the tub, install the spare tire and jerry cab, and on and on. This phase of the project is very, very far out, though I could see myself doing a test fit so I know if I need to make any small modifications to the body prior to decking.

This Only Works With Great Project Management

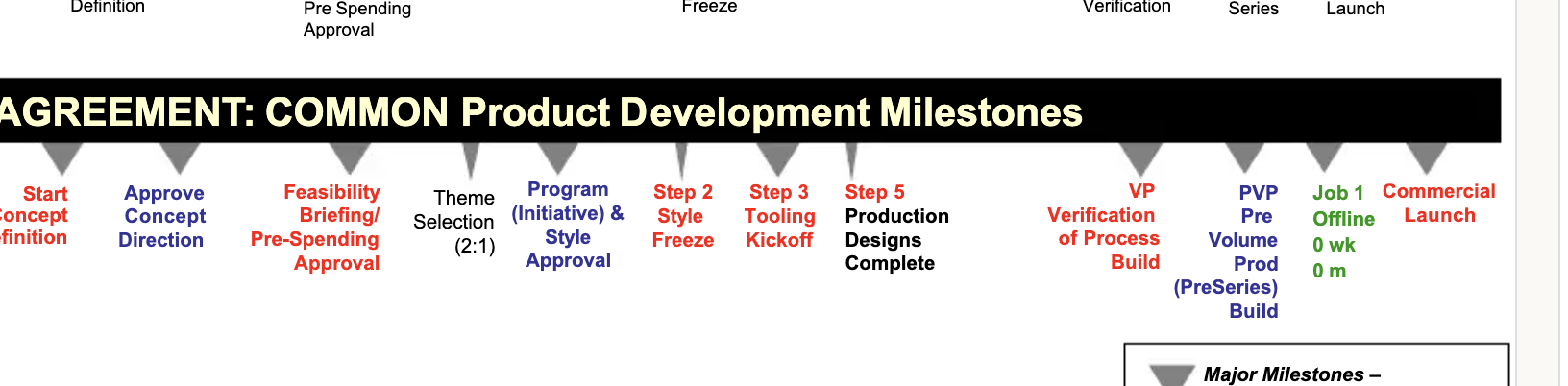

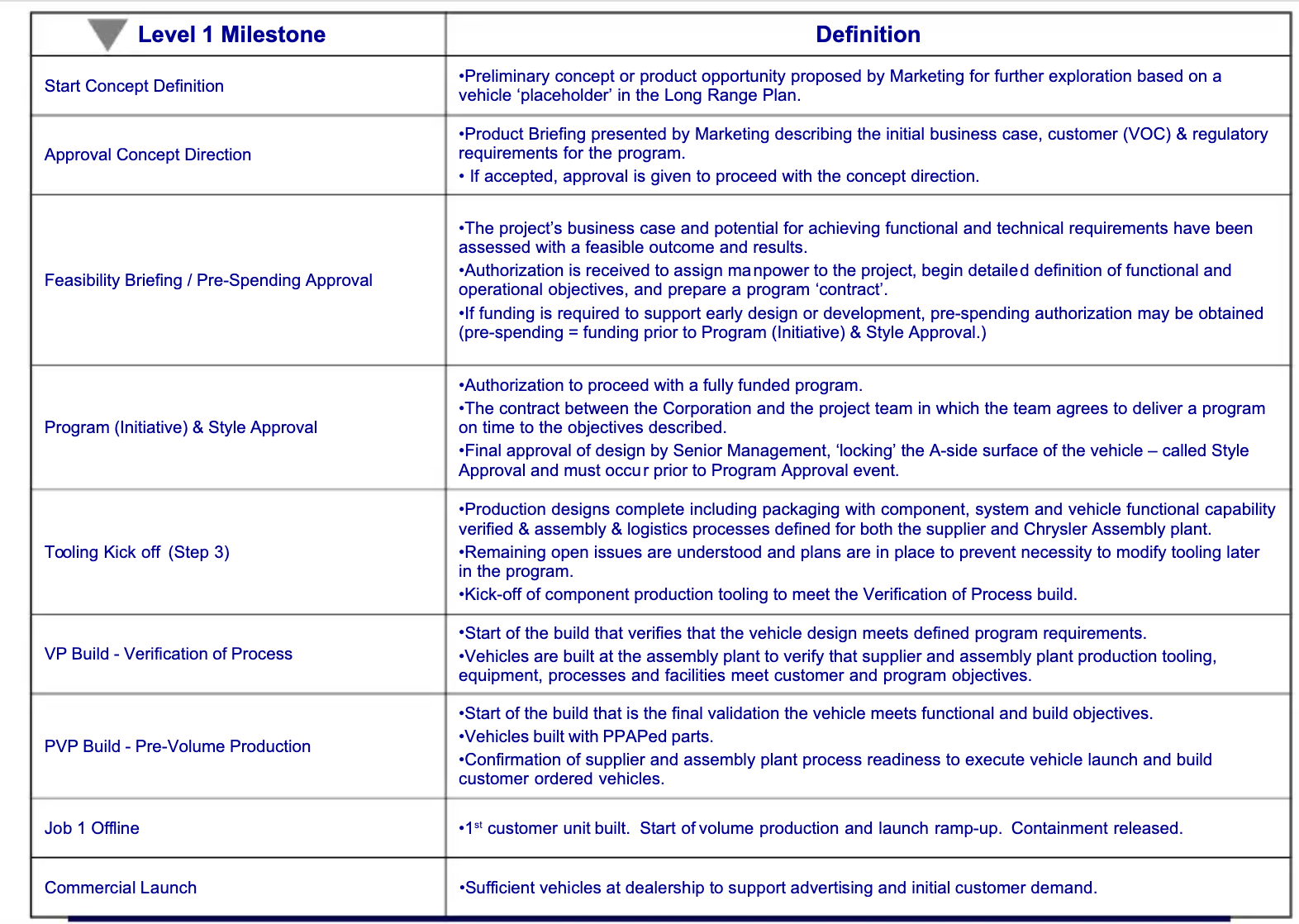

I’m building a spreadsheet that’s going to track progress. My plan is to manage the build similar to how Chrysler used to manage its vehicle programs when I worked there — via various milestones called “steps.” At Chrysler, these were called “CAD Steps,” because they involved determining the maturity of the vehicle’s CAD (i.e. packaging); in my case, I won’t be using CAD, but I’ll come up with equivalent milestones.

As you can see, the big milestones are Feasibility Briefing (called Fies Brief), Step 2 (style freeze), Step 3 (tooling kickoff), Step 5 (production designs complete), VP and then Job 1. Job 1 is, in my case, the Easter Jeep Safari; that ends on April 5 — Easter, so I need to be there by April 3, meaning I should leave no later than the 1st. VP-builds will happen by March 5 — that’s when I need a running, driving machine. As for the other steps, I’m just going to redefine them; here’s my rough schedule.

- Start Concept Definition: Preliminary concept pitched. Complete

- Feas-Brief: Business case and assessment of feasibility. Complete

- Step 0: Create a full schedule and bill of materials (BOM): Sept: 17

- Step A: Chassis rolling on axles/suspension: Oct 15

- Step B: Chassis brakes and steering complete: October 30

- Step C: Parts vehicle attained: November 15

- Step 2: Powertrain complete: December 1

- Step 3: Paint compete: Jan 1

- Step 5: Body Installed: Jan 15

- VP: Early build running and driving: March 15

- Job 1: Vehicle heads to Moab: April 1

I’m still working through my project management spreadsheet/bill of materials, so I’ll be refining a few of these dates in the coming days, but those look about right.

This is going to be a heck of a project.

[Ed Note: David mentioned the idea of building a brand new WWII Jeep to the team at eBay, and they loved the idea so much they said, “How can we help?” Their financial support and David’s Jeep-obsession are the fuel behind this crazy build.]

I’d suggest a publically accessible dashboard to monitor and track progress. Something like monday.com or similar makes nice Gantt charts and allows anyone to view them. That way the whole world can keep you accountable to the schedule. You may also be able to crowd source parts that way.

Why does it have to be original? Why not stay with the “all new” theme, and drop in a turn-key (whatever fits)? That’s an even bigger time saver AND it’s more of a new car.

Also, Fred Williams tie-in? This will be interesting.

David,

I’m sure my idea has already been presented to, or considered by you, but if it hasn’t, here goes.

I would consider reaching out to David Freiburger and/or Rick Pewe, both are flat fender Jeep fanatics, and both (especially Freiburger) are located not far from you. They seem like pretty friendly guys who would be willing to help a fellow Jeep enthusiast out.

It could also be an opportunity for you to further network with other gearheads who have established their own following and platforms, same as yourself.

A cross pollination between y’all could potentially result in some entertaining content for all involved to use for cooperative and self promotion.

I’m just thinking out loud here…

I guess I missed that you have a deadline. One thing I think you will realize, if you make it by the deadline, is that vehicles are a lot more capable now than they were then.