Nissan isn’t in a great spot right now. The Japanese manufacturer is planning to close factories to stay alive amid a downturn in market share and profits, and right now, its survival is uncertain. But the company has just introduced something that might help: the most thermally efficient engine to be put in a road car, ever—at least, according to Nissan.

The engine, a 1.5-liter turbocharged three-cylinder unit codenamed ZR15DDTe, is already in production and can be found in Nissan’s Europe-market Qashqai small crossover, at the heart of the company’s new e-Power hybrid powertrain. The secret to the record-breaking efficiency, Nissan says, is valve seats that are sprayed into the cylinder head, rather than press-fit.

The tech, which Nissan calls the Strong Tumble & Appropriately stretched Robust ignition Channel (STARC), was introduced by the company back in 2021. But this is the first time we’re seeing it in use on a production engine. Here’s how it works, according to Nissan:

In conventional engines, the design of the intake port is constrained by the necessity for press-fitted, sintered valve seats, which limit the ability to optimize port shape for ideal tumble flow. Nissan engineers addressed this challenge by developing a novel valve seat using cold spray technology.

This process allows a coating to be directly formed onto the cylinder head surface, eliminating the need for a separate valve seat component and enabling the creation of an optimized intake port geometry. Furthermore, compared to similar methods, its higher thermal conductivity enables improved cooling performance around the valves.

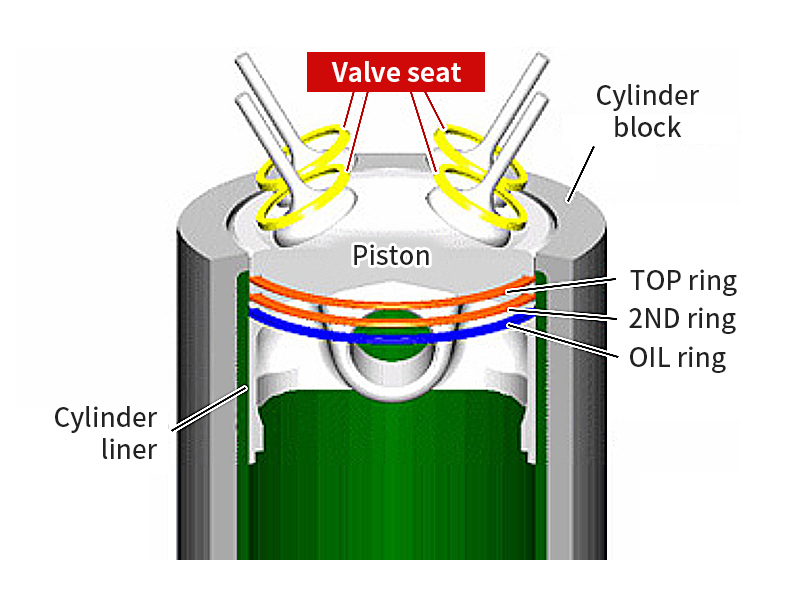

Here’s a look at a typical valve seat, via Japanese auto supplier TPR:

Those sintered valve seats are usually pressed into a cylinder head to seal off the combustion chamber using the valves:

Per Nissan, this typical method of valve seat manufacturing introduces compromises.

The use of a “cold spray” valve seat, Nissan says, means there aren’t as many hard edges in the pathway from the intake into the cylinders. The air has a smoother, less disruptive journey through the cylinder head, resulting in less turbulence and, as Nissan said, a better “tumble” flow. The tumble, in the case of engine science, is the actual rotational motion of the air/fuel mixture as it enters the cylinder. Having a healthy tumble means the air and the fuel can mix properly before it’s ignited. The more balanced the tumble is, the more efficiently that mixture will burn.

Nissan put together a helpful diagram (above) to show the comparison. On the left is a cross-section of a normal combustion engine, while on the right is the STARC tech. While the drawings aren’t very precise, the right side shows the straighter pathway into the combustion chamber. The zoomed-in photos, meanwhile, show the hard edges of the conventional valve seats compared to the smooth, uninterrupted edge of the spray-in material.

Anyone who follows Nissan closely will know it’s experimented with trick efficiency-minded engine upgrades before. The company’s variable-compression engines seemed like a cool idea, but fell out of favor after the NHTSA opened an investigation into reports of failures. Just last month, owners filed a class-action lawsuit over the engine’s issues.

Source: Nissan

Not only do the spray-in seats promise better efficiency, but they’re also installed in a far more interesting way:

The new valve seat is produced by spraying dissimilar metal powders at supersonic speed onto the aluminum alloy cylinder head surface, forming a robust and durable coating that adheres strongly without melting the base material.

Valve seats are what the intake and valves close against to seal the combustion chamber, which means they’re subject to intense heat, big swings in temperature, and lots of vibration. The automaker seems to have ironed out any potential problem points, though:

Cold spray technology operates below the melting points of the materials involved, enabling the bonding of dissimilar metals without melting. This process prevents the formation of excessive intermetallic compounds and micro-voids (porosity) that are common in traditional fusion welding methods. As a result, cold spray coatings exhibit superior adhesion, durability, and reliability—crucial qualities for engine valve seats.

This application represents a world-first in automotive engines and leverages Nissan’s extensive expertise in powertrain design, materials engineering, and manufacturing. The process incorporates a specially developed cobalt-free, copper-based alloy with excellent thermal conductivity, in-house nozzles inspired by polishing techniques used in forged mold production, and AI-driven quality assurance systems.

Adding these spray-in seats, Nissan says, raises thermal efficiency—that is, the amount of energy produced compared to wasteful heat—to 42 percent. That would make this engine the most thermally efficient to ever grace a production vehicle, beating out engines from Toyota and Hyundai, both of which claim to have 41-percent thermal efficiency. Interestingly, Nissan’s number falls short of the original 50-percent efficiency it claimed to achieve in 2021. To find engines more efficient, you’ll have to go all the way to Formula 1, where the hybrid power units see thermal efficiency numbers above 50 percent.

Source: Nissan

It’s likely impossible to test Nissan’s claims without a bunch of very expensive equipment and a team of scientists, which means you’ll just have to take the company’s word for it. The automaker performed a stunt back in August that had an e-Power-equipped Qashqai drive the entire length of the United Kingdom, where it achieved 75 miles per gallon. These are UK mpgs, so they might not necessarily match up with American figures (Nissan doesn’t specify how it made the calculations). Still, going a claimed 837 miles on a tank with 100 miles of extra range to go seems pretty impressive.

So, unless (until?) the lawsuits start to roll in, good idea, Nissan.

Top photo: Nissan

Geely is already achieving over 47% thermal efficiency with gasoline, 48.15% with methanol (incorrectly stated in the first article below as burning hydrogen) .

https://dieselnet.com/news/2025/06geely.php

https://www.autoevolution.com/news/geely-says-ai-helped-it-create-the-most-efficient-internal-combustion-engine-ever-252980.html