The death of the conventional gearbox wasn’t a murder – it was a mercy killing. The advent of the modern electric vehicle has allowed automakers to shed what is likely the most mechanically complex, costly, and now unnecessary part of a car. Torque converter? Don’t need it. Valve body? That’s black magic. Synchros? For what? 10 speeds? Sounds expensive.

A lot has been written about the slow death of row-your-own gear manual transmissions. I, too, mourn their eventual extinction. But if it’s any consolation, in an electrified future the same fate awaits the traditional slushbox automatic — and eventually, most gearboxes with more than a single fixed gear ratio. This time, though, it’s not millennials to blame for not knowing how to use three pedals. This time it’s the electric motor doing what it does best: ruthless efficiency.

Most enthusiasts know that electric motors (or electric machines, as they are often referred to in engineering circles) produce a lot of torque at low speeds. This is true, of course, but I think the understanding often ends there. What does the torque and power curve of the motor look like, and why? What tricks might automakers do to stretch the limits of a single speed reduction? And when might a multi-gear transmission still be advantageous in an electrified future?

My goal with this article, and perhaps future series, is to demystify some of the quirks of EVs. The average car nerd knows the four strokes of the internal combustion auto cycle by heart: suck, squeeze, bang, and blow. But I suspect that the workings of Maxwell’s equations, which govern what we know about electromagnetism and how EVs move, are more of a mystery.

EVs are often dismissed as soulless appliances, but I don’t think that’s fair. Turning electrons into motion is a choreographed act — a symphony of transistors pulsing current into tightly wound copper coils, conjuring magnetic fields through thin air that tug a chunk of steel and magnets into instant motion. It’s anything but lifeless. Maybe, with a little more appreciation for this, the loss of our right to row our own gears will sting a little less.

[Editor’s Note: Everybody welcome Zero Entropy! He is an auto industry enginerd who is going to impart some of his technical wisdom in the form of regular technical deep-dives! If you have any EV-related topics you’d like him to tackle, please let us know in the comments! -DT].

Understanding the Torque-Speed Curve

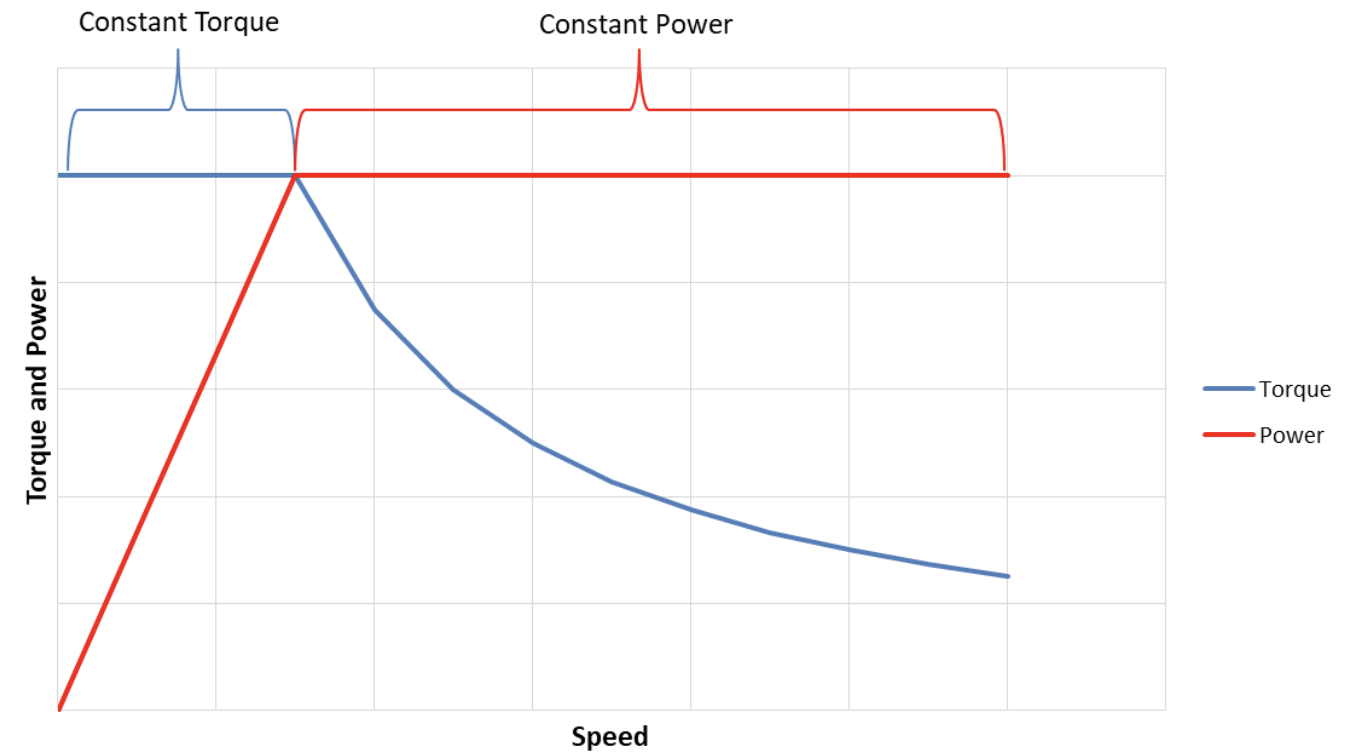

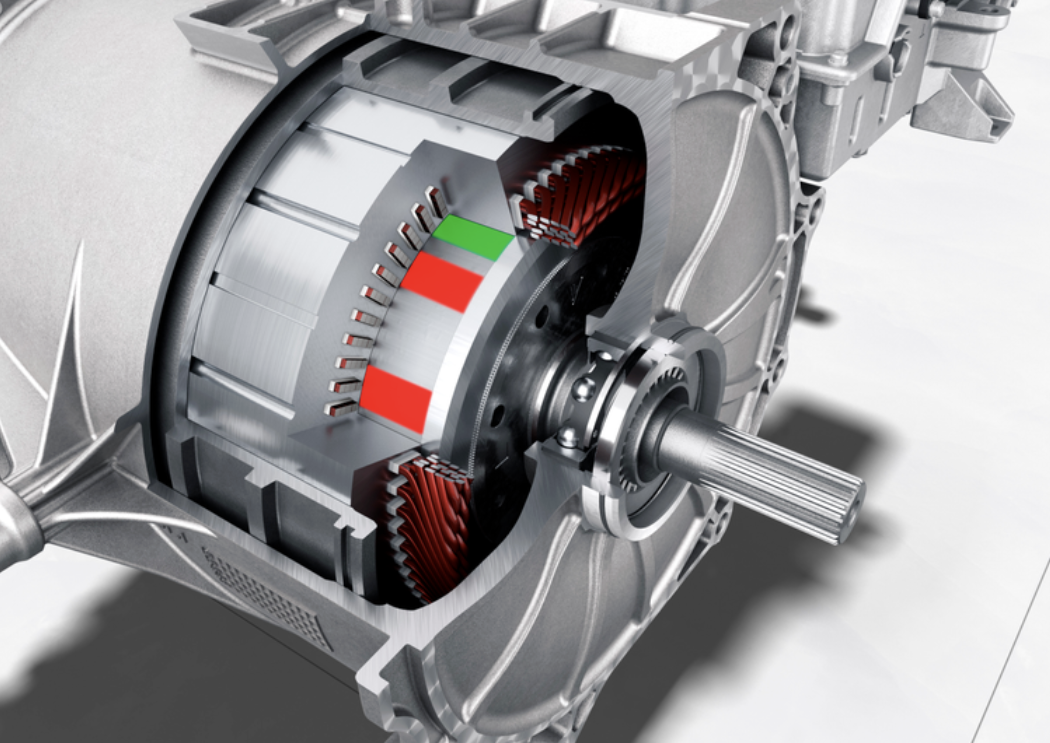

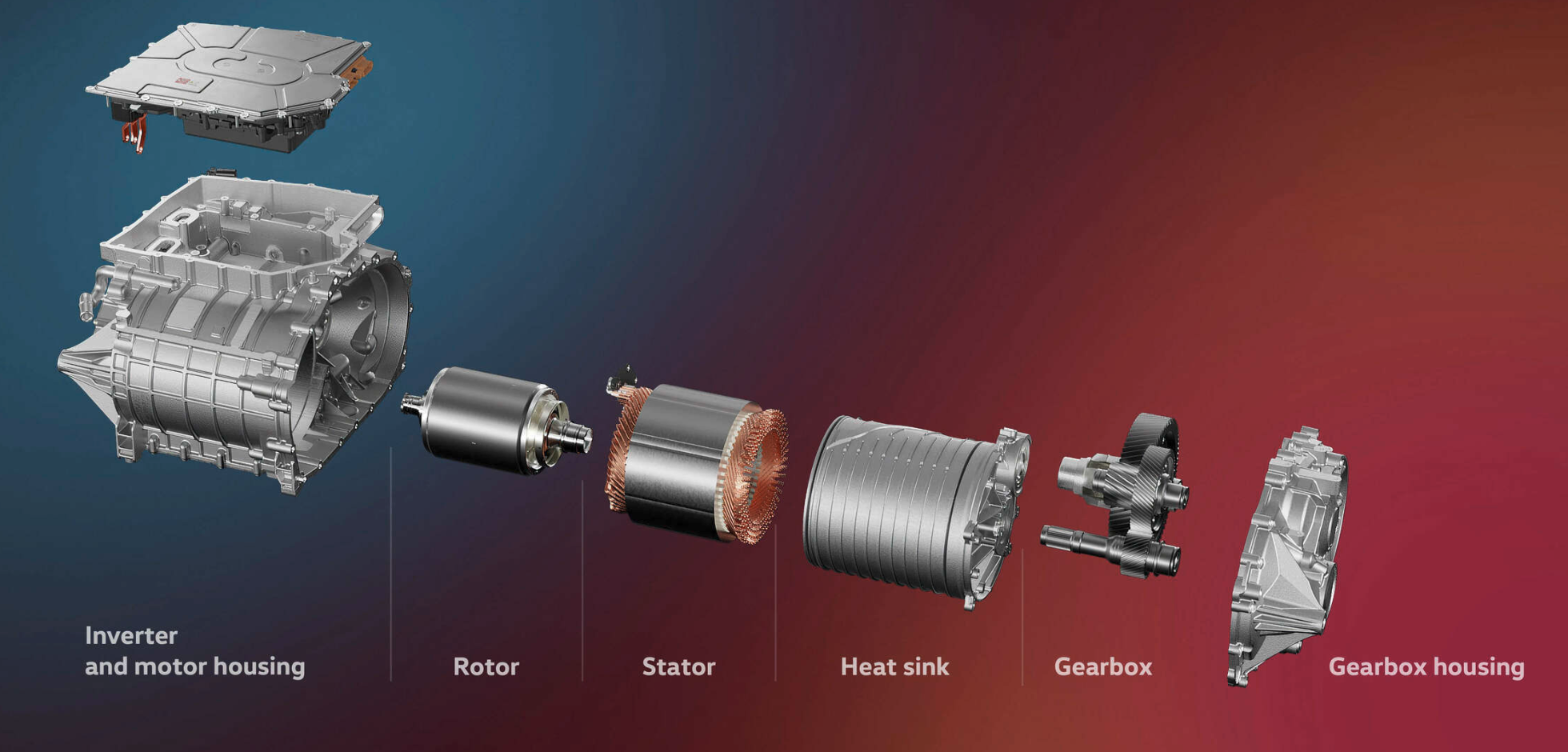

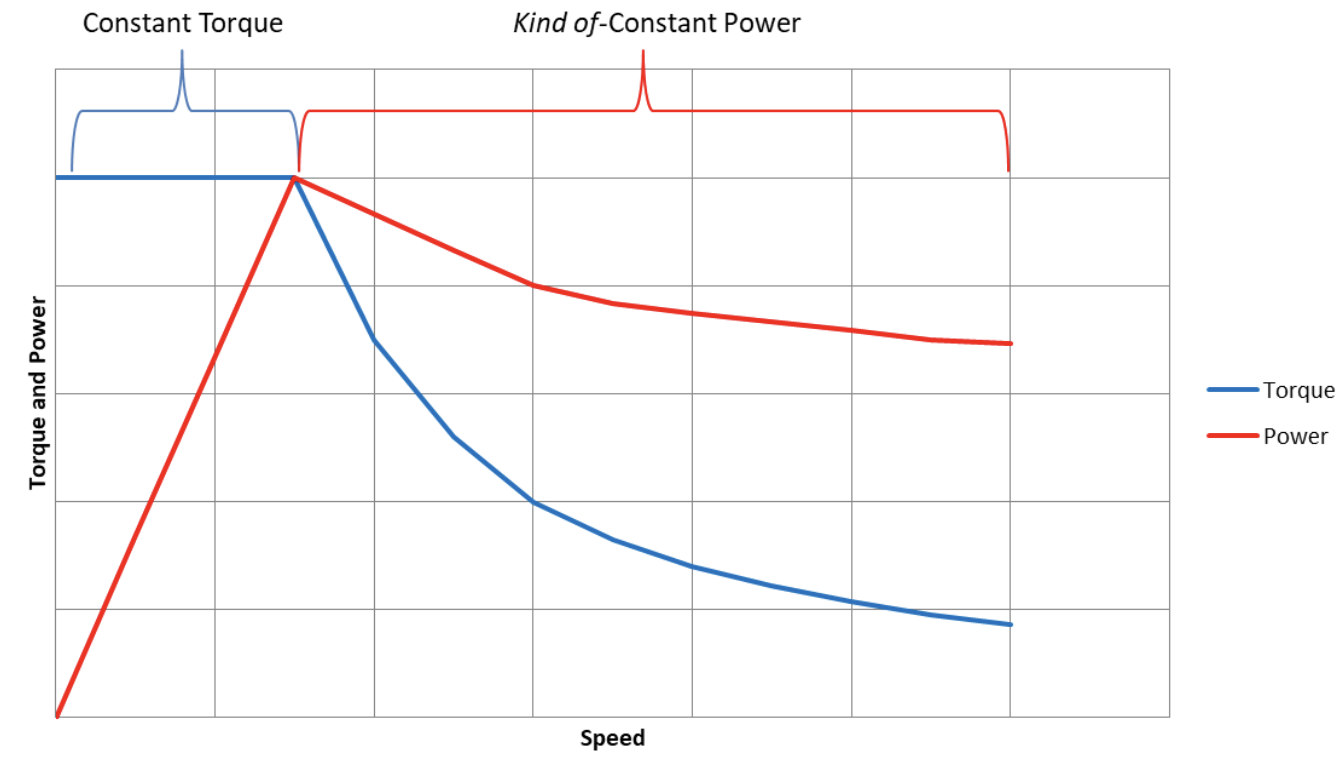

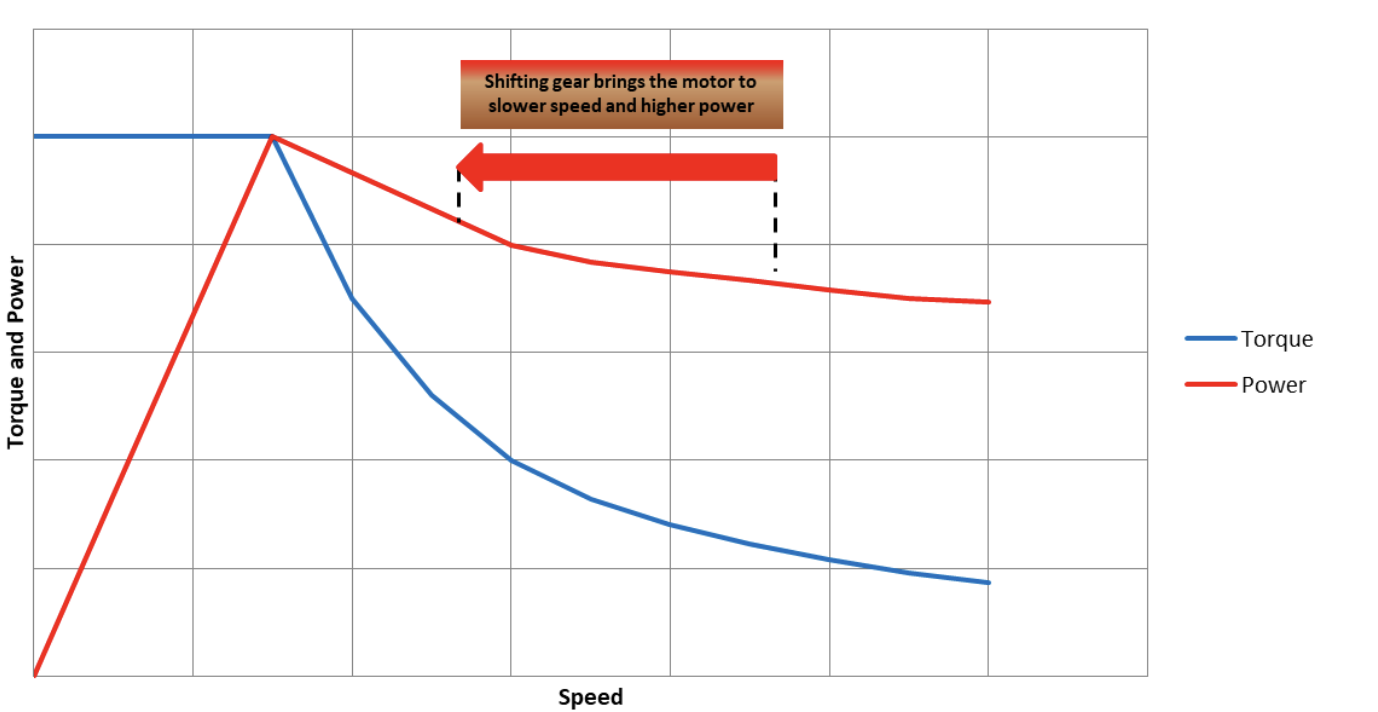

Appreciation for the electric motor should start with an understanding of the torque-speed curve. Most any type of motor found in an EV, be it induction, permanent magnet, wound field, or other will have a similar-shaped torque curve for the same fundamental reasons. Let’s dive into how that curve looks and why it behaves that way. We will use an interior permanent magnet motor as an example because it is the most common type of machine used in modern EVs and hybrids. The torque-speed curve can be divided into two sections: constant torque and constant power.

Constant Torque

If you’ve ever watched some of the viral EV acceleration videos, the ones with an unsuspecting grandma suddenly pinned back in her seat screaming, you know that the main performance aspect EVs excel at is making torque from a dig. It’s true that unlike the combustion engine, an electric machine can make all its rated torque from a stall.

At low to medium speeds, the torque is limited by the current flowing into the motor. The three-phase inverter (the power electronics box that feeds the motor) carefully controls the magnitude and phase of the sinusoidal currents flowing into each motor winding. Think of it like ignition or valve timing in an ICE — the current has to flow at exactly the right moment as the rotor spins.

As you might imagine, more current does equal more torque, but it comes with the same tradeoff every powertrain faces: heat. The inverter, cables, and windings all have some current limit, above which, bad things will happen and happen quickly. This heat does not go up proportionally with torque. The heat generated by a simple electrical resistor is defined by I^2*R (“I” being current, and “R” being the electrical resistance of said component). The squared term is the key here.

But what if we had really good cooling, you ask? Can we crank that Nissan Leaf to 11?! Well, sorry to burst your bubble, but even then, the motor hits an eventual plateau. The steel in the motor is only capable of so much magnetic flux density. When this “saturation” is reached, more current has dramatically diminishing returns. You end up making a heck of a lot more heat and not much more torque.

You might think that automakers, filled with warranty-obsessed bean counters, spec in a lot of safety margin into the peak current and torque limits of the powertrain. In actuality, the motor is usually designed fairly close to saturation levels. Those same bean counters want to get the most out of every bit of steel and copper they paid for. Careful monitoring prevents overheating. Sorry, tuners, there is not a lot of margin to boost your EV project here. EVs might be described by some as appliances, but they are not toasters.

In summary, the “constant torque” part of the torque-speed curve is limited by the current, thermal, and magnetic saturation limits of the motor and inverter system. To increase it costs real dollars: the motor gets larger, copper gets thicker, and cooling capacity increases. But overall performance is more than just low speed twist, what about high speed? To what speed can the system produce this torque, and why does it taper off? In the next sectio,n we will discuss the second part of the torque-speed curve.

Constant Power

Remember how I mentioned that the motor is often referred to as a “machine” in engineering circles? It’s a nod to the fact that the device can act as a generator, too. Understanding this is key to the second part of the torque-speed curve: the constant power region.

As the rotor spins, its magnets generate a voltage in the windings—thanks to Faraday’s law—that pushes back against the inverter’s voltage. We call this voltage back electromotive force or back EMF. It’s like trying to push water through a pump that is spinning the other way. The faster the pump spins, the higher the pressure opposing you is. In this case, the faster the motor spins, the higher this voltage gets. Eventually, the motor spins so fast that the back EMF equals the maximum voltage the inverter can apply (effectively the battery voltage in an EV).

When this speed is reached, the inverter can no longer push current into the motor. We are no longer limited by a maximum current, but rather limited by the voltage available from the battery and inverter at this speed.

The motor has hit a wall.

So how do we go faster? This is through some of the magic of modern controls in the inverter. This transition is referred to as the “Corner Point” on the torque-speed curve.

Beyond the Corner Point, the inverter is doing something called field weakening. Those permanent magnets spinning around in the rotor are producing magnetic flux, which is generating the back EMF that is in our way. To go faster, we need to reduce that flux and reduce the back EMF.

The inverter adjusts the phase (angle or timing of a camshaft lobe if you are thinking like an ICE) of the current so that it actually opposes the magnetic flux of the permanent magnets. Yes, we are using current to make the motor’s field weaker! We’re literally zapping the motor to make its magnets less magnetic. The result of this is lower back EMF, which allows faster speeds, but comes at the consequence of reduced torque.

This is why the torque speed curve looks the way it does.

The inverter can continue to field-weaken to faster and faster speeds. The torque will continue to drop. Power is torque times speed – so as torque falls and RPM climbs, the math works out neatly. The result is a broad, flat plateau of power delivery that feels like endless pull.

Electric motors have redlines too, based on mechanical limitations. The rotor will eventually fly apart at high enough speed from centrifugal forces! But their simplicity and compact design mean they can spin very fast relative to typical ICE found in everyday cars. Modern high-performance EVs are approaching 20,000 RPM. Even the Honda AP1 S2000 tachometer won’t suffice here.

This torque-speed story is why most EVs get away with a single gear. Between stump-pulling torque at zero RPM and that long, flat stretch of constant power to super high speed, there’s simply no need to shift. At any given speed the motor is capable of maximum torque OR maximum power. Shifting gears won’t change that.

Designing for Peak Performance

So is it that simple? There will never be a need for more than one gear?

Not so fast. Multispeed gear boxes won’t be totally dead in an electrified future, but I do think their application will be limited to special applications. Let’s dig into where there still might be life left.

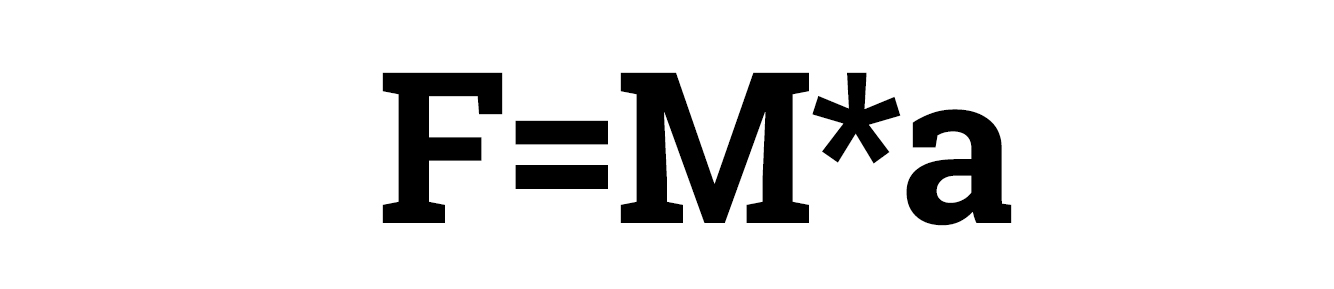

First, we need to go back to high school physics to prove something that may be obvious to some of you: That horsepower is the ticket to quick acceleration. I promise you this won’t hurt that much. Just rearranging two equations to prove the point. First, Newton’s second law. Force is the product of mass and acceleration:

Secondly, the definition of power is force times velocity:

Secondly, the definition of power is force times velocity:

If we do a little substitution, we get the following:

In a nutshell, acceleration is equal to power divided by mass times vehicle velocity. Put another way: for some given speed, the acceleration is maximized when the power is maximized. That wasn’t too bad, right?

Now let’s take that back to our torque-speed curve. This means that once we have gotten to a speed where the motor is in the constant power phase, the gear ratio no longer matters. Shifting gears won’t make it accelerate any quicker since the power is already maximized and constant!

At low speeds, however, gearing still matters. A lower gear (higher reduction) multiplies torque and lets the motor spin faster for a given road speed. Put the same as above, this means greater power is being produced for a given speed, and acceleration is greater.

So the gearing choice only really matters before you hit the Corner Point of the motor performance. In most commercial EVs, this usually happens around 30 to 40 MPH. After that, it’s all peak power.

But here’s the rub: the constant power phase of the torque speed curve isn’t actually so constant in the real world. I lied earlier. Like so many things in life, the reality isn’t the same as the idealized version on paper. Constant power isn’t usually constant.

The degree of drop off varies from motor to motor, but a more typical real-world torque speed curve may look something like this:

For most EVs, their power actually tapers off at higher speeds. This is due to something called power factor and imaginary power. Despite the name, it’s not make-believe. It’s a real phenomenon that has to do with inductance and reactive current. If you want to learn more about imaginary power and other wizardry, you’ll have to sign up for my advanced course. For now, you will just have to take my word on it.

If you’ve watched any of the viral YouTube videos of EVs drag racing some muscle car, you may observe a familiar pattern: The EV jumps out to a quick lead, but then as power tapers off, it gets slowly reeled in by the snarling muscle car. Who wins depends on how long the race is.

This is where a multi-speed gearbox can earn its keep. Shifting puts the motor back toward its sweet spot near that Corner Point where it makes peak power. This is part of the same reason an ICE car needs to shift, but just a lot more subtle because the power in the EV curve is still pretty high across the board compared to an ICE.

The best, and perhaps only example of this in a consumer vehicle, is the Porsche Taycan (and its Audi eTron GT sibling) with its two-speed gearbox. This is a high-performance vehicle, and the two-speed box helps keep the motor in a higher power operating condition, and it allows for some extremely high top speeds that may otherwise exceed the motor’s redline.

The other application I think we could see is some sort of multi-ratio gearbox in specialty off-road variants of vehicles.

We’ve established that EVs make tons of torque at zero or low speeds, so shouldn’t they be perfect for an off-road adventure through Moab? Yes, but the extreme cases still pose a challenge.

Imagine you are trekking over some boulders at an extremely steep angle. You’re inching over an obstacle, and the electric drive motors (presumably two or even four motors) are effectively twisting against gravity in a stall condition. They can make this torque, but heat can build quickly.

Using the motor to hold the car up an embankment is a lot like the first week you were learning to drive stick shift and you got caught in traffic on the steepest hill in town. Your poor clutch had to do the mediation between gravity on one side and an engine you are revving way too high on the other. I can still smell it.

Back to the EV; This is a case where a special crawl gear could be handy. Not because the motor isn’t capable of making the required wheel torque without it, but because it would run a lot cooler if it was geared down more. A greater reduction means the motor can be at a lower torque to make the same wheel torque. Lower torque means less current and less heat.

So in conclusion, while most EVs are perfectly happy with one ratio, there are still a few places — on racetracks and rock trails — where an extra gear or two can up the performance. Maybe the gearbox isn’t totally doomed after all.

A quick note about efficiency and economy: Yes, there is the small potential for a multi-speed gearbox to improve vehicle economy and put the motor in a more efficient operating condition, but any advantage typically isn’t worth the added cost and complexity of a gearbox like that, especially on an economy-focused EV. In general, the electric motor tends to be very efficient across the torque-speed range.

Cool Tricks Automakers Use Instead of Changing Gears

The single-speed transmission is adequate for most EVs as we’ve discussed, but it still has some disadvantages. Automakers have a few tricks up their sleeves to make up for it.

The first is to use different ratios for front and rear motors (in a dual motor AWD vehicle). The rear motor, for example, can be geared lower (greater reduction) to provide maximum acceleration off the line when the vehicle’s weight transfer is shifted most to the rear tires, giving them the most grip.

The front motor will be geared taller. As the vehicle gains speed and the rear motor crosses the Corner Point, its power will gradually drop off, but the front motor will be hitting its stride and is no longer grip limited at this speed. Overall power never fades.

The driver gets the benefit of two different ratios, each optimized for a different vehicle speed, all without shifting any gears!

But the most interesting trick might be what Kia is doing with the EV9. It has been reported that the EV9 has a motor that can switch the way the motor windings are configured on the fly.

Electric motors in EVs almost always have all three phases. Those three winding phases can be connected in two different ways: delta or wye. Illustrated below are the two configurations. The inverter will connect to the terminals A, B, and C and manage the rearrangement.

At low speeds, the motor is configured in wye mode, which generates a higher back EMF. This maximizes torque, but hits the Corner Point and is voltage-limited sooner. Switching to delta configuration lowers the back EMF at the terminals and allows higher speed before hitting its voltage limit. Changing between the two alters the torque-speed curve. It’s like having a two speed gearbox made from transistors, not gears. (See The Autopian’s deep-dive into Kia’s drive unit here).

It’s a reminder that while electric cars may have done away with overly complex mechanical gearboxes (engineering wonders in their own right), they haven’t killed ingenuity. Car people love complexity; carburetors, pushrods, turbochargers, and all the drama that comes with it. I think a lot of that love comes from seeing all these complex mechanical things in motion. With an EV, it’s a different dance that is more invisible, but one that I think is just as fascinating.

Top graphic images: BMW

Good stuff. We have a PHEV that shifts (BMW 330e) when running in electric mode and it’s so weird after coming from a Gen 1 Volt. The Volt was much more efficient in electric mode, but the 330e seems to make due with a much smaller electric motor. It’s interesting to see the different ways that manufacturers take on the new challenges.

I suspect that part of the reason it shifts is so that it’s already in the right gear when the ICE turns on, rather than just increased efficiency.

I have a 330e and that’s my speculation as well

The electric motor is mounted within the 8 speed ZF transmission between the flywheel and gearbox and it eliminates the torque converter. So the electric motor needs to use the same transmission ratios as the gas engine. It’s a very different approach. But I find that I really struggle to get over 3 miles per kwh. It is a X-drive model though, so I’m sure that hurts efficiency too. I could get over 4 miles per kwh with the Volt if I drove carefully.

My guess is that most of the Volt’s advantage comes from its optimized aerodynamics, especially if the 330e has very open, wide, draggy wheels.

I think the designers need to add choppers in the control circuitry.

I present to you the signature Montreal Metro sound: https://www.youtube.com/watch?v=E5WSYBDueVA

Maybe the team at Alfa Romeo could due it in a electric version of the Montreal.

doo-dooo-doooo!

Or the signature TTC subway sound for many years for the H5 subway trains which were the first TTC subway trains to have chopper controls and regenerative braking:

https://www.youtube.com/watch?v=oS87ZB7tWZ8

You kid, but this has been a possibility for about 15-ish years. Because the semiconductors in modern inverters switch at ultrasonic speeds (15-20khz if not higher for smaller ones these days), you can audio modulate the motor by essentially overlaying an audio signal (on the order of 10s to hundreds of Hz) into the control signal. Because what is a motor but a bundle of wires and magnets? Turn your whole driveline into a transducer!

Reference: https://www.youtube.com/watch?v=7BQ9lei_24Y

https://youtu.be/l12JMohNEv0?t=104 with a current-generation hobby-tier inverter.

Thanks for the links!

“Why do I have to take high school algebra? It’s not like I’ll ever use this stupid stuff again.”

Sunofabitch….

And high school physics.

You give me too much credit. I didn’t take physics in high school.

My kids would tell you that physics hadn’t been invented yet when I was in HS…

My kids say I discovered relativity by observing light bending around me….

To be fair, most engineers don’t use this stuff either 🙂

I have a BIL and some nephews who are engineers. I think they are basically “project managers” at this point.

That has been my experience over the last 30 years. My most engineering heavy job was when I was in aerospace and even then MAYBE 30% of my time was engineering based. I’ve been a corporate manufacturing engineer for an automaker for the last 10 years and now maybe 5-10% of my day is engineering. Far too much of it is accounting. I hate accounting.

Same here. I’m an engineer on paper for my role in building automation and controls. However, the last 10 years I’m basically an accountability baby sitter making sure things get done, compiling ROI, cheerleading, and driving adoption. I miss some of the real work but the paper is better over here. Such is life.

I wish I had been homebrewing in high school. The stuff I know about biology and chemistry now…

This was a great article, loved every word.

Thanks, Eric. I hope to do more like this!

I/We do, too.

Interestingly even though the all wheel drive HKG E-GMP (think EV6, Ioniq5/6 etc) platform has single speed gearboxes in the front and rear, the front still has a clutch because it can disconnect and spin down the front motor when its not needed. I’m not sure how much energy it actually saves, but presumably eliminating the drag losses in the reduction gearing and the winding losses in the motor/controller provides some reasonable increase in overall milage.

Great observation.

A permanent magnet motor has a little bit of drag when it is “off” and just freewheeling.

A clutch is one solution, but another is to use a induction motor as the secondary drive. It can freewheel without any cogging torque.

Most if not all AWD EVs use a clutch for one of their axles, unless they use an induction motor which has less drag than PMSMs when clutched in. I want to say the PMSM+clutch solution is becoming more dominant lately but I’m not sure.

Yeah- Tesla started with induction motors, but seems to have generally shifted to permanent magnet and hybrid reluctance motors instead. As I recall induction motors are somewhat lower efficiency though that can be drive cycle dependent. Think the key weakness though was rotor cooling. As there has to be significant current flow in the rotor to generate drive forces, there’s significant I2R heating. Getting sufficient cooling to the rotor is a major engineering challenge. To some extent that was the Achilles heel of the early model S- it was great for a few hard pulls, but in a track day situation the car would rapidly derate due to rotor temperature.

Loved the article. As another commented mentioned, I’d like more info on regen braking. I know it’s not super efficient; I’d like to know why, and what progress looks like in that area of research.

Regen is very efficient from the motor’s perspective! Still can be +90% efficient, just as motoring is.

Perhaps what you mean is that doing regen instead of coasting is wasteful. That is indeed true!

Your second comment here is worthy of expansion – I see a lot of EV owners (primarily Tesla drivers) who insist that OPD with regen is more efficient than coasting modes. I drive an Audi SQ6 that can do it both ways, and my own testing shows that D mode (with coasting) is better. I once ran across a car magazine article (Car&Driver?) exploring this.

I very much enjoyed this piece and look forward to more from you.

For sure. Different automakers treat what the brake pedal does differently.

In a Tesla, pushing the brake pedal engages the friction brakes, but in most other EVs, its still 100% regen unless you brake very hard.

Regardless, if you brake and then speed up when you could have coasted, that is a waste. So it all depends how you drive in OPD mode.

Great article, thanks. I thoroughly enjoy ripping my 2019 Leaf at 9/10ths most of the time while not being unsafe or even noticed by other traffic. My questions are mainly about practical use of EVs. 1) I have great mechanical sympathy for the ICE cars in our fleet, but none for the Leaf. Am I correct that strong acceleration and short trips that don’t get to operating temperature, whatever that may be, doesn’t really matter for EVs? 2) Is a one-pedal driving mode more or less efficient than other modes? Relatedly, in a regular mode, why is regenerative braking so tepid. Is this for braking smoothness, lazy Nissan engineers, or something else?

I’m also curious about improvements in battery chemistry and cooling technologies that are coming down the line.

I experimented over time with my Bolt and our Leaf with the one-pedal thing and it seems to me that it’s mostly gimmick. Yes, regen recovers some energy, but the one-pedal increased regen was almost counter-productive in the Bolt. I no longer use it in regular traffic, but at a drive-through or in stop and go traffic it’s nice.

For those EVs, even pushing the brake pedal is regen braking. So it shouldn’t make a difference. Just a preference thing.

If you brake very hard is when the friction brakes engage.

When I bought my Bolt in July of 2019, on day two I said “let me try this one pedal driving mode to see what it is about”. I have literally never NOT used it ever since. It has transformed my relationship with driving in Chicago.

Thank you, Echo Stellar.

I personally love one-pedal. I try to drive the same as I would without it, so it makes no difference.

I would add/argue that the ability to quickly coast/freewheel/declutch is valuable in winter driving, especially skid control.

You can maximize regen braking just as well as in OPD mode as long as you’re given the right tools and know how to use them, but OPD likely makes it easier for the inattentive and uneducated common consumer. My Ford hybrid has a ‘braking coach’ display in the gauge cluster which shows how close you are to hitting the max regen limit before having to blend in some friction brakes, and it decreases with speed and at high battery SoC. Because I pay attention to it, I’ve learned how to brake to maximize regen without needing OPD.

The regen braking on the gas pedal in either regular mode or OPD is just a difference in throttle map tuning trying to feel a certain way, so one’s not inherently more efficient than the other. Regen braking in regular mode is weaker to feel natural to an incoming ICE car user who’s used to light engine braking rather than unhindered coasting.

Regenerative braking is tepid in regular mode to make it feel more like a gasoline car’s engine braking for those transition to an EV from an ICE.

Same reason that some EVs creep when the brake is released.

This is why simpler hybrids are going to take over the mass market from DI gas turbos mated to 8 – 10 speed autos.

Better experience and way more reliable.

Great work! Give us more!

Could you possibly explain why BEVs seem to not be compatible with things like buttons, knobs, mechanical door handles, simple glove box latches, manual air vents? Is it in the motor winding?

I, too, lament the death of buttons!

Wow, this is great info! I’d really love it if at some point this expert could explain how regenerative braking is managed/modulated. I’m a technical training instructor for a well-known automaker, but none of the literature that I have ever seen has explained HOW the system varies the charging output of the electric machine. We teach about the braking system – the input from the brake pedal (and/or other inputs) and the blending of friction braking with regen is not a mystery. But how does the system vary the charging output of the e-motor?!?

Great question. This topic does deserve its own article too.

In short, regen is controlled the same way that positive motoring is controlled: by modulating the magnitude and angle of current into/out of the motor.

The transistors in the inverter you should think of as bi-directional switches. Controlled appropriately, the inverter is capable of allowing current to flow either direction.

A deep dive into “field oriented control” (the basis of most EV motor controls today) would be quite a lesson, but one I’m up for!

Observation: older EVs have have much higher torque ratings than modern EVs.

Example: Chevy Spark EV (400 lb-ft) to Chevy Bolt EV (266 lb-ft) to upcoming reincarnated Bolt (169 lb-ft)

I infer this reflects engineering evolution behind the scenes. What is going on and can it be explained with concepts covered in this lesson?

As a practical matter, I would also like to know where this is likely to go in the future. Whether it is “Don’t worry about those misleading numbers, it’s still the same driving experience” or if we’ll end up with “This custom EV built in 2035 has the motor of a 2013 Spark EV, before they took all the fun out of EV motors.”

I am curious about this too, but I can tell you if you’ve never driven a Spark EV, it’s a hoot.

This is a really good observation. When GM came out with the spark, it was a bit perplexing why the motor was so high torque. I can’t speak to their logic, unfortunately.

In the motor world there is a saying: “Power is free, torque is what you pay for”. It basically means that to get higher torque, the motor has to get bigger. That costs real money.

But to get higher power, it just needs to have a higher voltage applied to it (pushes corner point to faster speed) and spin at a faster speed. From the motor stand point that is “free”.

So yes, it would seem the Spark EV motor could have been cheaper if it were designed smaller and geared down more to compensate.

The spark was a bit of an unusual setup, think GM was playing around with packaging optimization. The motor was actually coaxial to the drive shafts, and used a ~3:1 planetary reduction that was somewhat wrapped around the differential. I think the motor ended up having a much larger diameter than might otherwise be used in order to fit the drive shaft through. End result was a motor with a much lower top RPM, but much higher torque to compensate. Was great fun to drive in the city, and could hold its own on the highway.

Some explanatory pictures:

https://endless-sphere.com/sphere/threads/2014-chevy-spark-100kw-permanent-magnet-motor.58465/

I suspect having lower peak torque saves money in other areas as well… such as how beefy the CV axles, motor mounts and related bits need to be to handle that peak torque.

The Spark EV had 3 different motor / battery combinations in its short life and low volume (about 6500 total). My 2016 Spark EV dropped down to a 327 lb-ft motor but changed the gearing to give the same torque at the wheel as the earlier versions with a 400 lb-ft motor. It was a wild car and would spin the wheels up to about 30 -35 mph at will and basically dangerous in the snow or heavy rain. Massive torque steer too and the car would zig-zag back and forth in the lane as the wheels took turns gripping or breaking traction. That said it only went 0-60 in 7.2 seconds despite the small size and light weight.

Today I have a 2017 Bolt EV. It is a much better vehicle all around and also faster despite the extra weight. 0-60 in 6.5 seconds.

Both the Spark and Bolt EVs were let down by absolutely horrible stock tires. The Spark came with Ecopias and the Bolt Michelin Energy Savers. I swapped both to performance all-season which made a big difference.

2016 Spark EV

140 hp

327 lb-ft

350V Battery

19 kWh Battery

2866 lbs

82 mile range

7.2 s 0-60

2017 Bolt EV

200 hp

266 lb-ft

400v Battery

66 kWh Battery

3583 lbs

259 mile range

6.5 s 0-60

Thank you for your first hand experience data points, supporting the “don’t worry too much about misleading numbers” side.

Something not specifically mentioned is that EVs have been moving to higher voltages over time. 350V to 400V to 650V to 800V. As Zero said above the higher the voltage the higher the power and the more balanced the HP / Torque ratio.

Early EVs were lower voltage / high amps = low power / high torque.

Some Chinese EVs are moving to 900 and 1,000V battery packs to let them charge 250 miles of range in 5 minutes.

Additional fun factoid from someone else that is mostly an EV guy and only became a diesel mechanic by accident:

A lot of legacy and current industrial drive systems, such as trains and bigass paper/rock mill machinery, also used Y-Delta switching to get higher startup torque and then switch to a higher operating or cruising speed. I was enamoured with the announcement that it was making a comeback.

It was a cheap way to get “gears” in some small EV projects I was involved in.

For sure. What is old is new again. Reminds me of how BMW is using wound field motors with brushes in their EVs too.

Dude, I was EVEN MORE excited to hear that. I never expected that to come from a German company. That is like Harbor Freight logic. Literally free field weakening and cuts everything expensive and rare out of the motor.

Brushes?!? Isn’t that a wear part? How long before those wear out? Maybe it’s an attempt to BMW-ify the EV, making it great to lease but expensive to own.

Yes, but much like an alternator, you pop it out and put new ones in. And being a central part of the whole affair, I’m hoping it’s sized for 200+K miles. A field brush typically isn’t conducting more than a few amps on a continuous slip ring (not a segmented DC motor commutator ring) and can last forever.

(Maybe this is where the German Logic comes in…. to replace the traction motor field brushes, you need to Remove the Car Around It first)

Bingo. Leave it to ze Germans to find ways to maximize maintenance needed for a bev

Do brushed motors have the same torque / speed relationship as the curve shown in the article? That is my understanding (brushless improves efficiency / life) but to first order the EM phyics are the same

They essentially do. In fact, the “constant torque, constant power” curve is first associated with wound-field DC motors from over a hundred years ago. Which is why the two of us are so giddy about it creeping back into the modern EVs.

What modern AC inverters offer is flexibility and configurability. The speed-torque characteristics of an old DC motor are baked into it permanently, and you can only modify so many inputs to effect your desired behavior without turning it into smoke bomb.

(Keep in mind that BMW isn’t using “brushed dc motors” in their newest power train, but an AC motor that happens to have the permanent magnets replaced with a field coil, like a very overgrown alternator; itself a technology from Ye Olde Dayes)

Oh, that makes more sense. You get a lot of the advantages of the induction motor (ability to turn off the field windings) but the greater efficiency of an actual connection to the windings rather than using magnetic induction to energize them (with the downside that you now have a wear item where the induction motor does not). Am I in the right ballpark?

Not necessarily greater efficiency in the general sense, since you now have another source of friction… but you avoid having to depend on rare earth minerals sourced from questionable places to supply the strong magnetic field. There are always tradeoffs.

They were probably fine with losing 2.36% efficiency in the long run versus making the motor cost hundreds of dollars less and not dependent on international political whims. Just make the battery 2.36% larger.

Thumbs up, Prog Chorls. Right on here.

It’s a cost trade off they are doing. Considering the global tensions around rare earth right now, it may be a wise choice.

I meant slip ring (brushed) AC / alternator style vs AC induction motor – which Ive read are used to reduce losses when coasting / a second motor is inactive. With the alternator style I can just open the circuit and kill the field winding – something that can’t be done with a permanent magnet motor.

I’m thinking the losses are lower through the brushes/slip rings than via the large air gap the magnetic induction has to pass through on an AC induction motor – or is the cylindrical geometry such that the magnetic flux doesn’t get wasted in empty space with the large air gap needed in the induction motor? Transferring electricity through the air via AC induction (with no ferrous toroid like a transformer) seems incredibly inefficient to me, but that is just my gut feeling after dabbling in voice coil design. I have this feeling that AC induction motors are not very efficient, but I’m not sure where I got that impression

Other than the rare earths and the back EMF when coasting, I’m guessing brushless DC wins on all the performance metrics?

Induction motors usually have very tight airgaps specifically to not ‘waste’ said flux, yes. All other things the same (e.g. if your permanent magnet, field-wound, and induction rotors were all perfectly smooth cylinders), the field-wound motor will have brush friction to contend with.

That Wye inverter looks suspiciously like a flux capacitor….

Zero Entropy messing with the space time continuum

Really wish I was smarter/had the attention span to better understand all of this info. Regardless, appreciate the deep dive. It might make more sense after my 9th or 10th read

Glad you enjoyed!

Nice write up! It’s worth nothing that parallel PHEVs often have interesting electric motor + gearbox arrangements owing to the direct gas/electric propulsion (excluding range-extending EVs here).

My wife’s CX-90 PHEV has an electric motor in place of a typical torque converter, and this makes for some interesting driving dynamics if you’re paying close attention. In full EV mode, the transmission will shift 1-2 times from initial standstill, and you can definitely feel it. I’d love to know which of the 8 speeds the transmission skips to in EV mode, but as soon as you put the transmission in manual mode, the ICE kicks on, assuming you want a more “sporty” drive.

In hybrid mode, the 2.5L NA engine feels turbocharged, with the electric motor adding torque between the ICE and the transmission. There’s even a “boost” function at wide open throttle that applies full motor to the ICE, and makes an otherwise large 7-seat SUV feel much more spry than it really is.

In generator mode, the ICE is held at higher RPMs and the electric motor bleeds off engine power to recharge the battery while the ICE also powers the transmission. This is typically done on freeway stretches when the car is cruising and doesn’t need all that much horsepower to maintain speed anyway.

You are correct, JP15. Many hybrids still use interesting transmissions. Powersplit or so called “E-CVT” is really interesting too. It allows series or parallel mode or any combo of them!

I’ve been borderline obsessed with eCVT’s since I first learned how they work. They are the rare modern example of a solution to an engineering problem that is both elegantly simple and incredibly robust.

Agree. Powersplit transmission is mechanical engineering peak in my mind.

I’ve owned two 2nd gen Prius and driven every gen for at least a week along with some Camrys and RAV4s. Some Ford’s with the powersplit as well.

As for as efficiency and reliability they are great but they are SO annoying to drive because they act just like an old belt and cone CVT where the revs jump to peak and the engine drones away.

I’m a much bigger fan of the latest generation Honda 2 motor hybrids with a much larger electric drive motor that feels much more like driving an EV.

We have 2 Toyota E-CVT’s in the family now, both with over 250k mileage. These are an elegant, robust powertrain solution. Yes, the elec motor will act as a ‘hill hold’ or ‘turbo boost’ function if called upon. I run my ’14 Camry in “eco” mode 99% of the time and am amazed by the throttle response if I put it in “normal”. Just starting to see an efficiency drop at 256k mileage on the factory battery. Daughter is loving an ’09 Prius that is still getting 45 mpg.

Yeah, eCVTs are really fascinating. When I first heard about them, I wrote them off as the rubber band type CVTs found on ATVs until I researched them.

Then I learned they’re more like double differential tank transmissions where a control power source can continuously blend inputs to a single output. A tank transmission works in reverse where a control motor can variably split the engine output to each tank tread without braking (so not a “skid steer”).

eCVTs and tank drives would be another great writeup!

Auto transmissions are way too complicated. I had a friend whose “transmission was failing” according to the GM/Saab dealer repair shop and of course wanted to replace it.

After he personally checked the codes (using my decoder), turns out that some electronic sensor for the air intake was affecting the transmission! Fixed the air intake sensor, and voila!

I had something similar happen with an AT. I had a CEL come on, followed by and AT light. Took the truck to my transmission guy (the rare super honest mechanic, more on that in a minute). Left it for him to test drive and run some errands (with my permission) and he called me the following afternoon and that he found my problem. I go and he has the hood up in the shop. He showed me the two EGR-related codes that were causing the CEL, then the transmission codes. Turns out my EGR sensor was bad and the code was causing an issue with the transmission control module. He said he could replace the sensor but he’d have to charge me shop labor, or it was two bolts and a plug and was under $30 and showed me exactly where it was. Like I said, he’s a good dude. Too bad he sold his shop and retired, there aren’t enough people around like that.

And now you know why there’s added resistance to EVs. We don’t need as many people on the assembly line, unions will have a problem with that. Companies that are component suppliers for transmissions right up to the actual manufacturers see their future extinction.

EVs still have gears and differentials though. There’s still a need for precision-milled and heat-treated gears, bearings, lubrication components, driveshafts, etc.

It’s not like the entire purpose of a transmission is obsolete, our current perception of a vehicle transmission is just changing.

I would describe what is covered in the post above more like a torque converter. LOL

It’s not that gears aren’t needed, it’s that the volume is going to drop a lot. Also I don’t know many (if any) EVs use driveshafts; they just run a dedicated motor on each axle.

I guess I should have clarified I meant half-shafts, not a center driveshaft.

The VAST majority of EVs have a transaxle-type drive, similar to a FWD gearbox. The electric motor has some reduction gears, those spin a conventional differential, and that differential outputs to half-shafts, just like any FWD car. AWD is achieved by putting another motor/reduction/differential package on the other axle, except in the weird quad-drive EVs, where there’s a dedicated motor for each wheel (quad drive Rivians or the G-Wagon EV for example).

Agreed. Volume. A lot less parts means a lot less factory labor.

In no way does one planetary gear cover the loss of manufacturing a whole transmission, from the labor and part supplier side. It’s like a Lego set with 5 pieces vs a set with 400 pieces.

Sure, but isn’t that always how technology works? I mean, the market on typewriters went away with computers. Are you saying we shouldn’t have computers to keep the typewriter makers in business?

Companies either adapt to changing markets or cease to exist. Think Palm and Blackberry after the iPhone came out. This is hardly unique to EVs.

Note that I’m not saying EVs should be the only vehicles out there (I have both EVs and ICE vehicles for different purpose), but changing markets and suppliers having to deal with doing things differently isn’t even remotely a new concept.

Maybe, but it seems like that ship sailed a long time ago. Assembly lines have been installing one sub-assembly instead of doing all the work on the line for a long time. Interiors arrive at the line as a bunch of sub assemblies often made in non-union shops.

On top of that, as more automakers explore the concepts of Tesla’s “unboxed platform”, the whole idea of how the car comes together on the assembly line is going to change.

https://electrek.co/2024/09/11/tesla-reveals-modular-unboxed-ev-manufacturing-process-patent/

Squeezing cost out of the assembly process is never not going to be a thing.

I recall Formula E vehicles still having a gearbox with their dual electric motors. Curious how that works and if that could/should make it to production cars.

In Season 1, the car was 100% spec and had an off the shelf racing 6-speed. In season 2 and after, manufacturers could design their own powertrain, and gear counts quickly fell to 3-speeds, 2-speeds, and converged on single-speeds after only a couple years as inverter design advanced. The significantly faster Gen 4 cars coming late next year (600-800hp!) might see a return of 2-speeds if there’s enough high speed tracks.

Every EV I know of uses at least a single-speed gear reduction, not direct drive.

So the Season 1 cars were akin to the Crap Era EV conversions that were based on cars with transaxles and kept the stock gearbox since the alternative was doing an entire different suspension.

You could probably say so. There’s some valid reasons for what they did, the biggest probably being that they were already planning to open up development after only one season. As a fledgling series, they didn’t have much budget and needed to keep the cars cheap to maximize participation. Plus, it was 2013/2014, EV tech was very new, so suitable racing single-speed drive units likely didn’t exist yet and designing their own would be expensive.

This is a very good, and unexpected, explanation. Still, the magnetic structure of a motor and its efficiency is going to be optimal at one rpm, even though it can be made to work well over a wide range. I don’t know how fact the typical EV motor turns at highway speeds but I’m guessing it’s closing in on 10,000 rpm’s. And heat loss that requires a cooling system is an efficiency problem. You paid for that heat. With batteries being so heavy and expensive, an EV should be designed to eliminate as much waste as possible in the form of reduced friction / better aero, and bettter motors and inverters with reduced losses.

Optimal across a wide RPM range, with ridiculous levels of efficiency. That being a problem with almost no waste heat being generated for cold climate heaters.

IIRC DC motors change speed with voltage, AC with frequency. Low loss either way.

Isn’t that kind of slow? 🙂

More effort needs to be placed on making the batteries last longer before replacement. Not only normal wear and tear, but any other random issue that causes batteries to die.

Generally speaking, an electric motor is highly efficient across a pretty wide operating condition. You may be surprised to see such a map.

You are right that there are certain areas where it is more efficient than other operating conditions, but those differences are small enough they don’t justify the added expense of a multi speed gearbox.

Fantastic! I thought I’d forgotten all this stuff but it all came shambling out of the back closet in the brain box covered in 40+ years of dust. Great read, I’ll gladly consume more of this content.

This a great primer on motor theory for ANY non-expert. Wish I had had this 25 years ago or even during my engineering coursework.

Thank you, CorvairFan.

Studying field theory was not my favorite back in the day, but I loved this. More please.

Thank you for the explanation! A lot of this goes on in the electric RC world too. Picking the right power combo is definitely a science with a bit of art mixed in.

Funny, I grew up in the RC world and credit my hobbies for my career now.

“Video killed the radio star,” except it didn’t… We need more cars like the Taycan with a transmission applied to an EV. Reading about the BMW i7 awhile back, I was surprised by how much steam it apparently loses at higher highway speeds.

Perhaps weaker electric motors routed through a transmission in a car that’s just a small cheap light (economical?!) runabout thing like was available in the 70s/80s/90s would be a better path forward than giant electric pickups nobody wants with enough battery for literally 10,000 iPhones.

Every 10,000 F150 Lightnings is enough to power 87 million iPhones.

There’s an exploding global industry for lithium batteries, mostly covering utility energy storage for hundreds of millions of people or more. The smaller amounts allotted to EVs and other applications will grow increasingly irrelevant.

The funny thing is that the F-150 Lightning’s battery pack is actually fairly reasonably sized at 100kWh base and kinda large at 130kWh for the extended range, compared to the monstrosities that are the GM pickups and Hunmer which are up to 200kWh.

Thanks for the deep dive on this! As MechE who worked in steel for 20 years or so, these are all terms the EE’s always discussed. Thanks for the clear, simplified explanations.

Thanks, Tbird! Hope to do more.

Please — so many other professionals can benefit from these as well. I wish I had access to this in engineering school or earlier in my career. Would have served me well 30 years ago.

This is so cool, Thanks. Now I have to figure out which unit to give this to my physics class to read? Newtons second law, current, circuits, the future of physics. So many good choices.

You sound like a great teacher!

Electric motors and automatic transmission are the exact same to me in regards to them both being witchcraft. Beyond the scope of my small mind. But you’re absolutely right, Electric motors are simpler witchcraft and make even the slower EVs more fun (after all, that instant torque is fun regardless of top speed).

It’s the opposite of turbo lag!