Nissan isn’t in a great spot right now. The Japanese manufacturer is planning to close factories to stay alive amid a downturn in market share and profits, and right now, its survival is uncertain. But the company has just introduced something that might help: the most thermally efficient engine to be put in a road car, ever—at least, according to Nissan.

The engine, a 1.5-liter turbocharged three-cylinder unit codenamed ZR15DDTe, is already in production and can be found in Nissan’s Europe-market Qashqai small crossover, at the heart of the company’s new e-Power hybrid powertrain. The secret to the record-breaking efficiency, Nissan says, is valve seats that are sprayed into the cylinder head, rather than press-fit.

The tech, which Nissan calls the Strong Tumble & Appropriately stretched Robust ignition Channel (STARC), was introduced by the company back in 2021. But this is the first time we’re seeing it in use on a production engine. Here’s how it works, according to Nissan:

In conventional engines, the design of the intake port is constrained by the necessity for press-fitted, sintered valve seats, which limit the ability to optimize port shape for ideal tumble flow. Nissan engineers addressed this challenge by developing a novel valve seat using cold spray technology.

This process allows a coating to be directly formed onto the cylinder head surface, eliminating the need for a separate valve seat component and enabling the creation of an optimized intake port geometry. Furthermore, compared to similar methods, its higher thermal conductivity enables improved cooling performance around the valves.

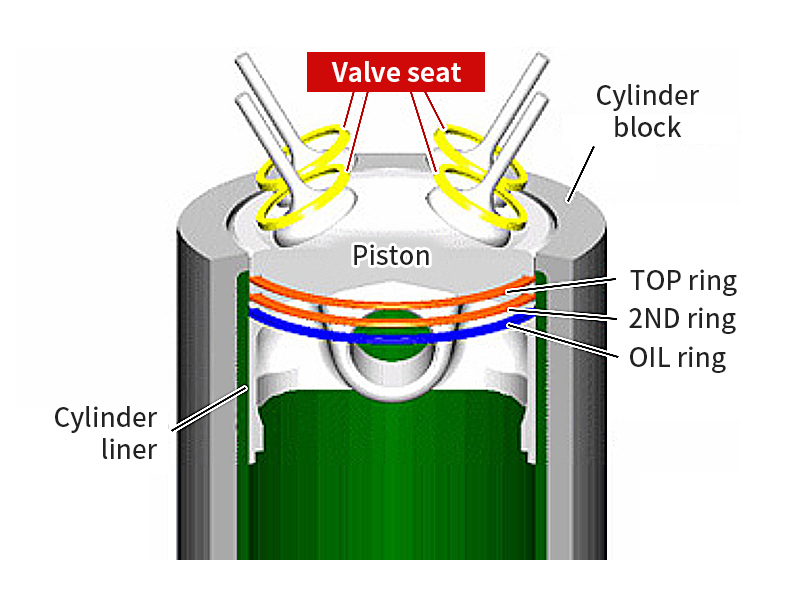

Here’s a look at a typical valve seat, via Japanese auto supplier TPR:

Those sintered valve seats are usually pressed into a cylinder head to seal off the combustion chamber using the valves:

Per Nissan, this typical method of valve seat manufacturing introduces compromises.

The use of a “cold spray” valve seat, Nissan says, means there aren’t as many hard edges in the pathway from the intake into the cylinders. The air has a smoother, less disruptive journey through the cylinder head, resulting in less turbulence and, as Nissan said, a better “tumble” flow. The tumble, in the case of engine science, is the actual rotational motion of the air/fuel mixture as it enters the cylinder. Having a healthy tumble means the air and the fuel can mix properly before it’s ignited. The more balanced the tumble is, the more efficiently that mixture will burn.

Nissan put together a helpful diagram (above) to show the comparison. On the left is a cross-section of a normal combustion engine, while on the right is the STARC tech. While the drawings aren’t very precise, the right side shows the straighter pathway into the combustion chamber. The zoomed-in photos, meanwhile, show the hard edges of the conventional valve seats compared to the smooth, uninterrupted edge of the spray-in material.

Anyone who follows Nissan closely will know it’s experimented with trick efficiency-minded engine upgrades before. The company’s variable-compression engines seemed like a cool idea, but fell out of favor after the NHTSA opened an investigation into reports of failures. Just last month, owners filed a class-action lawsuit over the engine’s issues.

Source: Nissan

Not only do the spray-in seats promise better efficiency, but they’re also installed in a far more interesting way:

The new valve seat is produced by spraying dissimilar metal powders at supersonic speed onto the aluminum alloy cylinder head surface, forming a robust and durable coating that adheres strongly without melting the base material.

Valve seats are what the intake and valves close against to seal the combustion chamber, which means they’re subject to intense heat, big swings in temperature, and lots of vibration. The automaker seems to have ironed out any potential problem points, though:

Cold spray technology operates below the melting points of the materials involved, enabling the bonding of dissimilar metals without melting. This process prevents the formation of excessive intermetallic compounds and micro-voids (porosity) that are common in traditional fusion welding methods. As a result, cold spray coatings exhibit superior adhesion, durability, and reliability—crucial qualities for engine valve seats.

This application represents a world-first in automotive engines and leverages Nissan’s extensive expertise in powertrain design, materials engineering, and manufacturing. The process incorporates a specially developed cobalt-free, copper-based alloy with excellent thermal conductivity, in-house nozzles inspired by polishing techniques used in forged mold production, and AI-driven quality assurance systems.

Adding these spray-in seats, Nissan says, raises thermal efficiency—that is, the amount of energy produced compared to wasteful heat—to 42 percent. That would make this engine the most thermally efficient to ever grace a production vehicle, beating out engines from Toyota and Hyundai, both of which claim to have 41-percent thermal efficiency. Interestingly, Nissan’s number falls short of the original 50-percent efficiency it claimed to achieve in 2021. To find engines more efficient, you’ll have to go all the way to Formula 1, where the hybrid power units see thermal efficiency numbers above 50 percent.

Source: Nissan

It’s likely impossible to test Nissan’s claims without a bunch of very expensive equipment and a team of scientists, which means you’ll just have to take the company’s word for it. The automaker performed a stunt back in August that had an e-Power-equipped Qashqai drive the entire length of the United Kingdom, where it achieved 75 miles per gallon. These are UK mpgs, so they might not necessarily match up with American figures (Nissan doesn’t specify how it made the calculations). Still, going a claimed 837 miles on a tank with 100 miles of extra range to go seems pretty impressive.

So, unless (until?) the lawsuits start to roll in, good idea, Nissan.

Top photo: Nissan

While lack of efficiency can cost you some money lack of reliability which I’m going to guess is probable here is going to cost you a hell of a lot more money. I’m all for efficiency but once efficiency reaches a peak and reliability drops severely we need to rethink things.

Show me an automaker that is spending money on ICE development after 2020, and I will show you an automaker going bankrupt.

It is a dead end.

Unless your main market is the US, then it is the whole country that is fucked.

Blah blah blah blah blah blah electric electric blah blah blah

We will see.

That’s a pretty narrow-minded view of the industry, probably focused on the conditions of your own domestic market. There are billions of people that live in countries that won’t have widespread EV infrastructure for decades. Even in the US where such a large percentage of people live in single-family homes with garages, there are still tens of millions of people who live in apartments or have to street park and don’t have the ability to install their own charger. South Asia, SE Asia, South America, Eastern Europe, you think those regions will be 100% EV in 5-10 years?

Would go well w/ my Fuel Shark which is working amazing! I’m so impressed w/ it!

If Nissan’s future is STARC, perhaps it might be less bleak. But then again, it’s Nissan, so all bets are off.

Nissan claims this offers 42% thermal efficiency. This is only 1% than Toyota’s A25A-FKS that was introduced over 7 years ago.

This isn’t impressive at all if that’s all they’ve achieved. If Toyota were to put the same tech in a 1.5L 3 cylinder, they’d likely achieve the same results as Nissan’s hypermiling stunt in the UK.

What confuses me is why BMW isn’t advertising how they’ve managed to make their engines relatively efficient without massive hybridization.

What kind of stumps me is that they already had 50% thermal efficiency reached years ago with the e-power driveline… so i guess it’s just another improvement at this point.

Though don’t forget that we really are in the diminishing returns part of the ICE lifecycle. Doubt it’s going to cross over 51% any time soon outside of the lab

Now up to 5% more Big Altima Energy!

This should really help when evading the authorities, using a flatbed towtruck as a launch ramp or testing the top speed rating of your donut spare tire.

OK. 2 things I am curious about:

Not an expert – but I’d imagine one reason is because the tolerances are orders of magnitude above standard road engines. They have to get the engines up to full operating temp before they’re even started.

Also, engines are most efficient at full throttle.

No idea on the caramel nuggets, though.

F1 engines are built to an entirely different purpose with lifespans measured in hours and a few thousand miles (last I knew, they’re designed to last 8 races or they’re penalized). They don’t meet the emissions standards of road cars, either, but the main thing is that thermal efficiency does not necessarily translate to a vehicle going farther on a unit of fuel. It’s a measure of how much of the fuel used is converted to work vs heat at highest efficient operating load and engine speed, that work being hp. The great majority of the time, a road car engine is operating at lower loads and partly closed throttle, which is less thermally efficient than peak, however, it’s also requiring only a small fraction of peak hp, which means it burns a lot less unit fuel per distance travelled. A race car is concerned with converting as much fuel to power as fast as it can practically use it, but a road car is more concerned with going as far as it can on a unit of fuel. If we’re talking about going the greatest distance per unit fuel used, being a couple percentage points more thermally efficient doesn’t mean much if that engine is burning a lot more fuel to go the same distance. All things being equal, if you had two engines making, say, 18 hp to propel a car at a steady 65 mph, the more thermally efficient one at that same load and engine speed will allow that car to travel a greater distance on the same unit of fuel, but the real world is messy and cars are a collection of compromises that are operated over a wide range, so thermal efficiency is only one small factor in a car’s mileage. Requiring less hp for a given task (lowering weight, improving aerodynamics) is going to yield much better results in regards to mileage than thermal efficiency going from something like 36 to 39%. One of the reasons for the 4-cycle’s continued success is not its thermal efficiency so much as its ability to stretch out the useful time the fuel’s energy can be used for work. Where higher thermal efficiency makes more of a difference is when the engine is used as a generator, like in a hybrid, where it can run within a narrow operating range, sized to match the charge rate of the battery so that it runs at its highest thermal efficiency when charging and shut down when the battery doesn’t need a charge, then the battery can go on to meter out that energy at a much slower rate.

This is an informative and useful reply. Thank you.

Diesel engines have higher thermal efficiency and are in production…. At least mention them before going to Formula one. Your kids school bus is more interesting.

I think the required complexity to squeeze more mileage out of engines, adding multiple points of failure (in case of the variable compression engine) and CVTs shows that the ICE engine development regarding efficiency has peaked. It is time we stop wasting time to try to improve efficiency by 1% and focus on the next era of car propulsion –> electric motors. What needs more time is the battery (chemistry), more optimimal charging and secondary benefits like V2G (vehicle to grid) where individual cars help to balance the electric grid.

Next we can ditch all the efforts to try to get oil from the most complicated places like 2 mile deep wells on land and at sea and fracking which is polluting aquifers in the long run. Just build more solar panels in places where there is a good amount of sun, place windturbines where there is a good amount of wind and invest more in harvesting 24/7 energy from waves and geothermal.

While I drive two V8s which use a lot of premium gas – I know for the benefit of humanity it is better if we electrify most cars/transports as fast as possible.

What we don’t need is EVs with 1000+ horsepower, what we want is relative light, safe, efficient EVs with just a single engine, making say 200 horsepower, making very good use of the stored electricity in modern batteries like the newer sodium-ion ones which use much less ‘dirty’ elements like kobalt and lithium.

I understand people need and want to keep their job. If you are an ICE engine designer then you maybe have no chance to learn and chance how to become an EV designer. But should we hold back humanity to save jobs of a few people at the expense of polluting our environment? Oil spills. Coal mining. Burning gas. It’s not helping us. I’m no treehugger, but to be honest – trees do help to make oxygen, something we like to breathe as humans.

But in the end it is not environment or pollution that is good for people ; it is that electric cars are just CHEAPER to run in the long term. You plug them in at home (in your garage, driveway or at the sidewalk) and when there is light it can charge from solar panels nearby, or far away. High voltage power lines allow electricity to be carried from hundreds and even thousands of miles (!) away so hot states can help cold states. Without the dependency on middle eastern oil, polluting shipping and huge risks to the environment like another Exxon Valdez or Deep Water Horizon event.

Again I love the complex engineering which goes into variable compression engines, CVTs – all the good stuff to squeeze better mileage out of a gallon of gas, but it has not made BETTER cars for the petrol heads. It only makes better cars for people who actually don’t CARE about cars, else they’d never be buying 1.5 liter 3 cylinder powered cars in the first place. Give those people that EV which is cheaper for them to run, with less maintance and a much lower impact on the environment.

Well hold on there mister.

This is to much sanity for a barely moderated internet forum. You should add at least one political hyperbole or conspiracy theory.

All coal miners will die from hunger if we don’t keep our coal fired power plants running! There, that’s a good reason to keep the fires burning.

Ok, I’ll give.

How many bicycles do I have to give up for a steam locomotive?

TBH I can appreciate steam locomotives more than high speed rail.

However when you rely on them on a daily basis then they might run out of steam.

Having designed a few cylinder heads, including some with high-tumble ports, I think Nissan is overstating the geometry advantages of spray-on seats.

Weird they aren’t mentioning the cost saving from not having to machine the bore for the seats, or fitting the seats, or the seats themselves.

Nice to see this comment as my instinct was to question just how much of a difference it makes in the real world, particularly in regards to potential longevity compromises, and if it wasn’t just that it’s cheaper.

It may also be possible to fit slightly larger valves into the head due to the lack of material needed to house the seats and provide radial stiffness to retain them. I hope they do the endurance and failure tolerance (overheating?) tests. It would be like Nissan to introduce something new and soon find out that it doesn’t do well in the real world.

Yeah, there might be an extra mm or so in the valve diameter. It’s more removing the machining access for the seat bore than it is for hoop stress for seat retention.

They will do all the usual durability testing to validate the design. One of the most brutal tests is a thermal cycle, where you run the engine under load at peak revs on a engine dyno to get everything as hot as it’ll go, then take all the load off so it just pulls cold air through the engine to rapidly cool it all down, and repeat, for hundreds of hours. It’s a great way to make your exhaust manifold crack.

And they’ll have a durability fleet doing all kinds of driving up to test for weird real world scenarios like lots of short journeys where the engine never warms up, or going peak load from cold.

Bear in mind though that all manufacturers do this already, and yet every reliability nightmare you’ve ever heard of has still got in to production.

I also note there is no mention of having to grind? the seat after spraying to get the proper geometry of the seat to match the valve.

Hopefully this engine is better than the problematic variable compression KR series engines Nissan has been selling.

Dear Nissan… take the hint… it’s not the engines that cause the most troubles for your customers… it’s that little box of rubber bands attached to the engine which you think seems to qualify as a “transmission”.

Surely you don’t mean the JATCO Xtronic, the most elegant and finely crafted

shoebox of rubber bandstransmission ever forged by mortal hands.And if it’s not that little box of rubber bands attached to the engine, it’s the dealerships.

I get the gist, but am unqualified to speculate as to whether or not this will turn out to be a durable way of seating/sealing valves that can last at least 250Kmiles/the life of an engine. I’d be a bit worried that it wouldn’t, and from what I’ve read of Nissan’s other three cylinder engines derived from/designed with Renault, they’re not exactly known for their durability.

Anybody else remember Honda’s adventure to Nikasil plated cylinders in the 90-91 Preludes that promised increased durability but wound up just being oil burners?

Oh yeah, and BMW and Jaguar…

I had BMW M60B30 with infamous Nikasil block…. looks like mine either has been replaced under recall or survived by not being driven until modern days but ya

Same with my Jag. It was one of the last Nikasil blocks, but I think late enough that they had gotten past the high sulfur gasoline problems. I never had any problems with it, but it would definitely be a throw away engine. The block will however outlast all the cheap/brittle thermoplastics that will cause other catastrophic failures. We’ve been deep into the era of disposable cars for more than 2 decades and it’s only getting worse.

I suspect spraying on the valve seats will lessen the longevity of the heads.

Not only that- once the valve seat is worn out, there is no way for an engine rebuilder to re-spray that magic spray on the reground valve seats. So these cylinder heads are throw-aways.

These valve seats may last slightly longer than Nissan VC engines and CVT’s, which isn’t very long.

We had a Pathfinder rental with a CVT already going south at 30k miles.

Other OEMs trying to figure this out with bigger budgets: Tony Starc built this in a cave!

Oh, I’m sure they’ll be great for 100s of thousands of miles!

Nissan*, nobody is going to buy on tech like this, especially with the track record of failure you’ve had. Get your normal shit right first.

*I don’t actually believe Nissan will see this comment.

Luckily the rest of the car won’t last 100’s of thousands of miles neither. Nissan thought of everything!

I love the progress in engine science. 50 years ago it would have been “is it burning at least some of the gas?”

I think 50 years ago is right around the time they said “hey, what if we send that gas we aren’t burning back through for a second pass”.

Man, to have started my engineering career off in the 60s would have been one hell of a ride.

Funny! Imagine using paper and slide rules and Super expensive HP calculators with LED screens.

It was around the time that they decided that lead wasn’t the best octane enhancer. Or that untreated exhaust emissions wasn’t healthy to breathe in.

The gasoline internal combustion engine has come a long way.

Kudos to the engineers who made it possible, because they had to do it with slide rules, primitive non-CNC machining, and a fuel delivery system that was best described as ‘an organized fuel leak’.

It’s one thing to build a house using power tools. It’s another to do it with hand tools.

I’m glad I live in a power tool age.

They always knew the danger of lead additive and it was only the adoption of catalytic converters that forced them to change.

AI isn’t great at a lot of things but it sure is better at generating acronyms than this. Yeesh.

Are UK miles and gallons different than US miles and gallons?

Yes, they’re 1.2 US gallons.

Miles are the same, though. The gallon difference is because different products used to have different gallons, and when the UK and US eventually decided to standardize on one for everything, we each picked a different one to use as the baseline

The US used the old English wine gallon, the UK sort of split the difference between the corn gallon and the ale gallon

Yeah, I assumed it was related to all those crazy old measurement “standards”, like hogsheads, where container volume varied by the specific product.

I forget how many gills in a hogshead. Thank the science gods for the metric system.

I hate that I still have to deal in Imperial measurements for anything and that my damn brain still has to do conversions in my head to metric in order to picture some things because I grew up with the common use of Imperial stupidity and part of me is stuck on it. I wrote a book series with animal protagonists and I had them relate measurements to their body length of themselves or other known animals. I realized partway through that my limited intellect animals basically used their own Imperial system.

In addition to the difference between US and UK gallons, the testing in the UK is different than US EPA testing. Even when looking at cars that are identical in both markets, and adjusting for the difference in gallons, you’ll generally see much higher fuel economy results in the UK than in the US.

Take the third-generation Prius, for example. US rating: 50mpg. UK rating: 72.4mpg (but those are imperial gallons). Convert the UK rating to US gallons, and you get a UK rating of 60.3mpg… which is still substantially higher than the rating in the US.

UK miles are the same. UK gallons are larger. UK fuel-economy testing is much more lenient.

Okay, I understand the lab tests may be run differently and produce different results. How the heck is there variation in an actual drive around the UK? Either the car used four gallons to travel 300 miles or it didn’t.

And now you understand why liters per 100 km are used in the rest of the world.

It used 4 english gallons, which is 4.8 American gallons. 300 miles is 300 miles.

Just for fun: UK gallons are sold in litres.

“Toyota and Hyundai, both of which claim to have 41-percent thermal efficiency. Interestingly, Nissan’s number falls short of the original 50-percent efficiency it claimed to achieve in 2021. To find engines more efficient, you’ll have to go all the way to Formula 1, where the hybrid power units see thermal efficiency numbers above 50 percent.”

Maybe this comment explains why?:

“Honda hit approximately 40% thermal efficiency in the late 90’s with the Insight 3 cylinder. Nissan’s 50% figure takes into account the hybrid system converting momentum into electricity, and then later back into kinetic energy. Toyota and Honda hybrid systems do the same thing, they just don’t claim it in their thermal efficiency figures, so Nissan’s figure isn’t apples to apples. The engines in all 3 are around 40% thermally efficient.”

https://www.motor1.com/news/722314/toyota-claims-game-changing-engines/

I found this explanation down a rabbit hole discussing the upcoming Prius engines:

“Gen 6 will more than make up the usual Prius generational progress in fuel efficiency that did not come with Gen 5.

The all-new 1.5-L naturally aspirated engine that will power Gen 6 Prius will result in a 30% increase in both thermal efficiency and horsepower, increasing the 41% thermal efficiency of the current engine to 53%.

This will bring the EPA fuel efficiency to around 75 mpg. Hypermilers will easily average around 100 mpg. In populated states like California, driving a Gen 6 Prius will be cheaper than driving a BEV.”

https://priuschat.com/threads/gen-6-prius-engine-will-be-a-%E2%80%9Cgame-changer-%E2%80%9D-achieve-a-53-thermal-efficiency.249167/

Take this with a HUGE grain of salt for the link provided did not specify any numbers only promises TE would be better than now. Perhaps Toyota didn’t want a repeat of Mazda’s unkept promise of 56% TE with Skyactiv3. Whatever happened to that?

As an engine science fan: Neat

As a former automotive machinist: Sigh. This will just make engine repairs more expensive since you have to toss the whole head instead of replacing the seat. Not that modern engines ever get repaired anyway. Single point of failure? Toss the whole long block.

Yep. Another non-rebuildable component.

Hopefully it holds up for the lifetime of the chassis. I suspect this is the kind of thing that will either hold fine, or fail rather quickly and result in a consumer lawsuit.

It’s in a hybrid generator application, so I assume Nissan will be able to control the RPM, temp and fuelling within a fairly narrow band?

How often does a valve seat typically go bad and what is the usual failure point?

If you overheat the engine, sometimes the valve seats will fall out of the head and tear everything up as they get pounded by the pistons. Hemis are apparently prone to dropping valve seats.

The failure is usually seen as recession, which is where the valve seat wears away at the point where it contacts the valve. Recession happens to all engines as they wear, and happens faster if the seats are made of a softer metal and/or the valve springs are heavier, making it particularly common in old pushrod engines. Some experience pitting, though that’s usually a symptom of a different failure mode that leads to contaminants in the valve seat (like particularly egregious carbon deposits). Like Lincoln said, overheating can cause valve seats to fall out, but it can also cause them to go out of spec, becoming misaligned or going out of round. You can usually re-grind your valve seats a couple times, but each time you lose a little bit of compression as you let the valves move farther into the head, increasing combustion chamber size.

I’ve only heard of valve seat replacements on modern (21st century) engines when it comes to rebuilding for high performance applications,

With spray-on valve seats, I imagine it’s the same as spray-on cylinder liners, which can’t be machined.

Spray-on cylinder liners can be honed with the proper equipment.

Honed, but not machined.

Early VW Vanagons (mine was a first year, 1980) had valve seats come loose, flip, and jam the valve resulting in the engine not running and the risk of severe damage if continuing to run the engine. Fortunately when this happened to our bus, I was able to find a mechanic familiar with the problem and the proper solution, and I was able to drive that bus for a decade afterwards. The tow home was a whole different story.

I hear you, but how many modern engines are getting full rebuilds these days anyway? I assumed most are just recycled rather than rebuilt.

At least you could just replace the head. It seems like they’re still using typical cylinder sleeves, so the long block could be rebuilt.

They aren’t unless it’s for performance applications. Also depends on the cost of the engine.

There may or may not be a couple Lamborghini engines out there that had the crank bores sanded by my own hands because there wasn’t enough meat to hone.

Unfortunately, I concur with JP15. Engines nowadays are more often replaced rather than rebuilt. Even head work like valve seats might be cheaper to replace when factoring labor costs, work warranty, and turnaround time. The open question here is if this tech will outlast the rest of the engine or cause its premature retirement (and likely the entire car, depending on how long it takes to fail). Doesn’t bode well for future collectors, but the future doesn’t bode well for anything.

Uber-thermal-efficient direct injection already has challenges in not having enough heat.

Nissan’s not the company I expect to rely upon.

Enough heat for what?

Primarily heating up fast enough to reduce chance of oil dilution, and then (arguably/allegedly – seems partly debated) hot enough to ‘burn off’ some of the accumulated fuel in the oil system. Most famously with the Honda 1.5T engines which needed to be reprogrammed to improve heat-up.

It’s exasperated with high-thermal efficiency, cold temperatures, and short trips.

Seems easy enough, add a block heater.

I have more faith that this will last compared to their variable compression. The E-power system uses the engine solely as a generator, so they can run this engine at a constant RPM and fairly consistent load.

The fact that they’re likely running it purely in it’s peak efficiency range, is probably how they can make their thermal efficiency claim. But I am not an engineer.

I think it’s generally rated at peak, though being able to run it as a generator means maximizing use of that efficiency and as long as the output can be fully utilized, which I imagine it would.

Now, I totally trust that the cold spray technology works, I just have ZERO faith in Nissan doing it well

Could be worse, could be Stellantis.

I’ve been waiting for an OEM to use it. About time.

I guarantee many others are watching to see how this thing fails and can learn from it.

To be fair, they’ve been doing it for 10 years with cylinder liners. Nissan can actually make a pretty solid engine when they want. They definitely have in the past.

“Having a healthy tumble means the air and the fuel can mix properly before it’s ignited.”

Soooo, you’re saying there’s a chance that the Tornado Fuel Saver actually DOES give me more power and better fuel economy? 😀

If this is a success, do you think will Nissan build STARC Tower and get Robert Downey Jr. to do commercials for them?