A car enthusiast’s dream is for the world to reproduce their favorite automobiles. That way, instead of having to rely on a depleting stock of ancient, worn-out parts, you’ve got a never-ending supply of new (and often improved!) components. There is really only a handful of cars on earth that, decades after official production, are still being made, and the World War II Jeep is one of them. While the bodies and frames are manufactured in the Philippines — a country that turned leftover WWII allied Jeeps into a significant part of their cultural identity by creating “Jeepneys” — the brand new engines are actually built in France (also a country with a rich WWII Jeep heritage). Here, have a look at my shiny new motor.

When I first started down the road of trying to build a World War II Jeep from scratch using parts from eBay, I wasn’t really aware of just how many reproduction components were available. While it’s well known that Willys bodies can be purchased brand new (the bodies rust out frequently, so folks have been buying new tubs for many decades), I wasn’t sure exactly what the frame and engine situation was. I’d seen reproduction frame sections, and I’d heard rumors of a reproduction Willys L-head “Go-Devil” engine, but I wasn’t sure they were still out there.

Well, it turns out they are. I already showed you my new frame from the same Philippines factory that made my new body; now let’s have a look at my shiny new motor.

The engine and all of its components arrived in a bunch of boxes fastened to a pallet.

Not keen on trying to lift the 500 pound unit, Video Manager Griffin and I unstrapped each individual box and, one by one, threw them in the bed of my new Jeep Comanche work-truck.

Upon arrival at my house, we spent an hour searching for all the keys to the cars in my driveway, and then moving those cars; only then could we back my Jeep Comanche up to my workplace so we could take out the boxes and see what was inside. And, well, it was glorious. Look at this incredible new engine block — which came in a wood crate just like you’d expect from a “crate motor” — flown all the way from France:

Here’s a close look at the deck:

Here’s one of the cylinders:

Though the engine has been lubricated to keep off rust, one of the cylinders has a bit of surface oxidation, so I need to take care of that ASAP with some Crocus Cloth:

Here’s the water pump mounting point:

And here are a few looks at some cooling jackets:

The engine came with new pistons and rings:

In addition, I bought a new cylinder head:

I bought a new intake manifold:

I bought a new exhaust manifold:

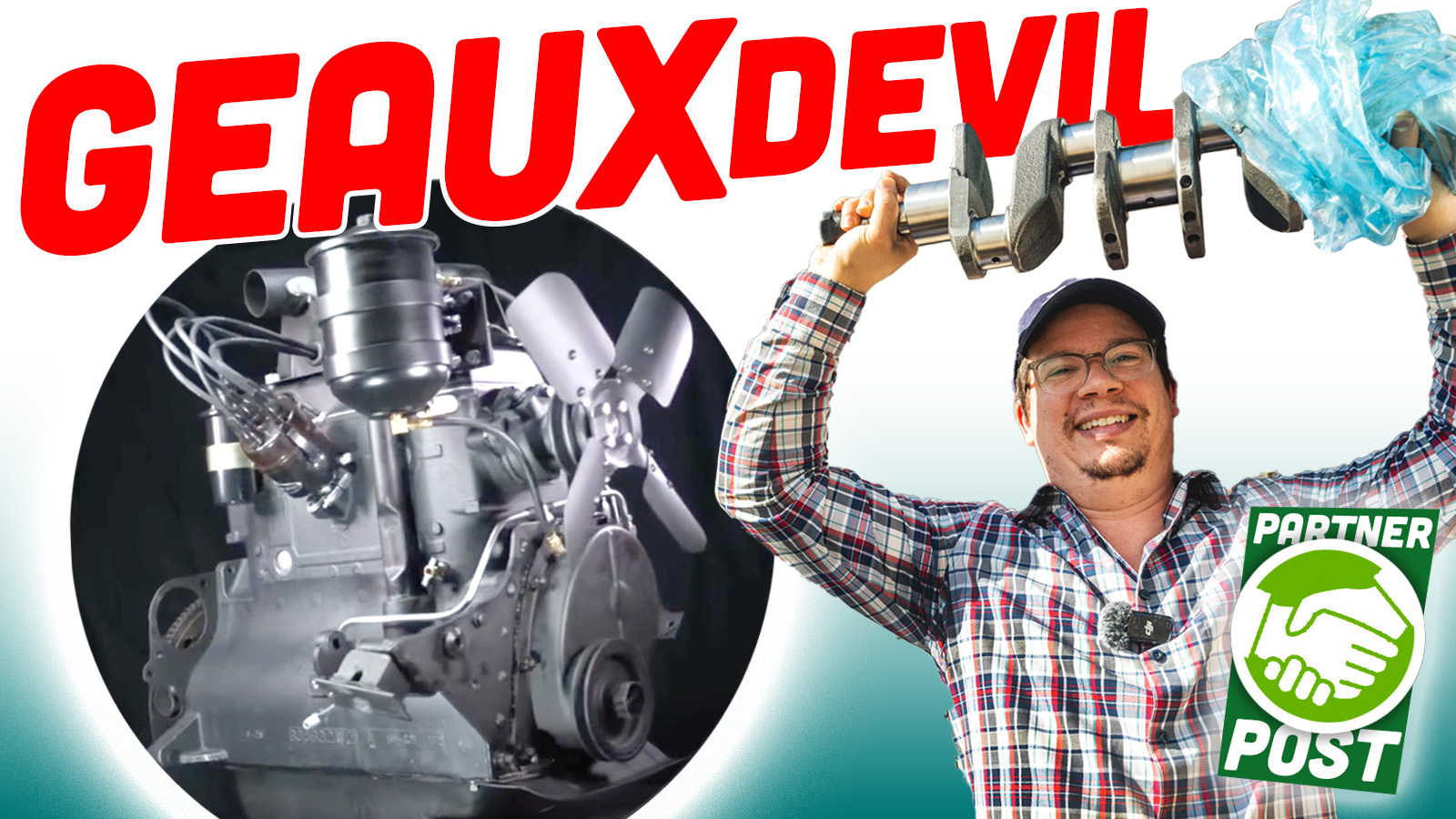

I snagged a new crankshaft:

Here I am holding that crankshaft over my head for the photo at the top of the article:

And I purchased a new camshaft:

I also got a bunch of other smaller parts like timing sprockets and gaskets and bearings (plus I accidentally got an extra set of pistons and valve guides, since they came with Kaiser Willys’ kit):

All of the main engine parts — the block, the pistons, the head, the crankshaft, the manifolds (not the camshaft) — come from the same company in France.

It Comes From A French Company Made Up Of Jeep Enthusiasts

The brand new engine block is based on the original 1940-ish drawings from Willys-Overland. A French company called “Willys Owner Product,” made up of Jeep enthusiasts, actually manufactures loads of brand new Willys Jeep parts. The company’s website (shown above) is a bit bare, having only a “contact us” section and also this little statement about the company:

Willys Owner Product (WOP) manufactures quality parts true to World War II originals.

We manufacture, wholesale and retail and are expanding our range over time.

We are committed to reproducing parts that comply with their technical and aesthetic characteristics.

The WOP brand is new, created by enthusiasts based in the South of France,

and is sold by several distributors in France and Europe.

But a big Jeep supplier called Jeep Sud Est (translates to Jeep South East, presumably because it’s based near Avignon in southeastern France — see above) gives us a few details about the block on its website:

New WILLYS MB US WW2 version molds made using original plans and three years of studies and tests (2019-2022).

Willys Go-Devil engine block for Jeep Willys, Ford, Hotchkiss.

- Casting 100% conforming to the Willys MB model (Casting die number: W2)

- Each block is engraved with its unique serial number, on a lower location; visible but discreet.

- Delivered individually in a wooden crate, lubricated for long-term storage.

- Sold with 6 sand removal tablets, oil pipe plugs, rear bearing discharge oil tube.

- The 8 valve guides are mounted.

- Comes in black.

- Comes with 4 STD pistons + 4 pins

This Willys block is unique, because we made it “universal”! It can be composed with the elements of a chain distribution as well as a distribution by pinions (3/8 flange caps and 1/8 npt jet provided)

Jeep Sud Est’s site also features this video of the engine being assembled:

Some of the description (especially the bit about “sand removable tablets”) seems like a bit of a translation error, but that’s fine, since I actually bought the new engine from the eBay store of an American supplier, Kaiser Willys. Here you can see the listing:

And here’s Kaiser’s description of the new block from France:

These are bench tested and ready to be rebuilt as your new 4-134 L engine.

Can be used as either a gear driven engine or chain driven engine.

All machined surfaces are milled to original design specifications.

It is made with a formula of current cast iron reinforced with the same coefficients of expansion as the originals.

Included with the kit:

-Set of 4 standard pistons with pin

-Set of standard piston rings, 1

-Crankshaft rear bearing drain pipe

-Oil galley plugs

-Set of 5 main bearing dowels

-Set of 5 freeze expansion plug

-Camshaft expansion plug

-Set of 8 valve guides installed– Cylinder Bore: 3.1255 +/- .0005

– Valve Guide Bore Diameter (In & Ex): .374 +/- .0005

– Valve Seat Surface Width: .09375 to .125 +/- .0005

– Tappet Bore Diameter: .626 +/- .0005

– Oil Galley Taps/Plugs: NPT 1/8 & NPT 3/8

– Oil Galley Taps – TaperedEach block has an individual serial number. These were constructed using original plans and over three years of studies and tests on (2019-2023).

They are each coated with a rust inhibitor and shipped in a wooden crate.

Why Does France Build World War II Jeep Parts?

The cool thing about World War II Jeeps is that, as a symbol of freedom, they’re beloved all across the globe. I once took my grandpa for a ride around the Tegernsee in Germany thanks to a bunch of German and Austrian WWII Jeep enthusiasts; the Jeepney-loving nation of the Philippines actually builds its own WWII Jeep bodies and frames; and France — well, you could argue that France loves WWII Jeeps just as much as anyone.

The history of the World War II Jeep in France is deep and rich. Obviously, France became familiar with the Willys MB and Ford GPW when the U.S. brought the vehicles to the European theater, but what’s fascinating is that — after the French military adopted WWII Jeeps and kept purchasing replacement parts from Toledo — the country actually began building its own World War II Jeeps. Built well after the war, this French Jeep wasn’t called a Willys or a Ford, it was called a Hotchkiss. As M201.com — a website dedicated to the WWII Jeep-based Hotchkiss M201 — describes, it all started out with a weapons company founded by an American named Benjamin Hotchkiss:

Benjamin Berkeley Hotchkiss was born in Watertown, Connecticut in 1826. He became a skilled designer in the family’s engineering business with a passion for weapons but having failed to interest the US Government in his designs he moved to France where he set up the Hotchkiss Company in 1867…Hotchkiss died in 1885 but the company continued with his personal passion..

Per M201, by the 1930s, the French company Hotchkiss was in the business of building military vehicles — ambulances, tankers, and various cars. It even built a 1939 Hotchkiss R15R Command & Reconnaissance 4×4. During the war, a Hotchkiss employee began interfacing with Toledo’s Willys-Overland:

Henry Ainsworth, M.D. of Hotchkiss, escaped to London at the beginning of the war where his knowledge of military vehicle manufacture was put to good use involving liaison with Willys-Overland. After the war he returned to France to re-establish Hotchkiss as a motor manufacturer. He was also interested in manufacturing jeeps and in June 1952 SOFIA (la Société Financière Industrie et Automobile – a Hotchkiss subsidiary) gained a licence from Willys in the U.S.A. to manufacture both spares and jeeps as Willys Overland France (WOF). The jeeps would have been based on the Willys CJ2A/3A design but final agreement with Willys (owned by the Kaiser Corporation) took until 1954 and the jeep became based on the later CJ-3B.

Even though Ainsworth wanted to build 4x4s a decade after WWII Jeep production had ended, he did not decide to build 4x4s based on the latest, greatest design, which would have been the M38A1 — the more powerful “high hood” Jeep upon which the CJ-5 would be built. No, Ainsworth decided to stick with the original WWII Jeep design, which had been out of production since 1945:

By the end of 1955 the French army decided to stick with the simple and proven MB design rather than continue to consider more advanced jeeps from other manufacturers. These included Delahaye who had now been taken over by Hotchkiss to form Hotchkiss-Delahaye. In 1956 Hotchkiss merged with Brandt to create Hotchkiss-Brandt and it was from the Brandt factory (complete with test track) in Stains on the Northern outskirts of Paris that the majority of the 27,628 Hotchkiss M201 jeeps based on the original MB design were produced for the French Government between 1957 and 1966.

And so that’s what you see in the photo above. It looks exactly like a 1941 WWII Jeep, and yet what you see there is actually a 1962 model!

These Hotchkiss Jeeps are actually known to be extremely well built, with many Willys MB and Ford GPW owners using their parts as high-quality replacements to keep their 80 year-old machines on the road.

That’s all to say: I’m quite hopeful that my French Jeep engine parts will be high quality. We’ll find out when I put it all together.

Speaking of, I have to go. I have lots of work to do!

[Ed note: David mentioned the idea of building a brand new WWII Jeep to the team at eBay, and they loved the idea so much they said, “How can we help?” Their financial support and David’s Jeep-obsession are the fuel behind this crazy build. – MH]

Have you tested it?

It may only run in reverse.

-Jeremy Clarkson

When this is done I want to see a race between this and the Citroen 2CV that’s been plotted out somehow to be a fair fight. Maybe throw in one of the weird vehicles owned by Mercedes, like maybe that Vespa knockoff.

And so it begins…

It’s not AI. It’s just French!

Take a look at the thumbnail on the most recent video…

https://www.youtube.com/@RexsHangar/videos?view=0&sort=dd&shelf_id=3

“…truly interesting but obscure, and very French…”

That may have been the inspiration. Haven’t watched that video quite yet. Interwar France is an interesting place.

Am I reading this right…5700 USD for a bare block?

For reference you can get a new Dart SBC block for less than half that.

Looks like that included shipping (and likely tariffs), which must be a big chunk of it

If you know prices of SBC anything, it’s hard to justify dang near anything else. Look up how much it costs to rebuild an aircooled 911 motor… now realize they make barely 200hp.

Ahh, I posted pointing to an old air-cooled Porsche block after you, but before I saw your post.

In my world a simple cast iron flathead Jeep motor seems more analogous to a SBC than anything Porsche.

Kind not tho. If you think about the tooling required to make any of the parts, it’s all about the same. The difference is volume, and porsche parts and ww2 jeep parts are next to nothing compared to the volume of small block chevy anything.

For reference, you can get a block for a 1964 Porsche 911 for somewhere between $49,000 to $71,000.

All things are relative.

I got a new fully dressed Chevy 350 installed for about that last winter.

It’s a specialty item made in small quantities.

My guess is soft plugs. Did it come with six soft plugs?

My thoughts too. To plug the holes where where they removed the casting sand.

In the US they are generally called freeze plugs or core plugs.

Poor Griffin, I sure hope that he is being paid by the hour! 😉

I may have missed this in previous posts… But David, is your wedding band off off road tire treads?? That is amazing!!

He did make a post about his ring a few months ago. He bought it from an etsy seller. I have been wedding band-less for a few years and I plan on ordering one from that seller.

I missed the original article, but I was able to find the article with a search. Thanks!

I’m afraid to use wedding bands ever since I got mine caught to a hook ad almost injured myself, and then I heard horror stories from my mates at the shipiard I worked ages ago… And I don’t even wrench (at least not like DT)!

I don’t trust myself with even the silicone ones when I’m at work. I also do a lot of woodworking at home. My wife and I aren’t really jewelry people so she doesn’t mind.

Silicone wedding bands are great for folk who work with their hands!

Yeah I totally wear a silicone band on a daily basis. My fancy nice ring I actually got married with is in a fancy box.

The Autopian YouTube video of David opening the many boxes was like watching Ralphie opening his Red Rider BB rifle Christmas present.

Ralphie/David: “Oh, it was beautiful. I could hardly wait to try it out.”

Congratulations. Don’t shoot your eye out.

Congrats. Luckily the motor is easy to work on but I bet the little parts will be the hardest to deal with like the gaskets, shaft gear keys, and all of that stuff. Best of luck. I helped my buddy rebuild his 49 and he opted to get an the oil filter parts as his did not come with one.

Gonna need con rods

Facts!

I never knew Hotchkiss was founded by an American.

I imagine the box under the carb mount on the intake manifold bolts up to the butterfly valve on the exhaust manifold for carb preheating? That’s certainly an engine block.

That looks like fun to build from all new. You going with gear or chain drive for the cam?

Gears>chains>belts.

And as we know DT views belts as an abomination and unacceptable unreliability.

So gears.

I know he does.

Although timing belts can be a pain, I personally don’t think it’s unrealistic to get in there for service every 100k miles or so – especially when replacing the oil and water pumps goes along pretty easily with that service.

Every engine I’ve designed (that’s actually got made) has used belts. I’m fine with belts, they tend not to wear out the parts they run on (unlike chains) and don’t whine like gears.

I just sold my gear-driven quad-cam engine and I miss the noise, but it’s not great for NVH in a car.

As long as the belt lasts a solid 100k miles I’m fine with it too. I’ve heard of timing belts with a 60k mile interval, and IMO that’s too frequent for a major service.

Well, it’s chain as the other option, not belts. I imagine he’d prefer to go with gears, but I don’t know how different all the parts are between the two and what else he’s ordered, if one is easier to find, etc. And is there a different cam or is it just the drive off the end that gets changed out between the two? (I would expect that would require an idler gear as direct drive off the crank would rotate the cam the opposite direction while a chain would rotate the same direction.)

Gotta go chain. WWII Jeeps only used chain. (CJs used the same motor, but with gears. Sometimes those would fail, as they were phenolic/fiber).

Oh, yeah, fiber timing gears… that’s a stumbling block with my project ’54 Panhard Dyna Z, as it has a fiber timing gear, and I need to source a metal replacement before I can even think about running the engine especially since it’s been sitting a while. Fiber gears tend to start disintegrating if they’ve been sitting too long.

So, yeah, a pox on fiber gears!! They’re surprisingly common, though. Very early Beetles used fiber gears and switched to metal sometime in the early to mid 50s. Many American cars used fiber gears through the 50s and into the 60s if not even later. Cadillac was still using fiber gears as late as the early 90s though it seems like by then most Cadillacs had switched to timing chains so I think the data I saw was actually for factory parts for older models still being produced OEM.

ETA: I daresay there’s a good number of us that’d be interested in an article about fiber gears especially since it’s a little hard to wrap one’s head around the idea of using fiber for actually running anything inside an engine…

Wow, I don’t know how I never knew fiber timing gears were a thing. I wonder if it was an NVH solution.

Yeah, NVH was apparently a significant part of why manufacturers used fiber gears, hence Cadillac being such a long-time holdout.

Cool, thanks! Seems like they missed the point of gear drive.

How long before Team WOP (is someone going to tell them?) starts cranking out 4.0L straight sixes?

Sacre bleu!! Superbes pommes de terre galopantes!! Don’t know why I was so astonished when I saw the headline especially since I’m in the midst of getting a 1954 Panhard Dyna Z back on the road where I’m finding the French vintage automotive scene to be pretty vigorous. Fascinating to read about the history of the Jeep in France.

“Upon arrival at my house, we spent an hour searching for all the keys to the cars in my driveway, and then moving those cars”

That was so damn relatable it made me laugh out loud and most ruefully. Good to know there’s a plural number of us out there.

“Some of the description (especially the bit about “sand removable tablets”) seems like a bit of a translation error”

Yeah, not sure about that one. I’m not fluent at all in French, alas. My kid who just recently moved several states away to embark on a new career was picking up some French partly through some travels in France & partly through our work on the Dyna Z so that was helpful especially since translation apps aren’t always all that accurate. When we first started working on the Dyna Z I was perplexed by a translation app consistently returning translations about candles until my kid told me about “bougies” actually being what the French call spark plugs even though it literally translates as “candles.”

Curious as to what else you’ll come across in the course of doing your Gallic engine work…

Galloping potatoes?

Yeah, it was something I saw many years ago in either an old Tintin comic book (as an exclamation by Captain Haddock) or a parody thereof and I found it pretty amusing. I’ve not come across the expression again despite re-reading most of Hergé’s oeuvre (including much of The Adventures of Jo, Zette and Jocko but not any of Quick & Flupke) since then so I’m inclined to think that where I saw it was actually in a parody that had a bit of a mashup with Graham Kerr (the Galloping Gourmet.) Yeah, I used to read the occasional fanzines & other such self-published publications in the 80s, most of which simply are not online, hence the lack of success with online searches for that expression.

Also quite possible that I simply came up with it myself back in the 80s, as it was a strange decade (after all, it was the same decade that brought us things such as the Suzuki Mighty Boy and Madness doing TV commercials for the Honda City), lol.

I once had a Halloween costume as Captain Haddock accompanying my son as Tintin, which was a little obscure, since he normally looked sort of like Tintin, and since I looked somewhat like captain Haddock at the time, I carried a large sign that read

“ Billions of bilious blue blistering barnacles in a thundering typhoon!”

and everyone got it.

I think galloping gophers is as close to galloping potatoes as Hergé got.

An Autopian article on Hergé’s automobiles would be good.

That’s great about the Halloween costumes!

Yeah, galloping gophers is more like Hergé than galloping potatoes…

Some 20 years ago there was a model car company on the internet that put together a pretty dang comprehensive series of model cars (scale 1:43 IIRC) from the Tintin comics (including a Panhard Dyna Z!) complete with figurines of Tintin, Milou/Snowy, Captain Haddock, etc, etc. They appeared to be of high quality (the prices certainly reflected that!) & I’ve always kicked myself for not coughing up the dough to acquire the whole collection though I really didn’t have the wherwithal for it at the time (after all, I was raising two kids on a very modest budget.) Now that my kids are all grown up and I have a little more wherewithal, that company is no longer extant, alas.

Yeah, it’d be great if the Autopian did an article or even a series on Hergé’s automobiles.

ETA: turns out there’s a company that has revived the series & it’s indeed mighty pricey: https://hornseys.com/product/the-tintin-model-cars-1-24-scale-the-complete-set/

Though at least one can get individual models: https://hornseys.com/product-category/tintin/tintin-vehicles-scale-124/

As someone who had all Tintin albums basically memorized, I can confirm that galloping potato exclamation is a fugazi and not an OG Haddock phrase.

In German, it’s also ‚spark candles‘

‘Spark candles’ seems a lot more fun than ‘spark plugs’

So… An entire engine from the EU. I am still making my way through the article, but a quick search found no mention of tariff or customs… I’m quite shocked, since my main EU supplier won’t even send a bolt to the US rn.

eBay shows the location as South Carolina, and shipping is by UPS ground – if it was imported after the tariff nonsense began that has all been taken care of by the seller. But it’s equally likely that it was imported before it all took effect.

The ebay seller Kaiser Jeep may price that into its cost.

It’s not so much the cost, more that nobody is certain what they’ll end up paying because the calculations are so complex. Even if you were sure, there’s no guarantee it wouldn’t have changed between leaving France and arriving in the US. It’s not a good time for importers at all.

Well hey, at least the rates are staying consistent, and not, you know, changing every other day based on some dude’s whims or anything – that’d be a real disaster, amirite?

The article is way better than the movie.

The only good point in the YouTube version is for a second while examining the head, you said “Willis”. just as John Willys would have pronounced his name.

Imagine parts finding pre-Internet, life is good for hunting these days.

Beautiful pieces, congratulations!!

I just watched the 40th anniversary release of “Back to the Future.” Can’t help feeling DT has found his own time machine. Future to the back, my friend!

Why didn’t you push the reference jeep with one of the running Jeeps?

David! Unless you’re planning on working on that engine literally tomorrow, grab a can of WD-40 or any other kind of oil, and douse that engine to keep it safe from rust. And anything else that has machined surfaces you need to protect.

Great advice; I did indeed spray it down!

You may want to put in some desiccant packages too if you can plastic wrap the block. Do keep the desiccant where you can pull it out easily and away from direct contact with the block.

First – Griffin, my man, you are an excellent sport. 😀

Second – this unboxing video brought a huge amount of joy and I’m eager to see what’s next.

It would be great if the L block could be bolted up to the basic Harbor Freight engine stand; that would be $100 well spent. 🙂

I’m wondering if emery cloth would be a little harsh for removing the surface rust: it could damage the cross-hatch on the cylinder wall. Maybe a pass with a green scotchbrite pad would be sufficient, or a soft brass wheel brush in a cordless drill if it requires something with a little more cojones.

As good as HF $100 engine stands are, you can likely find a slightly dirty HF engine stand for around $50 on marketplace. Then sell for $50. They will forever be $50.

That’s a good point

But I thought of something: in the spirit of the project, maybe David should buy a random engine stand from eBay 🙂

I don’t share your interest in Jeeps, But this series with you building one from parts has been extremely interesting, Keep up the good work 🙂 Loads more pictures would be appreciated.

I wonder what other cars could be built this way, Maybe the VW Beetle ?

Jason doesn’t need another project…

Oh crap – Mrs. Torch is here! Everyone hide the spare Pao parts!!

Quite possibly the Model T Ford.

A lot of the model T parts were made from proprietary steel alloys, the frames and axles were a vanadium chrome alloy. The Rouge complex was really something.

My grandfather built a baby lima bean processing warehouse using about 60 or so model T rear axles, steering wheels, and bearings, and as a result we had a huge pile of other model T scrap that we would make stuff out of. It’s amazingly tough steel.

He had a fondness for interesting metals. We also had a few tons of oil well drilling rod and a high tension power line tower that got knocked down by a truck.

I’m fairly certain you could build a 67-72 Chevy C-10 from scratch, and maybe a 1st gen Mustang.

Yeah, and when I was in high school in the early 80s I remember people claiming that there were more ’68 Pontiac Firebirds out there than the factory actually produced because people would build more than one Firebird using parts salvaged from one junkyard Firebird in addition to using parts ordered from the factory or the aftermarket…

If you are in the US you are quite well catered for it seems.

https://raybuck.com/product-category/body-sheetmetal/bodies/

The original Mini. New bodies are still available if you don’t want to weld your own. Drivetrains, interiors, subframes, suspension, everything is available.

Good call on the Mini, And it seems the MG.

https://www.bmh-ltd.com/body-shells/

It sounds like you can’t get new axles, though, which kind of disqualifies the Jeep. There’s doubtlessly plenty of cars that can be rebuilt mostly from new parts, but I wonder if any can be truly built from new?

The Citroën 2CV! The Lane Motor Museum has such an example albeit sans body:

https://www.lanemotormuseum.org/collection/cars/item/citroen-naked-2cv/

A few years ago Jason drove that one (with a smol Otto) for one of his videos:

https://youtu.be/REOYnoDdXK0?si=3MBUA2zYA3ZjZGb7

VW Beetle

Ford model A

Ford 65 Mustang

VW Bus

Porsche 356

Porsche 911

Chevy Camero

Citron 2CV

Morris Minor

Fiat 500

Isetta 300

Renault 4

I’m sure there are others

Mon dieu!

Looks like everything is falling into place nicely, can’t wait to hear what trails you do at Moab in Easter.

Be sure to leave all the parts out unprotected, and maybe hit them with a spray of salt water every once in a while, so you will know how to work on them after they are crusty and rusty.

This has a chance to enter the pantheon of all time great DT builds, right up there with POStal and Cactus.

It will have its place in the lore for sure! This one doesn’t feel as hopeless as those two projects but I have no doubt the hopelessness can grow and become something beautiful and despairing.

Then we can start to refer to David as “a fine wreck of a man. “