Six-stroke engines are having a moment. Porsche made waves last year for patenting a six-stroke powerplant that promised more efficiency and power by using a funky planetary gearset attached to the crankshaft, adding an extra compression and power stroke. Now, Mazda’s patented a six-stroke engine of its own, and it might have the potential to keep internal combustion relevant for longer.

Before diving into Mazda’s six-stroke engine, it’s important to understand how a standard four-stroke engine works. Every new gas-powered car you see on the road today uses the four-stroke cycle: Intake, compression, combustion, exhaust. Air and fuel come in, the mixture is pressed into a small space by the piston, the mixture is ignited by the spark plug, pushing the piston down (or inward in the case of a flat motor), then the burnt air and fuel are pushed out of the cylinder. Easy enough, right?

Unlike the Porsche six-stroke, which doubles up on the compression cycle to re-burn used air and gasoline, the Mazda engine has a traditional bottom end, with pistons that move up and down in a fixed distance. Instead, all of the magic happens on the top end, where the engine—get this—creates its own supply of hydrogen by separating it from fuel on the fly.

Source: USPTO

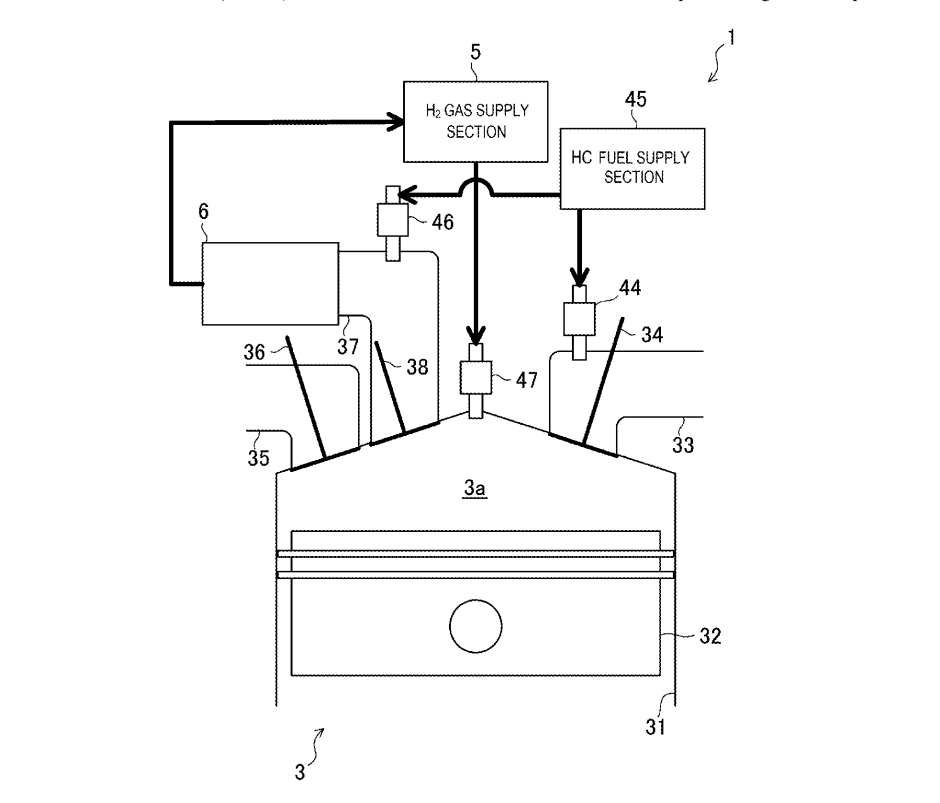

Here’s how it theoretically works. The first three strokes—intake, compression, and expansion/combustion—work normally. But instead of pushing the burnt exhaust gases to the atmosphere on stroke four, the exhaust is directed, via a valve on the head (38 in the image above), into a separate port (37), then fuel is injected via a separate injector (46) before the mixture heads to what Mazda calls a “decomposer” (6).

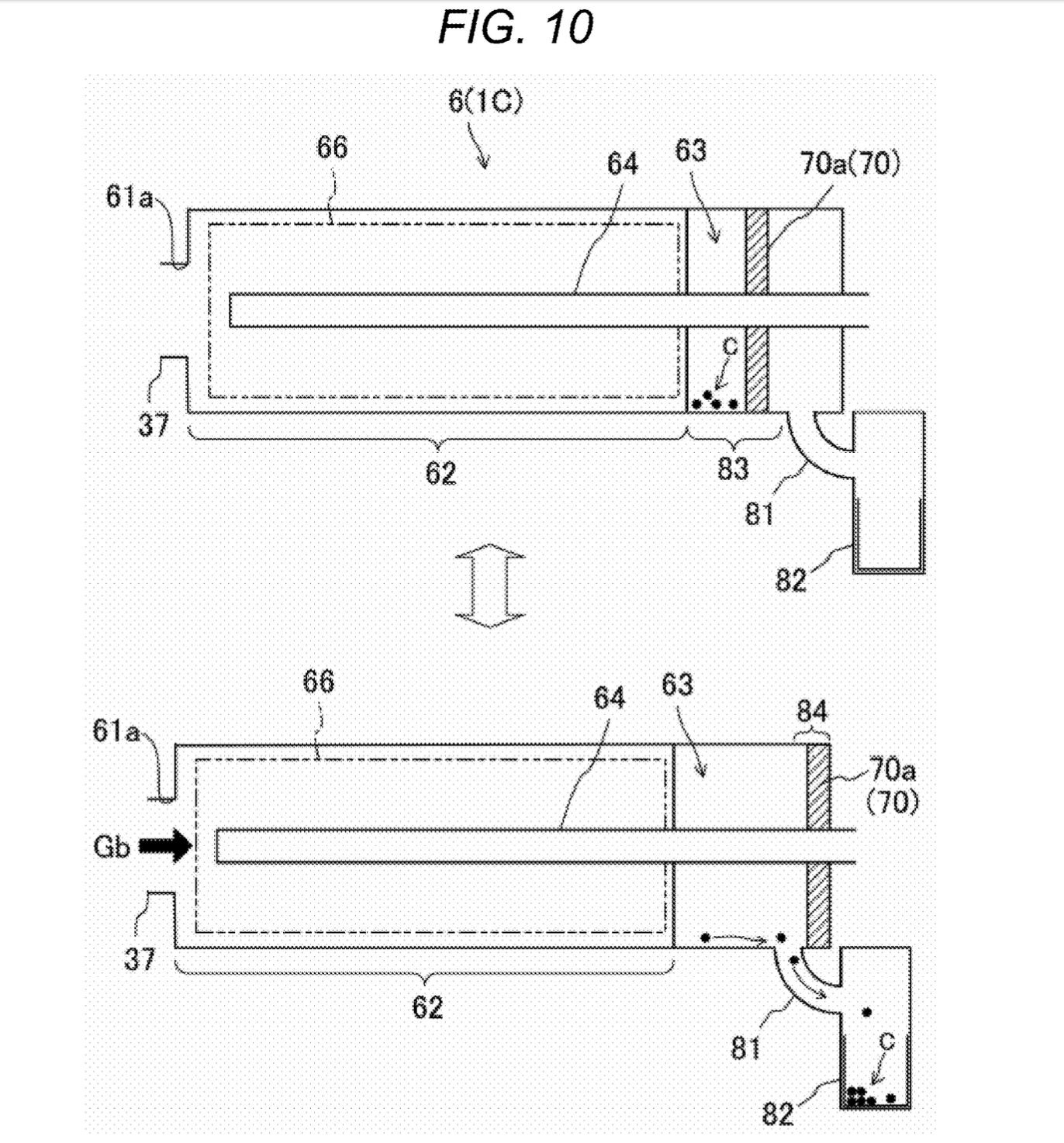

Think of a decomposer as a type of catalytic converter. The engine’s exhaust gas in the exhaust stroke is used to carry injected fuel through the decomposer, and heat up the catalyst so it functions correctly. Hydrocarbons in the fuel that was injected into the exhaust air pass through the decomposer, which separates the carbon and hydrogen, trapping the carbon and letting the hydrogen pass through.

Here’s the inside of the decomposer. On the left, the exhaust gases enter, and only the hydrogen is able to pass through.

Source: USPTO

In Mazda’s patent, both the carbon and the hydrogen are immediately stored elsewhere in the car—the carbon to be removed later during a routine service is stored in the decomposer, and the hydrogen to be re-injected into the engine to act as a fuel is stored in the “hydrogen fuel supply section.” The fifth stroke takes air back into the cylinder, while the sixth stroke finally pushes air into the atmosphere. From the patent:

[stroke 5, S5] is a re-expansion stroke. In the re-expansion\stroke S5, the piston 32 is lowered. The on-off valve 38 is opened in the re-expansion stroke S5. When the on-off valve 38 is opened, some of the residual gas in the decomposer 6 is discharged from the decomposer 6 to the combustion chamber 3a. Since the inside of the decomposer 6 can be scavenged, the high-temperature combustion gases can be guided into the third port 37 in the next cycle. Opening of the on-off valve 38 in the re-expansion stroke S5 is advantageous in reducing pump loss of the engine 3. S6 is an exhaust stroke. In the exhaust stroke S6, the engine 3 discharges the combustion gas in the combustion chamber 3a through the exhaust port 35 by raising the piston 32. In the exhaust stroke S6, the exhaust valve 36 is opened. The combustion gas in the combustion chamber 3a is discharged to the exhaust port 35. In the exhaust stroke S6, the intake valve 34 and the on-off valve 38 are closed.

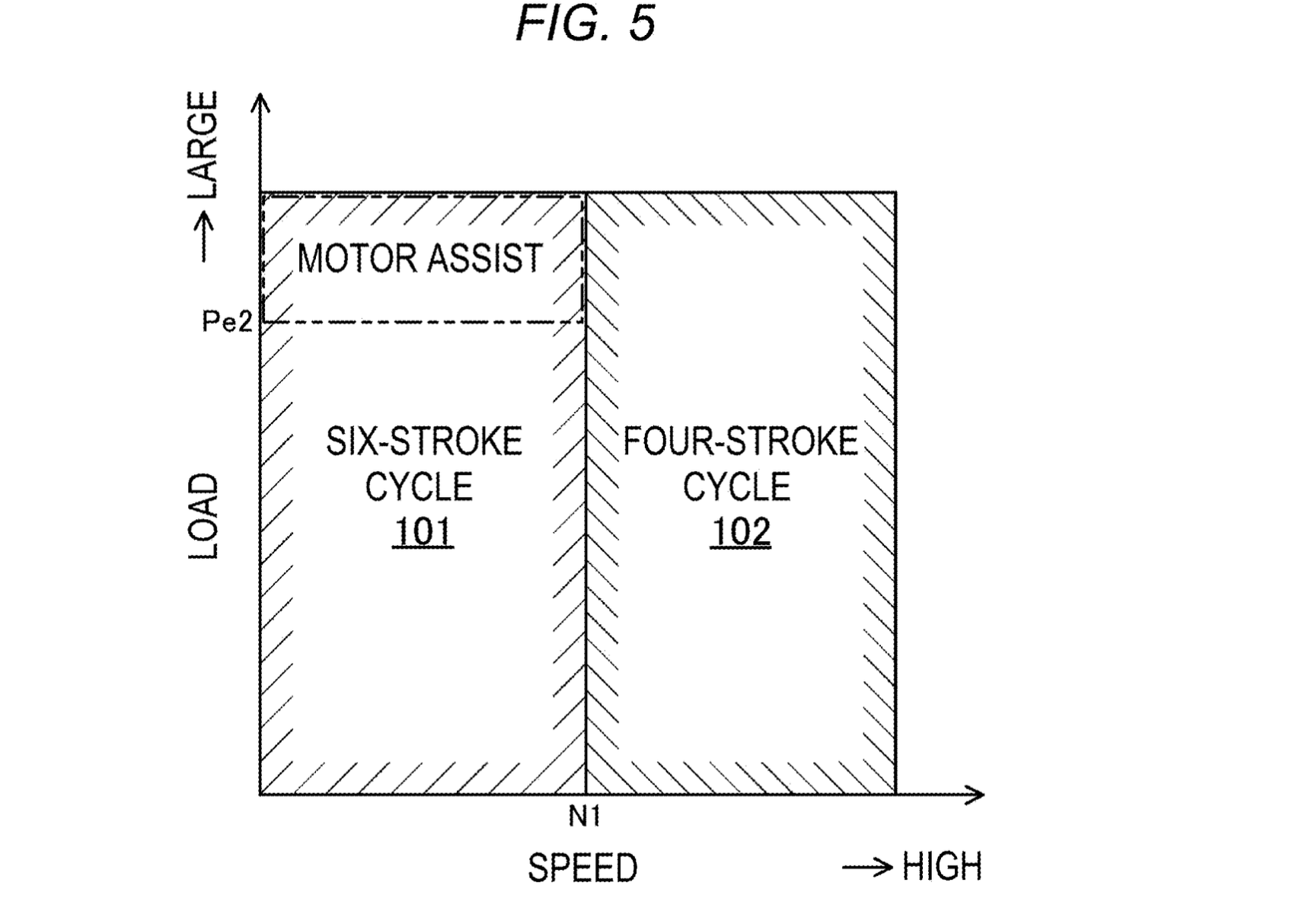

It’s important to note that Mazda’s six-stroke engine can also run on four strokes, for example, if it doesn’t have sufficient hydrogen on tap. Once the car’s onboard hydrogen supply is ready, it switches to six strokes, where the process begins. There’s an example control map below of load vs engine speed vs which process might be appropriate:

The result of this system? Ideally, near-zero carbon emissions. Sounds like the basis for a utopian society where cars still have great-sounding engines and global warming is a thing of the past, right? Well, not so fast.

Source: USPTO

For one thing, Mazda’s idea seems incredibly complex. The patent drawings make this concept look simple, but it would involve adding several new parts to the cylinder head—one of the most crowded parts of a modern engine. An entirely new valve path is needed to direct the exhaust gases to the decomposer, and another injector has to be added to feed the decomposer, and one to feed hydrogen into the cylinder. Not to mention a tank for the hydrogen needs to be placed somewhere onboard, and space needs to be made for the decomposer itself. And as Mazda points out in the patent, it would need to employ hydraulically or electronically controlled actuators for the valves, similar to Koenigsegg’s Freevalve tech.

Source: USPTO

Plus there’s the control strategy. Here’s a little example, which references the image on the left and the one above the one directly above:

“if the engine 3 is operated in the first region 101, the controller 21 executes the operation in the six-stroke cycle, that is, the operation using the hydrogen gas as the main fuel (step S4). On the other hand, if the engine 3 is not operated in the first region 101, that is, operates in the second region 102, the controller 21 executes the operation in the four-stroke cycle, that is, the operation using the hydrocarbon fuel as the main fuel (step S5)…When the engine 3 is operated in the six-stroke cycle, the controller 21 estimates the carbon deposition amount in the catalyst 66b based on the signals from the hydrogen gas sensor 25 and the like. When the carbon deposition amount is excessive, the function of the catalyst 66b is impaired. As a result, the produced amount of the hydrogen gas is reduced [0155] The controller 21 compares an upper limit value Ds of the carbon deposition amount, which is set in advance based on an experiment or the like, with an estimated value De of the carbon deposition amount (step S6). As a result, if it is determined that the estimated value De of the carbon deposition amount is equal to or greater than the upper limit value Ds of the carbon deposition amount, the controller 21 executes a carbon removal mode (step S7).

There’s also the issue of that stored carbon (in 82 above). As CarBuzz points out, gasoline is mostly carbon by weight. That means for every gallon of gasoline burned by Mazda’s six-stroke, you’d get about 5.5 pounds of carbon in the decomposer’s “collection box” (82 above). Multiply that by 15 gallons—the size of a fuel tank—and you get roughly 82 pounds of carbon every single time you burn through a tank. Which means it would have to be emptied and properly disposed of every time you fill up your car, which seems like a massive pain.

[Ed Note: With the engine running often in 4-stroke mode, and the reality that, even in the 6-stroke mode not all carbon from the fuel will end up in a form that can be captured, especially since it’s being mixed with exhaust gases, this may not be as big of an issue at “82 pounds per fill-up. Also, if you’re curious whether carbon capture after a regular combustion event might be simpler, Mazda breaks down advantages to this “reforming system” that splits hydrocarbons into hydrogen and carbon:

In the vehicle, on which the engine using the hydrocarbon fuel is mounted, in order to collect carbon or carbon dioxide, it may be considered to:

(1) collect carbon dioxide after combustion of the hydrocarbon fuel; or

(2) decompose the hydrocarbon fuel into carbon and hydrogen gas before combustion of the hydrocarbon fuel and collect carbon.In consideration that collected carbon dioxide or carbon is stored in the vehicle, (2) may be viewed in terms of fuel economy performance of the vehicle due to a reason that carbon dioxide is heavier than carbon. In addition, in the case of (2), it may also be possible to use the hydrogen gas as the fuel for the engine. It is also noted that when the hydrogen gas is combusted, no carbon oxide may be produced due to the combustion. Thus, it may be considered to mount the above-described decomposition device onto the vehicle.

It’s a wacky idea. -DT]

This is all just theory, of course, just like the rest of this engine. Whether its efficiency can actually overcome its complexity is anyone’s guess until Mazda actually puts something like this into production. That seems pretty unlikely, given the difficulties mentioned above. Still, it seems like a clever idea, and an indication that human ingenuity will keep pushing so internal combustion engines can live on in a cleaner, more positive light.

Top graphic image: USPTO

This article included significant input from David Tracy

So item 6 is Beethoven?

You take that Bach, sonny boy!

My understanding was that fuel splitting and reforming, while quick, was not as quick as a single stroke of an engine at 2000 RPM or more. I’m curious what prevents the 5th stroke “re-expansion” from drawing some of the un-reformed fuel back into the cylinder where it would be exhausted, resulting in very high unburned hydrocarbon emissions coming out of the engine (if the aftertreatment system is hot, these could potentially be cleaned up, but they still represent a loss in efficiency). Maybe a one-way-valve type mechanism could be used just after the fuel reforming membrane to trap the H2 on one side, but I think you’ll still run into issues Presumably only a small amount of the exhaust is sent into the reformer during the 4th and 5th strokes, otherwise you’ll start racking up significant pumping losses too.

I’ve worked on a variety of novel engine concepts, many involving additional strokes etc, with one of them (5 stroke, DBDC+EC in GM parlance) getting as far as designing one, having 5 running example engines built that we put thousands of hours on running, and publishing papers on it (which is why I can talk about it).

https://saemobilus.sae.org/articles/downsized-boosted-dilute-combustion-exhaust-compounded-dbdc-ec-experimental-engine-design-thermodynamic-model-comparison-performance-potential-predictions-2021-01-0443

That was my thought, as well. I think this is just one of those ideas they patented for the sake of it rather than intent to produce.

It’s Mazda though, I’ll wait for the inevitable prototype pentagonal-shaped rotary that gives us two more apex seals to worry about.

I still feel like it’s not as complex as the Tiguan’s miller cycle turbo electronic cam engine, made by VW, the name you can trust in super reliable engines.

Also I still feel like a fuel cell car with a reformer that can basically do a similar thing as this would be better, less moving parts, runs on regular fuel, same performance as electric. But at least they’re trying.

So looking at figure of the decomposed I’m seeing H2 and O2 together in a very hot decomposer. That could be a problem.

Unless the first combustion of H2 is lean, there shouldn’t be much O2 present in the decomposer. There will be some (there’s never complete combustion, and often the hydrocarbon fuels we use have some oxygen content, especially with 10-15% ethanol mixed with gasoline), but it likely won’t be anywhere near the rich flammability limit.

Fair point and done right it might keep the catalyst hot.

“There’s also the issue of that stored carbon (in 82 above). As CarBuzz points out, gasoline is mostly carbon by weight. That means for every gallon of gasoline burned by Mazda’s six-stroke, you’d get about 5.5 pounds of carbon in the decomposer’s “collection box” (82 above). Multiply that by 15 gallons—the size of a fuel tank—and you get roughly 82 pounds of carbon every single time you burn through a tank. Which means it would have to be emptied and properly disposed of every time you fill up your car, which seems like a massive pain.”

The solution is obvious! Yet another extra cycle that uses the pistons to squeeze that carbon into diamonds! How hard can it be to get a compression ratio of a gazillion to one?

I see a battery powered tool which clips on to the carbon box, opens a valve, gets a shot of carbon, closes the valve and then compresses it into barbecue briquettes…

Still goes into the atmosphere but is reused.

And I can bet you can get some sawdust in the mix to give that wood smoke taste.

Why not just BBQ on the fly? Throw some meat into that system and by the time you get where you’re going you’ve got dinner too!

A yakitori grill built into the dash is such a ’50s car concept.

Who said grill? I’m talking BBQ!

Just drive along leaving a little trail of diamonds behind you. Perfect!

Pretty sure this is how Fancy Kristen back at the old lighting site used to roll.

Maybe it’s just me, but it seems like discarding the overwhelming majority of the mass of the gasoline wouldn’t be great for fuel economy.

The energy from burning a fuel comes from breaking the bonds between atoms, not the mass of those atoms, but that’s about as much chemistry as I can remember.

I don’t think they’d have gone to the effort of applying for a patent if they hadn’t already done the maths and decided that there is a potential advantage to this method.

That’s what happens in every combustion-engine car. All the mass goes out the tailpipe. Heck, MORE mass goes out the tailpipe. For every gallon of gasoline (about six pounds) you burn, you get about 20 pounds of CO2 and about 8.5 pounds of water straight out as exhaust, since the oxygen in the CO2 and the H2O is from the atmosphere when you burn all the C and H in the gasoline.

Wikipedia tells me that octane (C8H18) is about 44 MJ/kg.

That kilogram of octane contains 158g of hydrogen, which is about 120 MJ/kg (using lower heating values because that’s what they have listed for the octane), so 19-22 MJ from the 158g.

The carbon would have a value of like 27 MJ (high heating value—LHV isn’t listed) if it was just coal.

So you take 44 MJ and turn it into like 20 MJ, plus flammable solid waste.

[…if I’m doing this right. There are two reasons you become a mechanical engineer: one of them is chemistry, and the other one is electricity.]

Hmm. I think something can’t be exactly right, since starting with something that if completely burned produces 44 MJ, seems to result in components that yield 20+27=47 MJ.

Ha, funny! And similar phrases can be made for and against the other disciplines. I say that as someone who had a few years of EE before switching to ME.

“…roughly 82 pounds of carbon every single time you burn through a tank. Which means it would have to be emptied and properly disposed of every time you fill up your car, which seems like a massive pain.”

Seems to me the car could just deposit the carbon on the roadways – it’s heavy and sticky enough that we would not have to repave roads anymore!

(Hey – where’s that GM-patented device for spray traction on icy roads?)

Wait you’re cooking here

Nope. That carbon would be in the form of incredibly fine soot which is a pollution of its own.

Time to start home-manufacturing calligraphy ink. Etsy here we come!

I mean its just lamp black. All you need is a kerosene lamp and boom, your steam punk ink store is set!

I love that Mazda is out there working hard to try new things. I was just watching a video of Mazda’s 1991 787B rotary LeMans winner and the sound was amazing. This is how you run a company folks. 3 stage shiny paints, cars that are fun to drive, having a roadster that is affordable as your “halo” car.

Speaking of which, I wonder what happened to those Skyactive-X semi-dieseling engines that were supposed to replace the previous Skyactive-<other letter> eventually.

This is some wild stuff! I love how out there Mazda always is with their engineering, they work so hard for such a small company.

Pretty much all engine design advancements were seen as too complex to work at some point.

I’m hoping we at least get to see a prototype at some point. This would be super cool to further kill emissions on an EREV setup.

You could probably change generator strategies to balance power output with emissions/efficiency gains, since you’re not driving the wheels directly.

Having briefly owned a ’77 VW Bug about 25 years ago, I’m now thinking about maybe, just maybe, giving fuel injection another chance. No promises, though.

We went from a metered fuel leak to active injection. It was a HELL of an advancement.

Oh, I wasn’t thinking of giving modern fuel injection a chance. No, no, no, no. Not that.