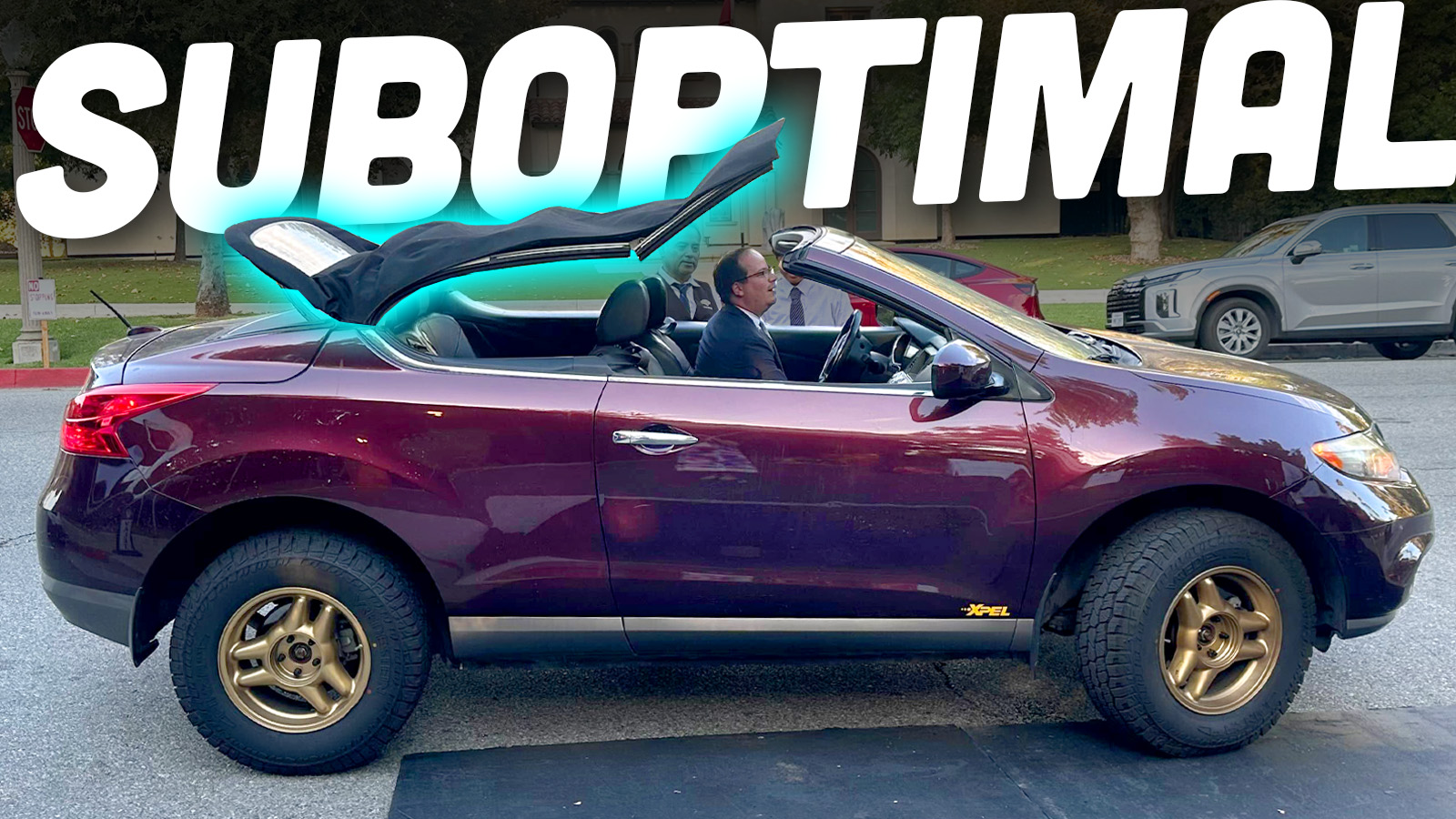

The Nissan Murano CrossCabriolet (like The Autopian’s XPEL CrossCab) is one of the biggest misfires in automotive history. When it was revealed in 2010, Nissan was proud to proclaim itself as the first to mass-produce a convertible crossover. It had what Nissan North America’s then-vice president described as an “extraordinarily engineered convertible top,” a phrase that even then they had to know was tempting fate. As it happened, nobody really wanted a convertible that was both uglier and more conspicuous than the alternatives. After just a few disappointing years, the CrossCabriolet was discontinued. The ones it did sell? Fraught with problems, and it’s almost entirely because of that quirky convertible roof.

Understanding what’s wrong with the CrossCabriolet’s roof requires us to rewind back to how and why Nissan built the vehicle in the first place. Apocryphally, the wife of then-CEO Carlos Ghosn loved her Murano, but wanted a roof-down experience. Despite being known as an austere CEO, Ghosn forced the unconventional CUV through development according to Car and Driver. Whether it was to test a radical new niche product or to satisfy Ghosn’s wife, the CrossCabriolet was born, and with it came a substantial reengineering of the Murano it was based on.

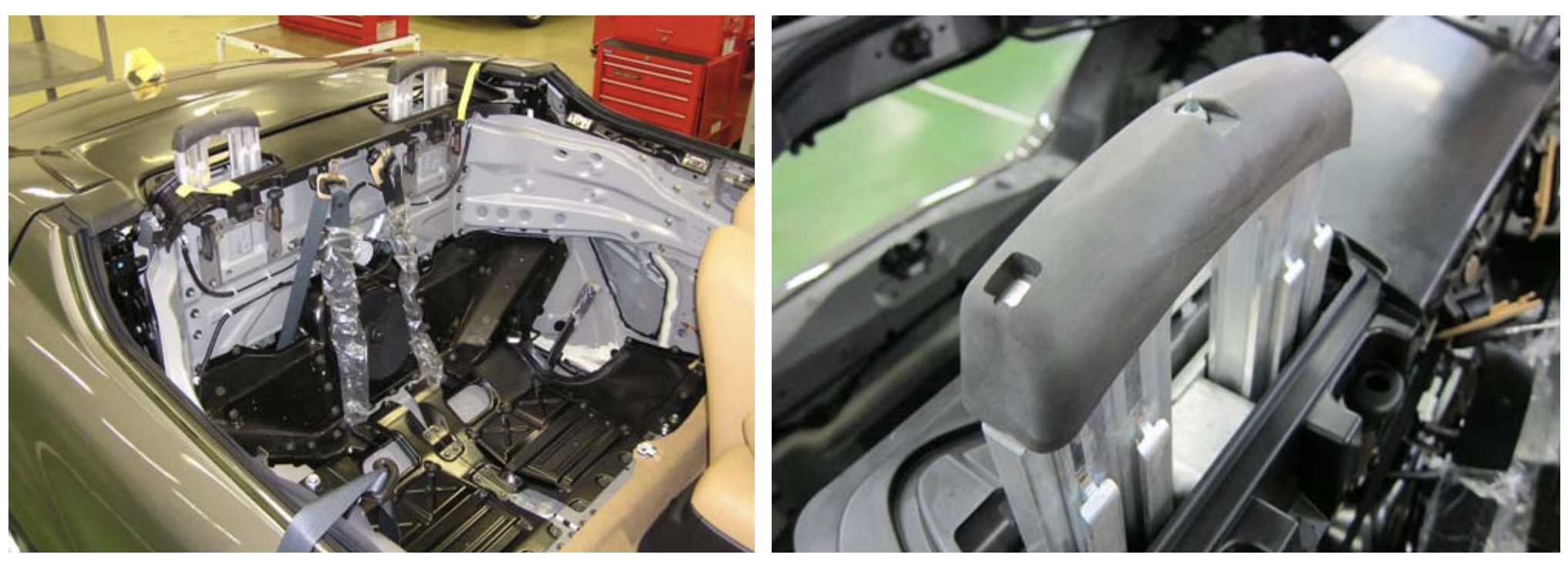

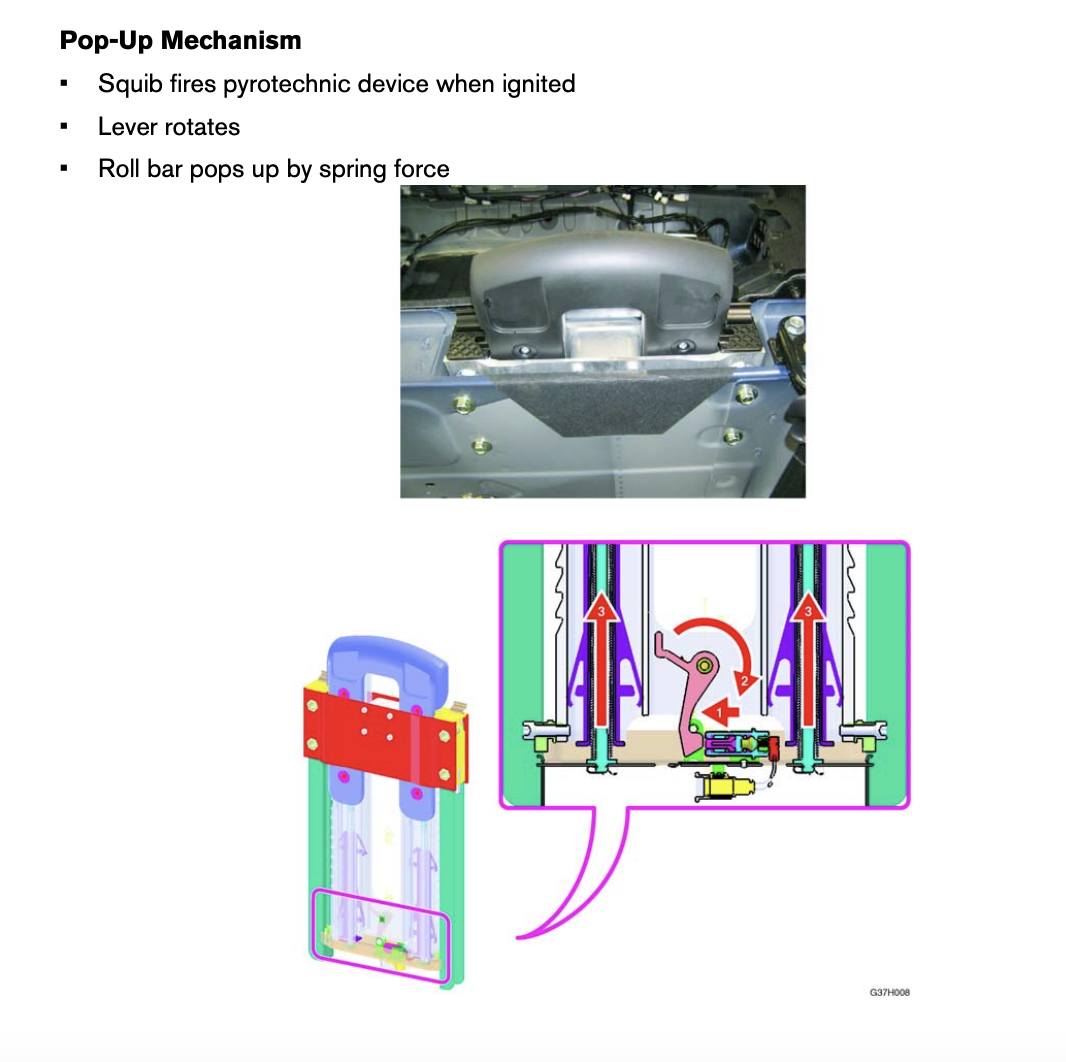

The CrossCab reused the Renault-Nissan D-platform of the regular Murano, and became the only vehicle on said platform to feature a convertible top. With no fixed roof, the B-pillar was eliminated to make the CrossCab a two-door, using doors almost eight inches longer than the four-door model. That also required reinforcing the A-pillar and adding pop-up rear roll hoops behind the back bench, which now sat two to the hardtop’s three. [Ed Note: This isn’t that important to this story, but I can’t not show you the rear structure of the CrossCab, and the roll hoop pyrotechnic functionality:

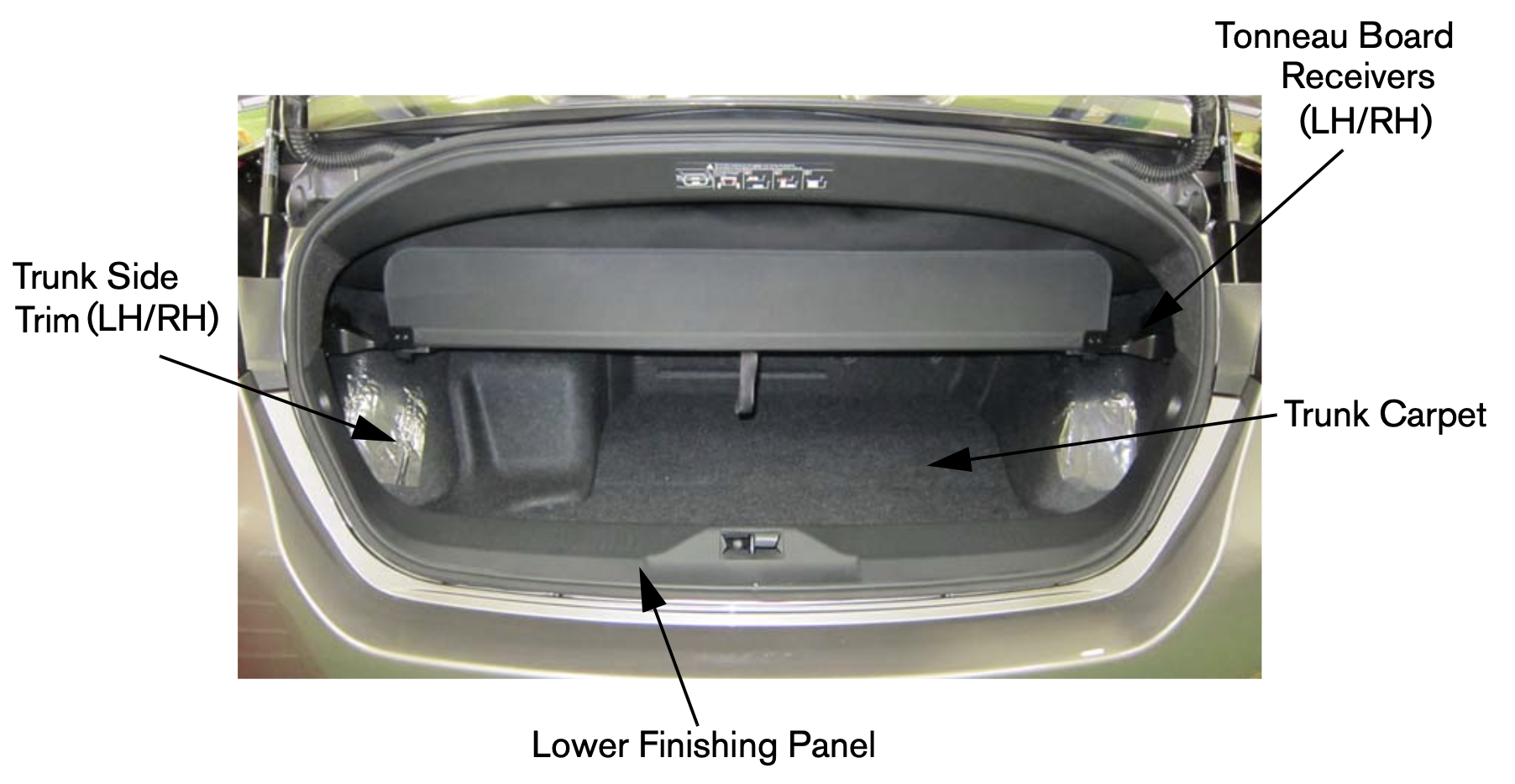

The CrossCabriolet’s trunk was reconfigured to accommodate the roof mechanism, which could be actuated by a button on the center console or “request switches” on the outside door handle. There are various issues with how the roof was packaged, designed, and controlled, so let’s start with the system that moves it—the hydraulics.

The Hydraulic System

While the idea of a hydraulic roof is deeply offensive to me as someone who’s taken multiple DOT4 showers trying to bleed my MR2’s dragging clutch, it’s a common style of convertible roof mechanism. According to aftermarket hydraulics supplier Top Hydraulics, the basic design is shared by the 2008-2014 Ford Mustang, BMW Z3 and Z4, the C6 and C7 Chevy Corvettes, Chrysler PT Cruiser, McLaren 650S, and many others. If it’s fine for the everyperson’s car and the oligarch’s alike, then a hydraulic roof should be fine for the CrossCab too, no matter how I feel about them. Maybe it’s the lifelike throbbing some of them do that disturbs me, but I digress.

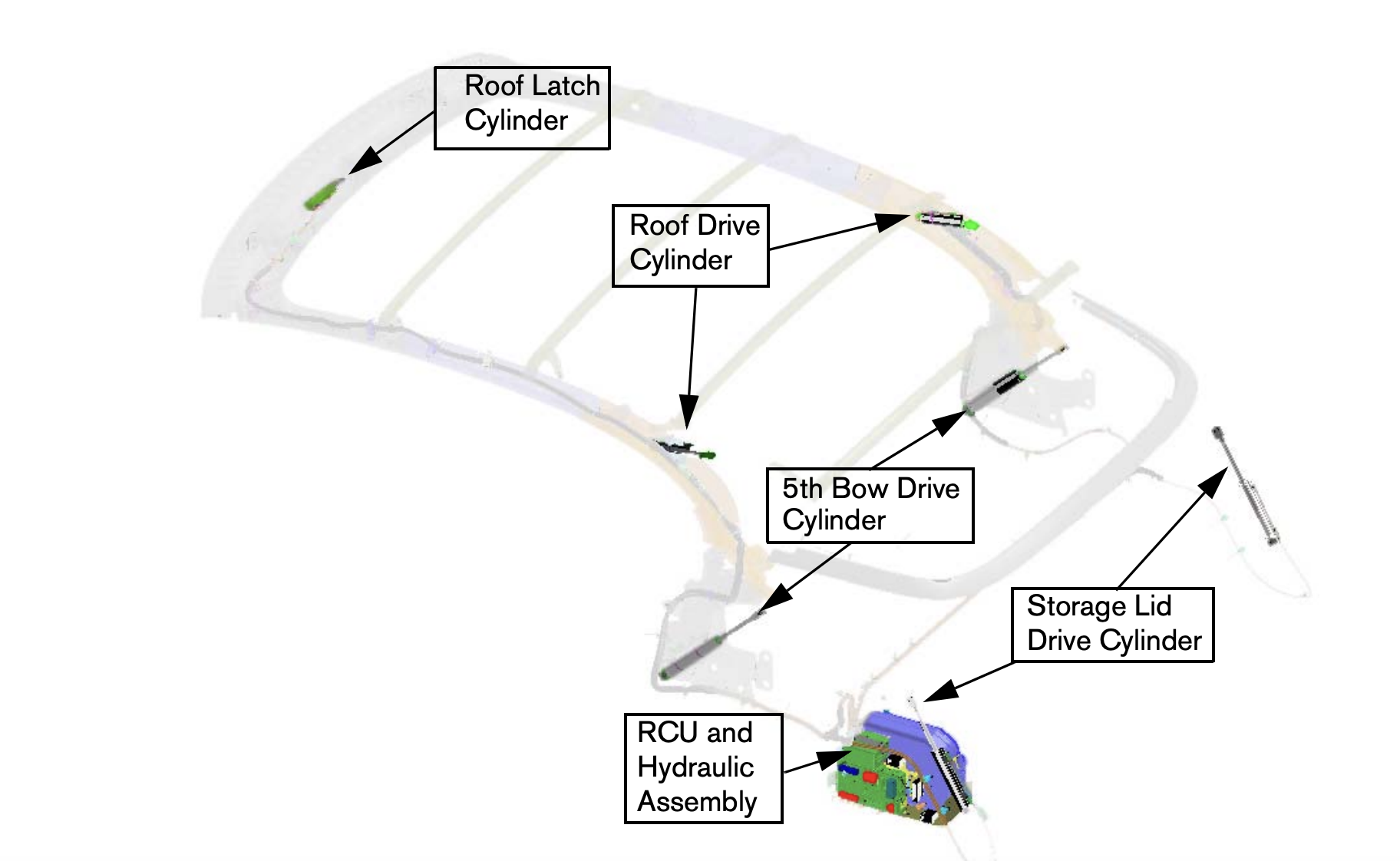

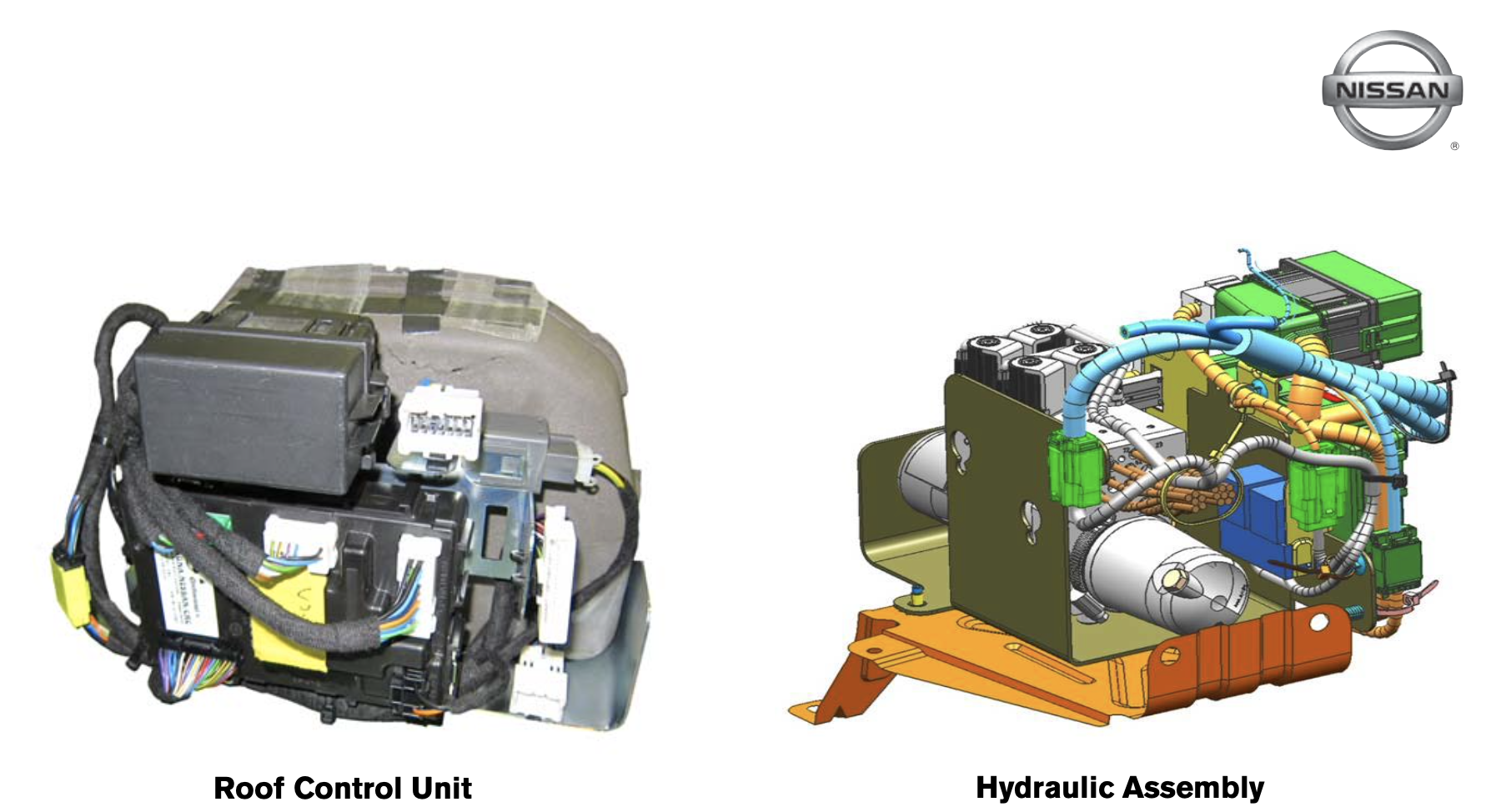

In the CrossCab, the hydraulic roof is controlled using body-interfacing electronics, chiefly a roof control unit (see above) that operates the pump based on input from various sensors. The rest is a series of hydraulic lines, cylinders, motors, and switches strung through structural “bows” that use bungee cords to keep the headliner in place through the roof’s range of articulation. When you take the top down, a lid behind the headrests opens up by extending over the trunk, so the whole assembly can collapse into an area partitioned off from the trunk. Here’s a look at it in action — it doesn’t go well:

TSB’s Out Of The Gate

Problems with the CrossCab’s roof presented themselves immediately upon market-launch. The CrossCab’s roof alone accounts for several Technical Service Bulletins dating back to January 2012 according to NHTSA’s database. For those unfamiliar, TSBs are not quite recalls, though some can be handled at no cost to the customer when a car comes into a dealer for work. They differ from recalls in that they’re typically for fit and finish issues rather than safety problems, though not exclusively. Some can address mechanical issues that can lead to early part failure, like this one advising Ford techs to replace turbo oil supply filters to prevent early turbo failures from recurring.

Anyway, TSBs for the CrossCab started with something basic: adjusting the bolts for the convertible top’s outer flap. Nissan’s TSB doesn’t even specify a functional issue, so it seems this one was just about appearance. But trouble would arrive in December 2013, when Nissan determined the top’s rear skylight could come loose from the frame. That’s this rather confusingly small window up top:

April 2014 saw another pair of bulletins come through, this time for improperly adjusted “pressure links” that could cause the top to look all rumpled, not to mention more problems with the skylight glass. One document says it’s “normal for the headlining to contact and rub on the tops of the rear headrests when opening and closing the soft top.” The last quality-related TSB came through that November, reporting manufacturing errors with the roof cover hinge. Part of the hinge could have a burr along its edge that could fray the fabric top, though it was a simple fix. Sand it smooth with emery cloth, repaint the area, and it was good to go.

The Trunk Situation Is A Problem

From there, TSBs tended to concern the availability of replacement parts, though we’ll get to that later. Instead, CrossCab owners found more immediate problems with their cars’ roofs. Remember how I said the roof storage compartment had been partitioned off from the trunk? Well, Nissan didn’t use a hard plastic or metal divider, but something closer to a plain fabric tonneau cover.

This was presumably so owners could make use of the space the collapsed top occupies while the roof was up. Trunk space is sorely limited either way, with 12.6 cubic feet of space with the roof up and just 7.6 with it down. That’s negligibly more than you get in a McLaren 750S.

What little owners could fit had to be loaded in accordance with warning labels found inside the trunk. In short, they prohibit wedging in anything that could deform the cover in any way. If that were to happen, the partition has a removable crossbar with a sensor that will signal the roof not to open if the partition isn’t in place. Wouldn’t want anything to jam it up, of course. This can also happen if the mount for the crossbar comes loose for any reason, as one technician on a shop management forum noted.

While Nissan hoped the label would be enough to prevent owners from loading the trunk incorrectly, a sticker doesn’t make up for the fact that the CrossCab’s trunk is a small, oddly shaped space. It also goes without saying that things can move around inside the trunk while you drive, and get into places they aren’t supposed to be. If you know Murphy’s law, you know that’s an inevitable outcome. Even if it’s an edge case, it can still make things a whole lot worse when it coincides with one of the CrossCab’s other design oversights.

Let’s say you’re a snowbird who puts their CrossCab in storage for the winter, as I’ve seen multiple owners attest to doing. It’s the first sunny, 70-degree day of Spring, and you’re hauling your CrossCab out of storage for a cruise. Only, it seems you forgot to hook up the battery tender last fall—rats! A dead battery. Well, that’s an annoying errand to run, but not the biggest issue. You exchange the battery, and the CrossCab fires to life. Only, something’s wrong. The dashboard displays an error message about the roof being partially open, even though it’s fully closed. The windows don’t work either.

While you could say there’s some user error involved in failing to hook up the battery, batteries can also go bad if a car’s alternator gives out or if it develops a parasitic draw somewhere. When any of these happen, they reveal a peculiarity of many modern cars’ body electronics when 12-volt power supplies go faulty. Insufficient current or total loss of power can cause body modules to lose calibration, which is to say they lose track of where the mechanisms they control are.

With power windows, resetting them is often as simple as running them through their whole range of motion and holding the switch after you’re done, as this Wikihow article illuminates. This is obviously more complex in a convertible that has to keep track of the roof’s position, but in the CrossCab, there’s another layer of problems. When its body module loses track of the top, it defaults to thinking the roof is partially open rather than fully up or down.

Because the computer thinks the top is moving, it thinks the roof’s cover is open, and therefore in the path of the trunk lid. That disables the trunk’s electronic latch release, meaning the CrossCab’s trunk—along with the potentially offending cargo divider sensor—become inaccessible through normal means. They aren’t fully sealed off, but opening the trunk from here requires a method most CrossCab owners have never had to employ up to this point: A hidden physical key.

CrossCabs’ key fobs contain slide-out physical backup keys, which like most automotive keys are double-sided (meaning teeth on both sides of the blade). Unlike most car keys though, there is a right and a wrong way to insert it into the CrossCab’s trunk lock cylinder, which is hidden above the license plate. The key’s plastic bow (the technical term for the grip) must be oriented downward with the key’s offset blade upward for the key to go all the way in and turn the lock cylinder. And because the physical key is almost never used, the cylinder tends to be almost seized, and require significant force to turn. If that sounds stupid, then you’re in agreement with a professional locksmith I talked to about the problem. (Hi Kim!)

It Can Be Opened By Hand, But It’s Tricky

Once the trunk is open, though, owners can rearrange its contents to un-trip the partition sensor. If something more serious is wrong, the convertible top can be opened and closed by hand according to Nissan service literature. That said, the manual says it requires two people, tools, and stripping pieces of trunk trim out, so it’s not something owners can do in a pinch. While onerous, the procedure itself is also still easier than finding someone willing to perform it. Or for that matter, do any kind of service on a CrossCab’s roof.

Owner’s Aren’t Thrilled

Many owners who haven’t had the instructions laid out for them (or don’t have the mechanical ability to follow them) have taken their cars to dealers, only to be met with various frustrations. Owners’ forums are littered with reports of dealers outright refusing to work on CrossCabs’ roofs, with YouTuber savagegeese (who bought a well-kept example) claiming he watched a dealer tech profanely state they’d sooner be fired than work on a CrossCab’s roof.

“Fuck that. You’ll have to fire me before I work on that car.” – Nissan dealer technician quoted by savagegeese

When owners aren’t turned away, they’re often quoted truly astronomical repair costs. Owners have received estimates of $1,800 for a motor replacement when side flaps won’t retract, $8,000 for a repair that reportedly failed, $10,000 to fix concerning noises at just 29,000 miles, or even $19,000 for an entire new roof. This goes without mentioning some of the other roof issues that have presented over time, such as at least two reports of bent frames. The Savagegeese video linked above relayed verbal instructions not to operate the top in weather colder than 40 to 50ºF, which may sound extreme, but it’s a more cautious (and probably safer) boundary than the 32ºF minimum specified in an August 2014 TSB.

“I am so screwed by Nissan I can’t even begin to tell you. I have the 2011 Nissan CrossCabrolet and the top broke. Apparently it is the hydraulics and the top is stuck in the down position and the top cover wont go all the way closed. The top always had a problem because it would hit the back seat going up, but I would help it and that usually did the trick. Anyhow, I was putting the top up and the whole thing froze. Apparently, the hydraulics froze up. THE COST OF THE REPAIR IS $19,000. I REPEAT $19,000. I am not kidding. Apparently the parts run $16,000 of that repair cost.” – Brad S. on CarComplaints.com

Of course, some owners have circumvented these extreme costs. One forum poster says they were quoted $2,700 plus labor for a replacement body control module, only for an indie shop to pop the trunk and fix the top within five minutes. Another owner who was asked $9,000 for a replacement roof controller bought a $2 set of vise grips to open the trunk, reinstalled the partition bar, and restored their roof to operation on their own. Whether it’s greed, incompetence, or both, dealer service departments are about useless when it comes to fixing CrossCab tops.

“$8,000 is a true figure of what they charged us to fix the convertible roof. Now it is broken again and they won’t do anything about it…. It has low mileage because my husband only drove it in the summer. He loved this car. We bought this car after he recovered from a server [sic] stroke. He has dealt with [a Nissan dealership] and also Nissan Corp. Right now it is not drivable because the roof is half way down. My husband called a tow truck and they refused to tow it because it was not safe with the roof half way down. He called the dealership and asked if some one could send someone out to look at the car since he could not get it towed and they said no. They have our $8,000 and we have a car we cannot use.” – Susan H. on CarComplaints.com

But there’s less and less that DIYers and indie shops can do as roof problems get more serious. According to the Nissan service manual, there is no way to service the roof hydraulics. Zero. Zip. None. Here’s the direct quote:

“The hydraulic pump assembly is located in the trunk on the left side, with a cover installed over it for noise reduction. The hydraulic pump is not serviced separately. If the hydraulic pump requires replacement, it is serviced as an assembly with the hydraulic cylinders and lines.”

One owner tells of a machine shop installing bleeder valve-equipped hydraulic cylinders into their car’s top, though they emphasize it was an extreme fix forced by Nissan’s apparent apathy toward serviceability. Multiple owners have described the CrossCab as an “orphan” vehicle, and it’s even easier to understand when you see how dire the parts availability situation has historically been.

The Supply Of Replacement Parts Is Dire

Though the CrossCab lasted into model year 2014, a June 2015 TSB stated that parts availability for the roof assembly, hydraulic system, and cover were already “restricted.” That was at least partially reaffirmed as of a June 2019 TSB, which addressed only the complete roof assembly. As of this April, one owner (who themselves faced a $13,000 repair estimate) claimed there are just seven new replacement tops left in the United States.

“I straightened out the bent linkages and was able to manually close the top, but with the interior trim pieces broken, the top was not taut. The vehicle is in great shape and my wife loves the car, so we bit the bullet one time. […] After examining the top, which couldn’t be repaired this time, [dealer] technicians looked over the entire car and gave an opinion to/not to replace the top. This is an expensive option (13K) but the top was FUBAR.” – PaulE on NissanMurano.org

The computer that operates the roof, known as the Top Control Module (also called Roof Control Unit), is also in questionable supply. Mechanics have sometimes misdiagnosed other malfunctions as TCM failures, and have sometimes pushed owners toward this pricey repair when it’s not needed. Those that don’t thoroughly research their cars get stuck looking for a replacement, and the small number of CrossCabs sold means few are in junkyards. Ergo, used parts are hard to come by for those who don’t already have parts cars. (Savagegeese’s video noted they’re far from unheard-of in this community.)

TCMs do indeed fail though, and while one CrossCabber says they’ve successfully repaired two TCMs, many have had to depend on new-old parts stock. It’s as eye-wateringly pricey as we’ve come to expect from this car, too: This Nissan dealer quotes more than $2,600 while other sites list it for even more—and that’s assuming they can actually provide it. As anyone who’s owned an old JDM vehicle knows, parts retailers themselves often list out-of-production items as being in stock, only to update their listings and refund customers when their suppliers inform them otherwise. At times, I’ve waited weeks for parts to ship, only to get a refund and an email saying the parts don’t exist. I’m sure CrossCab owners have been through the exact same ordeal.

“Brought the car to a local Nissan dealership. They say they looked at it, and then suggested I should replace the entire roof because one of the small bars in the corner of the roof frame is bent, and that bar is not available. The entire roof will cost about $15,000. This does not surprise me. They are trying to make it so ridiculously expensive that I will go away.” – Freefall Wile on NissanMurano.org

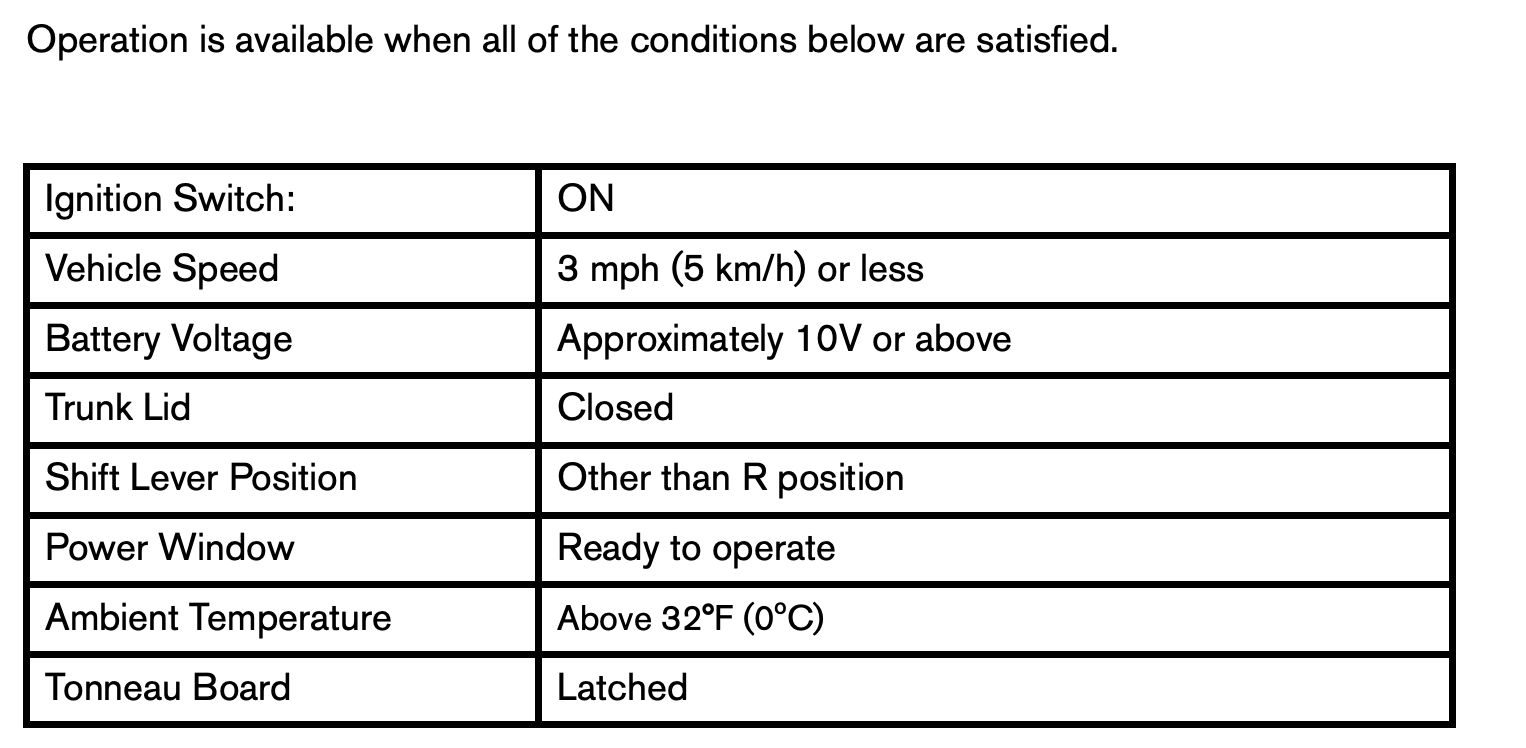

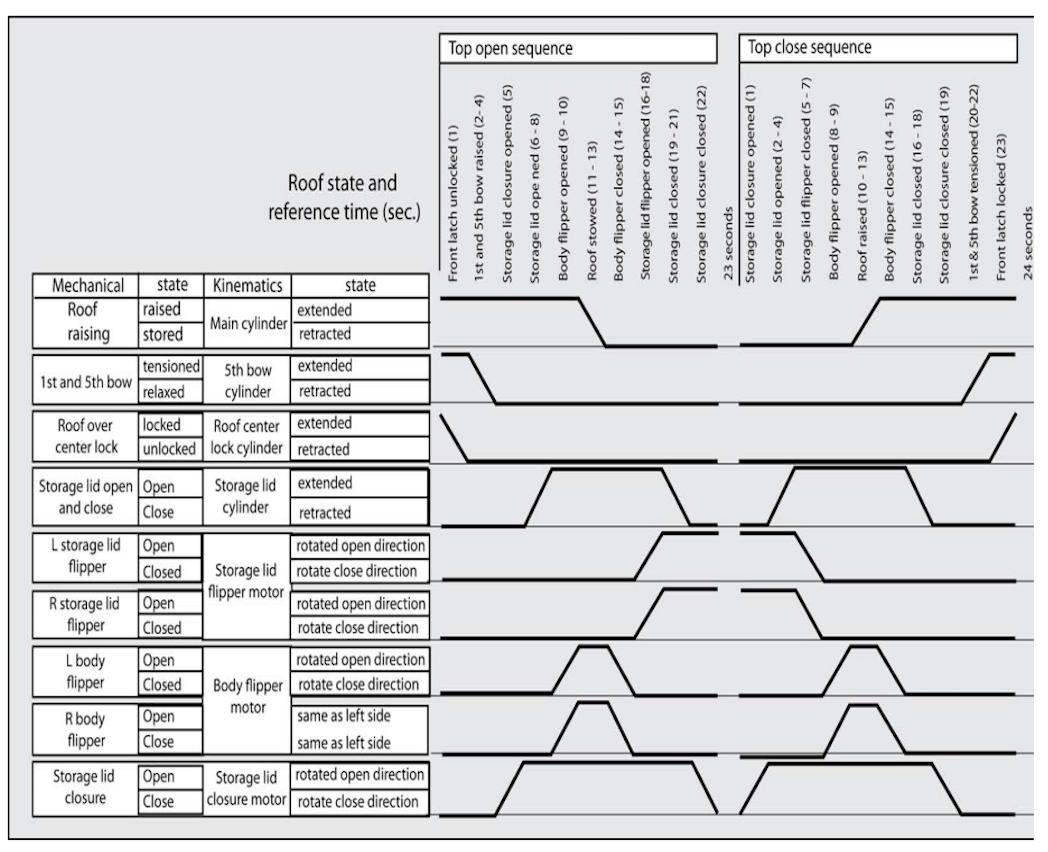

[Ed Note: Let’s dig into the actual Nissan service manual. It begins by stating the conditions needed for the top to move:

The document then discusses the basic mechanism by which the roof moves; it involves bungee cords:

As the convertible top is articulated, the bows act on bungee cords to fold the headliner material as the top folds. The bungee chords can be serviced seperately from the headliner if needed. There are two guide pins and two strikers mounted on the first bow; one hydraulic cylinder operates the two strikers. There is a position sensor on each striker to monitor the position of the locking mechanism. The position sensor is provided on the 1st bow to monitor the lock status.

And here’s the part about the Roof Control Unit and the hydraulic pump assembly, whose CAD image you can see below:

The roof control unit is mounted to the hydraulic pump assembly, located in the cargo area behind the trim panels. The Roof Control Unit (RCU) is replaceable. When replacing the RCU, remove the pump bracket from the body first because the 3 RCU securing hooks are behind the pump bracket.

The RCU does not require initialization because it reads each actuator position each time it is operated. The hydraulic unit consists of a hydraulic pump motor that drives the hydraulic pump; hydraulic pump relays 1 and 2; switching valves 1,2,3,4 and 5; and the hydraulic pump temperature sensor. The hydraulic pump controls the hydraulic system operation according to control signals received from the roof control unit. Hydraulic pump relays 1 and 2 control the direction of the hydraulic pump motor rotation. The switching valves control the hydraulic circuits for each cylinder. The temperature sensor mounted on the hydraulic assembly measures the temperature of the hydraulic pump and fluid

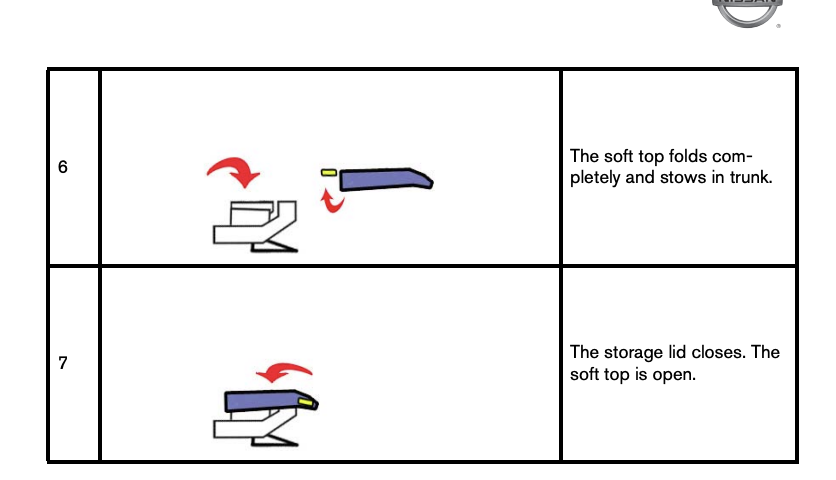

Here’s how Nissan shows the top operation using five little shapes:

And here’s a cool diagram describing the kinematics of how the system works:

Anyway, I thought those diagrams were interesting. -DT]

So what of the CrossCab’s long-term future? As eminently hateable as this car is, there are vanishingly few other cars that offer the same high-riding, open-top driving experience without the ricketiness of a Jeep Wrangler. It retains a dedicated fanbase of longtime owners, plus new emigres drawn specifically by the revulsion that the CrossCab instills in people. The very features that make the CrossCab a one-of-a-kind driving experience are the ones that make it so polarizing, and therefore appealing to hardcore enthusiasts like us.

Whether or not any of us like the CrossCab, we can agree: It gives us something to unite over. It’s kind of like a Tesla Cybertruck in that regard, only better-engineered and not as ugly. [Ed Note: A reminder that I actually kinda like the Cybertruck! -DT]

Happily for them, they’re not up shit creek when it comes to maintaining their vehicles. They share leads on shops that won’t snub their business, and speak of reproduction roof frames and tricks to compensate for failing hydraulics. Love it or hate it, the CrossCab’s stalwarts will fight for their silly cars’ continued existences. And frankly, I hope they win.

With every passing year, fewer and fewer of these already rare ragtops will remain. Some of you may have already seen your last roadworthy example and not known it. Lasts often come and go unannounced that way, recognized only in retrospect. Appreciate the Nissan Murano CrossCabriolet before it becomes even more of a unicorn, because with a roof this finicky, it’s probably a matter of time before the only ones left are in museums.

That ending was weird but I love the technical details.

I saw one in my friend’s neighborhood the other day! I have no idea if it’s roadworthy or not. I didn’t get a super close look at the roof, but it seemed mostly closed and looked a bit rough, so I imagine it doesn’t work well.

They could have used one of the replacement roof boxes to smuggle Ghosn out of Japan.

There is a reason that Nissan is known as the Chrysler of Japan and that is the quality of their engineering.

And their ability to constantly be on the verge of bankruptcy.

True. Also always in the shadow of the 2 big players in their home markets.

This really makes me appreciate the manual top in my Miata.

I recently picked up a ’15 SLK250 for my daughter (hand me down from generous grandpa). Hardtop convertible. The top hadn’t been used in years. Watching the choreography among all the parts is … concerning but they actually seem to be pretty reliable, or at least the forums aren’t filled with horror stories. Yet.

What if you want to use the convertible in less than 32°?

I would then, probably, recommend a Miata with a manual top.

Apply hairdryer to the ambient sensor until the desired temperature is reached?

This is a bit inflammatory, especially considering the events of the past week. Let’s not continue to spread hate, please.

It’s unacceptable, and something I should have removed; my sincerest apologies. I clearly edited this piece too quickly (I was focused on making sure we get all the nerdy details of that service manual!), and skimmed to the conclusion which seemed like it was just a summary of the article. But wow — again, it’s my job not to let stuff like that reach your eyes; this will not happen again!

It would have been so much simpler if Nissan had done what RR/Bentley had done years before with the “new” Corniche/Azure – and simply emulated the roof and retractable headrest mechanisms from Mercedes-Benz

Does the First-gen Toyota Rav4 not count as having a convertible option, considering it’s a “CUV”? Or the Suzuki Sidekick? (similar style roof as found on the Jeep)

Or is there some sort of convertible gatekeeping because those two didn’t have frameless windows so the sides were fully open – nor a complex mechanism to break down on them?

Its only a half convertible since the front seats have a roof

The Sidekick is no more a crossover than a contemporary YJ Wrangler was.

I dunno that I’d call the first-gen Rav4 a convertible in quite the same fashion. Ragtop, yes, but it still had a roll bar partway down the body. The Sidekick also was body-on-frame rather than a unibody CUV, was it not?

Aww man, SubToptimal was right there for the top shot, it’s even called a TOP Shot!

good lord, how I regret not thinking of this

Imagine being married to the CEO of an international corporation and still having to drive a Nissan Murano.

True. But later on, she also had the excitement of being the former spouse of an international fugitive. I’m sure it’s exciting for his current wife. The Murano, not so much.

Re the editors note: Its a good day anytime an engineer gets to use a pyrotechnic device in their design. I’m still bitter that a client had a strict “no explosive bolts” policy 15 years ago. The shenanigans I had to go through to get the same functionality as an explosive bolt…

In a previous career, I designed airbag inflators and other pyro devices for the fledgling “airbags in all cars” period of the mid-90s to 00s. Sometimes, something that goes bang is the correct answer. However, you have to remember that every pyro device is an one-shot, so repair/replacement is always required after use.

One device we designed and prototyped was a pyro-driven cable cutter (these are not new tech) to reliably depower the high-voltage power cables in EV’s. A pyro-driven non-conducting wedge would fire through and cut the thick copper cables to isolate them from battery power in the event of a serious crash. The idea was to make the high-voltage wiring safe for first responders in the event of a crash requiring extrication of trapped passengers, at the expense of needing to replace the cut section of cable to restore power or make repairs. None of the automakers were interested, so the project was shelved.

In 7 years, the only problem I had with my Ragtop PT Cruiser was where to stash the snap on tonneau cover when not in use. I usually kept it in the trunk, but that would become problematic on road trips, with the limited trunk space. At least the top didn’t reduce that 13.3 cubic feet, as it sat in it’s reserved space.

Chrysler also reduced complexity with a manual twist lock at the windshield that had to be released and secured again with every drop and raise of the top.

Loved that car; only sold it because I needed $$ for my home purchase!

Without seeing one of these up close, this seems like it should be something that can be entirely rebuilt as a separate system outside of any of the existing controllers and with its own user-activated switch. Do whatever signal trick you need to give the BCM the idea that the top is closed to keep that happy, then any failed hydraulics should be something that can be replaced by OTS industrial stuff of the same spec, and something like a raspberry pi used to handle the control sequencing, timing, and even have a temp sensor that would prevent operation below the recommended threshold. The inherent design issues would still be there, but the parts would not be subject to the whims of old factory unobtainium controllers, be more serviceable, readily replaceable, and possibly more robust. Is it worth it for this thing? Not to me, but if I had one and loved it, I’d figure it out (or junk it in frustration). As for the mechanical parts of the top, I don’t know, but I would think they could be repaired/replacements fabricated by outside sources.

When Ghosn’s wife is the only person who asked for this.

The engineering flaws are entirely insignificant compared to the design flaws.

This is probably the fate of most of today’s very complex cars. The complex systems cannot be serviced by owners and critical parts will not be available after 10 or 15 years or so. As vehicles age and spares dwindle, otherwise usable cars will become bricks. Even if the spares are available, the diagnostic and service equipment and service tech know how will also become scarce.

This is already a problem in the aerospace industry with aging programs that are past end of life like the B1-B or KC-135, where damaged or retired aircraft are cannibalized to keep a dwindling fleet operating

People said that about the Aston Martin Lagonda, yet there are still many running and even some with the original digital dash. There’s a thriving culture around fixing and maintaining Buick Reatta CRT touchscreens. Where there’s a will, there’s a way.

I admire these crowd sourcing support teams but today’s cars are far more complex. Where are you going to find a control module for a 2025 M5, let alone the know how to program it in 30years?

Look a the tailight situation for the Cadillac XLR.

And yet people have found workarounds. Maybe not pretty ones or easy ones, but ones that keep their cars on the road all the same. I guess I just don’t want to be a doomer about these sorts of things. I like to believe that someday someone will be able to figure it out and that we’ll have access to better electronics that can emulate older hardware. It’s better than assuming the worst because as much as we bitch and moan, computers aren’t coming out of cars any day soon. Might as well try to adapt and figure things out sooner than later.

Those are significantly simpler electronics with fewer anti-consumer measures in place. Maintaining ’80s electronics, even crappy ones, is still objectively simpler than keeping a more complicated modern car in tip-top shape.

I’m not saying it will be easy, I’m just saying that with enough time I believe there are people smart enough to figure out most things or at least produce work arounds for them. Hey, Ubisoft’s The Crew just became available to play again.

I have that worry about some PCU’s and all these other modules on unloved cars. Something popular to mod like a Mustang or a truck will be fine because of tuners, but will somebody’s 2000 Mercury marauder still have correct chips available? Likely not

Huh. I wonder which company did the hydraulics.

(Source: worked for a company that did hydraulics.)

There’s gotta be someone out there who can make an open source embedded RCU replacement. It might not be easy to get it to appropriately talk to the car, but it seems well documented.

Typed on my 1970s IBM Beamspring converted to USB using an open source capacitive sense controller.

The Autopina? Fancy now, are we?

My 07 Miata roof is manual and simple enough that you can raise and lower it with one hand in seconds — not too different from opening an umbrella when it rains. Like so many modern auto snafus, most of the pain with this Nissan was from automating something that shouldn’t have needed it.

The entire car was something the universe didn’t need.

But if I recall correctly, in a Miata you can manually open/close the top while sitting in the driver seat, right? Automating it, assuming you can do it reliably, makes sense if you’d otherwise need to get out of the car to move the roof.

I’ve never owned a convertible. How much of a PIA would it be if you did have to get out of the car every time you wanted the top up or down?

I have a GM scissor top (71-76 full size car), another notorious convertible mechanism. The top powers down fine, but I do have to get out and help it up because the tension cables on the middle bow have snapped again, and while replacements are available, I’ve been lazy. Even then, putting the top up or down is maybe a 30 second affair. It’s not a big issue.

I had a 2CV with a manual roof (manual everything) that required walking around the car to roll up the roof or close it. Not a pain at all because the start and end of every journey involves being outside of the car anyway.

It was more of a pain dismantling the tent that is the S1 Elise roof then storing it in the car. But I fixed this with a hard top, which was leak free, quieter and didn’t look like I’d made it myself.

While I’m also a fan of manual operations over power, I don’t think that’s a practical option here. The Miata doesn’t require as big and complex of a mechanism as it isn’t covering two rows of seats and have to stow into as awkward a space. You’re also talking a completely different demographic that I can’t imagine a manually operating top would appeal to even before factoring in the multiple steps with large, awkward parts that would need to be manipulated by hand. I think the main thing here is that the vehicle was never intended to be a convertible, the form does not lend itself well to such a thing, I’d bet the budget was pretty minimal, and this was Nissan who built it, so it didn’t have much of a chance before they even started.

Yeah, and when my Miata’s top wears out, it should be a few hundred bucks worth of parts to replace.

I had a MX5 NC PRHT. These are complex and electric/hydraulic. It never failed.

I have read stories about the MX5 roof failing, but these seem to be scarce.

I think the difference might be that this was not a Nissan MX5, Nor a Mazda Murano.

There are countless very reliable electronic roof mechanisms and have been for decades now. Even DaimlerChrysler-era Mercedes took great care to make sure their state of the art industry-changing folding metal hardtop was very robust on the original SLK even as the cars otherwise basically disintegrated around them.

Ghosn-era Nissan hacking the roof off of a four door crossover SUV in favor of a retracting fabric top that looks extremely complicated from the outside is an entirely different kettle of fish.