I’ll rebuild an engine if it needs it. I’ll tune a carburetor if it’s out of tune. I’ll even weld in a rust hole if there’s something that needs patching. Why, then, is removing the plastic-dip from these Foxbody Ford Mustang split-tri-spoke wheels bothering me so much? Why is this such a pain in the rear?

The Autopian’s partnership with XPEL has us installing an amazing wheel/tire combo onto our 2014 Nissan Murano CrossCabriolet: Foxbody split tri-spoke wheels with incredible Vredestein all-terrain tires. I cannot wait to show you.

But I’m going to have to wait, because none of it is installed yet due to a small issue that has ruined many a car-person’s week: Plasti-Dip.

If you’re not familiar, Plasti-Dip is “an air-dry, specialty …. peelable, flexible, insulating, non-slip, durable rubber coating.” You spray it on a wheel/body panel/fence post or whatever, and before you know it, you’ve got a thin coating of rubber clinging to your object.

And boy does it cling. Really, really hard.

I didn’t even realize these Mustang tri-spoke wheels that I bought even had a coating on them until I started cleaning them in preparation for paint. Then I saw a little peeling, and figured I’d peel the rest off. It’s not happening. No matter what I try, I just can’t get this stuff off without risking damage to the rather minty tri-spoke underneath.

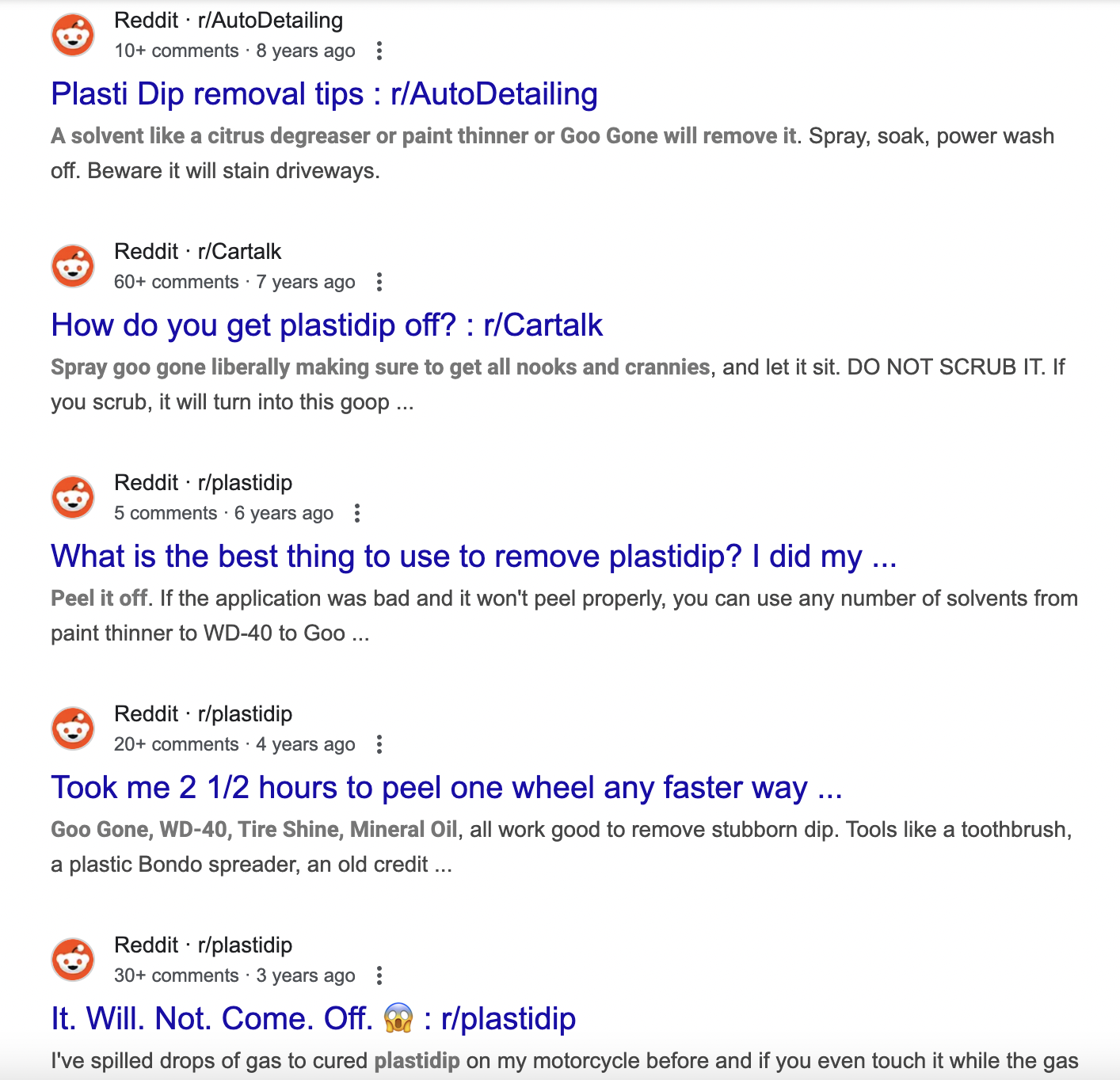

And this isn’t just a “me” issue (though I’ll admit I’m a Plasti-Dip amateur), it’s a problem many others are facing. Check it out:

“It. Will. Not. Come. Off.” with the horrified face is my favorite, though “Took me 2 1/2 hours to peel one wheel any faster way to get it off” is up there, too. The latter feature a few recommendations, like this one from RussianInAmerika:

Goo gone let it sit for 10 minutes; spray it again and let it sit another 10 min; right after go to local car wash with the rim brush and let it do its thing; goo gone after that again and let it sit for 10 min and then a pressure washer/scrub for minimal work/best outcome.

Goo Gone, WD-40, Tire Shine, Mineral Oil, all work good to remove stubborn dip. Tools like a toothbrush, a plastic Bondo spreader, an old credit card, I’ve used duct tape, all to get the peeling started. Once you have it started, I’ve used a heat gun or a hair dryer on lowest setting to help loosen dip too. Power washers and coin op car washes work well to spray clean dip.

For now, this whole Plasti-Dip removal process remains the bane of my existence.

Ah, the latest in the long running “I bought some dodgy problematic crap and it turned out to be a real pain in the ass” series, I see.

You either use old brake fluid or wd40 to loosen it up. Then you should be able to wipe it up.

SN95 not Fox Body. 1994, and maybe 95?

To be fair, Plasti-Dip is only hard to remove if it wasn’t properly applied. Unfortunately the vast majority of home Plasti-Dip jobs were definitely not properly applied as evidence by the horrible condition it’s always in almost immediately… I’ve used Plasti-Dip a few times and it’s always held up beautifully and the one time I had to remove it, it came off in nice big sheets almost like a wrap.

I hate to be that guy but those are not foxbody wheels, but 94/95 Mustang GT wheels.

I’ve had a lot of success by soaking plastidipped wheels with wheel cleaner, then spraying it with a pressure washer, it usually makes pretty quick work of it.

Might be time for the old stand-by!

BRAKE CLEANER!

Oh wait…..you’re in California – you can’t get the good shit. The stuff that gives you the ability to taste colors and smell sound.

Wouldn’t a blow torch work? It wouldn’t get hot enough to melt the rim, but surely it will turn the dip into crusty carbon that can be scraped away.

The credit card is the best solution. Use it to buy another set of wheels.

Maybe it’s a Zen thing, and instead of trying to remove the Plasti-dip from the wheels, perhaps you should attempt to move the wheels from the Plasti-dip.

There is no spoon

We told you to take the blue pill, but did you listen? Noooooo! You just had to take the red pill, and now Ozzy’s dead, Trump got a second term, and no one can get the plasti-dip off their wheels.

If Nickelback comes out with a new album this year, we’re blaming you!

I have had success using a “clinging” type paint remover. The particular one I’ve used is Abatron Clearstrip Gel, but any clinging stripper will work. Abatron and others like CitriStrip are low-VOC. The trick is to heavily cover the coating to be removed with the stripper and then cover the stripper with plastic film. You can use plastic wrap or drop cloth. The plastic film will cling to the stripper and prevent evaporation so you can let it work overnight or longer. I recently stripped two coats of paint and a coat of bed liner off of a pair of Jeep half doors and it was almost effortless once the stripper did its thing.

I have dipped about three cars and have tried various things to remove thin dip when it was time to remove it. As some have said, a good solution is to just spray more dip over what you want to remove to make it thick enough to peel off.

Dipyourcar.com sells a Plastidip-specific solvent that works quite well. Of the other solvents, I had little to no real-world success with Goof-off or Goo-gon or WD-40. The only one that worked well for me was De-Solv-It, which is a citrus degreaser. That, a toothbrush and disposable rags worked best (besides the expensive stuff from dipyourcar.com).

I wonder if Vanilla Ice uses that…

“If there was a problem, yo,

he-Solv-It”

Gasoline?

Maybe he will light it on fire then?

David this sounds like a great excuse to get an abrasive media blaster 🙂

I had the same thought… sand blaster. Or maybe the walnut shell blaster they use on sooted up TDI intake manifolds. I’ve never used either, but I bet you would think it’s fun!

They are awesome, I have one I picked up for $40 and will often blast, sweep up the walnut / sand, and blast with it again on a driveway. Only problem is you need a properly big compressor which I’m not sure he has or the space for one.

I can’t wait til abrasive media blaster’s next album…

I PlastiDipped my 911’s wheels because they were so. damn, shiny and I hate shiny. Sprayed them satin charcoal metallic and they look terrific. I was aware of this problem so I sprayed on four solid coats. I won’t ever remove it unless I have to, but if I do I hope my due diligence gets me something.

The MyMechanics guy on Youtube used dry ice to remove old sound deadening from the floors of the car he is restoring, it made the material crack off in sheets. Might work here?

Just plastidip the desired color you want over the existing stuff if you want the cheap route.

Otherwise with that much effort I’d just have them professionally refurbished (though admittedly I have a buddy who does wheels so it’s only like $75-100/wheel for me).

…Doesn’t Galpin have a program for that? Surely you could get some sort of discounted rate for such a thing? Or are you using your suffering for article fodder (which is understandable)?

Pasti-Dip was one of the most cursed trends in the automotive hobby.

WTF?

Send them to a machine shop and have them media blasted. If you’re too cheap for that, rent a big air compressor and blaster gun, do it yourself in the driveway, have fun cleaning up.

Stop wasting time doing things the dumb way, you’re an adult with shit to do and a family to tend to. Time is precious and you’re wasting it on stupid crap. They’ll look brand new when you get ’em back and then you can finish them to your liking.

Walnut blasting should get the coating off without damaging the finish underneath. Alternatively, we have had good success with dry ice blasting – advantage is there is no media to clean up when you are done. Never had it damage a surface that we were blasting.

Dry ice blasting sounds like fun!

Sometimes I feel like David’s stalwart insistence on wasting as much of his own precious, finite lifetime as possible on unpleasant and unproductive tasks is rage-baiting to make folks like me comment on these articles. Other times, I suspect it’s a serious financial trauma that he needs to talk to a therapist about.

Spend another day scrubbing wheels to save $40 or spend your day writing popular articles that drive upwards of $41 worth of views and eating canapés with Elise (NHRN) and Delmar (NHRN). Seems like an easy choice. I know David’s suffering generates engagement, but I have a feeling that it’ll dry up unless it’s directed at something more satisfying.

So here are some of my suggestions to productively milk the last bucket of David’s misery before turning a new page for Mr. Hollywood:

Set a budget and some on-the-clock time during the day to properly document the repair/build of one of your many shitboxes. See how that goes and maybe do one every other year. Call it a Five-Year-Plan.

Set a budget and a deadline, make it your full-time job and fix them all, any cars that can’t be registered and driven in California by the deadline (some number of weeks or months) get sold. Call it a Great Leap Forward.

Set a budget and just pay someone to fix one of your cars, while you work on another, with the aid of a punch-card for time spent on it, including going to buy parts, doing research and a per-diem for every day that the vehicle doesn’t work. Figure out how much your time actually costs, and whether that’s a fair price to you. Call it a Labor Theory of Value.

Right? Seriously, sometimes it feels like David is trying to make himself the James May of this site. We know he’s smart, maybe smarter than most of the rest of the contributors, but he does this dumb stuff that makes our heads shake.

I think it’s the “a thing has been done, probably by humans, how hard can it be for me to do it?” Followed within the speed of thought by, “ I would be a fool to not do it myself or spend more than what it would cost me to do it at $10 a day, and it will be fun too!” Completely bypassing the “do I even want it?” part of the cost benefit analysis.

In other words words David is pretty much like the optimized version of the Autopian readership that thinks that driving a WWII amphibious truck to Terra Del Fuego, boating to Antarctica, driving across Antarctica in the, amphibious truck, then boating to the horn of Africa, driving up the center of Africa, boating across the Mediterranean, driving across Asia to the Aleutian Islands, after which it’s a simple matter of driving back to the greater Los Angeles area.

I mean, it’s certainly possible, right?

And how hard could it be? The only real obstacle would finding a rust free DUKW, and rust is something David is a master of so really the whole thing is as good as done.

Probably bringing David’s wife and child ( real names omitted) along would be wise too, otherwise they would be missing out on the adventure of a lifetime, and would complain about it forever.

And the rest of us would be all “oh it’s easy for David to do that, he gets paid to write about it.”

Is that pretty much the consensus here or not?

If David takes your advice for trip routage, I hope he waits a few years for Delmar (NHRN) to be old enough to remember. I have some patchy memories of trips from N California to SoCal when I was three bordering on four. Memories get a lot more solid, reliable around Y5.

True, supposedly I was involved in some long distance trips in my family’s MG TD wedged behind the seats as three year old that I don’t remember at all, although a do remember being wedged back there in a parade with my mom driving ventriloquist Paul Winchell – interesting guy also the voice of Dick Dastardly and inventor of an artificial heart, first trip I sort of remember was age seven to the Seattle world’s fair, but mostly because the enormous (to 7 year old me) 170mm nuts that attach the space needle to the ground.

I do remember suggesting driving from California to the NYC worlds fair to my grandfather when he bought a new Mercedes and five of us went on a 7000 mile pre-interstate road trip. No AC, and entertainment by puppet shows. That I remember.

Well, that’s a lot! I remember Paul Winchell, but never drove with him.

An MG TD is pretty cool. I’d probably remember that ride. Although I remember rides in my parent’s ’61 Olds 88. When I was 3 or 4.

I have been to and up into the Space Needle a couple of times. I did not check out the nuts that anchor it to the ground.

In the late 90s. I worked at KIRO and we had a CCTV camera installed on the top deck of the Needle. I went up, got a safety harness and cleaned the lens of the camera. The Eye of the Needle. was what they called it.

Harry Wappler and his son Andy were such wonderful people to work with. Andy had a 944, which I congratulated him for four, (lol).

I don’t think it’s anything that intentional. He’s just a dude who really likes doing things himself. Both the thrill of victory and the agony of defeat are sweet to him because he gained the experience of going through it. Then he tells us about it just because we’re here and he treats us as friends that he can vent to or lean on. And he might get a helpful tip to boot. It’s just that simple – nothing rage-baity about it.

In my teens, I spent an entire week sandblasting, polishing, and clear coating the wheels on my brother’s ’86 Acura Integra. A month later he totaled it. Someone at a wrecking yard got a really nice set of wheels.

DT, maybe paint stripper? It’s nasty stuff but it would definitely work.

My son bought a VW GTI that was in great shape, except the previous owner had plasti-dipped the stock wheels and then had damaged the wheels horribly trying to get it off. There was no solution but to trash the wheels and put on a new set of Enkeis.

My uncle taught me this trick-

But a cheap can of Plasti-Dip and reapply a thick coat over the existing areas that still have the dip on it. Think of the old dry erase board trick, when you go over the older applied dip, it needs the chemicals to convert it back to a liquid, which the new spray will apply to the old dip. IMPORTANT- Wipe quickly before the new dip loses the chemicals in the air.

I’ve never tried it, and just made that up, but it should work YMMV.

My uncle taught me a different trick-

Apply a thick coating of Plasti-Dip on top of the existing thin layer, let it set and it’ll incorporate the thin layer, making it peel as advertised.

I’ve also never tried it, and also just made that up, but it also should work YMMV.

This is actually the recommended removal technique listed on the can for multiple brands.