The Worst Mustang Ever. It’s been a dream for decades, and while Ford has made some valiant efforts to achieve it in the past – many would mention the Mustang II here – I’m of the opinion that so far, Ford has not achieved this goal. Some say it’s a pipe dream, that the true Worst Mustang Ever (WME) only exists on paper, and can never be truly realized. But I beg to differ; I have just realized that, thanks to some incredible technological advancements made in the development of the Mustang GTD (which, by the way, you can read about in incredible detail here) it is now technologically and economically possible for Ford to build a Mustang so deeply flawed, so wildly misguided, and so ill-conceived that it has a real chance of becoming the Worst Mustang Ever. And it’s all thanks to one key component developed for the Mustang GTD.

Yes, you read that right: part of the development of what is easily the fastest production Mustang ever is the key element in making the Worst Mustang Ever. Previous speculative designs for a WME have all required too much custom development and bespoke parts; they were too expensive to actually ever be possible to make real, because there are still, if you can believe it, many in positions of power at Ford who believe any money spent in the development of a genuinely terrible Mustang is too much money spent. That’s why for this to work, it needs to use components already in production, and thanks to the GTD, we’re finally there.

What is this crucial component? Glad you asked! It’s the Rear Engine Mounting System (REMS), which is used to connect the output shaft of the GTD’s 815-horsepower Predator engine to its rear-mounted transaxle. You can see it being installed by a technician here:

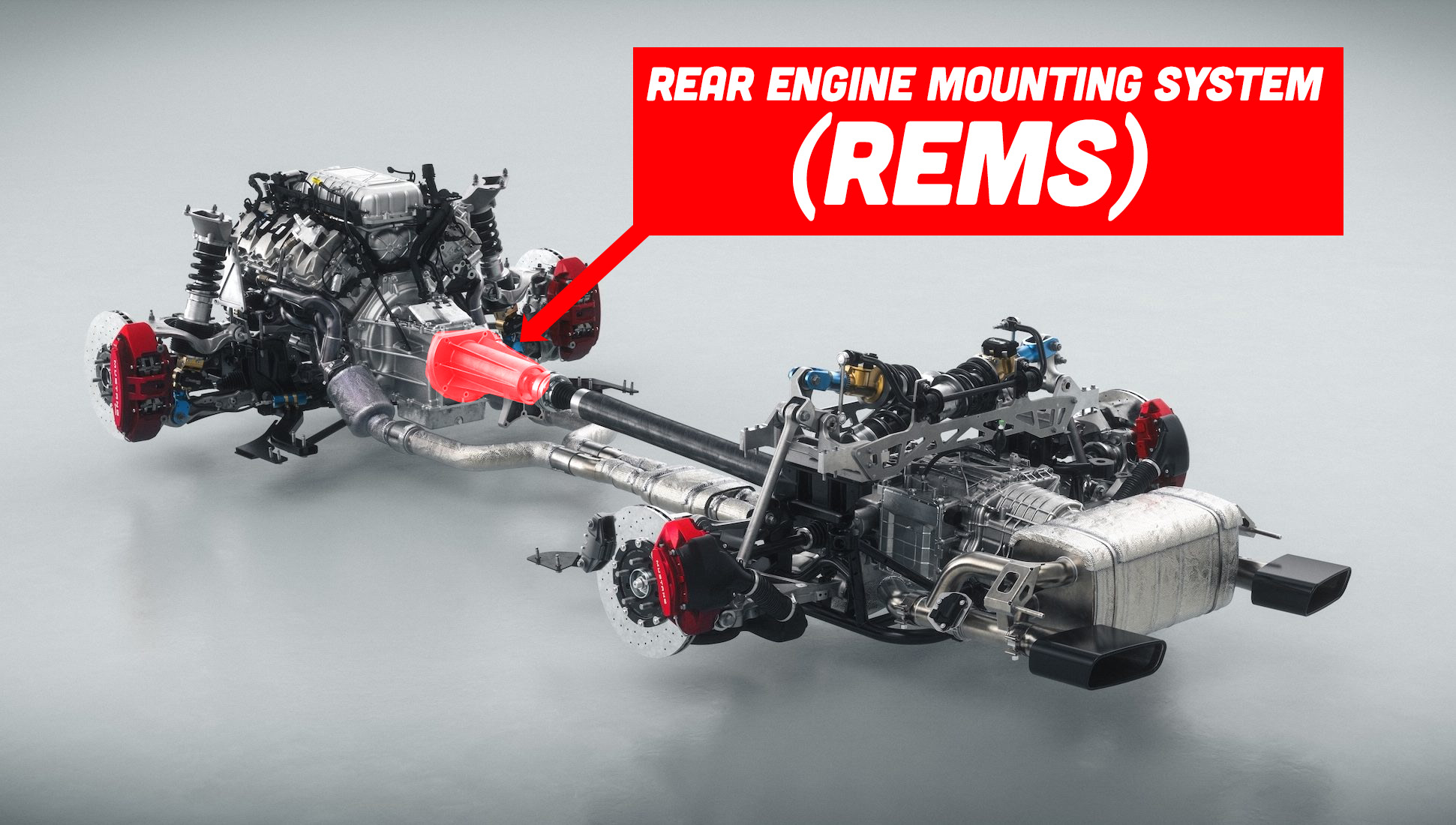

…and here it is, shown where it fits into the drivetrain of the GTD:

Now, you may be wondering just how this one crucial component for the GTD can be used to make the Worst Mustang Ever. The answer has to do with the fact that the Predator engine is part of Ford’s modular engine family, which also includes the 5.0-liter V8 used on the Mustang GT. This means that the REMS will bolt right onto the 5.0 engine.

This is the crucial step to making the Worst Mustang Ever. Remember, only the Mustang GTD has a rear-mounted transaxle. All other Mustangs use a transmission bolted right to the engine, which then spins the driveshaft that connects to the differential at the rear axle. So, to make the WME, all we need to do is replace the transmission with the REMS, which will bolt right into place without any trouble:

Essentially, we’re doing a Transmission Delete option for the Mustang GT. And that one change alone will definitely make a Worst Mustang Ever possible. Ford is in a unique position in the entire automotive industry to make this happen; while there are other cars without a traditional transmission, they’re all either electric or hybrids (like the upcoming new Honda Prelude); no other carmaker currently has the components needed to make a transmission-less combustion car other than Ford.

So, what would this Mustang WME (that’s my suggestion for the name) be like? Well, it would be quite similar to a base Mustang GT, just without a transmission. Maybe it could be optioned with some really terrible stuff, too, like a head unit that only plays true crime podcasts and always-on heated seats, or something like that. Those details can be hammered out later. But I’d like to avoid having a clutch or anything like that, to keep costs low.

Right now, I’m just thinking about the performance that this unique 5.0/REMS drivetrain would offer. Because figuring this out involves math, I involved our own in-house engineer, David Tracy.

I asked David to help me figure out what the acceleration would be like using the stock 486 horsepower/418 pound-feet of torque engine, and using the final drive from the manual transmission car, which would give a final drive ratio of 3.55. David looked at how much torque the engine makes at idle, about 650 rpm – it’s about 25 lb/ft – and with a tire size of 27 inches, he figured out how much thrust the car would make:

Basically, the thrust at the wheels is going to be:25 lb-ft * 3.55 = 89 lb-ft at the rear wheels. Divide that by the radius in feet (yes I’m mixing units now) and you get a thrust of only 79 pounds!

My god. You could push the car faster.

“So, what we could do to figure out how slowly this thing will accelerate is this:

We could take the torque curve, and convert into a table. Then we can basically figure out, using simply F=ma, what acceleration would be at the start using some assumptions for friction (we know the mass, we know the force). Once we have the acceleration in m/s^2, we, I think, could just build a table that steps up the time in set increments, which will yield a new vehicle speed at the new time. That vehicle speed would correspond to a different (higher) engine speed and thus different torque, which would change the acceleration, which would change the vehicle speed, which would change the torque, which would change the acceleration — it’d be a cycle. And also, drag would change with velocity as well.The short of this is, though, that you’ve gotta push this or let the starter motor crank for a while so you don’t stall the motor. At about 15 mph, the thing is idling nicely, and when you step on the gas, you’ll feel the force of a pre-teen pushing on the rear of the car.”

I didn’t want to make David have to make a whole table, as “pre-teen pushing car” levels of acceleration were good enough for me!

The top speed should still be basically the same, or close enough, so eventually you could get this thing going fast – it would just take forever. I think the glacial acceleration coupled with the incredibly clunky starting and braking and driving process would make this thing a slow, dangerous, uncomfortable, inefficient, miserable car. In short, the Worst Mustang Ever. And it could all be done with parts already in production! Plus, the added advantage of zero possibility of transmission problems!

There’s never been a better time at Ford than the present to build and sell this truly Special Edition Mustang. What Mustang collector would want to be without the Worst Mustang Ever? None! They could make a limited edition of these to make sure they were collectible, say, 5000 or so? And they could badge it as having GTD TECH INSIDE! This is gold! Gold!

Don’t leave money on the table, Ford! You’ve made the Best Mustang Ever already, so I think it’s time for the counterpart that everyone is demanding, even if they don’t realize it yet. Make the Worst Mustang Ever real.

Torch, don’t ever change you wacky wonderful little dude!

So, with a Coyote, you’re going to have a bellhousing vs the dry sump stuff. So put a torque converter in there and the viscous coupling will solve your stalling/starter worries. The torque multiplication will be negligible but it’ll drive like the worst Jatco XTrinic CVT ever. Or a broken 2005 Freestyle (that may be redundant). Oh, oh, I know, it’ll be like a Powershift/DPS6. Actually no, that’s still worse.

It’ll maybe be too good and fully realized with that tiny bit of tractable improvement.

I think what you need here is a 1.0 Ecoboost triple and Powershift hacked in where the GTD puts that fancy pushrod suspension. THAT would be WME. Tooling is already written down for all that stuff

“David looked at how much torque the engine makes at idle, about 650 rpm – it’s about 25 lb/ft”

No. Try like ~150 ft-lb. Also, it’s lb-ft or ft-lb as Torque = Force * Distance, not Force/Distance.

So, 474 lbs of thrust, or a sumo wrestler.

This article is proof they don’t drug test at the autopian.

How do you drug test someone who WFH 3000 miles away from HQ? Get Sally and/or Otto to do it and text the results to David?

Things would be a lot less fun if they did.

Would lead poisoning flag on a drug test?

No, it gets better(by which I mean worse). That RMS bell housing uses a Modular bolt pattern, meaning you are not limited to the 5.0 Coyote. Every RWD Ford engine uses that bolt pattern. So you could have any choice of options: the 2.3 from the base Mustang and Ranger(yikes), the various EcoBoost V6s(yikes), the Godzilla 6.8 and 7.3 big blocks(this would definitely be the most useful, best accelerating option), or the 6.7 Powerstroke(it would accelerate relatively well but a 6.7 Mustang would be terrible for other reasons).

How much weed did you smoke before you wrote this?

You are correct though, this would somehow be even worse than the Mocky.

Exactly what I came here to say as well lol

Could it still blunder out of Cars & Coffee and end up on the median? I think that’s critical.

Please stop giving them ideas.

I think you’re overcomplicating things. Do you really want to spend the money on a GTD carbon fiber driveshaft? A far cheaper solution is to start with ANY automatic transmission model, remove the transmission but leave the torque converter in place, and then fabricate a splined “extension” to lengthen the existing and more importantly cheap driveshaft directly into the torque converter. Make sure you have an o-ring on the extension where it goes into the torque converter so it can’t be replaced, and now you get to advertise lifetime transmission fluid as a potential benefit. For extra cost savings start with the 2.3 ecoboost motor, and remove the “boost” portion.

In fairness, if you removed all the other guts from the transmission, there’d be plenty of room for spare transmission fluid to ‘soak up’ all that lifetime metal shavings and other accumulation. Sounds extra reliable to me, and there’s even fewer parts to break!

too many bearings… Think like an accountant!

I don’t know…

Still sounds better than the Mustang II I had in high school.

Was just going to say: this performance precisely matches that of our old Pinto…last Ford the old man ever bought.

So, you’re turning this Mustang into a sprint car. Just a release cable that disengages the drive line.

And, as a former driver of a Mustang II, I would probably choose the Mustang WME over the Mustang II.

The only problem I see with this is city driving. There’s a lot of start/stop, so you’d need a pretty hefty battery – and to be safe you’d want to plug it in overnight.

Also of note, since you’ve got that powerful of a “starter”, you could probably do away with the dino juice motor altogether, and just go with the electric. Maybe even put a small frunk up there with the space saved by removing the gas engine.

Give it a swanky trim name that harkens back to the glory days of the muscle car era mated with a modern techno letter thing that’s all the rage today (maybe “Mach E” or something terrible like that).

And THAT, my friends, would be the worst Mustang ever.

Also, I think some math in the article might be off. 650 rpm idle = 2.5 mph would mean that 6500 rpm (redlineish?) would be 25 mph. I’m getting 650 rpm / 60 / 3.55 *27/12*pi =~21.5 ft/second, or just short of 15 mph at idle

You’re right. I think it was my conversion from rpm to rad/s that was all out of wack. In any case it’s just 650/3.55, converted into rad/s is 19.174. Multiply that by the radius in meters (0.3429), and you end up with 6.6 m/s or just under 15 mph.

So what’s the all-important 0-15 time?

You jest, of course, but this concept is only a couple of steps away from what could be a Pretty Good Hybrid Mustang (Mustang PGH?). Keep the clutch, but put an electric/electro-hydraulic actuator on it, instead of hooking it to the clutch pedal. Replace the flywheel with a ~200 hp pancake motor, like those Porsche resto-mods use. Then replace the GTD’s transaxle with an electric motor good for around 200 hp and gear it down until it delivers right around 500 lb-ft at the pinion of the differential. Up to around 35 mph or so the electric motor drives the wheels, and the V8 is declutched from the driveshaft, running the electric motor like a generator. Above 35 the clutch engages and drives the rear wheels, with the electric motors helping out up until about 60 or so, at which point the engine could drive the car by itself at cruise just like you were driving around in top gear. This is a hybrid done like Honda and Mitsubishi does it, but one that could still do 0-60 in less than 5 seconds. Find a place to stick a ~1 kWh battery (maybe put it where the spare tire used to go in more civilized times) and you’re set!

(Also FYI you misread the horsepower curve as the torque – it makes about 25 hp @ 1000 RPM, but that translates into right around 150 lb-ft. Still a funny article!)

Alex Issigonis – yes, the groundbreaking designer of the original Mini – is way ahead of you. Just yesterday I was at the British Motor Museum looking at the “gearless” 9X, a proposed replacement for the Mini that he designed. No transmission, just a torque converter. Apparently it was a bit slow off the line.

And Buick was way ahead of Sir Alex with the Dynaflow. At least it had a ‘switch pitch’ stator in the torque converter to increase the torque multiplication factor at low speeds. Plus it was normally bolted to a 401 Nailhead v8, which made huge torque right at the converter stall speed. Basically a hydraulic CVT, which were both much more reliable and much less efficient than the CVTs we know today.

I’m thinking it would be better with a clutch, but a starter delete, so it would need to be roll started every time. Better only encounter stop lights on a downhill grade.

Then again, that would enable reverse via a passenger pushing the vehicle with the clutch disengaged. Without a clutch, only way to reverse would be spinning the engine backwards, which would certainly help with the goal.

I think someone needs to do this experiment- is it possible to rig a way to manually flip a switch, and reverse the starter motor direction for reverse?

That was done by Bond on their “minicar”. They’d actually start the engine backwards so you had four reverse gears. Don’t try that with a four stroke…

Interesting, guess you’d have to shut the engine off to go between forward and reverse? I do wonder what would happen on a 4 stroke engine, with fuel disabled. Or maybe with fuel, that might be more exciting. If I was a cat, I definitely would have used up way more than 9 lives with foolish curiosity.

Yes, shut the engine off and restart. Apparently you choose which direction the engine would run by which way you turned the key. Boy, you’d want to make sure you had that right before letting out the clutch!

Early boat engines were like this – “ratchet engine” is a common description

Probably still faster and quicker than my built Jeep TJ.

But I feel like this would make for an interesting experiment, especially on a dyno. It would be silly, but I’d watch and/or read about it.

I am pretty sure that technically , the best kind of correct, since Ford is the only com6thats makes the Mustang they have in effect already made the best and the worst mustang. Like a Guinness Book of World Records each of those can be beaten. And in retrospect did the person who started the Guinness Book of World Records do so after drinking a lot o Guinness Beer?

It was started by the beer company

I’d say I want more companies starting stupid shit like Michelin star restaurants (a tire company that judges the finest foods??) but in today’s world we’d get an Amazon branded TV service or a Tesla branded diner.

Oh, wait.

I’m probably wrong, but if 4th in the Mustang’s transmission is 1.00, wouldn’t this be equivalent to leaving it in 4th all the time? If so, it still might be quicker than any base engined Mustang prior to ’94 or so.

This was my same thought, and I’m fairly sure its correct.

Yes, but there’s still that pesky clutch, easy starting, and no GTD parts if you just leave it 4th!

(But seriously, I immediately thought of the time Clarkson took a Z06 on the Top Gear track in 5th only)

I think that the 2.3 Lima/Pinto engine shares a bellhousing pattern with the SBF, so why not put the REMS in a 1975 Mustang II??

That, would be the worst Mustang ever.

I think it does share a bell housing pattern with the old Ford small block, but alas, that’s a different pattern than the current Modular bell housing pattern.

🙁

Do it in a 1974, the shorter nose ensures anything bigger than a cologne is a tight fit. This would in fact be slower than a normal 2.3 automatic car, but not by much

Pretty sure that 90% of GTDs will end up garage queens, making semi-annual appearances on the Mecum or B-J block, and accruing mere dozens of miles, just like the Ford GT, which actually is a supercar.

So after the Jeep build, this needs to happen, as it involves multiple site sponsors. A Mustang GT should be readily available at any Copart where Cars and Coffee is held. The offending part can be donated (borrowed [stolen under cover of darkness]) from the Gossin GTD and Bob’s your uncle!

It would be far too easy to install a lower final drive to ease the load on the starter. You’d still need just as beefy a starter, though, since it would be solely responsible for moving the car in reverse, and your top backwards speed, already a measly 2.5 mph, would be affected by the final drive.

Unless you figure out a way for a Coyote to run backwards (inb4 Acme jokes)

Two stroke Coyote conversion here we come

Well I’d be careful about that approach. You can start out with the intention of only stroking a coyote twice but if it’s breeding season he just might make you his beetch.

If it is Acme you just hit the reverse switch.

Just goes to show how much heavy lifting the transmission really does. The engine usually gets all the fanfare, but it’s nothing without a transmission.

Unless it is electric

This is batshit crazy. But I enjoyed it so, hey, yet another post here that I didn’t know I needed.