When it comes to engines, everyone is always looking for more. More horsepower, more torque, more efficiency. One company has a rather interesting take on how to allegedly get a lot more performance all around, just by giving your diesel engine dimples.

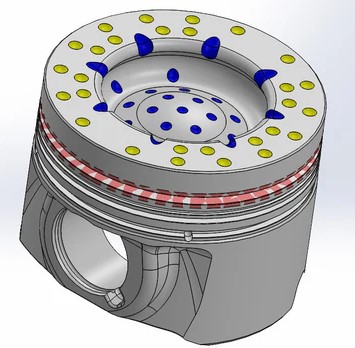

That company is called Speed of Air. Based out of Reno, Nevada, it specializes in designing pistons that might remind you of golf balls. That’s because they’re covered in lots of little divots—which the company refers to as “turbulators” for their effect on the air inside the engine. With their eye-catching design and purported performance benefits, they’ve been making some waves online of late. You might have heard of them on YouTube, where they’re routinely advertised by big diesel channel Dave’s Auto Center.

The physics of why dimples make golf balls fly better is well understood. But does applying the same technique to pistons have any real effect on performance or emissions? Could they really provide huge boosts to horsepower and slash fuel use by huge percentages? Let’s talk about it.

Dimples

The crux of the whole dimples phenomenon comes down to fluid mechanics. Weird structures and shapes can do all sorts of things to the flow of a fluid and create positive or negative effects for a given application. Sometimes, it’s intuitive—it’s pretty obvious why a smooth, streamlined bullet train can go faster than a slab-sided locomotive, for example. And at other times, it’s not intuitive. For example, take the common golf ball and the characteristic dimples that improve its performance. Why do they matter?

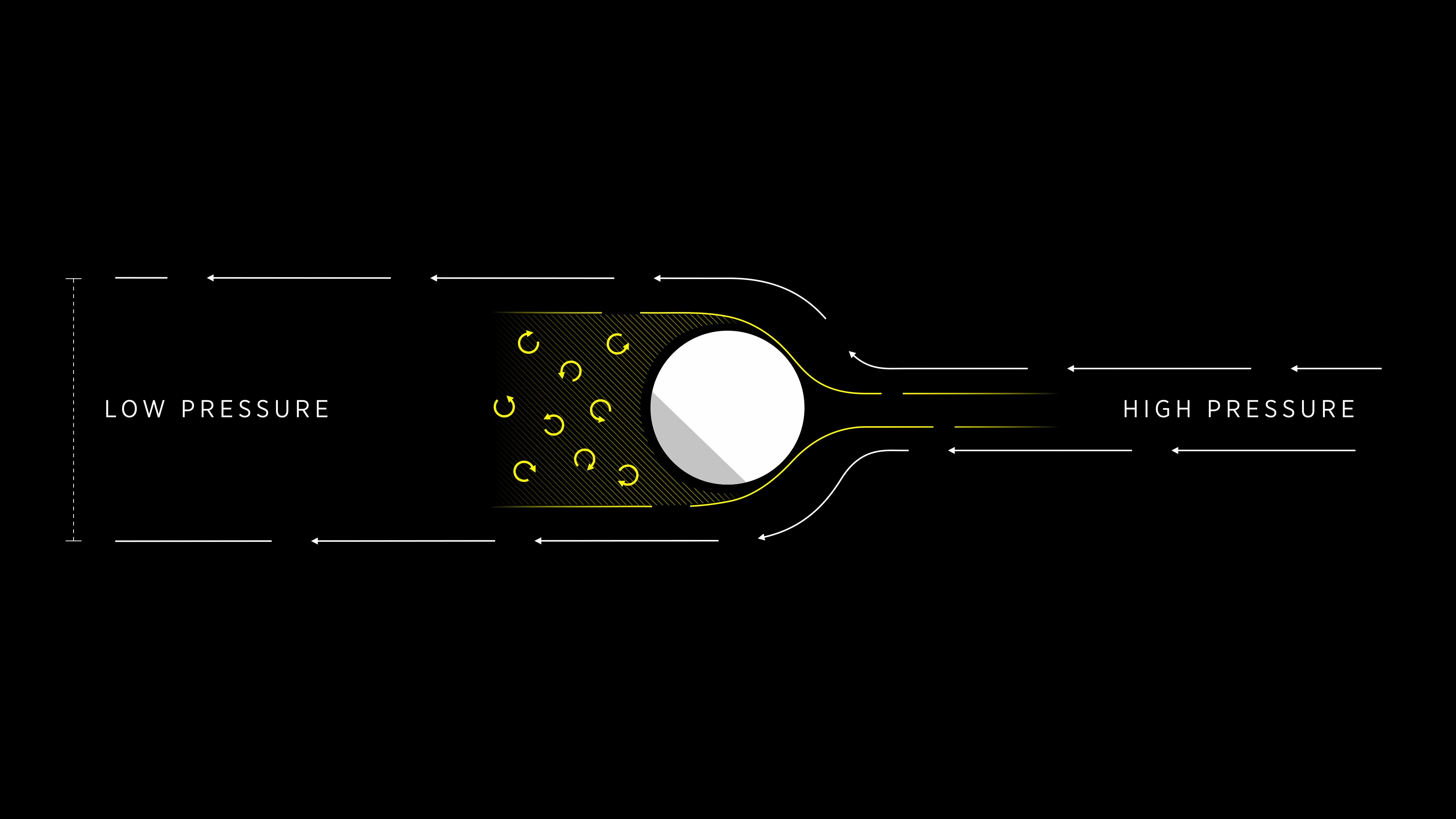

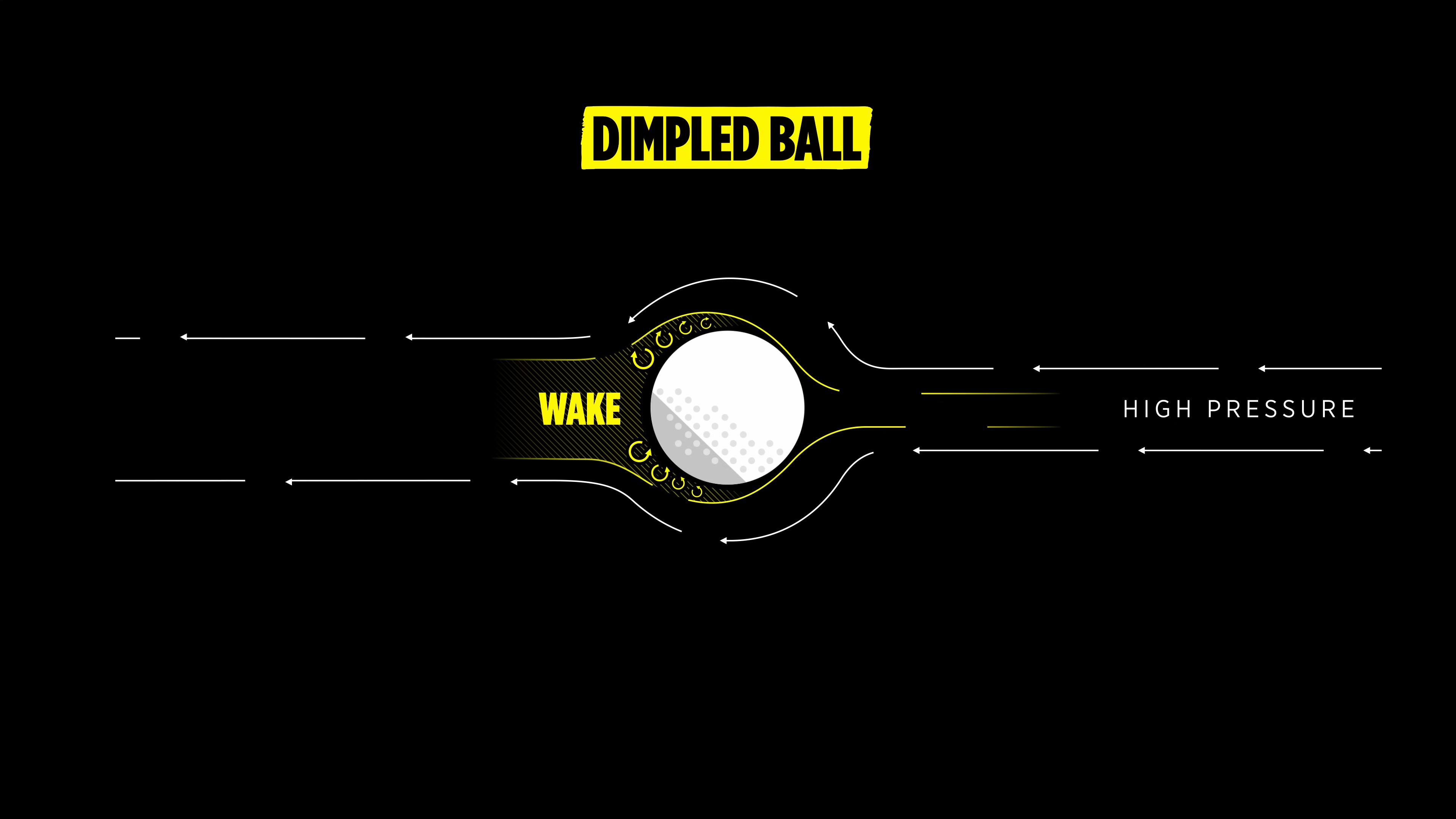

We can understand how the dimples affect the ball by examining what happens as it flies through the air. If the golf ball were a regular sphere, the small boundary layer of air flowing around the ball would remain smooth as it passed over the ball and experiences laminar flow. The laminar boundary layer separates from the golf ball quite easily as the ball flies through the air, leaving a large low-pressure area behind the ball—a wake—which creates a lot of drag, slowing it down. However, if the ball is dimpled, the immediate boundary layer around the ball becomes turbulent. This turbulent boundary layer sticks to the ball a lot better, helping guide the airflow around the ball and creating a much smaller low-pressure region behind it. The smaller wake comes with much less drag, and the ball can fly farther.

Golf brand Titleist has a great explanation of how dimples make its golf balls fly farther.

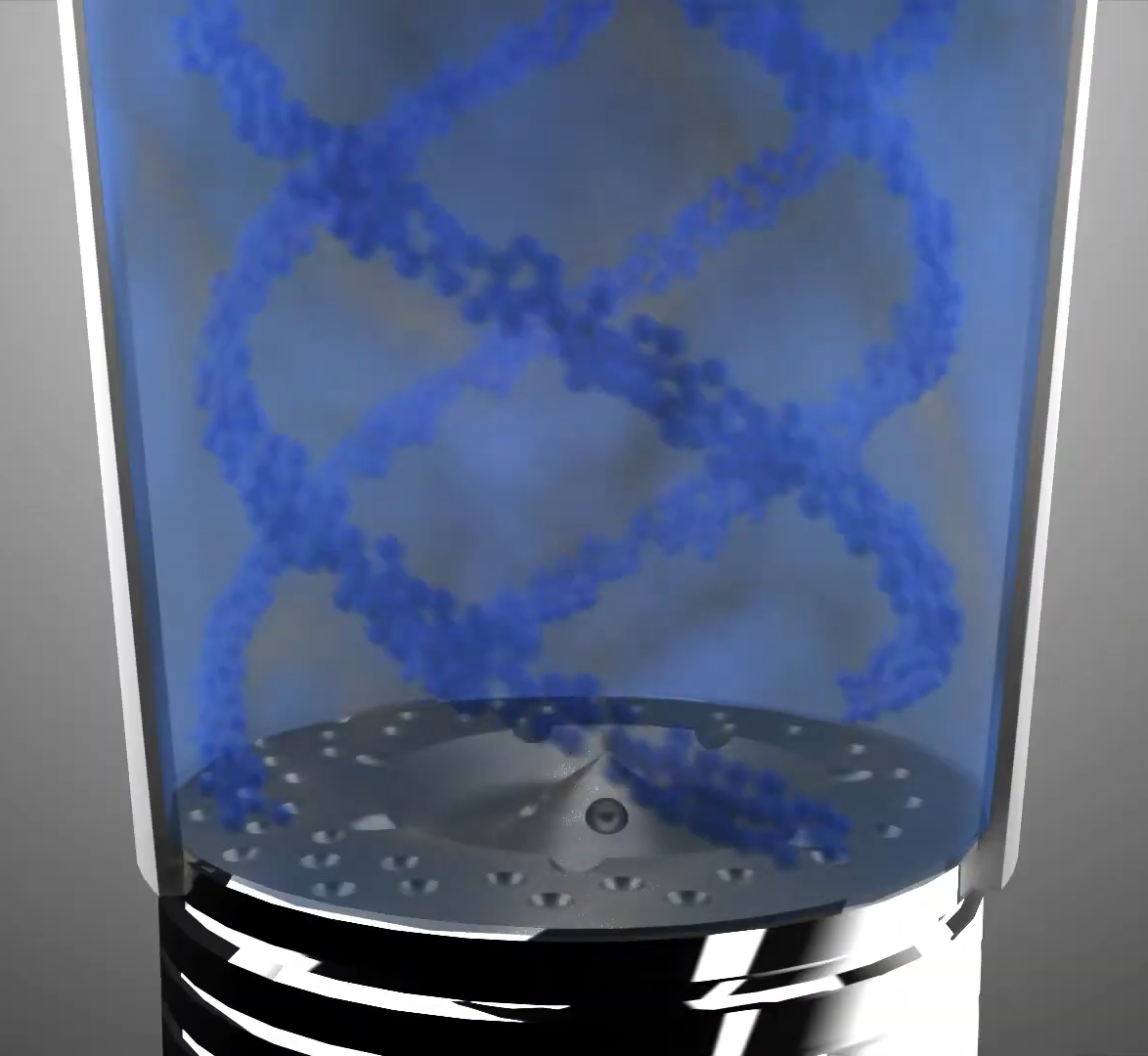

Of course, a golf ball is not a piston. Nevertheless, the idea behind Speed of Air’s invention is that dimples could be used in a similar way—controlling the boundary layer of air on the piston as it moves through the combustion process. Hence the dimples being referred to as “turbulators.” They’re there to generate turbulence and control how the air inside the cylinder interacts with the top of the piston itself. It’s not about cutting drag or anything like that, just about changing how the air moves inside the cylinder itself. The company says it combines the dimpling with special proprietary thermal coatings on the pistons to further improve performance.

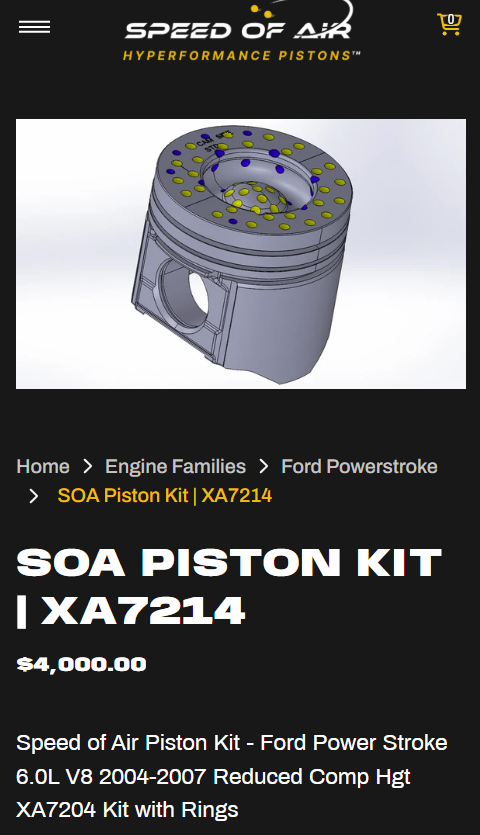

The company primarily offers pistons for common diesel engines. The product range includes piston and ring kits for Cummins, Ford Power Stroke, and GM’s Duramax engines, as well as the Mercedes-Benz OM642. Speed of Air also offers a limited range of pistons for small-block Chevrolet gas engines.

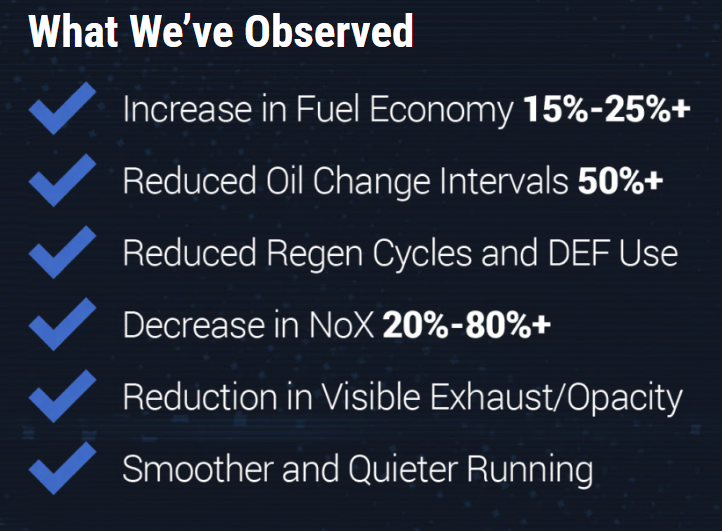

Ultimately, these dimpled pistons are supposed to lead to performance gains in diesel applications, which are the company’s prime focus. “On average, our customers experience fuel savings greater than 20%,” reads an FAQ on the company’s website. The company also says improved combustion leads to maintenance benefits. “Speed of Air Hyperformance Pistons allow for a more complete combustion process, which in turn reduces soot deposits in your engine lubricating oil,” reads the website. “For a well-maintained engine, we recommend extending your oil change intervals by 50% after your break-in period.” The company also references testing by a company called DFC Diesel which allegedly found “5% increases in torque and horsepower” and nitrogen oxide emissions reduced by up to 80%. Other claimed benefits include reduced exhaust opacity from lower soot, and quieter engine running.

The question is—how does creating turbulence on top of a piston help in an engine? Speed of Air explains in somewhat vague terms on its website:

Speed of Air’s patented technology influences the thermo-physical boundary layers within the combustion chamber of the engine. As is the case for the golf ball, dimpling the surfaces inside the combustion chamber, coupled with our proprietary mix of coatings, creates a thinner and well attached turbulent boundary layer between the air-fuel mixture, its flame front and the combustion chamber walls. This thin, turbulent layer allows the combustion flame front to progress much closer to the cool metal walls of the combustion chamber thereby increasing overall combustion efficiency.

It’s a little hard to parse. The explanation appears to be that the dimples on the pistons are supposed to allow the flame front inside the combustion chamber to reach much closer to the piston and chamber walls, which apparently increases efficiency by some mechanism.

That explanation seemed vague, so I went looking for further resources. I found a video the company posted to YouTube in 2021 which explains its technology. “Speed of Air technology works by affecting the fluid boundary layer within the combustion chamber,” states the narrator. “Much like a golf ball, the thin boundary layer inside the combustion chamber remains attached to the surface longer, resulting in better homogenization of the air fuel charge and greater stability and duration of the flame front.”

The basic idea seems to be that a more stable attached boundary layer on the piston helps create a more homogenous mix of fuel and air in the cylinder, leading to more complete combustion—thus boosting efficiency, power, and torque, while cutting carbon buildup in the engine.

It’s a little strange to have two such different explanations for how the technology works, but nevertheless, these are the materials that Speed of Air has made available. The latter explanation perhaps feels like it has a stronger basis in some sort of physical reality. Engineers are always tweaking engine designs to finesse how air and fuel mix and burn inside the cylinder, with an eye to ensuring the fuel burns as cleanly and completely as possible. The video from Speed of Air doesn’t appear to explain how dimples and a turbulent boundary layer precisely achieve this better than traditional techniques, but there’s a basic logic behind what’s being said.

[Ed Note: Indeed, optimizing fuel-burn is an extremely complex process. Back when I was an engineering intern at Cummins, I learned about just how precisely the company designs the tops of its pistons to optimize combustion. Based on all the simulation and testing Cummins has done over the years, I strongly doubt they’d have missed a simple dimpling solution, and the fact that this tech isn’t in production should give everyone pause. – DT].

Without running a full computational fluid analysis on the Speed of Air piston design, it’s not easy to determine the exact fluid mechanics at play inside the engine. The explanations are also simplistic and vague enough that it’s hard to really get a good sense of whether the concept has value. However, there are other areas we can look at to better understand what’s going on with this technology.

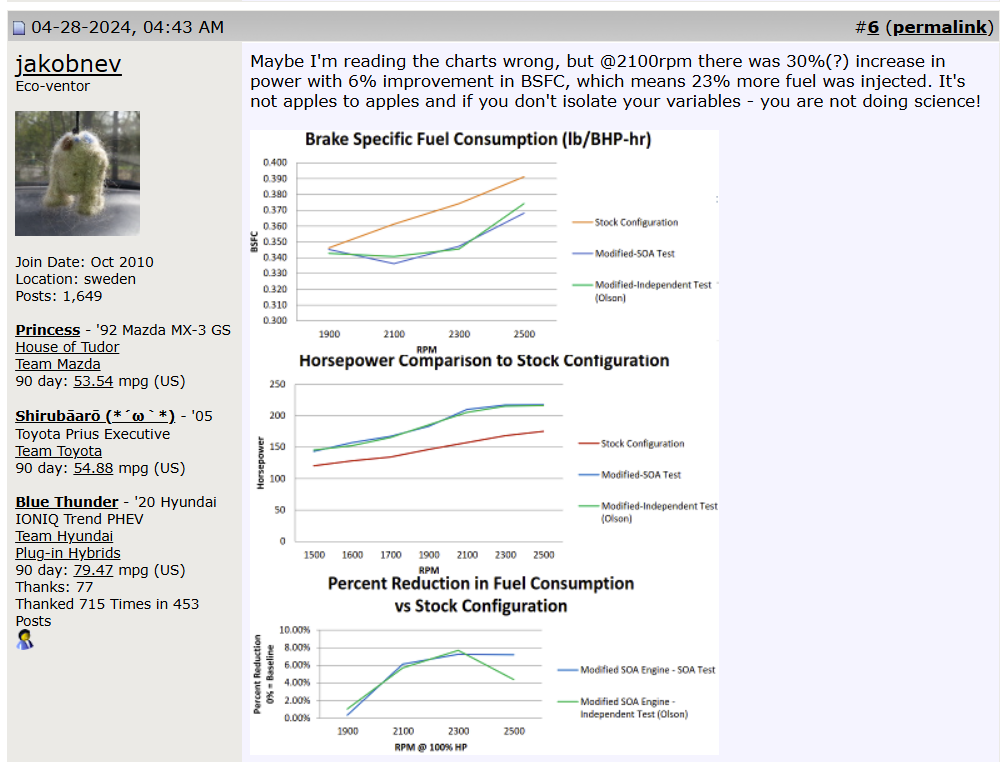

There are some doubts around the technology from commentators online.

Supporting Documents

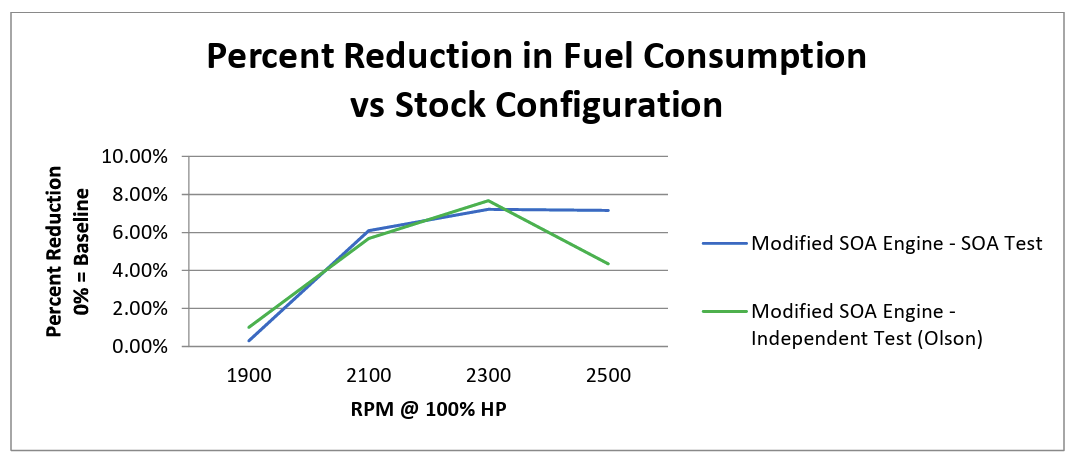

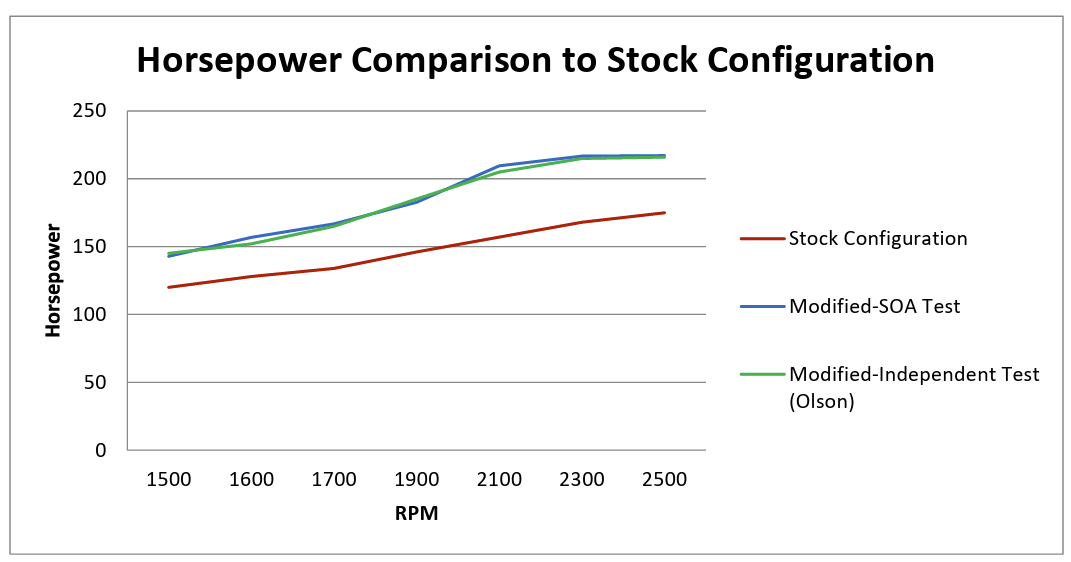

As you’d expect, Speed of Air provides a range of testing documents to back up its claims. Prime amongst them is a report on an unspecified 5.9-liter Cummins diesel engine, tested in both stock form and again with Speed of Air pistons. The report contains some graphs with what appear to be astounding results, indicating the engine gained somewhere in the realm of 30-40 horsepower by switching to Speed of Air pistons, quite a wild figure indeed. Other graphs indicate fuel use dropped by almost 8% under certain conditions, while hydrocarbon and nitrogen oxide emissions were both reduced as well. Speed of Air’s website indicates this was an independent test with the report prepared by Olson-Ecologic Engine Testing Laboratories.

Another test was apparently undertaken by the SEMA Emissions Compliance Center. The testing concerned a 2015 Chevrolet Silverado 2500HD fitted with a Duramax 6.6-liter LML turbodiesel engine. Graphs state the Speed of Air pistons achieved a 60.5% reduction in output of nitrogen oxides, a 93.5% reduction in visible black smoke, and passed a battery of emissions tests without incident. It’s also worth noting that Speed of Air has received a SEMA award for Best New Performance Street Product in 2023 for its piston designs.

Speed of Air also has a list of individual anecdotal data provided by various customers. These consist of dyno sheets from various trucks built from 2001 to 2014, which have been equipped with Speed of Air pistons. Some show minor gains to torque, others show gains of hundreds of horsepower—but it’s not clear if these comparisons are being made after solely changing the pistons in a given vehicle. They also contain customer anecdotes that report positive experiences with the product. For example, a report from Matt, the owner of a 2010 Ford F550:

This is my 2010 Ford F550 that I put a DFC Diesel engine with Speed of Air Hyperformance pistons. The previous engine had upgraded turbos, camshaft, ported heads, AFE intercooler and a Spartan tune on the 210HP Tow Performance setting. The truck has a 3 inch lift and is on 37 inch tires and with camper weighs nearly 19,000lbs and the trailer with my SXS is another 5,000lbs. Prior to the engine the truck was averaging about 40 lph (5.8 mpg) and after the engine has been averaging 34 lph (6.9 mpg) a 16% increase. The engine is noticeably quieter and I have seen a drop of peak EGT’s of around 150-200 degrees. There is less turbo lag and I get up to speed quicker at 1/3 throttle than I did at ½ throttle before and is easier to maintain speed on hills using less throttle input as well. I have put on nearly 10,000kms (6,000 miles) since installing the engine and based on my results am expecting to save over $12,000 within 100,000kms (60,000 miles). Just how well the truck works now alone was worth the investment the fuel savings are just an even greater added bonus I would definitely recommend to anyone needing an engine replacement.

Overall, there’s a collection of figures to peruse that seem to support Speed of Air’s claims. However, it’s always important to take things with a grain of salt when you’re reading them on the same website that’s trying to sell you a product. Unfortunately, my research didn’t turn up a whole lot of tests out there from third parties that aren’t directly involved in selling the product itself. Thus, it’s hard to get a balanced idea of just how good or bad these pistons might really be. It would be a different case entirely if we were seeing various automotive magazines or other outlets testing them in the absence of sponsorship and the like, but it doesn’t appear there’s a lot out there yet.

First impressions on the SOA pistons for the M57.

byu/Xallyeah inE90

One Reddit poster claims to have obtained prototype Speed of Air pistons for the M57 BMW engine, with positive results in terms of low-end torque output and reduced exhaust gas temperatures.

It’s perhaps no surprise that there aren’t more tests being done out in the wild, given the cost involved. A set of Speed of Air pistons for a V8 diesel like a 6.0-liter Ford Power Stroke can cost in excess of $4,000—more than double what you might pay for a traditional set from another manufacturer.

Market Realities: Why Isn’t Everyone Doing This?

It’s difficult to say whether dimpled pistons work or not solely based on the resources available online. Speed of Air presents some graphs with great numbers, but it’s always hard to trust an “independent” report published on the company’s own website. The company’s explanations of its own technology are also limited enough that it’s hard to glean what the real mechanism of improvement is, or what the benefits might be.

However, we can speculate based on what we see in the broader automotive world. The simple fact is that Speed of Air claims huge fuel economy gains—on the order of 20%—from its piston technology. Given that it largely involves drilling a few small divots into a piston, it’s perhaps shocking that no other OEM has explored this area before. Indeed, we’ve seen other manufacturers such as Volvo boast about gains from their own advanced “wave” piston designs, which involved far more complicated geometry for fuel economy gains of just 2%. If they could achieve more gains just with a few vertical hits on the piston milling machine, you’d think they’d do it.

If it only took drilling a few dimples to improve fuel economy by 20%, you’d think everybody would be doing it. Automakers spend huge sums on computational modeling and real-world testing to optimize their engine and combustion chamber designs. It’s hard to imagine that in over a century of development, something as simple as a few dimples didn’t occur to anyone, given the apparent outsized gains on offer.

Dimples on pistons sound great—if they’re good on golf balls, they must be good for engines, too, right? However, you don’t have to go far to find skeptical comments online, on hypermiler forums, diesel forums, and beyond — many asking why dimples aren’t prevalent in the auto industry. It’s one of those cases where extraordinary claims require extraordinary evidence, and it doesn’t necessarily feel to some that Speed of Air has it. After all, one might expect every second engine builder out there to be raving about piston dimples if the 20% fuel economy benefits alone were there to be had. “Independent” studies published online by the manufacturer itself generally aren’t enough to convince the broader masses.

As for why OEMs haven’t jumped on the dimpled pistons, there are some theories. “It could come down to a cost versus benefit question that the aftermarket doesn’t typically need to answer,” stated Motor Trend in an article on Speed of Air in 2023. ” The extra time cost of machining a piston with these features potentially outweighs the benefits of how a piston performs without them.” However, these statements seem to ring a little hollow when stacked up against the stated 20% benefits to fuel economy and additional emissions benefits that Speed of Air claims. OEM pistons already undergo delicate machining in the production process; it’s hard to imagine that a few dimples would cost so much as to negate such huge savings in fuel economy.

An Expert Take

As part of our due diligence, we asked an independent engine expert for their comment on the Speed of Air technology. They hadn’t seen the product prior to our email, but instantly spotted some areas of concern. Speaking on condition of anonymity (because they prefer not to have their name associated with something negative), they stated responded to the Motor Trend article with the following:

I hadn’t heard of this one before, but it is contrary to design practices I have used my entire career. Surface area-to-volume ratio in a combustion chamber has a profound effect on efficiency and emissions through heat transfer and wall wetting mechanisms. And yes, lowering surface area is the preferred direction, contrary to the impact of adding dimples. The radiator in your car is a perfect example of increasing surface area (via fins) to increase heat transfer. In an internal combustion engine you do NOT want to transfer heat away from the combustion chamber. Indeed, thermal efficiency is highest when combustion is adiabatic (no heat loss).

The primary source of unburned hydrocarbons is surface quenching in crevices. Minimizing combustion chamber surface area where quenching can and will occur is the preferred direction. I am quite surprised by their claim that carbon deposits will decrease. Again, I would expect carbon to deposit readily in the cavities created by dimpling. I also don’t like the sharp edges produced in the combustion chamber [in some Speed of Air designs]. These edges are going to get very hot and likely produce undesirable combustion effects during prolonged high-load operation.

Finally, it is difficult for combustion chamber surface details to have a significant impact on global performance parameters like power. The claim of 15+% increases in torque and power are ludicrous. I am instantly turned off when I see ridiculous claims like that. The argument that OEMs don’t do it because of cost is equally absurd. I did engine development in an OEM for 13 years, and anything that would produce the power and emissions benefits quoted would be adopted immediately. The cost of dimpling surfaces pales in comparison to the cost of precious metals for emissions compliance.

Bottom line, I’m not at all interested in adding dimples to the pistons in my Chevy truck!

[Ed Note: I sent this expert’s thoughts to Speed of Air for comment. I haven’t yet heard back. -DT].

Ultimately, if Speed of Air’s technology really is as good as it claims, it will come to dominate the market in the next few years. Diesel engine manufacturers would be lining up around the block to license the company’s patents if 20% fuel economy gains are on the table, to say nothing of the claimed benefits to emissions and everything else. Double-digit gains cost tens or hundreds of millions of dollars in research and development. Speed of Air could make huge sums overnight just by selling access to the technology without ever having to manufacture another piston again. The fact that you can open up just about any OEM diesel engine and not find dimpled pistons suggests they’re maybe not quite as magic as the claims suggest.

I can’t say for certain whether Speed of Air’s pistons have huge benefits or not; I can only present the evidence available as it stands. In any case, when it comes to new automotive technology, it pays to cast a careful eye over what you see. Examine the claims, explore the science behind it, and rationally assess what everyone else is doing. That’s how you spot the technologies that work from those that don’t.

Image credits: Speed of Air, Volvo, Titleist, Cummins

Forget the power or efficiency claims – the NOx emissions reductions claims alone would have every diesel OEM buying these pistons by the millions. The SCRs and EGRs are such a huge problem on diesels that this magic bullet would be a God-send.

Also, “93.5% Visible Smoke Reduction” …what? That year truck should be equipped with a DPF, so there should be 0 visible smoke to begin with, and how can you quantify a “visible smoke reduction” with such a precise number?

Both you and I know that those trucks with built engines have neither SCR nor DPF… Talking points about externalities are even more horseshit because the target clientèle for these gives no fuck about the smoke output

isn’t the gas motion on top of the cylinder already pretty turbulent??

back of the envelope calculation for reynolds number:

Re=(gas velocity times characteristic length divided by kinimatic viscosity).

at 1000rpm, a 100mm stroke equivalent to about 1.7m/s gas velocity.

use a square bore/stroke characteristic length L of 0.1m

and swag kinimatic viscosity of 5E-5m2/sec

then

Re=[(1.7m/s)(0.1m)/(0.00005m2/s)

Re=3400 …>2300, thus turbulent…

oops, misread kinematic viscosity graph…5E-6m2/s not 5E-5…mea culpa

Re=34,000. >>2300…

The SoA dimpled pistons with their claims of improvements in power and fuel mileage would fit well in a 1960’s JC Whitney catalog.

Meh. This works better.

https://www.youtube.com/watch?v=jTSEB-ihmfs

“turbulators” – No doubt heavily inspired by the incredible tech of the “Turbo Encabulator”.

I don’t even think this supply’s inverse reactive current…

If there was 25% gains to be had gm or Ford would grab it like they grabbed 1k ft-lbs diesels. That seems a mpg improvement a few hundred in installed costs they could pass on.

Yeahbut remember when they conspired to destroy the guy that invented a carburetor that runs on water or something? They’re probably dropping chemtrails over this company’s headquarters right now.

Not a chance they are really seeing the gains they claim; you just are not going to get that kind of power increase out of that.

I would be interested in seeing what the static compression ratio of those vs. the stock pistons and the fuel map between the two is as well as if any changes were made to cam or injection timing.

I know the Autopian wants to do their due diligence, but this seems like obvious snake oil to me. I’m no combustion engineering expert, but anyone promising a 20% efficiency gain that hasn’t already been found by OEMs is absurd. Glad to see the expert chiming in saying as much.

It’s such a prevalent product that we had to talk about it.

The sharp edges and lack of depth in the dimples on the outer circumference seem to be the weakest part of the design if I’m reading and understanding everything correctly. Which makes me wonder why the pistons are machined instead of forged to shape to get rid of that.

Also, this is something it’d be interesting to test. Get an old Powerstroke F-250 that can’t pass inspection because of rust (or just a spare engine from a junkyard), replace the engine internals with stock replacements, measure, then replace the engine internals with Speed Of Air replacements. Get dyno, steady throttle fuel, and exhaust emissions readings out of it.

And that test should be blind to the people conducting it. They don’t know anything about the engines and their internals, just doing the tests exactly the same way.

“Does this work?”

I don’t know. My unnamed source doesn’t think so.

Did they patent this design? Could make more licensing the patent then selling a few sets of pistons. If it worked of course.

Bet the VW executive that went to jail last month for Dieselgate is kicking himself for not using the dimples instead of software trickery – after all it lowers NOx 80%!

These unsubstantiated claims tee me off.

It’s enough to make a guy yell “FORE”!!!

So this SEMA award is garbage.

Virtually any industry award is garbage.

At SEMA the award is based on which product is the biggest fraud.

The one thing I haven’t seen mentioned yet that seems glaringly obvious to me is that every single case study mentioned is on an engine of (likely intentionally) unspecified age, but very clearly of some level of use and wear, meaning these pistons installed are a part of a fairly hefty rebuild of an engine. Fresh pistons and rings, some seals and gaskets at a minimum, all of this will drastically reduce blow-by, which will improve emissions, power, fuel economy, etc.

What I would love to see (but we never will see) is a side by side of a brand new engine with OEM equipment, and another with these snake oil pistons. And equal-wear situation back to back, and in larger numbers than singular cherry picked examples. Remember everyone, there may be a handful of testimonials and lab tests, but this company does not have to publish negative results, and every single result is 1: effectively an engine rebuild, and 2: a single data point for one engine configuration, and pretty much any and all data sets with a sample size of 1 are considered to be overwhelmingly statistically INsignificant.

I’d like to see some diesel engines be rebuilt with all OEM equipment and tested, I’d expect similar or better results to these dimpled pistons.

Yup, this is what I was thinking. No comparisons to a brand new car with the pistons swapped out.

Yes I’m sure if I didn’t put 3/8ths of my 7.3 piston rings in upside down I could net a 20% fuel economy boost too.

I’d rather have a 7.3 not like the ones here that do 0-speed limit that doesn’t need a calendar

wat

I had exactly the same thought. It is like when I used to work in manufacturing and would have vendors come by trying to sell their newfangled machinery on promises of 30% more thermally efficient or 25% less power usage. I would always ask for proof, and then ask for details on the case studies they used for their claims. 100% of the time it was on 30 year old, worn-out equipment, and new for new it was 1-2% gains offset by the fact that it would often take 500+ years to offset the install costs of replacing existing newish equipment with the vendor’s new equipment. However, if you didn’t think critically, the case studies could be very persuasive.

Two brand new stationary generators. Drop the pistons in one, otherwise unmodified.

Run them for a set amount of hours at full load (say, 1000 hours), measuring emissions and fuel consumption.

Drop the oil an analyze, then pull the engines apart and check for wear/carbon buildup.

There’s other ways to test, but commercial stationary equipment is pretty easy to replicate conditions close enough to each other.

You’ve basically just described a Project Farm test. 🙂

You know, if he could get a hold of a set, it would make for a killer video. Expensive as hell though, considering he buys everything sponsor-free.

Do you get a free Fuel Shark with purchase?

Fuel Shark alone should give similar results and be cheaper.

Put the two together and you’ll make more fuel than you burn!

I think the Fuel Shark would give better results- absolutely nothing. Whereas these things seem to dramatically increase your chances of serious combutsion chamber failure thanks to all the sharp edge corners and pockets for carbon buildup.

“Hi, Speed of Air? Anyone there? Oh, well, I just wanted to ask if the emission reductions claimed for your dimpled pistons are achieved all of the time or just when hooked up to emissions testing equipment? Can somebody please get back to me on this? You can reach me at this number. Ask for Oliver, thanks.”

Do they make pistons for TDIs?

“Hi Oliver, After reviewing our own tests, we have determined that our methods and equipment were valid and the results are reliable. Unfortunately we cannot disclose any further details than that, as it is our proprietary, trade secret technology. Hopefully this addresses any concerns you had and we can look forward to an order from you soon! Thanks!”

I look forward to the class action lawsuit.

The minute I saw that piston I thought, “those dimples are just going to fill up with carbon and stop being dimples.” If you already have good tumble of the fuel/air charge, I could see how reducing boundary layer adhesion would get you a teensy bit more charge in play for combustion, but not that much.

But there’s simpler math: 20% fuel economy gain from more complete combustion means there was 17% unburned hydrocarbons before, which is a few orders of magnitude higher than typical.

Supplier: I have good news and bad news. The good news is, we machined all 20,000 pistons you sent us. The bad news is that some ball bearings got loose in the equipment and now all your pistons have a bunch of dimples in them.

Speed or Air: Crap. We’re screwed.

Speed of Air Marketing Department: Hold my beer.

The hubris to think a manufacturer wouldn’t immediately jump on gains like that by just adding some dimples. It doesn’t help when you have “experts” like Dave who spend all their time hyping the supposed incompetency of the industry.

I’ve lost count of how often he has railed against emissions while simultaneously ignoring key fundamentals of what is being done and why. My personal favorite being the claim that the government mandates SCR (DEF) when in reality the government mandates limits and SCR is just the method everyone settled on to meet NOx requirements.

Said improvements are only achieved when dimpled pistons are used in conjunction with a Fuel Shark.

Dimpled pistons, fuel shark, and one of those weird metal tablets to drop in the tank and you may never need fuel again.

You’ll be pumping the excess fuel generated back into the gas station’s own tanks and charging them for the deposit! Buy your meter here!

And if your car makes too much fuel while on a road trip, I have this revolutionary new product so you can store it for later. It’s called the Fuel Saver MAX+ Titanium SmartIQ with the TurboSwirl PRO leakproof nozzle. The ads will have black and white clips of comically inept people standing around watching their car vomit gas into a ditch because they just have TOO MUCH and don’t know what to do with it all? Probably have a forest fire with a big red X over it. I know, we’ve all been there, accidentally set something on fire with all the excess gas our car made. But no more! Now using this revolutionary device called a “gas can”, you can siphon out the excess gas until you can sell it to your less-enlightened neighbors, or back to the guy at the gas station! But this isn’t your grandfather’s jerry can that lasted decades and didn’t leak and easily poured without a mess, no siree bob! This is the Fuel Saver MAX+. It’s got wifi. It’s got an app. You can check how much gas you have anywhere, anytime. You can track how much gas you made and share it with your friends! It has a built in, non replaceable battery to automatically siphon extra gas our of your car. It has a leakproof* nozzle so you’ll never spill a drop. Order now, only 5 easy payments of $59.95. But wait! There’s more! Order in the next 15 minutes and I’ll throw in the Fuel Saver MINI absolutely free (just pay $59.95 s&h). This little 1 gallon guy is perfect for your fuel shark equipped motorcycle, lawnmower, or other small power equipment. But Act Fast! Quantities are limited! Strict Limit of two per customer! This offer will NEVER be repeated! Tariffs WILL raise prices!

TAKE MY MONEY!!!!

Don’t forget the magnet around your fuel line to align the fuel to burn better!

Don’t forget the magnet on the fuel line

I’m not sure exactly what performance gains they’re promising, but in fluid dynamics, dimples, or a rougher non-uniform surface, will play a crucial role in breaking up the static boundary layer and creating more flow. If turbulence and moving air or fluid around is what you want then have it.

I remember some magazine in the 89s porting and polishing a head and intake manifold to a mirror finish, and discovering that it not only had a lower airflow but the fuel separated out and stuck to the newly polished surfaces.

At the time common wisdom was that smoother = faster.

In the other hand I knew a woman would respond to “you want to go home” with “what’s wrong with right here?” and she had dimples. I don’t know if that’s relevant. I was living in a 13 foot trailer in the parking lot of an art school so there’s that too.

I just wonder what the air flow in a cylinder looks like in the first place. Nothing like the smooth, relatively slow flow of air over a golf ball, I assume. I’m picturing near sonic gas flow and more of a vertical bounce off the surface of the piston.

Oh look, and insanely expensive Turbonator! I’ll take 2!

It’s about time this made it to the general public… We’ve been promised the turbo-encabulator for over half a century.

(brief explainer of how it works: https://youtu.be/bfhzo9OMfIg?si=jEQ4E69la96xxClB)

Almost all aftermarket modifications are junk being sold to people who don’t know better. Basically, this. It is an easy way to sell something inexpensive to make a lot of money. Almost none of the buyers will ever have any concrete way of knowing the impact of the modifications, and because they don’t want to believe they got taken, they will repeat the made-up initial claims to justify their purchase.

I suspect the venn diagram of people who buy this overlaps a ton with the folks who “do their own research” on topics that have already been settled for years.

Hey, just because the flat earth model makes absolutely no sense and cannot explain basic phenomena doesn’t mean that jackwagon8507 doesn’t make some good points about it, diesel engine upgrades, and the medical benefits of ingesting things that have been considered harmful for decades!

Hey, jackwagon8507 spent a solid 15 minutes watching youtube videos on the shitter, which makes his opinions every bit as valid, informed, and worthy of consideration as any so-called “expert”.

“Wake up sheeple”

[Looks at patent]

“Inventor name: A. Rodgers.”

…

There’s a patent? I figured there’d only be a Trademark involved.

The patent is “pending.”

That’s not surprising, nor concerning (in itself). Patent applications typically take years.

Sure, but saying that would spoil the joke.