Making cars, is, as you may have surmised, hard. They have so many parts! And all those parts have to fit together just the right way with other parts, and then you have to make sure that the whole thing doesn’t catch on fire or fall apart or slice off people’s earlobes or anything like that. On top of all of that mess, you also have to be sure you meet all of the laws and requirements of the country you’re trying to sell cars in, and that’s even more exhausting. It’s enough to take all of the fun out of building cars, and I suspect this is how British Leyland was feeling in the 1970s, because that would explain the thinking behind this incredible act of phoning it in I’d like to tell you about.

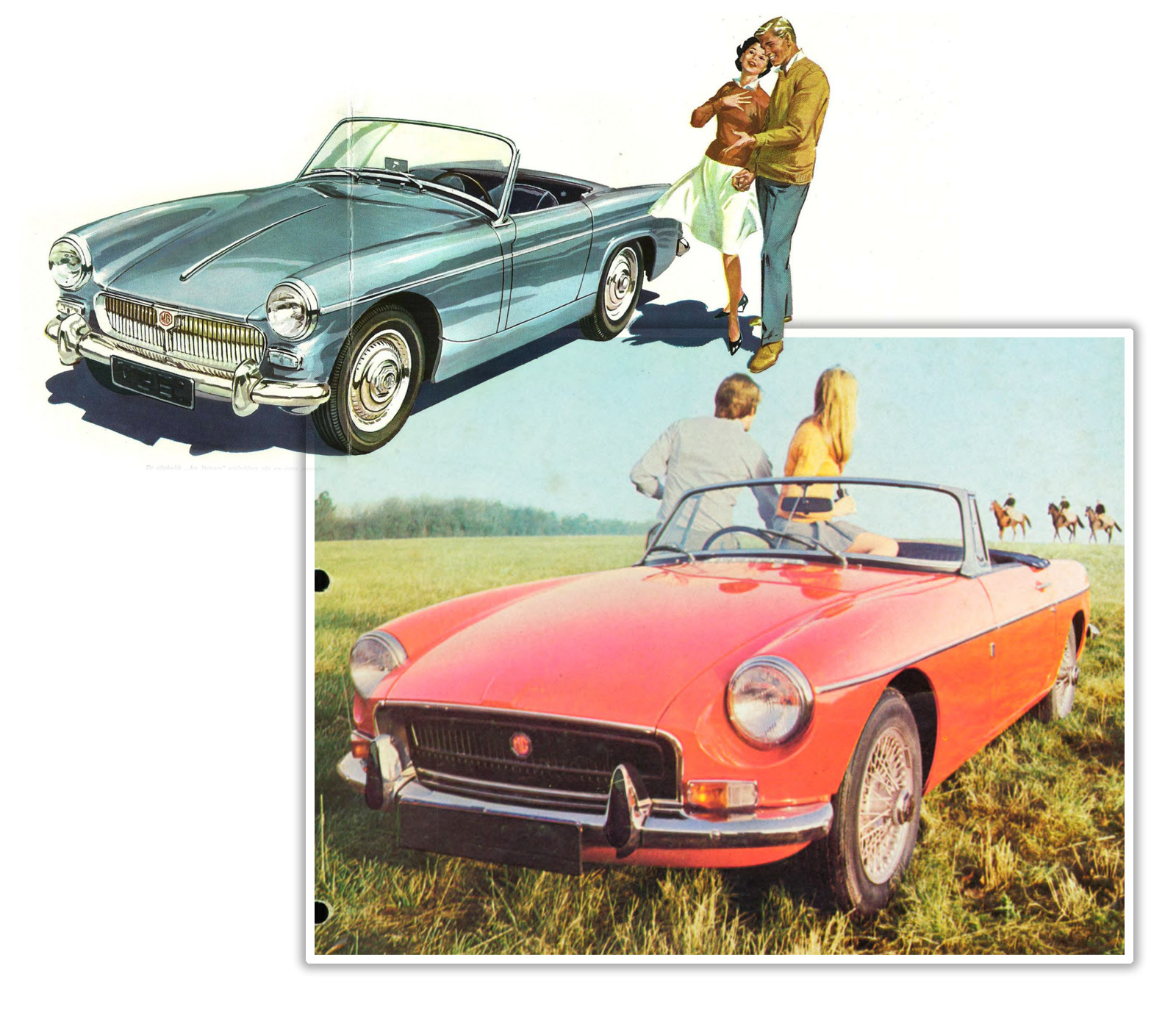

I suspect many of you already have heard about this, but it’s possible there are people out there who have not, so I think it’s worth retelling this story. The cars I want to talk about are the both from MG, the MG Midget and MGB. And, for proper context, it’s important to remember that the most important market for MG was North America, where they sold the majority of their cars; of about 528,000 MGBs sold overall, over 300,000 went to North American markets. That’s a huge chunk.

I think that’s all worth keeping in mind because it helps make the scale of this act of phoning it in even more impressive. The issue has to do with regulations America has for things like headlight and bumper height, which are mandated by Federal Motor Vehicle Safety standards 108 for lighting and 581 for bumpers. These height regulations have changed over the years, and has caused some companies to make some strange alterations to their cars to qualify.

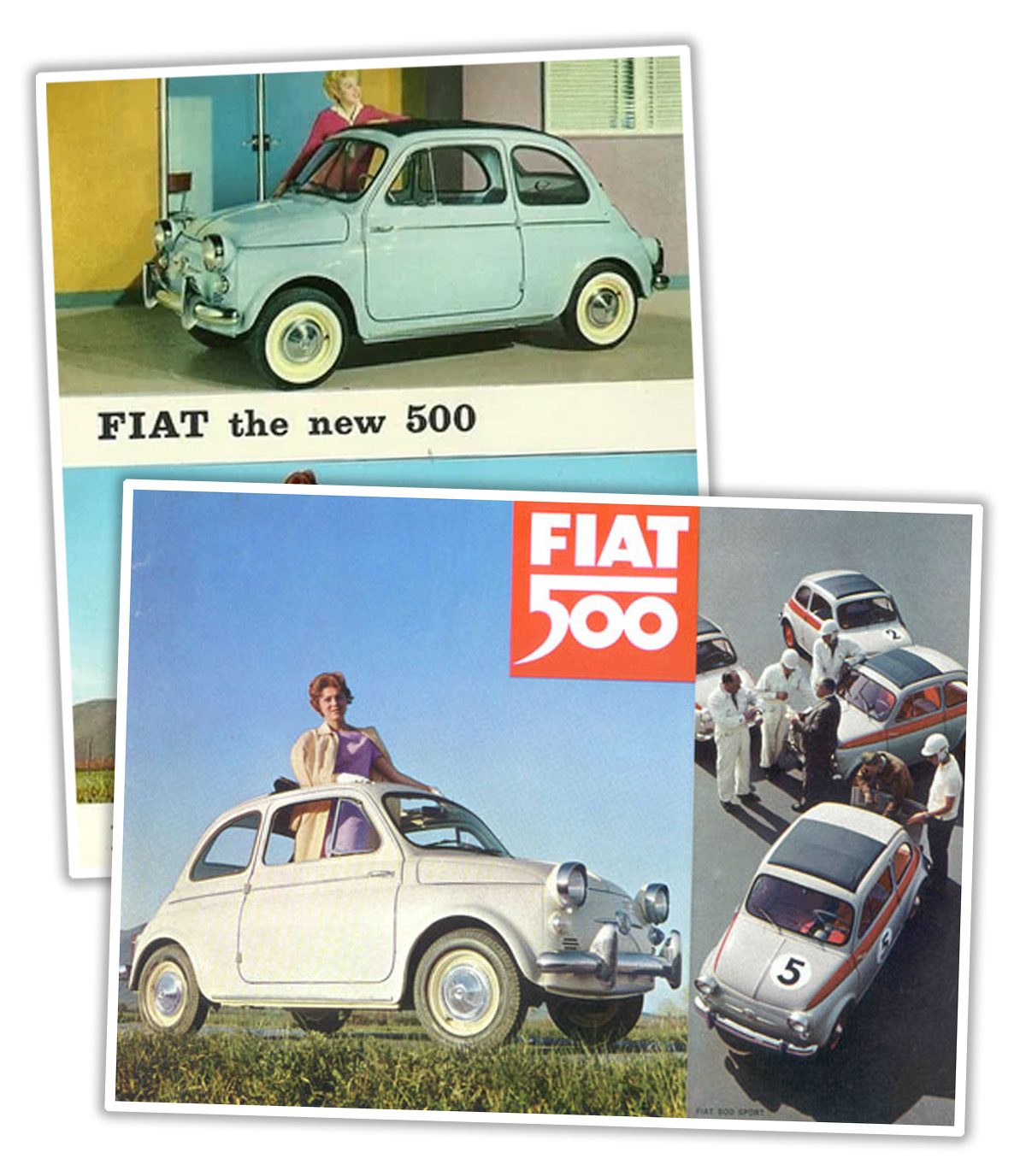

For example, look how goofy the US-market Fiat 500s looked with their tacked-on larger headlamps needed to meet the mandated height requirements:

That was a sort of phoned-in solution, too, but in Fiat’s defense, the US market for the 500 was quite tiny, and it really wouldn’t have made sense to redesign the entire front sheet metal for such a small part of their overall sales. With that in mind, the funny-looking larger headlamp units actually make a good amount of sense.

But let’s get back to MG; in 1974, America made some pretty big changes to their bumper and headlamp standards, mandating newer, much more robust bumpers capable of withstanding a 5 mph impact with minimal damage. The original bumpers on the MG Midget and MGB really weren’t up to the task, being somewhat delicate chrome blades:

Those bumpers wouldn’t cut it. MG had a sort of stopgap bumper with huge rubber blocks on them, nicknamed “Sabrinas” for a British model and actress of the era who, being a mammal, possessed breasts:

These, however evocatively named, were not enough, and by late 1974/early 1975, the rubber-bumper’d MGB and Midgets were born, much to the dismay of MG purists.

Personally, I think everyone who is throwing a fit about the look of these rubber bumpers (they’re really polyurethane over steel, and are quite beefy and heavy, weighing at least 50 pounds per bumper) needs to relax, because all things considered, I think they’re very well designed and integrate with the lines of the car very well. They don’t look like a tacked-on afterthought at all, but rather a seamless development of the basic design. I’ve defended these cars before.

I’m telling you this because it all makes the phoned-in part so much more baffling. Clearly British Leyland took these new bumper regulations seriously. They designed entirely new bumper units that seemed to meet the standards and worked with the cars design. There was only one problem:

They weren’t the right height.

Yes, the bumpers and, it seems, the headlights were about an inch too low to meet the American standards. How this didn’t come up in what must have been the extensive design process for these new bumpers is completely baffling to me, yet somehow, it didn’t. MG needed to get the bumpers and lights higher by about an inch or so.

So how did they do it? Did they redesign the bumper mounts and sheet metal of the fenders to give an extra inch or so of height? Nope. They just jacked the whole damn car up by about an inch.

Of course, this did nothing good for the handling, which was already compromised by the new heavier bumpers and, just to really put a cherry on top of this turd sundae, in 1975 and 1976 they also removed the front anti-roll bar. The result was the center of gravity was higher, the car rolled more in turns, had more weight to move around with an already smog-equipment compromised engine, looked off, and was just about worse in every way.

Oh, unless you backed into a hydrant. Then it was much better.

If MG was selling economy hatchbacks in America, maybe it wouldn’t have been a big deal. But this was a sporty roadster; good handling and fun driving is its whole raison d’etre, that’s why the thing exists at all!

It’s just baffling to me that this company, which not just understood the importance of the American market, but spent considerable time, effort, and money to make these new compliant bumpers, would somehow screw up something as basic as the required height, and then “fix” it with what is likely the absolute least amount of work possible beyond just lying about the height for as long as they could get away with it.

It’s an amazing act of phoning it in, one that deserves to be remembered. I think if you push on the suspension of these MGs, you can almost hear the designers and engineers saying “fuck it, good enough” with every squeak. It’s almost magical.

Soppy Brits. When we needed high lights we just put them on the roll bar, which for the MG is the front windscreen.

Didn’t think of that did you, you pommy so and sos.

Put a spring on one of the lights and you can use it for lamping rabbits.

In fairness, MG was given approximately £1.90 by the overlords of British Leyland to make the MG line comply with the new regs.

Ok, I’ll admit it. I agree with you on the MG’s plastic bumpers. I always thought they looked cool. As a former owner of a 1980 Triumph Spitfire, however, I didn’t have my plastic bumpers, but Triumph did a much worse job making them look like they belonged there.

My ’78 MGB was converted to chrome bumpers, middle wiper deleted and brought to the lower ride height. Every time I hit a bump, a vertebra gets compressed. In a few years, I will be about 3’6″

I didn’t realize that a middle wiper delete was a thing. That’s one of the first things that the youngins comment on when they see me with it out.

The previous owner of my B did the delete and did a really good job. Can’t even tell it was ever there. He also added a functional hood scoop and some aftermarket cold air intakes on the hood.

Owning a 74′ MG B GT, one with crome bumpers + the rubber blocks aka “Sabrinas”, this is very interesting to me.

While I knew the Sabrinas were to meet US crash regulation changes, I didn’t realize the Sabrinas were a less than 1 year add on.

Tks.and have a good weekend everyone!

I think the rubber baby buggy bumpers look good. Couldn’t they have made them an inch thicker? I mean, that’s what she said?

All this talk about quirky little British cars from the 70s, and not one mention of Lucas?

Torch… I think we’re going to have to have a trial separation for that sin. Then again, maybe I’m beating the outdated trope drum perhaps one too many times.

Regulations said the lights had be a certain height. There was nothing about them being required to function properly when switched on.

“Fuck it, good enough.”

-Mediocrates (470 BCE-390 BCE)

Patron Saint of UK Midlands.

Porsche did it as well. Maybe in a more not so seventies british way, but they did it!

MG was always going to MG, but you know who else “phoned it in” to meet US safety stadards for bumper height?

Porsche. The G-series 911s from 1974 to 1989 were also jacked up in North America. Put three owners together and the question will quickly devolve into “Did you lower yours to Rest Of World (ROW) height? I lowered mine to Rest of World height.”

Edit: Those three-quarter sleeve MG t-shirts were cool. Wish I till had mine, with a few decades of patina/fading on them.

I managed to cram a four year engineering degree into six years, having a total of three different majors. I started as an electrical engineer, mainly because my brother was one. I lost interest in chasing electrons after Circuits II. I realized that since I was a car fella and I liked working with my hands, mechanical engineering was the place to be. That was also the semester that Organic Chemistry, the only class where I earned a B-, was dropped from the core class requirements for most engineering disciplines.

The summer after completing Heat Transfer (Thermo III) and Advanced Dynamics, both classes that I managed to get into despite not having taken Vector Analysis (I ended up taking accelerated classes of Vector Analysis and Linear Algebra at the same time that summer; I do not recommend, unless you are into masochism).

I landed an internship at one of our National Labs, and they sent me to a convocation for aspiring MEs. I sought out several automotive engineers to pester at the seminar and I was quickly disabused of the notion that ONE engineer was responsible for designing a car. They told me tales of the design compromises they were forced to implement to utilize existing components and tooling, as well as the indifferent attitude of management to their plight.

It forever changed my perspective. Whenever someone bitches about “the engineer who made (this task) a pain in the ass”, I share my story and ask them to think about all the times their bosses successfully avoided logic. Working for a government lab reinforced my philosophy of absurdity.

My Pops fell seriously ill at the beginning of the following fall semester. The family land surveying business was in danger of closing without him (thabkfully he recovered and stuck around for another decade), so I made the choice to leave ME and transfer to Civil Engineering (I’m very civil; I always say Please and Thank You, get it? Wink wink…oh, never mind) in order to run the business and eventually take over.

That being said, it comes as no surprise to me that something as fundamental to the redesign as the bumper height is completely overlooked when wading through complex, and sometimes contradictory, federal regulations. Considering the number of separate yet interdependent systems that comprise the machine that is an automobile, it’s easy for a design team to overlook a crucial design change based upon an evolving regulatory requirement. One “small” change has a cascading effect, and it is magnified when it has to be shoehorned into the design at the last hour.

I have been involved in complex engineering and land development projects where arcane and vague regulations have been overlooked, mostly due to rolling changes driven by ‘design by committee’. The design team was forced to commit to last minute changes that resulted in clumsy, inelegant redesigns to accommodate schedules, budgets, and ease of construction. And I never had to use what I learned in Organic Chem when making those changes. Boo.

I often have to remind my classmates that I know twice as much engineering math as they do. Because I had to take all of the engineering math courses twice.

“Lane, I’ve been going to this high school for seven and a half years. I’m no dummy.”

— Better Off Dead (1985)

Actual lol

“Sorry that your mom blew up, Ricky”

Not gonna lie, I did a lot of studying for the test and learning the material after. Never time to do it right, always time to do it over

Undiagnosed sleep disorder. I was mostly unconcious during morning classes, had to teach myself until 2:00 or 3:00 AM out of additional books. A few hours of sleep, repeat. Still pretty pissed no one figured that out until I was about 26.

I actually prefer the look of the rubber bumper cars, and it was pretty straightforward to lower the car back to (slightly below) original height, while also replacing the outdated lever style hydraulic shocks with Koni adjustable gas ones. I also fitted a front anti-roll bar.

After 25 years of owning a ‘75 MGB, I now know that I vastly prefer the lines of the rubber bumper version to the chrome. It just looks more modern. As for the height increase, my B is by far the lowest car I’ve ever driven. I can’t imagine sitting even an inch lower, and the center of gravity on the 75-80 MGB is such that you really don’t need the brake to take any turn.

The sway bar deletion was weird, but by the time I got mine, it was put back on. Same goes for the one-carb half-assedry to meet emissions. Everyone just put the second carb back on and registered theirs with classic plates. Problem solved.

So, I agree about the peculiar moves MG made to stay alive during its final five years, but as is, my ‘75 B is the best $3,000 I’ve ever spent, and the overall most reliable car I’ve ever owned!

I am also a fan of the way the newer bumper looked, and it was hard to tell that the increased weight affected the car’s performance. I have a friend who owns pre-and post- models, and acceleration in both was…modest. They are slow cars that drive fast, though

You can argue all you want that those rubber bumpers don’t look too bad, Jason, but they look awful. The original front end has a really nice, classic look to it. The rubber monstrosities killed that, and didn’t compensate by looking sleek or modern. They just look ugly. Maybe part of this is that I grew up with riding around in my dad’s ’66 MGB, and really liked that car a lot. When the rubber things came out, I was appalled, and I’ve never gotten used to them. Of course, the rest of the changes just made everything that much worse.

I had a ’66 MGB as well… an orange MGB-GT. Knock off hubs (came with a lead mallet), positive ground, two 6v batteries under the seat and Lucas electrical. I loved that car. I first saw the black bumpered MGBs at the car show in Boston and hated the look. That said, today I learned that some people actually preferred the black bumpers. To each their own.

Yeah, my dad’s had the knock-off wheels as well. Very cool. His also had a removable hardtop I’ve never seen nor heard of anywhere since. It looked like a T-top, with a big green plexiglass piece over each of the seats (but they weren’t removable).

Hillman Imps were like that from day one even in the UK because they’d put the turn signals too low.

I was hoping to see this comment

In that case the real halfassery is that they never facelifted it in a 12-year production run.

They only sold about 400,000 Imps in 12 years in a factory that was designed to produce 150,000 a year. I don’t think they ever paid off the original tooling costs. The ‘Facelift’ involved moving the front suspension pivot down an inch so that the front wheels didn’t have negative camber.

And there’s something about a 3rd wiper too that was phoned in to cover the percent of the windshield that was required starting in 1969.

Respectfully,

3WiperB

Toyota Camry wagons had twin rear wipers. I don’t know if that was done to meet a regulatory requirement, but it sure does cause some cognitive dissonance when you realize what you are seeing.

Watching them in action.

It’s common knowledge to avoid this era of MGB for more that just the rubber bumpers. They should be cheaper to buy, but there’s always a reason for that. In California, don’t buy anything post 1975 that needs to be smogged.

I had one of the last 1974s with chrome bumpers. I just left the Sabrinas on, though it’s easy enough to retrofit the earlier chrome bumperettes. Some people retrofit the early style chrome grill as well.

As the former owner of a ’78 MGB – one of the rubber-bumper years – I do think the revised bumpers do look pretty good despite weighing as much as they do.

The ’71 Challenger had a smaller set of… Sabrinas on the chrome bumper. They weren’t an aesthetic success but they did protect the bumper on at least one occasion, so I guess it’s a wash.

It’s too bad that BL wasn’t able to paint the bumpers body color-I’ve seen a few examples that have been customized this way and it definitely makes them look better integrated. (I’m with you in that I think they look pretty good)

IIRC, BL tried this, but most automotive paint wasn’t flexible enough to not start to crack and flake off the polyurethane bumper covers, and the one that was only came in a few colors and was extremely toxic and difficult to use.

That’s interesting: I was always so focused on the chrome and rubber bumpers that I never considered they could be body color.

Well, hello!

https://www.mginfo.co.uk/upgrades4mgs/Body/images/mgs%20unltd%20001.jpeg

That looks… pretty good, though I’m a little unsure if I 100% like it. 🙂

Thanks for the new perspective!

Edit: also this

https://www.mginfo.co.uk/upgrades4mgs/Body/images/SGbumpers2.jpg

Interesting but I have mixed feelings. The front of the car looks a bt too modern to me and it doesn’t quite go with the rest of the car IMHO. That said, I love that these are both MGB-GT, my first car and an absolutely beautiful design I think…

Get the right shade of green, and, well, it’s still not really a budget RV8, but you know, it still kind of works.

https://www.mgexp.com/phile/1/87063/IMG_0732.jpg

https://www.classicandsportscar.com/sites/default/files/styles/article/public/2020-05/Classic%20%26%20Sports%20Car%20%E2%80%93%20MG%20RV8%20buyer%27s%20guide%20%E2%80%93%20LEAD.png?itok=HKowqbyJ

Back when I still went to car forums, there was a guy on the BCF who had a late MGB, painted a really nice shade of metallic red,with color matched bumpers, and it looked really good, honestly the way the car should have looked in about 1977.

I believe they were called Dagmars on the ’50s Cadillacs.

Ah the old metric to imperial convers…oh wait

However, they did a great job of meeting the new regs with the Spitfire.

I’ve never hated the rubber bumper MGs, but I’ve always preferred the Spitfire’s chrome bumper with rubber blocks setup for some reason.

At least one other British maker did more or less the same thing – federal Lotus Elans were a full inch higher off the ground than their Brit siblings. Way back then I owned a ’64 MGB with chrome bumpers and was appalled when the black bumpers came out. Still think they’re ugly. TR6s got huge protruding rubber blocks at the same time; don’t know about the ride height. And for the record, in ‘Murrica, those things were called ‘Dagmars’ fro essentially the same reason.

The DeLorean had the same solution when they went to sell it in the US.

Searched for this comment to see if anyone else remembered this.

MG spelled backwards is GM, so what do you expect LOL

When you consider that the double-nickel speed limit kept everything slow starting in 1974 – and US roads were in terrible shape – nobody was having any fun driving anyway.

Raising the car an inch probably saved a number of exhaust systems from being scraped off the bottom of MGBs.

They were probably starting to swirl around the toilet bowl around that point anyway. I don’t have my British Car industry dates memorized but the whole demise is good reading. Too bad, but a good story nonetheless.

This would have been around the time of the rumour that already rusting sheet steel was being used to press MGB body panels.

BL was effectively insolvent by the end of 1974 and was restructured under government control in 1975.

Management had also always shown a lot of favoritism toward Triumph in terms of R&D investments, even though MG was consistently the better selling of the two in the crucial export market of the US

Look, if you had expectations of British Leyland in the 1970s even doing things half-assed, you’re giving them too much credit.

Quarter-assed at most. When not on strike. Or going bankrupt.

This is like expecting ‘Standard of the World Cadillac of the 1960s’ in early 1980s General Motors. The parent had well killed the independent spirit by that point.

MG suffered the same fate under BL.

BeatingsCost cutting will continue untilmoralequality improves