Making cars, is, as you may have surmised, hard. They have so many parts! And all those parts have to fit together just the right way with other parts, and then you have to make sure that the whole thing doesn’t catch on fire or fall apart or slice off people’s earlobes or anything like that. On top of all of that mess, you also have to be sure you meet all of the laws and requirements of the country you’re trying to sell cars in, and that’s even more exhausting. It’s enough to take all of the fun out of building cars, and I suspect this is how British Leyland was feeling in the 1970s, because that would explain the thinking behind this incredible act of phoning it in I’d like to tell you about.

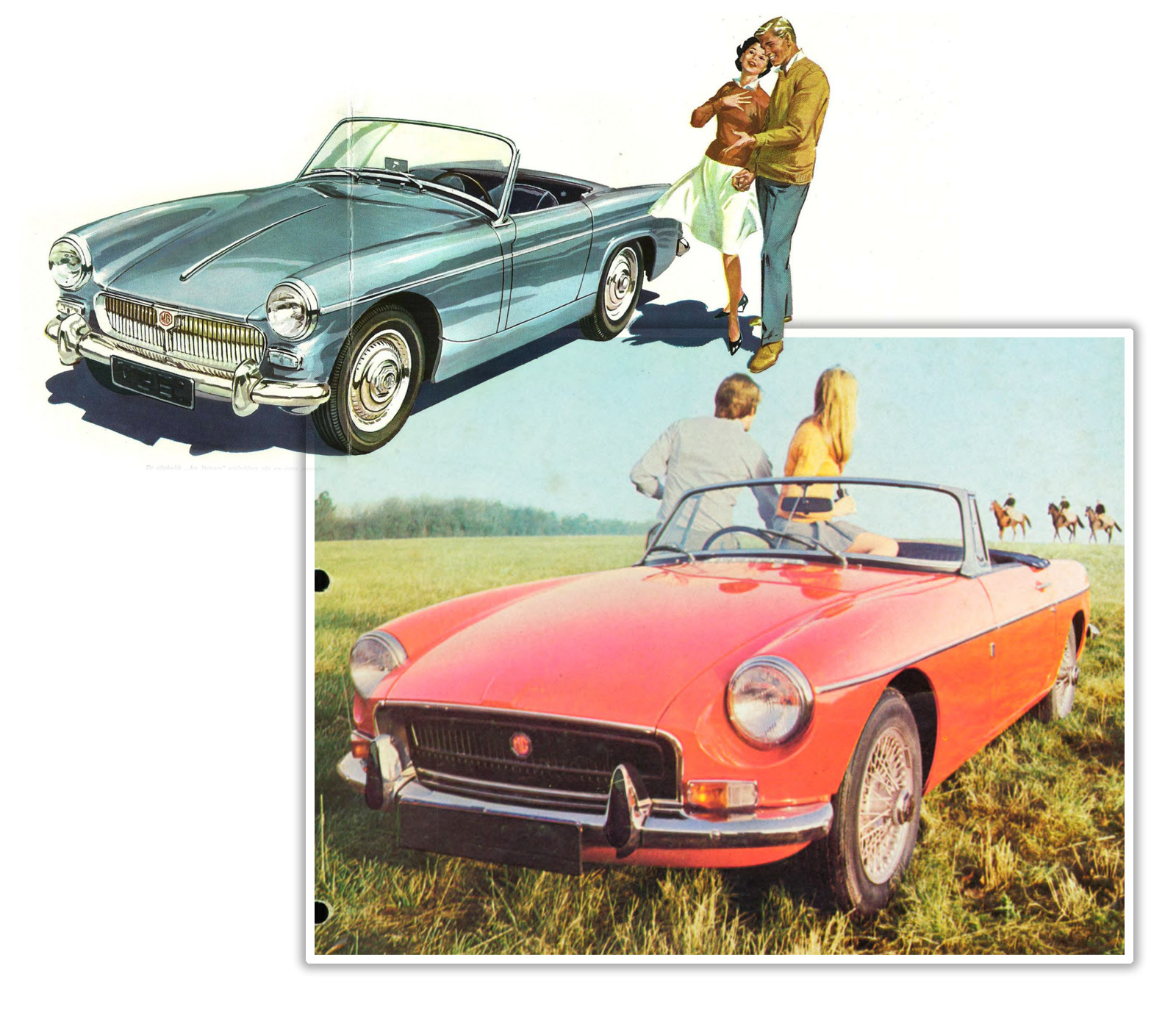

I suspect many of you already have heard about this, but it’s possible there are people out there who have not, so I think it’s worth retelling this story. The cars I want to talk about are the both from MG, the MG Midget and MGB. And, for proper context, it’s important to remember that the most important market for MG was North America, where they sold the majority of their cars; of about 528,000 MGBs sold overall, over 300,000 went to North American markets. That’s a huge chunk.

I think that’s all worth keeping in mind because it helps make the scale of this act of phoning it in even more impressive. The issue has to do with regulations America has for things like headlight and bumper height, which are mandated by Federal Motor Vehicle Safety standards 108 for lighting and 581 for bumpers. These height regulations have changed over the years, and has caused some companies to make some strange alterations to their cars to qualify.

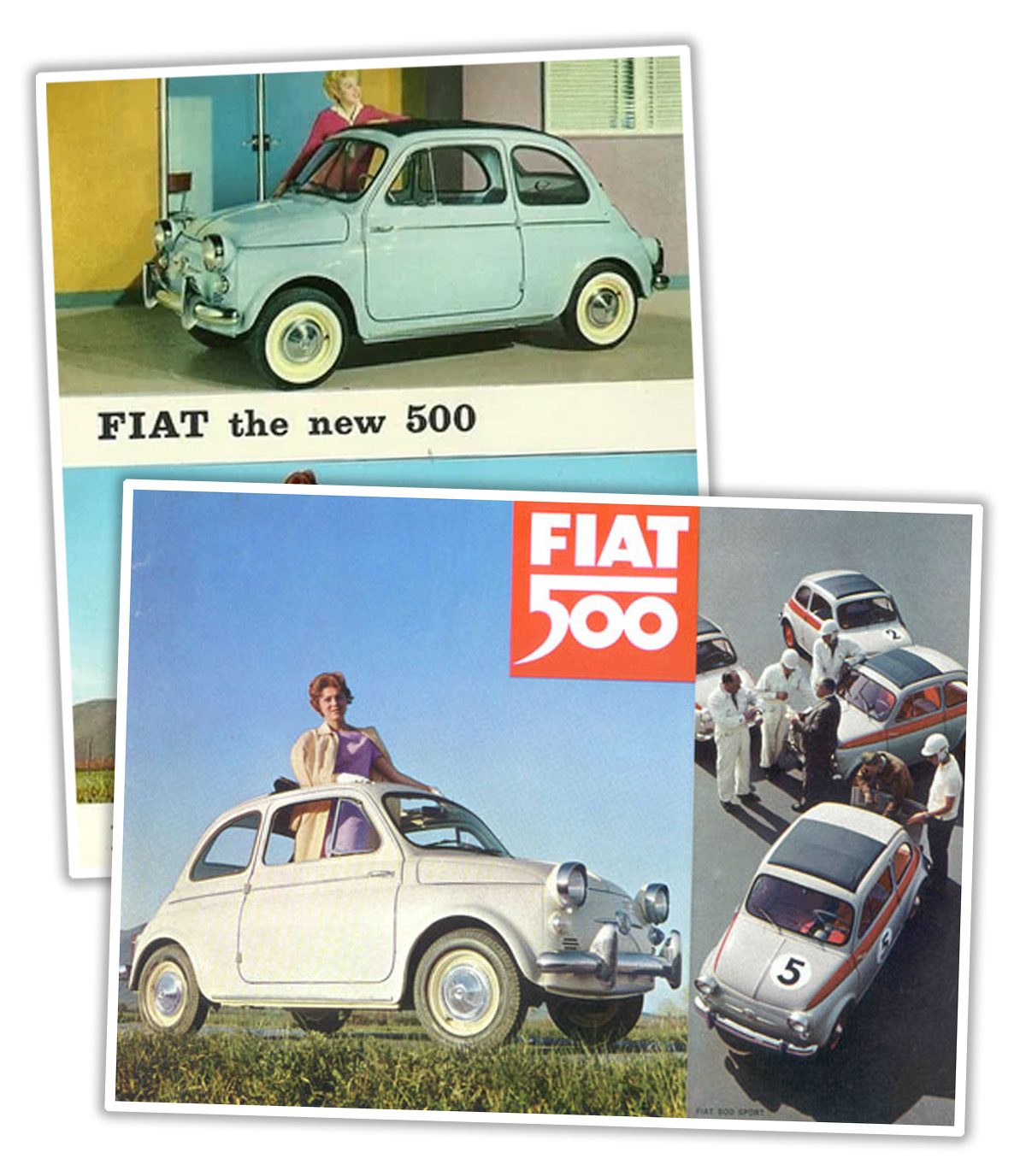

For example, look how goofy the US-market Fiat 500s looked with their tacked-on larger headlamps needed to meet the mandated height requirements:

That was a sort of phoned-in solution, too, but in Fiat’s defense, the US market for the 500 was quite tiny, and it really wouldn’t have made sense to redesign the entire front sheet metal for such a small part of their overall sales. With that in mind, the funny-looking larger headlamp units actually make a good amount of sense.

But let’s get back to MG; in 1974, America made some pretty big changes to their bumper and headlamp standards, mandating newer, much more robust bumpers capable of withstanding a 5 mph impact with minimal damage. The original bumpers on the MG Midget and MGB really weren’t up to the task, being somewhat delicate chrome blades:

Those bumpers wouldn’t cut it. MG had a sort of stopgap bumper with huge rubber blocks on them, nicknamed “Sabrinas” for a British model and actress of the era who, being a mammal, possessed breasts:

These, however evocatively named, were not enough, and by late 1974/early 1975, the rubber-bumper’d MGB and Midgets were born, much to the dismay of MG purists.

Personally, I think everyone who is throwing a fit about the look of these rubber bumpers (they’re really polyurethane over steel, and are quite beefy and heavy, weighing at least 50 pounds per bumper) needs to relax, because all things considered, I think they’re very well designed and integrate with the lines of the car very well. They don’t look like a tacked-on afterthought at all, but rather a seamless development of the basic design. I’ve defended these cars before.

I’m telling you this because it all makes the phoned-in part so much more baffling. Clearly British Leyland took these new bumper regulations seriously. They designed entirely new bumper units that seemed to meet the standards and worked with the cars design. There was only one problem:

They weren’t the right height.

Yes, the bumpers and, it seems, the headlights were about an inch too low to meet the American standards. How this didn’t come up in what must have been the extensive design process for these new bumpers is completely baffling to me, yet somehow, it didn’t. MG needed to get the bumpers and lights higher by about an inch or so.

So how did they do it? Did they redesign the bumper mounts and sheet metal of the fenders to give an extra inch or so of height? Nope. They just jacked the whole damn car up by about an inch.

Of course, this did nothing good for the handling, which was already compromised by the new heavier bumpers and, just to really put a cherry on top of this turd sundae, in 1975 and 1976 they also removed the front anti-roll bar. The result was the center of gravity was higher, the car rolled more in turns, had more weight to move around with an already smog-equipment compromised engine, looked off, and was just about worse in every way.

Oh, unless you backed into a hydrant. Then it was much better.

If MG was selling economy hatchbacks in America, maybe it wouldn’t have been a big deal. But this was a sporty roadster; good handling and fun driving is its whole raison d’etre, that’s why the thing exists at all!

It’s just baffling to me that this company, which not just understood the importance of the American market, but spent considerable time, effort, and money to make these new compliant bumpers, would somehow screw up something as basic as the required height, and then “fix” it with what is likely the absolute least amount of work possible beyond just lying about the height for as long as they could get away with it.

It’s an amazing act of phoning it in, one that deserves to be remembered. I think if you push on the suspension of these MGs, you can almost hear the designers and engineers saying “fuck it, good enough” with every squeak. It’s almost magical.

In MG’s defense jacking the whole car up was a cheaper solution than designing something properly and during the 70’s BL wasn’t really in the business of designing anything well so this might have been the best possible solution at the time.

The ’70s were a cesspool of half-assery.

I didn’t know about Sabrina, nor the suspension lift, but I thought the black rubber bumpers were hideous. So, I learned a couple things today.

The only bumpers of that era I liked aesthetically were on BMWs.

Wow, I’d somehow missed this one, hilarious. Also, if they had just painted the bumpers body color I don’t think anyone would’ve complained much about them, but the big mass of black doesn’t work well.

I wonder what ride height the MG RV8 had. Those were sold in the UK in the early 90s and used the rubber bumper MGB shell and a fuel injected Rover V8

The timing of this article is amusing for me. I was at a British car show last weekend and with all the MGs lined up in a row, it was easy to compare the rubber-bumpered ones with their predecessors.

They were just ahead of the curve. These days you jack up the ride height by an inch, call it the Wilderness package, and sell it for an extra $5k.

the TourX ad copy touted the increased ground clearance compared to the sedan/fastback.

They never say how much… turns out it’s 8/10”. Presumably really 2cm.

I have a theory on the screw up of ride height.

Before this article, I figured those bumpers were just a thin steel plate with a molded black plastic cap that was full of foam. In an accident, the bumper would explode, but the replacement cost would be so cheap that it would count as a 5 mph bumper (that’s what the Japanese did in that era). I really didn’t know it had robust steel under that rubber.

With that steel adder, the bumpers add 50 lbs to each end of the car. I’ve seen MGBs sink significantly when a driver climbs on board, and adding 100 lbs of extra weight on the ends likely caused it to sink too much.

With the porking up, MG had basically two options. The right way would be switch to stiffer springs so that the ride height was correct with the additional weight. The cheap way would be to put an extra coil in the existing spring. Going to a stiffer spring would have required different shocks and development time to get the ride and handling right. While keeping the same spring stiffness, just with an extra coil installed wouldn’t have to require that much change.

Same with the Delorean. They had to fit longer front springs at the last minute, and (reportedly) it ruined the Lotus-tuned handling of the car. When the ‘correct’ (i.e. non-stock) springs are fitted in the front, the car not only sits right and looks better, but handles well, too.

Talking about Lotus-tuned, on the Europa they jacked up the front end for the headlight rules by switching the, IIRC Triumph sourced, lower control arms side to side so they bent downwards lifting the car. Easy and just as light as they were before.

My first car was a 1978 MGB with the rubber bumpers, a red one just like the top picture. Seemed ancient when I got it for $1,500, but it was only 10 years old. I always thought it was a great looking car, I had a lot of fun and mishaps with it. If it started it was pretty reliable. Lucas electrics of course made it not start fairly often.

I had my rubber bumpers deleted. Also, swapping in V8 loads the car just enough to lower it back 1″.

https://imgur.com/a/qxxXa7d

That’s a beautiful ride.

I grew up in the 80s/90s across the street from a guy who always had a couple of MGs. As a kid, I always liked the look of the rubber bumper Bs better, so when the time came to find a fun car, my neighbor had a rubber bumper B up for sale and the choice was obvious. I look at chrome bumper cars and conversion kits from time to time, but after 19 years with the car I’m not super inclined to change it up.

I don’t mind the rubber bumpers. To me, the first MGBs are cool cars and look to be of the 60s, while the rubber bumper cars are also cool and seem to be about 10 years newer. Neither design is bad, it’s just different.

These cars were absolutely hated in the used car market, so for a long time you could buy them for peanuts. Today their value is almost equal to the earlier models, and they’re not scorned as much at car shows.

The one Midget related obscenity that Torch missed was that these rubber bumper cars no longer came with the traditional A series 1275 motor, nope – they had Triumph Spitfire 1500 motors and gearboxes. The had a little more hp from the greater size, and fully synchro’d first gears tho so…….tradeoffs!

And don’t forget the earlier half-ass fix of putting 3 wipers on the B and Midget to get the legally mandated windshield coverage. Some things should only ever come in twos. As the picture of ‘Sabrina’ alluded to.

Based on my teenage viewings of Total Recall, three seems fine in both cases.

As Al Bundy said, “and one in the back… for dancing.”

FJ cruiser has entered the chat.

Ha! I never knew the FJ Cruiser had 3 wipers! Granted that car looked ass to begin with, so no harm done.

NM

If three wipers are good enough for what Enzo Ferrari called “the most beautiful car in the world”, the Jaguar E-Type, then they’re good enough for the humble B.

Roadster only, BTW – the GT only had two.

I had to take a look at how Alfa Romeo and Fiat handled the mandates and Fiat’s solution was ugly but not as bad at the Spitfire and the Alfa handled the situation and their Spider came out quite well.

Bigger rims and/or more sidewall would have done the trick too.

That might cost $5 per car!!!

I would like one of the baseball T shirts in the top shot please. Large-tall size if it’s available.

That is more like quarter assed, aspiring to be half-assed

Buy new tall MG, go to parts department, buy springs for the prior year car.

That’s the other problem- the way they increased the ride height. The front cross member and steering rack are all different. You have to yank the engine to swap these out. They should have done it the way GM did its skip-shift mechanism in the Corvette. All you have to do is yank a fuse and you’ve bypassed it. It’s made to be easily defeated.

thats crazy… i figured it would have been done the cheapest way possible. Even springs feels like it would have been too expensive and they could have just used spacers.

They should have done that. That way you could just drop the spring pan (a really nifty feature in the MGB), toss out the spacer, and voila, back to original height!

I’m not trying to defend the half-assery of jacking up the suspension to meet changing US regs, but there is a certain logic to it. The big rubber bumpers obviated the need for sheet metal changes, but getting the headlights to the right height likely would have required, at least, revised front wings/fenders and, perhaps, changes to the entire front clip, which was likely beyond BL’s meager means at the time.

And they probably had closets full of sketches for new MG and Triumph sports cars and thought that this is just a short term solution: Allegro, Marina and Princess etc. are just around the corner! When these mainstream hits are released to the market, the BL will roll in cash from the export markets and surely then we can afford to bring the new special vehicles to the market?

At least on the US Spitfire the chassis had rails / legs facing rearwards behind the rear suspension offering some level of rear crash protection. The UK version had no such things.

I helped a buddy rebuild his Spit in the UK, the original chassis was rotten and there was a place importing rust free California cars. He got a really good used chassis and then cut the two rails off, even though he could have left them…

It’s been 40 something years and I still can’t believe he did that.

Chinese, Japanese, and Korean auto engineers will never come up with this level of half-assery.

Statistics suggests that their significant others are unlikely to provide the visual inspiration to the “Sabrina” solution.

I hear designers of all stripes are always looking for a couple of good pointers. For inspiration.

Supposedly, the new bumpers were intended to be painted body colo(u)r, but BL had a hard time getting the paint to adhere properly and just gave up and went with unpainted black. You occasionally see one that’s been painted, and the effect is much clearer, they do integrate pretty well and do make the car look a lot more modern for what had to be spare change money

It is somewhat telling that the later RV8, F, and TF all seemed to draw more styling inspiration from the rubber bumper B than from any earlier versions, so clearly the design can’t have been all that hated by the people working for the company that built it

After Googling what a painted one would look like, I think I actually prefer them black.

I was just saying the same! I will post my reply too.

My dad had a 1979 with the rubber bumpers so maybe I am biased, but I don’t like when they are painted. It looks TOO modern and accentuates the fact they are quite big; black is slimming. It looks like a cheap body kit on a car designed in the late 1950s; wrong aesthetic. Somehow the raw black is more fitting to the design.

I had a TR8 and I’ve seen color-painted bumpers. I thought they looked terrible, and unlikely to hold up.

21 year-old me put a sticker on the factory glossy black coating on my car’s bumper, though, which was a predictable mistake, so what did I know.

I have a rubber-bumper model, and I briefly considered painting them body-color. Then I saw one in person, and realized that I like black better.

I did lower the car back to it’s intended height, and luckily they put the anti-roll bar back for 1977 – 1980 so that’s not an issue for me.

I had to take a look at the black does work better. Oddly enough, they look larger when painted to match. This is definitley one of those times when you better have a Vegap level professional poker face when asked “Does this bumper make me look fat?”.

PS, used to be a couple of good businesses re-importing MGs, from California and other deserts only, back into Europe. Don’t know if they still going…