Imagine, you’re out on the trail. You’re enjoying a short break, when you see an old Jeep rattle by. Only, there’s something strange about it. It’s got a big old log strapped to its side!

When I first saw this out of context, I thought it was a traction thing. I assumed it was similar to the logs carried on tanks during World War II — logs that were used for filling ditches or otherwise clearing obstacles in tough terrain.

It turns out I couldn’t have been further from the truth. As it turns out, the log is actually an emergency repair. Let’s explore how a big chunk of wood can save your bacon in the backwoods.

The ‘Semi Float’ Axle

David was reminded of this surprisingly common repair after watching a video from YouTuber Dexter Browder, whom you might know from his popular DeXJs channel. Browder recently undertook a long day of wheeling at Windrock Park in Tennessee. Along the way, several Jeeps ended up battered and broken on the trail.

Chief amongst the wounded was a Wrangler, which suffered a critical failure. The rear left wheel was falling off the vehicle thanks to a broken rear axle. Visually, it’s a striking failure. It’s also quite a common one for certain Jeeps in hardcore situations (especially if the driver applies too much skinny pedal). It all comes down to a combination of weak shafts and the design of the rear axle.

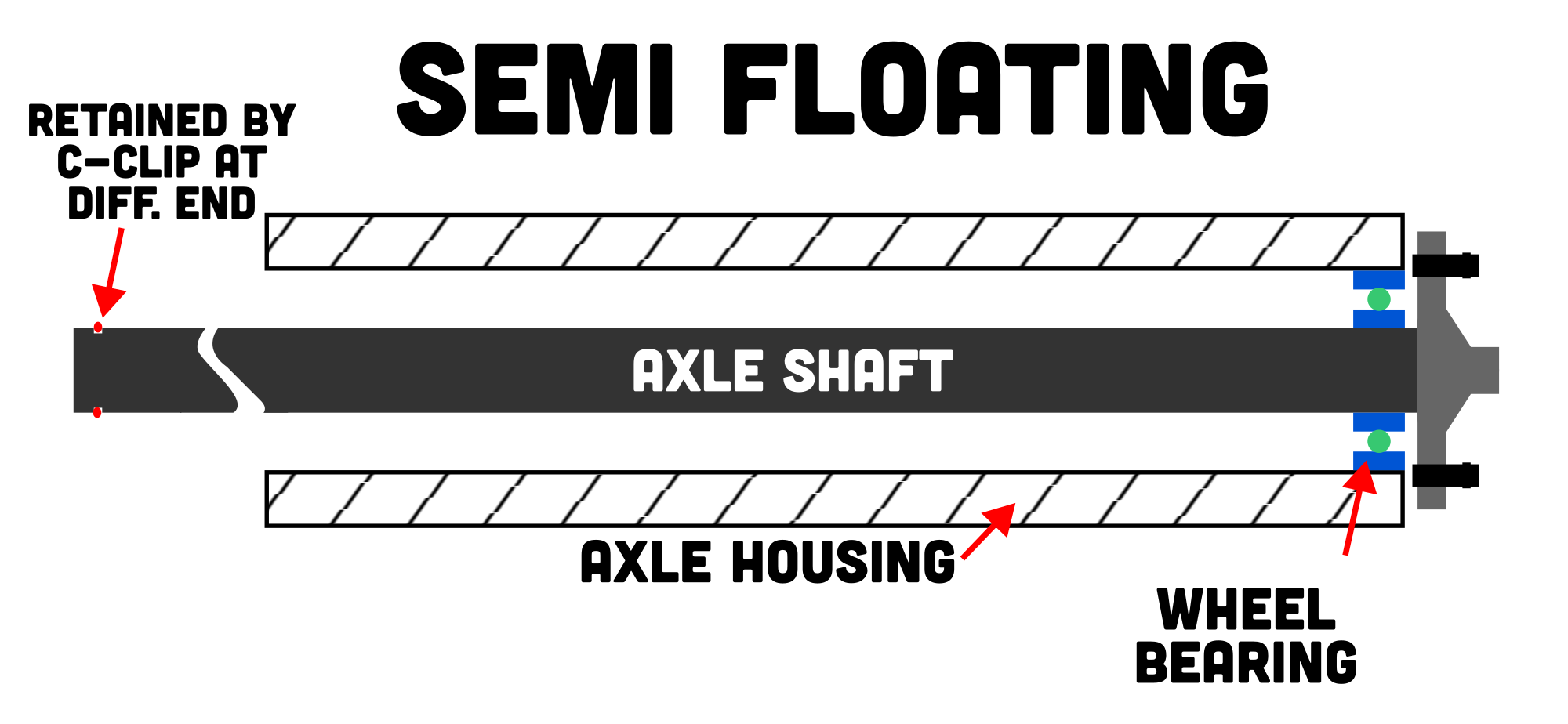

The Jeep shown above has the axle best known for such a failure: the Dana 35. These rear axles use what is called a “semi-floating” design, which played a critical role in the wheel coming off here. To understand why this happened, and why the log fix is so effective, we must explore one of the main differences between semi-floating and fully-floating rear axles.

It all comes down to how the axle shafts are held in place. In a fully-floating rear axle, the axle shafts are restrained from axial movement (i.e. pulling out) because they’re sandwiched between the differential gearing in the middle and the spindle at the end (the shaft has splines to transmit torque from the former to the latter). This design is very sturdy, thanks to the fact that the spindle transmits the weight of the vehicle to the axle housing/tube, with the axle shaft itself only having to handle transmitting torque.

A simplified diagram of a semi-floating rear axle assembly. Note how the axle shaft is retained by a small clip going into a recessed groove on the inside end of the shaft. If the shaft breaks, there’s usually little to nothing left holding it on to the vehicle. The shaft, with its pressed-on bearing, pulls out of the axle housing. Credit: Lewin Day

In a semi-floating axle, there is no spindle bolted to the end of the axle housing/tube to hold/sandwich the axle shaft in. Instead, the shaft is retained inside the differential with C-clips that prevent the shaft from pulling out. Toward the outer end of the inside of the axle housing, there is a single bearing that supports the axle shaft itself, and at the very end of the axle shaft is a flange to which the wheels mount. The wheel bolts to the flange on the axle shaft, transmitting the weight of the vehicle through the shaft, which then transmits that weight to the axle tube via the bearings.

If it’s still not clear, this video shows how a full-float axle’s axle shafts just sorta “float” between each wheel hub and the differential, and doesn’t have to see bending stresses from the vehicle’s weight, only torque from power transfer. You can see how, even if the axle were to break, the hub that the wheel is bolted to is attached to the axle housing:

Here you can see how the semi-float Dana 35’s shafts are held in place; each shaft rides on a bearing pressed into the housing, and the inside of each shaft is held into the differential with a C-Clip. You can imagine that, if the shaft broke, that axle (and its flange to which the wheel is bolted) would slide right out:

Thus, the semi-floating design introduces a unique problem off-road. If the C-clip fails, or if the axle shaft breaks, there is nothing else to retain the shaft to the vehicle. If this happens, the wheel tends to come off, since the wheel is fastened to the axle flange. The vehicle ends up with only three wheels, and usually winds up stuck.

That’s precisely what happened in this case and in so many others. It’s easy to see how the wheel has separated from the Jeep, and the axle shaft that has pulled out with it.

Indeed, from some angles, you can even see the outer brake drum, which is still attached to the wheel, while the brake backing plate and shoes are still attached to the axle housing itself. We don’t get a very clear look at the axle shaft itself, but it appears to have broken near the inside end. This is usually more common than the C-clip retainer itself failing, at least according to some anecdotal evidence from Jeep forums discussing the Dana 35 rear end. Whether it was the C-clips that failed or the axle shaft, the result is the same. The wheel comes off.

Enter: The Log

Unfortunately, when your axle shaft is busted and your Jeep is stuck on a steep trail, it can be hard to execute repairs. Few Jeepers carry entire axle shafts anyway, and popping open the diff to extract the broken parts and reinstall a C-Clip isn’t fun.

Thankfully, there’s a field-expedient repair that is both janky and perfect for this situation. What you ultimately need to do is find a new way to hold the wheel to the vehicle so that the shaft to which that wheel is bolted can keep riding on that bearing in the axle tube; this is where the log comes in.

The concept is simple enough. First, the wheel and what’s left of the axle are mounted back on the axle housing. A log is then placed along the side of the truck, pressing against the sidewall, with ratchet straps used to hold it in place. The wheel and axle shaft can no longer come out of the axle, because the log and the ratchet straps are pushing them back in.

If done right, the affected vehicle should be rolling at the very least. Driving is possible, but must be done slowly, due to the heavy damage to the axle and surrounding components. Going fast is a great way to rip the log and wheel right back off the vehicle.

Is it a perfect repair? Not by any means. For one, the log rubs against the tire and wheel. This creates wear and can puncture or otherwise ruin the tire in short order. Applying grease to the tire sidewall can help reduce this somewhat. Regardless, this fix can only work for short times at low speeds, or you’ll just rip the tire to pieces. One could imagine you might even set the log on fire if you drove too fast and built up too much heat. The fix would probably fail before you got that far, though.

You also don’t get any drive to the affected wheel. If you’ve got a locking differential, you’ll still get some drive to the other wheel on the same axle. However, if you have an open differential, you won’t get any meaningful drive to the opposite wheel. That’s because an open differential only gives the wheel with more grip the same amount of torque as the wheel with less grip. In the case where one wheel is disconnected from a broken axle, the differential is effectively delivering zero torque to that side, and so the other side will get zero torque as well. [Ed Note: You may as well remove the rear driveshaft at that point; of course, if you have a slip-yoke driveshaft that acts as a seal for your transfer case, that might not be a great move. -DT].

We’re told the Jeep in this video does have a locking differential. Still, the group decides to keep it hooked up to a tow vehicle to help it up most of the rest of the trail, since it’s severely crippled with one wheel out of action.

The log fix has other problems too. For a start, it’s quite unwieldy. If you’re on a difficult lumpy trail, there’s every chance you’ll catch the log on rocks or dips in the road, potentially ripping it off the side of your vehicle and causing further damage. It can also be difficult to execute, particularly if you’re in a smaller party. You need to be able to find a log, cut it to size, and mount it on the vehicle.

The off-roaders in this video used their vehicles to snap a tree down to size, but a saw or chainsaw is perhaps a more typical way to go. The fix naturally doesn’t work if you’re off-roading somewhere there aren’t any trees, fence posts, or metal pipes that you can use to do the job. You might also get in serious trouble for hacking up a tree, depending on the area you’re wheeling through.

This problem is why many hardcore off-roaders will upgrade to fully-floating axles. They’re usually less likely to break in the first place. Even if they do, they also don’t require such field expedient repairs in the event an axle does snap. Snap an axle shaft with a fully-floating axle, and it’s a minor bummer that doesn’t affect the ability of the vehicle to roll. Do the same with a semi-floating axle and you’re stranded until further notice. [Ed Note: There are plenty of semi-float axles that are much more robust than the Dana 35. The Chrysler 8.25 or Ford 8.8 come to mind. -DT].

Still, the log fix (used quite often, as seen in the YouTube video above by Enrique GuOr) is a useful hack to keep in the back of your mind. One day, you might find yourself stranded with a wheel dangling off your rig. With a few straps and a bit of know-how, you’ll be able to get yourself rolling again. Just don’t expect to see a lot of smiles when you limp past the ranger station on your way out.

Top image credit: DeXJs via YouTube screenshot

Very clever solution. MacGyver would be proud.

A steel yoke with two roller pins seems like a viable product for this problem.

Okay what the hell was with the video?

When someone asks me to help ID some old flat fender they have one of the first things I look at is that rear axle to see if it’s a full floater. Wartime were full floaters CJ’s were not. Of course, after 80 years and axle could have been swapped but it’s a good place to start. There’s a chance it could be a Korean war era M38 with a semi floater but there’s other things that stand out on those.

Fully floated axles are the way to go and frankly should be the standard for ALL solid axles.

Ik a guy who use to take series 3 Land Rovers re-engined with Chevy 250 Inline 6s down to Baja fairly regularly and when he’d snap axles they’d just drain the diff oil, pop the diff cover off, pop out the broken axle, put the diff cover back on, put the diff oil in, and keep driving. Whether it be in RWD only if it was a front axle, or 4WD (now FWD) if it was a rear axle.

I was half expecting the log hack used by Burt Munro in “The World’s Fastest Indian” when his trailer lost a wheel.

This is a common issue with drag racing as well, just no log fix allowed there. The ford 8.8 that DT mentioned still snaps c clips just as easily as others. Drag strips often have rules that for racing tires you can’t have c clips, so c clip eliminators or conversions to floating axle ends are common. Specifically a good choice is ford 9in ends welded to the ford 8.8.

I didn’t know logs would be used for trail fixes this way though, good article!

I’ve had an overheated bearing on a Ford 9″ cause the pressed-on bearing to slip off the axle just enough to disengage it from the diff spider. It happened when I pulled off the road up Mt. Hamilton in San Jose, and I didn’t even notice it happened. My friends and I went for a hike, and when we came back, the car was making a terrible grinding noise and wouldn’t move. I thought I blew the diff up, and maybe it fell to pieces when I pulled over. Ended up waiting like 10 hours for a tow truck (it was Cinco de Mayo and they were focused on profitable DUI tows, fuck tow companies all to hell) when I could have just pushed the freaking axle back in and (maybe) made it down the hill.

question is, why waste the time on an 8.8 when the bandaid fix indicates the 9 inch should be the rear to use. I think the fact that most axle houses stock and build their version of a 9 inch in about every flavor for just about any car suggests that as well.

I have seen a few 8.8’s in a jeep, I think they are stolen from Exploders with V8’s, but they don’t sound like that great of a design. Certainly not better than your basic D44HD

True going to the 9in is a standard step that’s hard to go wrong with, but the 9in is a lot heavier than the 8.8, so much so that it’s not a bad idea to just do the 9in ends on the 8.8 and save a bunch of weight, assuming you are not pushing over 1000hp for drag racing.

Reminded me of the TopGear episode when Hammond had to do that

Gotta be honest, as a Full-Floater man myself I have never really considered what to do if my c-clip breaks, but its always nice to tuck away this kind of bush repair information away in the event I wheel with those that do.

“It’s a jeep thing, you wouldn’t understand” I guess?

I’m with ya. Plenty of great PAVED roads I haven’t driven on yet.

You are missing out….just saying.

You mean off roading, or holding your wheel on with a log?

both really, but I understand if he has to do it for work. pretty much every mechanic I know hates to work on cars after work, they drive some of the worst deathtraps I have ever seen. That is actually why I never set up my own hot rod shop as I initially planned. Did not want to at some point hate the things.

Oh no, I’m not. I’ve spent the better part of four decades in land surveying, civil engineering, and construction. I’ve been driving 4X4 trucks through some of the most impassable terrain imaginable.

When I clock out, I’m done.

Also plenty of off-road capable vehicles that don’t seem to have the myriad of issues Jeeps have.

Also, disc brakes on a semi float axle (like the Explorer Ford 8.8 DT mentioned) can help mitigate this problem, as the brake setup helps hold it all together to get off the trail. Its like having a built in log!

Hey, that semi-floating shit is what the F-body Camaro/Firebird uses too! I’ve seen those C-clips before! So it’s basically like a Jeep LOL

Also, since Citroen is under Jeeps’ umbrella with Stellantis, too bad Citroen stopped using their hydro suspension, because you could drive on 3 wheels with no problem 😛

I had an axle come out of the diff on an f-body. It didn’t end well. Car was a total loss but nobody was injured.

😮

It was kind of funny, because I was backwards with the rear-end smashed into the guardrail when I watched my newly-liberated tire and axle come rolling down the road towards me.

Okay now I understand the log, what about the onion on their belts ?

thats the style at the time

But not white onions, those are reserved for the war.

In those days, nickels had pictures of bumblebees on them

Gimme five bees for a quarter!

anyway I was on my way to Morganville, which is what they called Shelbyville at the time

God, I love this website

we just had those big yellow ones

Love this kind of technical deep dive. I’ve learned more about suspensions, drivetrains, aerodynamics, etc from y’all than I have from anywhere else. Keep up the weird!

Minor correction, this is mainly an issue with c-clip semi floating axles. A semi floating axle with a pressed on bearing retainer, it will usually stay in the housing at least for a a short slow speed drive.

I wouldn’t say it is that minor of a correction, it is an entirely different way to retain the shafts.

The important part is this isn’t a semi-floating axle problem, it’s a c-clip axle problem. Not all semi-floating axles have c-clips. On a Ford 9″ or a AMC Model 20, for instance, the bearing is secured with a plate that bolts to the axle housing, and the axle just slides into the differential. I exploded the diff (broke both bearing caps) on my F-150 with a 9″ and still drove out on the front axle without having to do anything other than drive slower.

Also, I thought you were supposed to make a sled with the log and just drag the Jeep.

Yabba dabba doooooo!!!!!!

+1 came here for this

*cue the most hilarious scene from Top Gear ever*

Because they’re better than bad, they’re good.

from Blammo!

What holds your rims like ghetto shims

Over the rocks or in bogs?

What’s great for a fix, from your bag of tricks?

It’s LOG, it’s LOG!

Excellent work!

H/T to LTDScott for recognizing it and teeing it up!

Straight from the source.

Sure it can save a jeep, but can it save my walrus?

everyone wants a LOG!!!!!!!!

Except Mr. Horse.

My Dad used to talk about a different log “solution” for mountain driving.

In the early 20th century the old Model A and T Fords used to have to negotiate Tollhouse Road to get from California’s Central Valley (near Fresno) up into the logging country of Shaver Lake. That road was and is infamous for its twists and steepness. (A four-lane highway has since bypassed it, but the road is still there.)

When Dad was a young lad, going UP Tollhouse Road me and going in reverse in many sections, because the gear ratio of those old cars was lower in reverse than first gear forward, and first gear just couldn’t hack it.

But going DOWN Tollhouse? You had to tie a big ‘ol log to your bumper and let it drag behind you, otherwise you were eventually going over the side. The toll operators kept having to truck the logs back up to the top.

Dangit! Typo. Where’s the “edit” button?

”UP Tollhouse road me and going…” should read “Up Tollhouse Road MEANT going…”

Semi floating isn’t typically an issue if the axle isn’t an undersized turd. My rear axle is a tiny semi-floater on my 4×4, but it’s a Suzuki. My SJ (not XJ) Cherokee has a semi floater in the rear. Shit my LeGeNdAry 80 series cruiser had a semi-floating rear as well. They did change it to full floating the next year. Only rig I have with a full floating is my K2500, and that’s the biggest swangin’ tow axle they did on those trucks.

Logs are still part of Russian military standard equipment. “Unditching beam”, these are typically used by Soviet (and later Russian) ground crews to… un-ditch themselves.

Had something similar happen with my ’77 V8 Ford Maverick. Going down road one day and car suddenly slowed to a stop. WTH? Engine still running, driveshaft spinning. My buddy opened his door and goes ‘think I see the problem!’ Back rear tire sticking out from rear of car. BTW, jacking it up and trying to shove it back in doesn’t work. Tow truck time.

Too bad didnt have spare log and some rachet straps.

I was once behind an 70’s F100 that lost its semi float axle. Was interesting seeing the shaft push out around the corners until it let go. We honked a few times trying to alert him but no dice. Single lane canyon road so no chance to get along side him.

Ah the dreaded Dana 35 failure. I could never understand why anyone who was serious about wheeling would risk going out with one. The Chrysler 8.25 and Dana 44 don’t have this issue unless you’re running a non stock motor or do something incredibly stupid.

I’m all for being cheap but damn, even I’d spring for a fully floating axle if this was the downside of stock.

Man, I always drop my logs off the back bumper when I’m Jeepin’.

…

I’ll see myself out (for my morning dump).

*appreciative golf clap*

You need one of these. https://bumperdumper.com/

Hitch receiver toilet.