I feel like if there’s been a theme for this year so far, it’s that I’m learning new and fascinating things about inline-four engines that are laid flat on their sides. Engines which I’ve known about for years, but never really scrutinized before. For example, I found out all sorts of interesting things about the Wright Flyer engine, and now I find myself amazed by details about another inline-four engine laid on its side: the engine proposed for use in the Volkswagen prototype known as EA266, my favorite of the many never-realized VW prototype cars.

For those of you not familiar with the EA266, I have written about it a couple of times before, mostly over at The Old Site. But if you want a quick summary, EA266 was a Beetle-replacement project developed with assistance from a Porsche team led by Ferdinand Piëch, and was really quite a revolutionary design, or would have been, had it made production.

The core of what made this car so fascinating I think has to do with its incredible packaging design, one that got the absolute maximum amount of usable interior volume possible via some really bold approaches to packaging design. The engine, a liquid-cooled 1588cc inline-four design, was transverse and laid flat under the rear seat, driving the rear wheels via a transaxle; the fuel tank was in front of the dashboard, the spare wheel under the driver’s seat, and there were two good-sized cargo areas, front and rear. It’s an absolute packaging masterpiece:

It’s incredible, isn’t it? I think so. Of course, part of why I think so is that I’ve never had to try and access that engine to do any sort of repair or maintenance, but conceptually, I really admire this design.

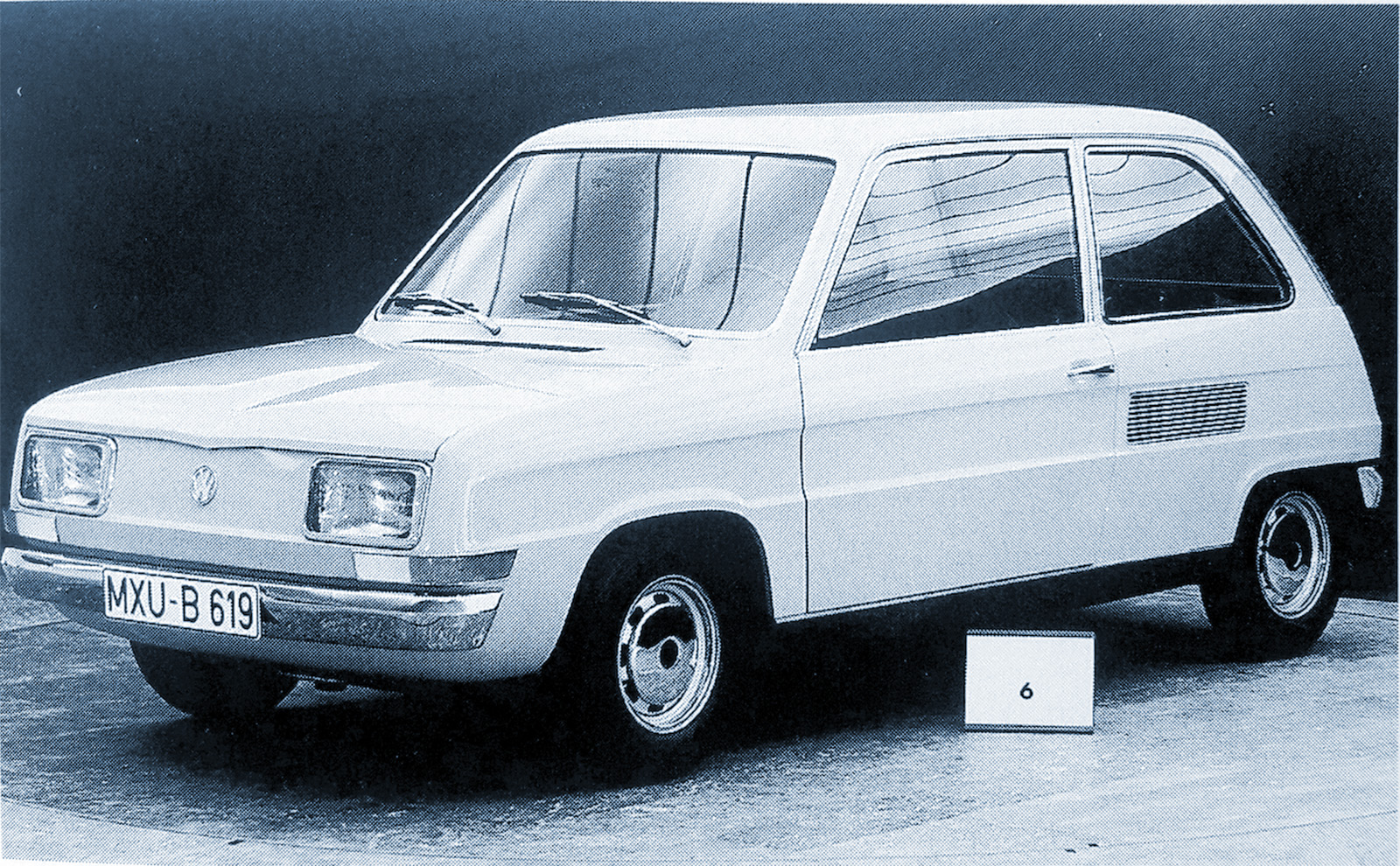

I think they were pretty cool looking on the outside, too; the top image here is an early body design, the middle picture and the bottom one (it’s next to the Beetle, second from left) shows its sleeker final look.

These were essentially pre-production cars by the point the lower pictures were taken, but things changed dramatically for VW when Rudolph Leiding, formerly head of VW Brazil, took over the company in 1972. Oneof Leiding’s first actions was to cancel the EA266 project, and moved the future technical direction of VW to abandon their old rear-engined, air-cooled ways and adopt the liquid-cooled, front engine/FWD tech from recently VW-acquired companies NSU and Auto Union, which gave birth to the Passat, Golf, and the whole path of modern VW.

It was kind of a shocking move, as the EA266 project was expensive and very close to production, and VW had a whole plan for an EA266-based lineup of cars, including sports cars and microbuses:

It’s all a fascinating sort of what-if to think about. And I was thinking about it recently because I happened upon a site that showed some interesting styling proposals for the EA266 that I’d never seen before, including this one from Pininfarina:

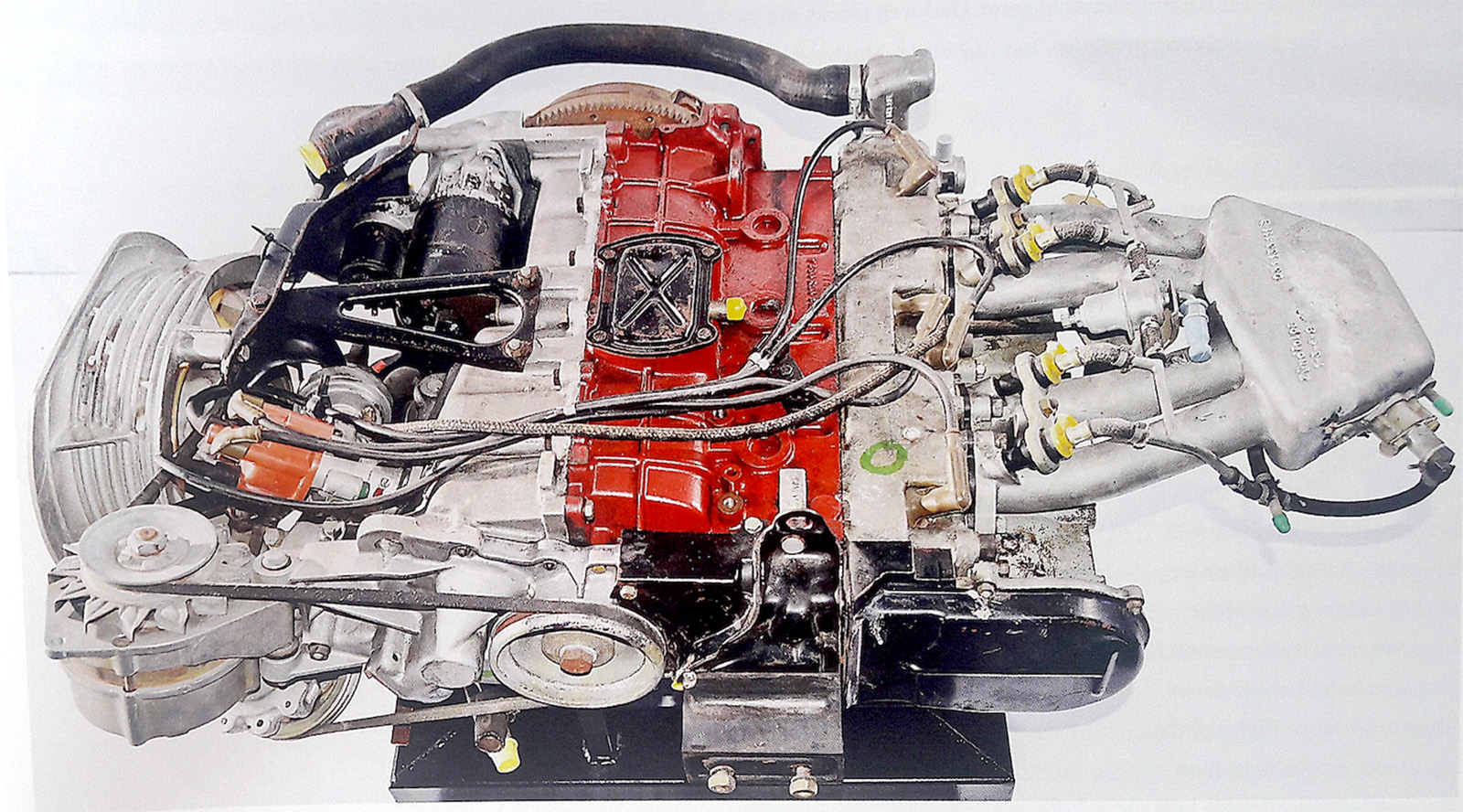

I don’t think it looks as good as the one that was eventually settled upon, but it is interesting, especially with those huge rectangular headlamps. But what I found even more fascinating was this picture of the EA266’s engine that I’d never seen before:

Previously, I’ve only seen this engine in schematic drawings or already installed in the car, where it was very hard to see. It’s quite wide, perhaps the result of making it so flat, and I think that ribbed unit at the far left was the fan/air duct assembly for what would have been a side-mounted radiator. The fuel injection and intake manifold I think is off to the far right, like some kind of quadrapus grappling at the engine, which is also interesting to see.

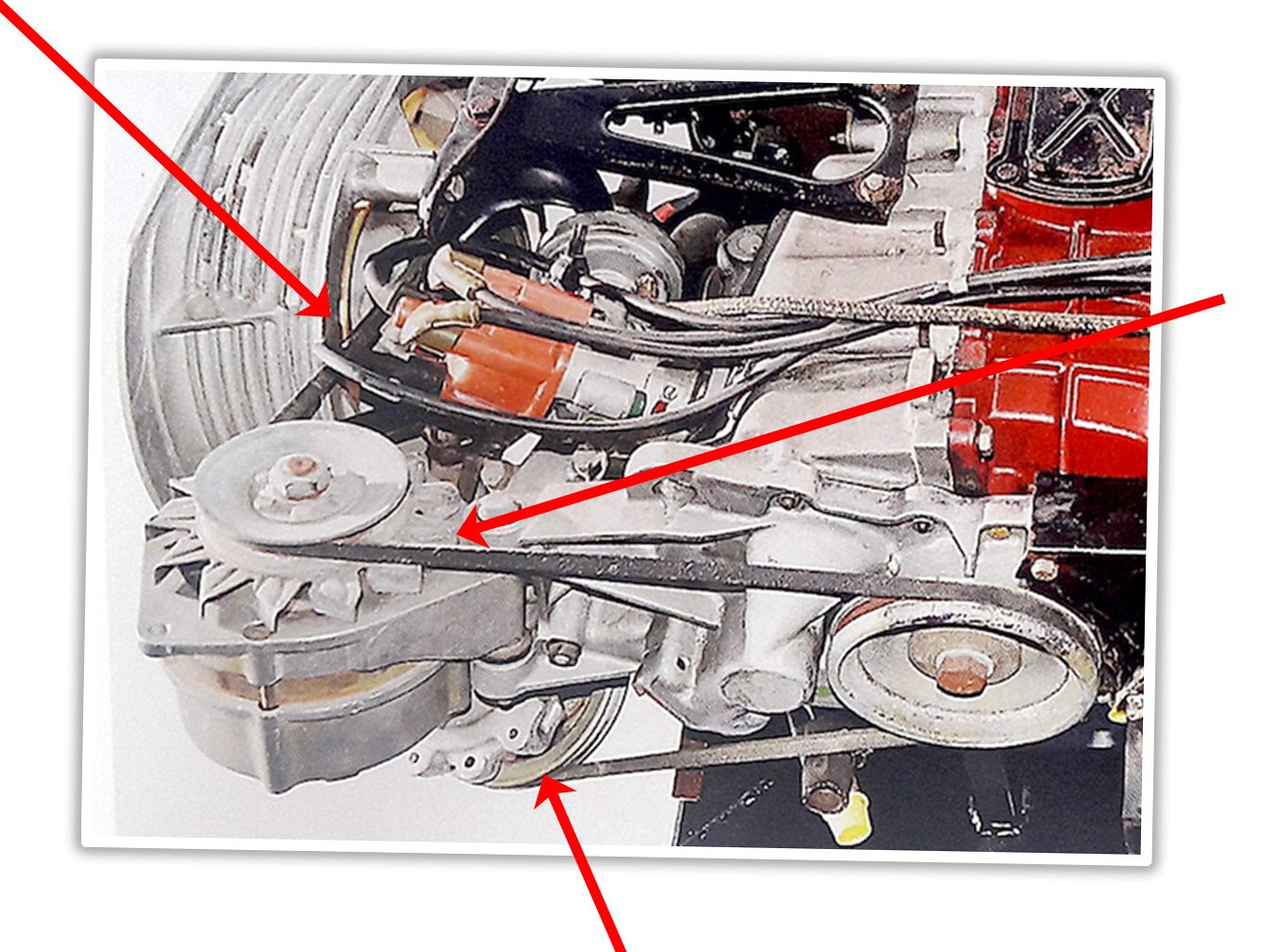

But what really caught my attention is the belt and pulley setup used to drive the accessories like the alternator and water pump, etc. It’s interesting because it looks like they contracted the design out to MC Escher. Look at this thing:

Look at these bends and twists in that belt! This is beyond a serpentine belt, which usually just serpents on a single plane; this is making all kinds of three-dimensional (possibly more, haven’t checked) twists and turns. And we’re just seeing one bit of it! Where does the other end of that loop go? Each of the three pulleys I can see here are on a completely different plane, and that belt is going to have to make some more crazy bends to form a workable loop. It’s astounding!

The closest I analogue I can think of on a production car is the Chevy Corvair’s right-angle-ish bend that its belt makes coming from the vertical crank pulley, then up and over the generator, turning to then drive the horizontal fan atop the engine:

Still, that looks downright tame compared to whatever is going on with the EA266’s multi-dimensional-serpentine belt!

There’s only one or two EA266s left in the world; if I ever get back to Wolfsburg, I’d love to roll under that EA266 and try to see just what the hell is going on there. I bet it’s sort of a mind-bending experience.

The Porsche design “new” VW logo is giving me art deco vibes.

I love how the Pininfarina design includes a non-stylized version of the side intakes on the ten-years-hence Mondial.

The schematic seems to be violating the laws of physics with the rear passenger’s feet and spare tire occupying the same space.

Maybe they’re implying the person would stick their feet on either side of the tire which sounds unpleasant.

I was briefly a Corvair owner. Mine never slung its belt but the fear was a constant. There were definitely belt fragments in the engine bay from previous slingings. I’ve heard stories from hardened Corvair owners that properly tensioning the belt ensures it will never fly off, but even those guys had extra belts stashed in their engine bays along with the two wrenches needed to install them.

So, yeah, that belt will never just fly off. Trust me.

Heated rear massage seats at no additional cost!

Ahead of their time.

I’m being silly, but this is the VW I miss, where they pushed innovation rather than chase it the way that have for years now

Does that mean if you didn’t keep up with your subscription payment the car wouldn’t run?

Also interesting how the distributor sticks out of what would be the oil pan on a more common engine.

It looks like the belt just loops around the fan pulley and comes back around to the front. Except for that weird angled lower pulley (power steering pump?) it’s a very similar route to the Corvair.

They would have to use belts designed for this purpose. I have a snowblower with belt routing like this. If I buy a cheap replacement belt based only on width / length, it will shred the belt in a day. I need to buy the specific one that can also handle the twisting.

I was just noticing the same thing, it looks like the belt runs that fan on the side

That engine diagram answers my question from the first picture – where the heck is the cooling? Not sure how that would have worked. Interesting packaging to retain a frunk while going watercooled.

Packaging miracles are often serviceability nightmares. I’m not sure if there’s ever been a car that had truly excellent packaging and was also easy to work on. The closest might be the original VW bus

Ferdinand Piëch assisted the project, so serviceability should not had been a priority.

Just check the engineering “marvelous” that he authorized while in charge of VAG (W blocks, V10 TDI, VW Phaeton et. al.)

I love that front end styling.

Hey this is a really neat des..

*Rear ends car in front and gets a face full of mid grade*

Yeah. You’d for sure want to splurge for premium.

As the owner of a Velorex 435 I’ll have to say that the presence of a firewall isolating the fuel tank from the passenger compartment in the VW design is nothing more than decadent Western bourgeoise infantile nannyism:

https://smallcarsclub.com/wp-content/uploads/2016/12/Velorex-453-0-08.jpg

Fascinating indeed. I’m sure they could have made it fairly easy to work on with properly designed access ports, etc., but being Germans, they probably wouldn’t have (evidence: the VW “service position” nightmare).

Side note: Seriously, can we consider retiring “stillborn” when referring to prototypes, or never-realized cars, or non-production models, etc.? “Stillborn” is a bit graphic and disturbing for several reasons, even if you or your wife has never miscarried a child (as mine has). I mean, afaik, we’ve stopped using “abortion” to describe a horrible mistake, as was common when I was younger (back in the 70’s), and I think it’s time to give “stillborn” the old heave-ho as well.

Agreed.

Think of all the special tools they could have sold which were the only way to access that one f$%king bolt needed to complete a repair.

Update: Thanks Jason (or whomever changed the title) for replacing that term with “Never-made”.

Serpents on a plane was the working title of that movie, wasn’t it?

If you had a way to use quick disconnects on the linkages and hoses, and then had bolts that would allow the entire engine/transaxle/rear suspension assembly to just “drop out” and roll out backwards, it would actually be easy to work on. Without that, it’d be a straight-up nightmare.

The one change I’d have made to the basic EA266 is make it a 4-door, and a 4-door only regardless of previous German home-market preference for 2-door cars.

Because presumably there was an access cover for that engine under the back seat cushion (looking at that belt it would hopefully include most of the riser from the footwell to the cushion, at least on the right side), and being able to pull the cushion and access cover out directly and lean straight over the engine would have a significant impact on serviceability.