When it comes to engines, everyone is always looking for more. More horsepower, more torque, more efficiency. One company has a rather interesting take on how to allegedly get a lot more performance all around, just by giving your diesel engine dimples.

That company is called Speed of Air. Based out of Reno, Nevada, it specializes in designing pistons that might remind you of golf balls. That’s because they’re covered in lots of little divots—which the company refers to as “turbulators” for their effect on the air inside the engine. With their eye-catching design and purported performance benefits, they’ve been making some waves online of late. You might have heard of them on YouTube, where they’re routinely advertised by big diesel channel Dave’s Auto Center.

The physics of why dimples make golf balls fly better is well understood. But does applying the same technique to pistons have any real effect on performance or emissions? Could they really provide huge boosts to horsepower and slash fuel use by huge percentages? Let’s talk about it.

Dimples

The crux of the whole dimples phenomenon comes down to fluid mechanics. Weird structures and shapes can do all sorts of things to the flow of a fluid and create positive or negative effects for a given application. Sometimes, it’s intuitive—it’s pretty obvious why a smooth, streamlined bullet train can go faster than a slab-sided locomotive, for example. And at other times, it’s not intuitive. For example, take the common golf ball and the characteristic dimples that improve its performance. Why do they matter?

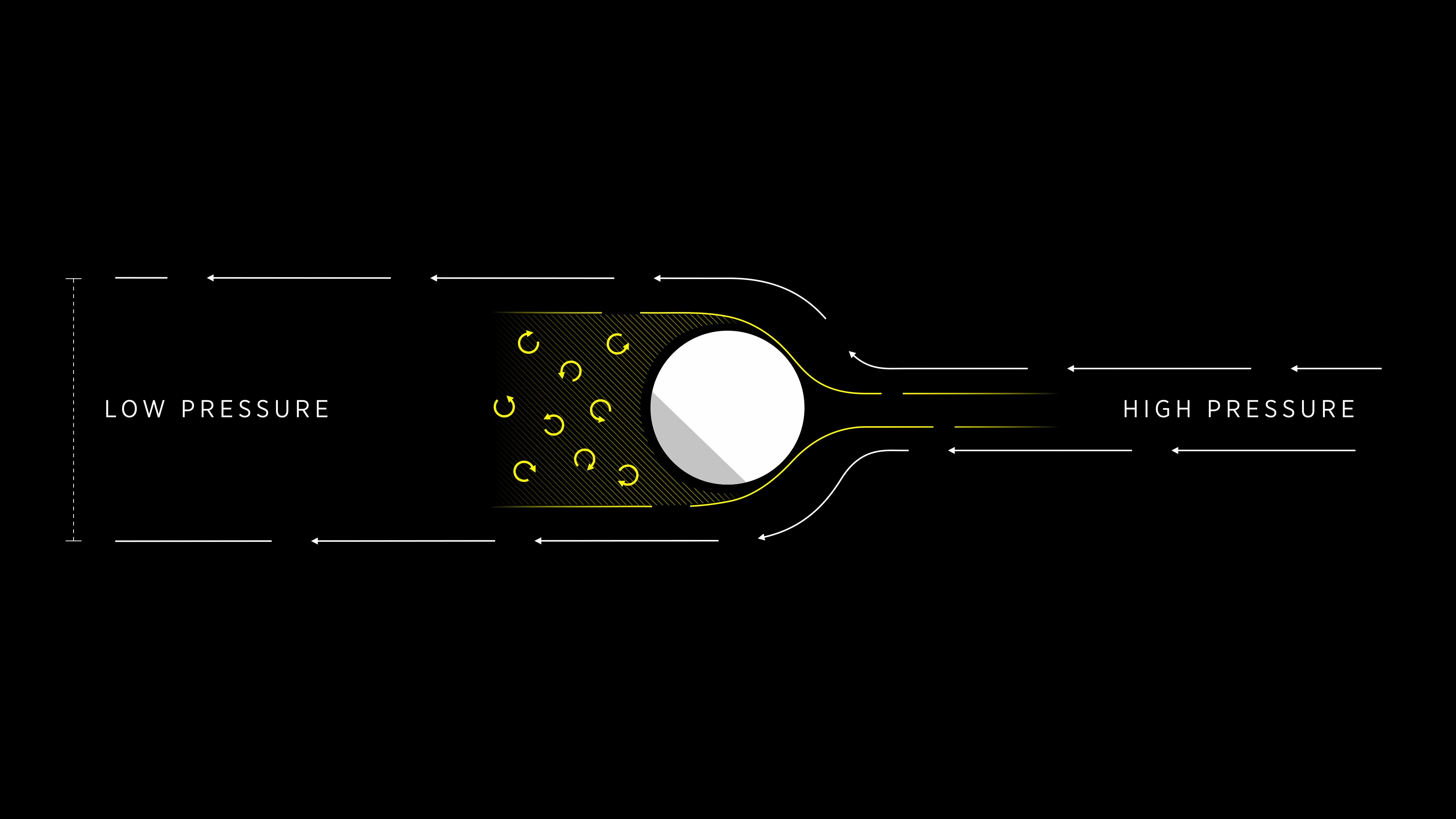

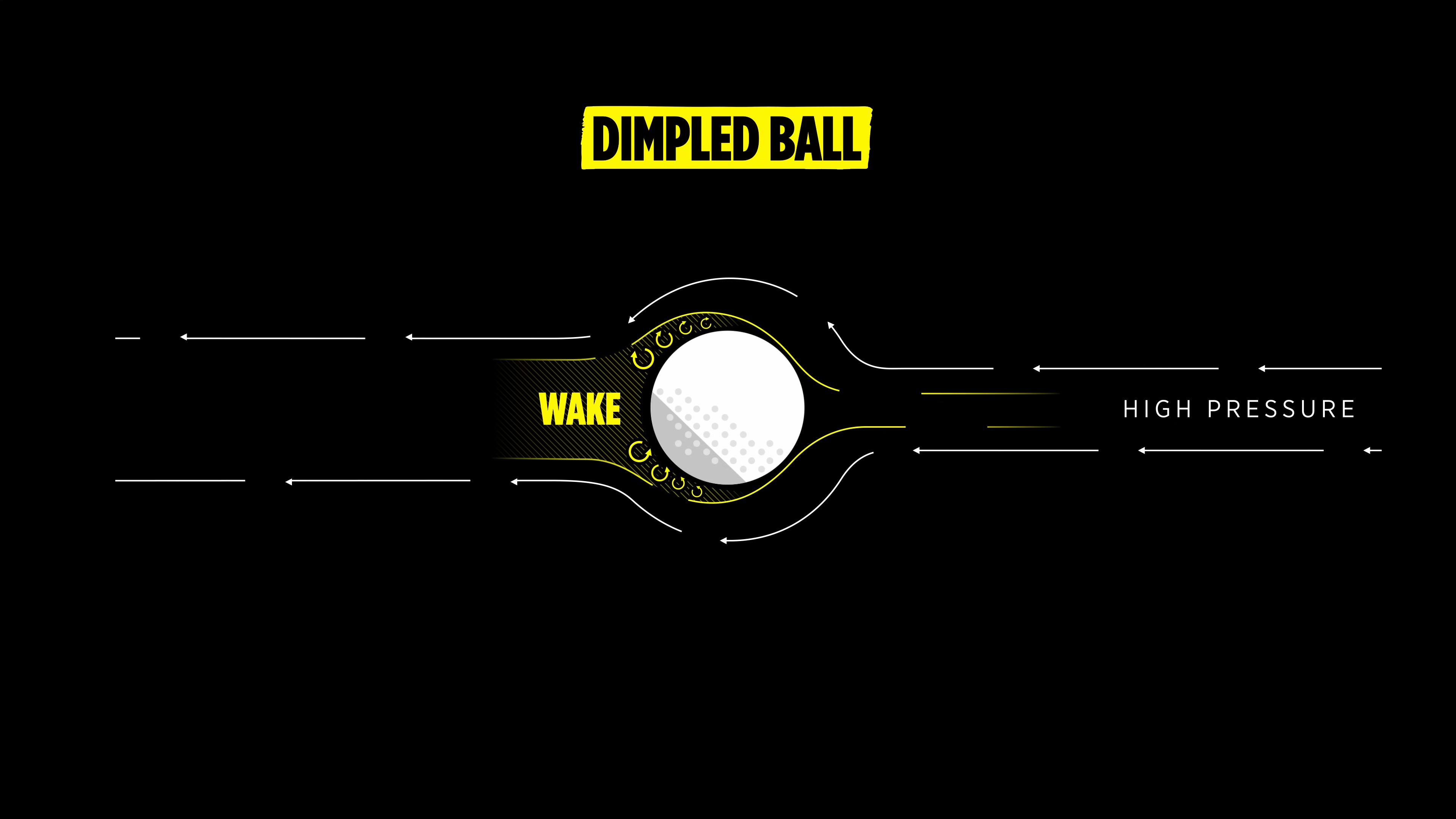

We can understand how the dimples affect the ball by examining what happens as it flies through the air. If the golf ball were a regular sphere, the small boundary layer of air flowing around the ball would remain smooth as it passed over the ball and experiences laminar flow. The laminar boundary layer separates from the golf ball quite easily as the ball flies through the air, leaving a large low-pressure area behind the ball—a wake—which creates a lot of drag, slowing it down. However, if the ball is dimpled, the immediate boundary layer around the ball becomes turbulent. This turbulent boundary layer sticks to the ball a lot better, helping guide the airflow around the ball and creating a much smaller low-pressure region behind it. The smaller wake comes with much less drag, and the ball can fly farther.

Golf brand Titleist has a great explanation of how dimples make its golf balls fly farther.

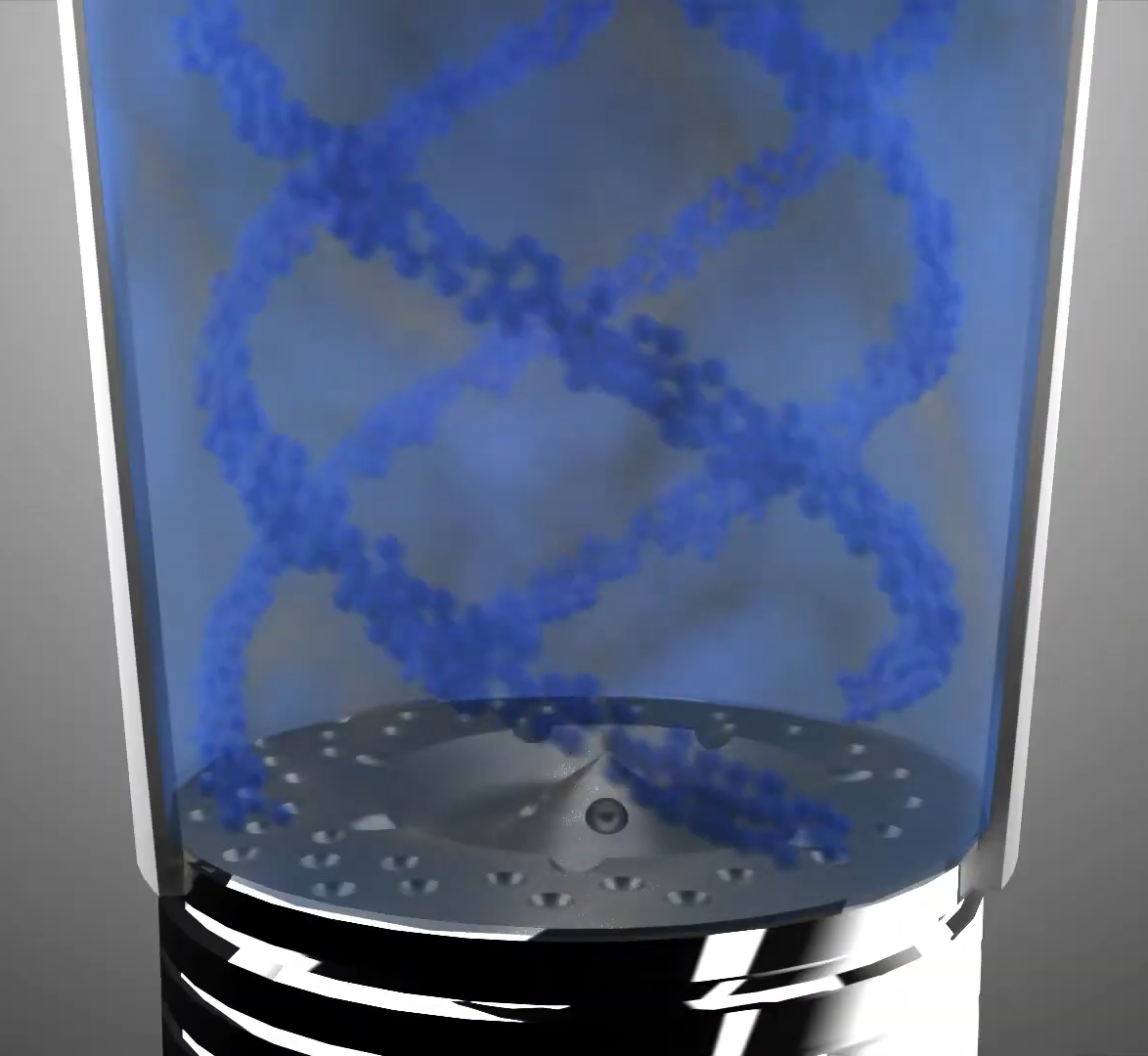

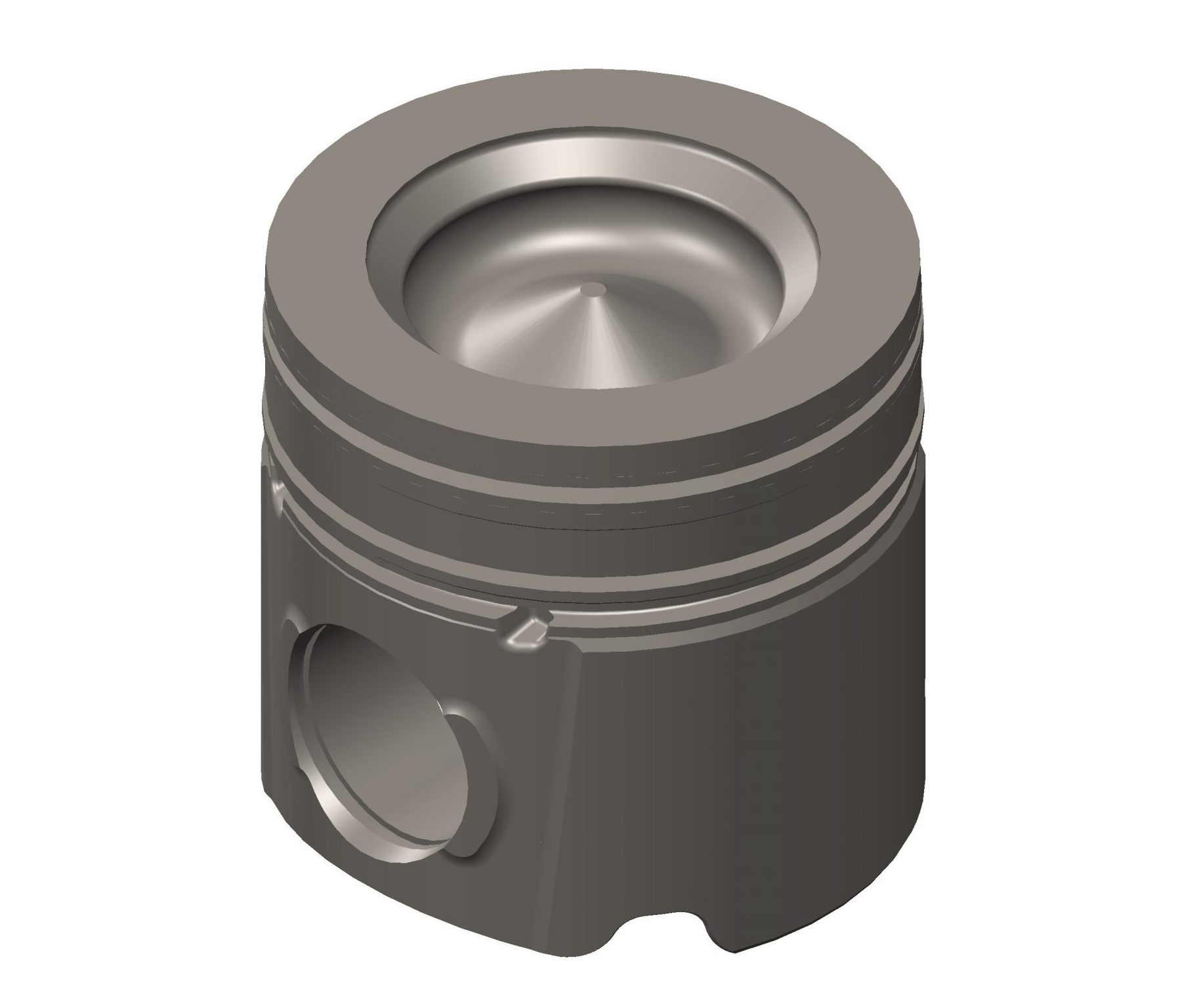

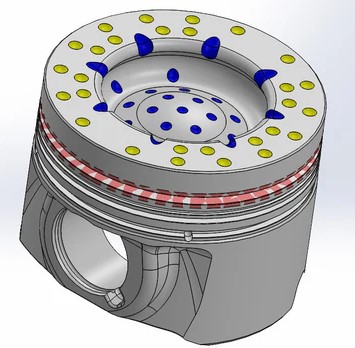

Of course, a golf ball is not a piston. Nevertheless, the idea behind Speed of Air’s invention is that dimples could be used in a similar way—controlling the boundary layer of air on the piston as it moves through the combustion process. Hence the dimples being referred to as “turbulators.” They’re there to generate turbulence and control how the air inside the cylinder interacts with the top of the piston itself. It’s not about cutting drag or anything like that, just about changing how the air moves inside the cylinder itself. The company says it combines the dimpling with special proprietary thermal coatings on the pistons to further improve performance.

The company primarily offers pistons for common diesel engines. The product range includes piston and ring kits for Cummins, Ford Power Stroke, and GM’s Duramax engines, as well as the Mercedes-Benz OM642. Speed of Air also offers a limited range of pistons for small-block Chevrolet gas engines.

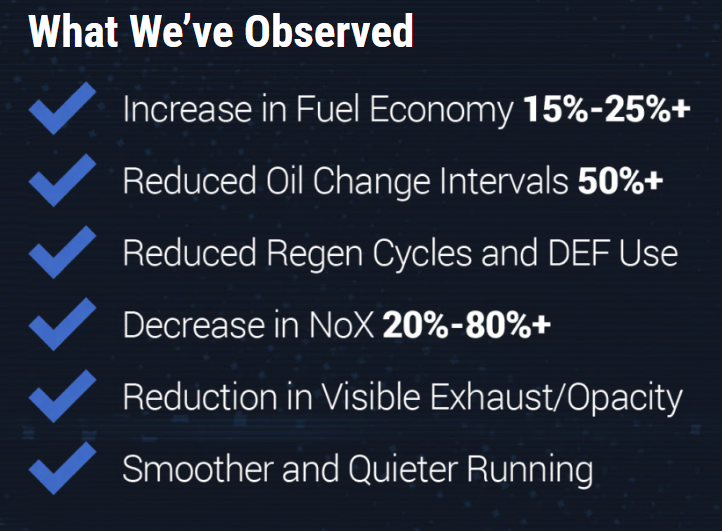

Ultimately, these dimpled pistons are supposed to lead to performance gains in diesel applications, which are the company’s prime focus. “On average, our customers experience fuel savings greater than 20%,” reads an FAQ on the company’s website. The company also says improved combustion leads to maintenance benefits. “Speed of Air Hyperformance Pistons allow for a more complete combustion process, which in turn reduces soot deposits in your engine lubricating oil,” reads the website. “For a well-maintained engine, we recommend extending your oil change intervals by 50% after your break-in period.” The company also references testing by a company called DFC Diesel which allegedly found “5% increases in torque and horsepower” and nitrogen oxide emissions reduced by up to 80%. Other claimed benefits include reduced exhaust opacity from lower soot, and quieter engine running.

The question is—how does creating turbulence on top of a piston help in an engine? Speed of Air explains in somewhat vague terms on its website:

Speed of Air’s patented technology influences the thermo-physical boundary layers within the combustion chamber of the engine. As is the case for the golf ball, dimpling the surfaces inside the combustion chamber, coupled with our proprietary mix of coatings, creates a thinner and well attached turbulent boundary layer between the air-fuel mixture, its flame front and the combustion chamber walls. This thin, turbulent layer allows the combustion flame front to progress much closer to the cool metal walls of the combustion chamber thereby increasing overall combustion efficiency.

It’s a little hard to parse. The explanation appears to be that the dimples on the pistons are supposed to allow the flame front inside the combustion chamber to reach much closer to the piston and chamber walls, which apparently increases efficiency by some mechanism.

That explanation seemed vague, so I went looking for further resources. I found a video the company posted to YouTube in 2021 which explains its technology. “Speed of Air technology works by affecting the fluid boundary layer within the combustion chamber,” states the narrator. “Much like a golf ball, the thin boundary layer inside the combustion chamber remains attached to the surface longer, resulting in better homogenization of the air fuel charge and greater stability and duration of the flame front.”

The basic idea seems to be that a more stable attached boundary layer on the piston helps create a more homogenous mix of fuel and air in the cylinder, leading to more complete combustion—thus boosting efficiency, power, and torque, while cutting carbon buildup in the engine.

It’s a little strange to have two such different explanations for how the technology works, but nevertheless, these are the materials that Speed of Air has made available. The latter explanation perhaps feels like it has a stronger basis in some sort of physical reality. Engineers are always tweaking engine designs to finesse how air and fuel mix and burn inside the cylinder, with an eye to ensuring the fuel burns as cleanly and completely as possible. The video from Speed of Air doesn’t appear to explain how dimples and a turbulent boundary layer precisely achieve this better than traditional techniques, but there’s a basic logic behind what’s being said.

[Ed Note: Indeed, optimizing fuel-burn is an extremely complex process. Back when I was an engineering intern at Cummins, I learned about just how precisely the company designs the tops of its pistons to optimize combustion. Based on all the simulation and testing Cummins has done over the years, I strongly doubt they’d have missed a simple dimpling solution, and the fact that this tech isn’t in production should give everyone pause. – DT].

Without running a full computational fluid analysis on the Speed of Air piston design, it’s not easy to determine the exact fluid mechanics at play inside the engine. The explanations are also simplistic and vague enough that it’s hard to really get a good sense of whether the concept has value. However, there are other areas we can look at to better understand what’s going on with this technology.

There are some doubts around the technology from commentators online.

Supporting Documents

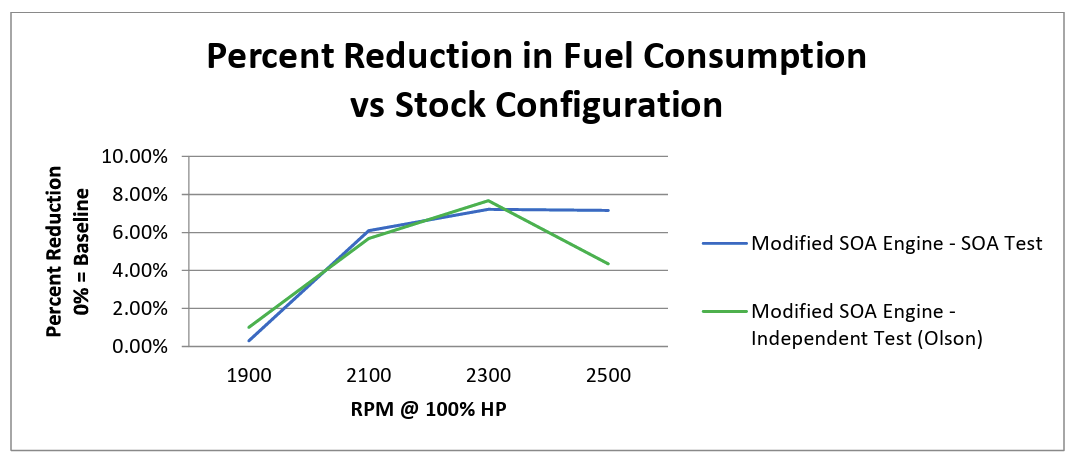

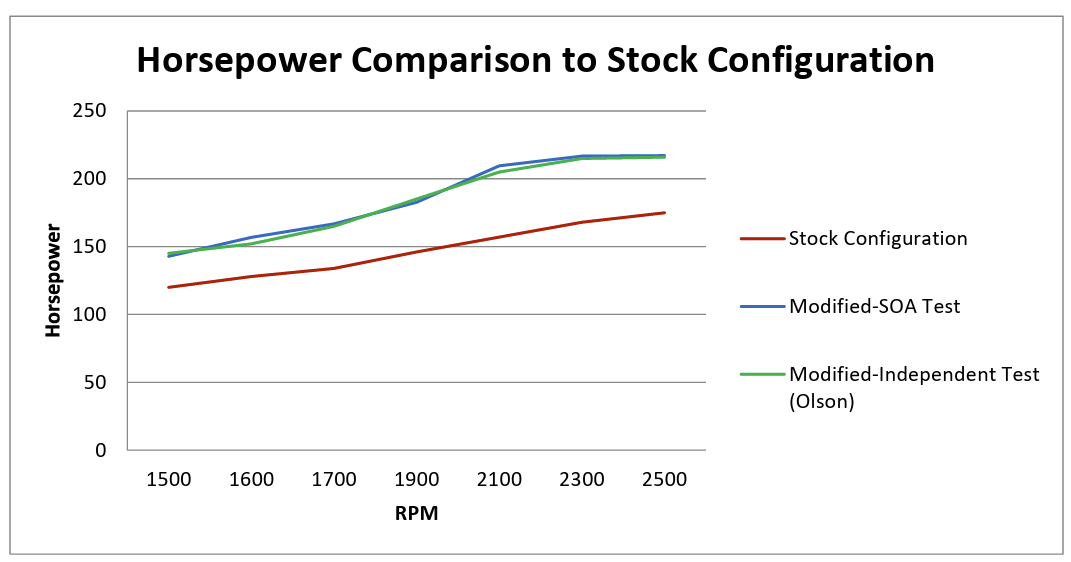

As you’d expect, Speed of Air provides a range of testing documents to back up its claims. Prime amongst them is a report on an unspecified 5.9-liter Cummins diesel engine, tested in both stock form and again with Speed of Air pistons. The report contains some graphs with what appear to be astounding results, indicating the engine gained somewhere in the realm of 30-40 horsepower by switching to Speed of Air pistons, quite a wild figure indeed. Other graphs indicate fuel use dropped by almost 8% under certain conditions, while hydrocarbon and nitrogen oxide emissions were both reduced as well. Speed of Air’s website indicates this was an independent test with the report prepared by Olson-Ecologic Engine Testing Laboratories.

Another test was apparently undertaken by the SEMA Emissions Compliance Center. The testing concerned a 2015 Chevrolet Silverado 2500HD fitted with a Duramax 6.6-liter LML turbodiesel engine. Graphs state the Speed of Air pistons achieved a 60.5% reduction in output of nitrogen oxides, a 93.5% reduction in visible black smoke, and passed a battery of emissions tests without incident. It’s also worth noting that Speed of Air has received a SEMA award for Best New Performance Street Product in 2023 for its piston designs.

Speed of Air also has a list of individual anecdotal data provided by various customers. These consist of dyno sheets from various trucks built from 2001 to 2014, which have been equipped with Speed of Air pistons. Some show minor gains to torque, others show gains of hundreds of horsepower—but it’s not clear if these comparisons are being made after solely changing the pistons in a given vehicle. They also contain customer anecdotes that report positive experiences with the product. For example, a report from Matt, the owner of a 2010 Ford F550:

This is my 2010 Ford F550 that I put a DFC Diesel engine with Speed of Air Hyperformance pistons. The previous engine had upgraded turbos, camshaft, ported heads, AFE intercooler and a Spartan tune on the 210HP Tow Performance setting. The truck has a 3 inch lift and is on 37 inch tires and with camper weighs nearly 19,000lbs and the trailer with my SXS is another 5,000lbs. Prior to the engine the truck was averaging about 40 lph (5.8 mpg) and after the engine has been averaging 34 lph (6.9 mpg) a 16% increase. The engine is noticeably quieter and I have seen a drop of peak EGT’s of around 150-200 degrees. There is less turbo lag and I get up to speed quicker at 1/3 throttle than I did at ½ throttle before and is easier to maintain speed on hills using less throttle input as well. I have put on nearly 10,000kms (6,000 miles) since installing the engine and based on my results am expecting to save over $12,000 within 100,000kms (60,000 miles). Just how well the truck works now alone was worth the investment the fuel savings are just an even greater added bonus I would definitely recommend to anyone needing an engine replacement.

Overall, there’s a collection of figures to peruse that seem to support Speed of Air’s claims. However, it’s always important to take things with a grain of salt when you’re reading them on the same website that’s trying to sell you a product. Unfortunately, my research didn’t turn up a whole lot of tests out there from third parties that aren’t directly involved in selling the product itself. Thus, it’s hard to get a balanced idea of just how good or bad these pistons might really be. It would be a different case entirely if we were seeing various automotive magazines or other outlets testing them in the absence of sponsorship and the like, but it doesn’t appear there’s a lot out there yet.

First impressions on the SOA pistons for the M57.

byu/Xallyeah inE90

One Reddit poster claims to have obtained prototype Speed of Air pistons for the M57 BMW engine, with positive results in terms of low-end torque output and reduced exhaust gas temperatures.

It’s perhaps no surprise that there aren’t more tests being done out in the wild, given the cost involved. A set of Speed of Air pistons for a V8 diesel like a 6.0-liter Ford Power Stroke can cost in excess of $4,000—more than double what you might pay for a traditional set from another manufacturer.

Market Realities: Why Isn’t Everyone Doing This?

It’s difficult to say whether dimpled pistons work or not solely based on the resources available online. Speed of Air presents some graphs with great numbers, but it’s always hard to trust an “independent” report published on the company’s own website. The company’s explanations of its own technology are also limited enough that it’s hard to glean what the real mechanism of improvement is, or what the benefits might be.

However, we can speculate based on what we see in the broader automotive world. The simple fact is that Speed of Air claims huge fuel economy gains—on the order of 20%—from its piston technology. Given that it largely involves drilling a few small divots into a piston, it’s perhaps shocking that no other OEM has explored this area before. Indeed, we’ve seen other manufacturers such as Volvo boast about gains from their own advanced “wave” piston designs, which involved far more complicated geometry for fuel economy gains of just 2%. If they could achieve more gains just with a few vertical hits on the piston milling machine, you’d think they’d do it.

If it only took drilling a few dimples to improve fuel economy by 20%, you’d think everybody would be doing it. Automakers spend huge sums on computational modeling and real-world testing to optimize their engine and combustion chamber designs. It’s hard to imagine that in over a century of development, something as simple as a few dimples didn’t occur to anyone, given the apparent outsized gains on offer.

Dimples on pistons sound great—if they’re good on golf balls, they must be good for engines, too, right? However, you don’t have to go far to find skeptical comments online, on hypermiler forums, diesel forums, and beyond — many asking why dimples aren’t prevalent in the auto industry. It’s one of those cases where extraordinary claims require extraordinary evidence, and it doesn’t necessarily feel to some that Speed of Air has it. After all, one might expect every second engine builder out there to be raving about piston dimples if the 20% fuel economy benefits alone were there to be had. “Independent” studies published online by the manufacturer itself generally aren’t enough to convince the broader masses.

As for why OEMs haven’t jumped on the dimpled pistons, there are some theories. “It could come down to a cost versus benefit question that the aftermarket doesn’t typically need to answer,” stated Motor Trend in an article on Speed of Air in 2023. ” The extra time cost of machining a piston with these features potentially outweighs the benefits of how a piston performs without them.” However, these statements seem to ring a little hollow when stacked up against the stated 20% benefits to fuel economy and additional emissions benefits that Speed of Air claims. OEM pistons already undergo delicate machining in the production process; it’s hard to imagine that a few dimples would cost so much as to negate such huge savings in fuel economy.

An Expert Take

As part of our due diligence, we asked an independent engine expert for their comment on the Speed of Air technology. They hadn’t seen the product prior to our email, but instantly spotted some areas of concern. Speaking on condition of anonymity (because they prefer not to have their name associated with something negative), they stated responded to the Motor Trend article with the following:

I hadn’t heard of this one before, but it is contrary to design practices I have used my entire career. Surface area-to-volume ratio in a combustion chamber has a profound effect on efficiency and emissions through heat transfer and wall wetting mechanisms. And yes, lowering surface area is the preferred direction, contrary to the impact of adding dimples. The radiator in your car is a perfect example of increasing surface area (via fins) to increase heat transfer. In an internal combustion engine you do NOT want to transfer heat away from the combustion chamber. Indeed, thermal efficiency is highest when combustion is adiabatic (no heat loss).

The primary source of unburned hydrocarbons is surface quenching in crevices. Minimizing combustion chamber surface area where quenching can and will occur is the preferred direction. I am quite surprised by their claim that carbon deposits will decrease. Again, I would expect carbon to deposit readily in the cavities created by dimpling. I also don’t like the sharp edges produced in the combustion chamber [in some Speed of Air designs]. These edges are going to get very hot and likely produce undesirable combustion effects during prolonged high-load operation.

Finally, it is difficult for combustion chamber surface details to have a significant impact on global performance parameters like power. The claim of 15+% increases in torque and power are ludicrous. I am instantly turned off when I see ridiculous claims like that. The argument that OEMs don’t do it because of cost is equally absurd. I did engine development in an OEM for 13 years, and anything that would produce the power and emissions benefits quoted would be adopted immediately. The cost of dimpling surfaces pales in comparison to the cost of precious metals for emissions compliance.

Bottom line, I’m not at all interested in adding dimples to the pistons in my Chevy truck!

[Ed Note: I sent this expert’s thoughts to Speed of Air for comment. I haven’t yet heard back. -DT].

Ultimately, if Speed of Air’s technology really is as good as it claims, it will come to dominate the market in the next few years. Diesel engine manufacturers would be lining up around the block to license the company’s patents if 20% fuel economy gains are on the table, to say nothing of the claimed benefits to emissions and everything else. Double-digit gains cost tens or hundreds of millions of dollars in research and development. Speed of Air could make huge sums overnight just by selling access to the technology without ever having to manufacture another piston again. The fact that you can open up just about any OEM diesel engine and not find dimpled pistons suggests they’re maybe not quite as magic as the claims suggest.

I can’t say for certain whether Speed of Air’s pistons have huge benefits or not; I can only present the evidence available as it stands. In any case, when it comes to new automotive technology, it pays to cast a careful eye over what you see. Examine the claims, explore the science behind it, and rationally assess what everyone else is doing. That’s how you spot the technologies that work from those that don’t.

Image credits: Speed of Air, Volvo, Titleist, Cummins

This is an interesting concept but really suspect in terms of how well it works. I’m going to throw in one of those turbonator intakes, if it’s for a gasoline engine split fire plugs.

In all seriousness the OEM, and suppliers spend a lot of cash on combustion analysis, like millions testing, simulations, etc. So if someone cracked it with some random idea, I guess pretty amazing, but well, I highly doubt it. If they cracked the code, you bet some suppliers or OEMs would be running over there with a nice acquisition offer or bid, and then part of the deal is ok this tech is ours now. Also for longevity of the piston, I wonder how that dimpling will soot up or maintain its shape over the long term.

Is “turbulator” just a contraction for Turbo Encabulator? I just figured that the dimples were there to supply inverse reactive current for use in unilateral phase detractors. But what do I know?

How any company could think for a moment that they could be taken seriously after claiming a 20% increase in fuel economy is beyond me. You wonder how many sets of pistons they actually sold so far?

At least these are only marketed for diesel. Screw up a modern DI gas engine piston like this and you will see some big changes… in curb weight, when detonation forces everything inside the engine out into the atmosphere.

I have to go with DT on this. If this actually worked, engines would come stock with these things. I mean, why wouldn’t they. This all smells like the oil of a snake.

Pretty much this. If they truly got the claimed “+15%-25%” in fuel economy alone, everyone would be doing it in every engine.

I combined these with a fuel shark and cant drive more than 50km before emptying my fuel tank, I have to give away fuel all the time

I guess it only improves American trash engines from Ford, Gm and Cummins since they did not have an improvement in VW’s TDIs which are the most popular

It could just be that they are crazy. Orbital developed a gasoline direct injector that worked back in the 1980s, for a long time the tech stalled because they wanted to sell complete engines to manufacturers, and there’s zero chance of that happening. https://en.m.wikipedia.org/wiki/Orbital_Corporation

I’d rather just keep using my amazingly efficient Fuel Shark! It really works great. Everyone uses them, right? RIGHT?! Ha ha

Honda went though a phase in the 1990s when they were boasting about the swirl effect of their patented designs on induction strokes, greatly improving efficiency.

Said swirl seemed to come mainly from grooves in the inlet valve…

Suppose the dimples could cause similar swirl.

Read a story about Frank Whittle, the most influential modern jet engine inventor, who in the early 1940s was struggling to get prototypes to manufacturing stage.

He spent months trying to control fuel injectors so there was a controllable flame in the combustion chamber, and also tried things like swirling the squirt…

Honda had some wacky ideas for sure! Back in the mid 90s, my first car was a 1982 civic wagon with a 1.5liter CVCC, (controlled vortex combustion chamber). it was 12 valve, with smaller secondary intake valve that opened just after the primary. They claimed the intake stroke created a vortex dragging more air in for a more complete burn for better power/lower emissions. There was an article about it that claimed at the time in LA, with a cat converter, the air from its exhaust was cleaner than the air it was breathing. I don’t know about all that, but it had 68 hp, a sweet Pioneer tape deck, ran like a top, and got over 40mpg on the highway. All with a carb and about 2 miles of vacuum lines under the hood.

So what I need to know is;

– Do I take a cordless drill with a 1/4″ bit to the top of my pistons?

– or do I just take a ball peen hammer to them?

If – IF – some of their customer testimonials are somewhat accurate, I would suspect it could be more due to the work involved in replacing the old worn pistons and rings with newer pistons, that might be lighter and/or have tighter tolerances than the worn ones. There’s always something to be said for “stage 0”.

I sure as heck wouldn’t risk my diesel truck’s engine with something like this. Maybe let Todd from Project Farm try one in a single-cylinder Briggs & Stratton with his see-through head.

It works really well if you just Believe it does.

No one can contradict their claims unless they spend huge money on testing to refute those claims, so they are golden. Even a Class Action group would have trouble justifying the expense because of how little they could ultimately collect from a small company after litigation costs, even if they fully won. It’s kind of a perfect fraud.

Have I told any of you about my mirror lined air filter housings? The mirrored walls allow for more air flow with less turbulence, thus improving power, efficiency, and emissions by as much as 28%. This works by reflecting the air molecules away from the walls, thereby reducing friction. While your gains may vary, the improvements will be felt immediately. Your car will leap from a stop, cruise more quietly, and laugh a gas stations. Fuel savings alone can recoup your purchase price in as little as three months (depending on milage driven) with reduced fuel costs for the remaining life of your car. Our advanced manufacturing process utilizes Metal Vapor Deposition technology to create the smoothest mirrored surfaces possible on the interior of our custom air filter housings. Prices start at $199.99 for most models. Get yours today!

Oh WOW! I gotta get in on that NOW. Paired w/ my Fuel Shark that is so amazingly efficient, I’ll basically never pay for gas again! Where do I sign up?!

We just need your full name, mother’s maiden name, birthdate, and social security number to process your order. Financing is handled by us so don’t worry about any notifications from credit reporting agencies. Everything is just fine. We’ll ship your product out immediately. Although, our shipping company has advised us there may be a small delay so don’t worry if you don’t receive it immediately. We did ship it, honest.

We also know a prince from a nice African nation who is looking for some help with bank withdrawals. Would you like to hear more about this amazing opportunity? We just need your email address.

Ok! Sounds great, grand, wonderful…I can’t wait!

Does anyone else remember/love the Mythbusters episode where they take a Ford Taurus, do an insanely complex gas tank setup so they can know exactly how far it travels on a specified amount of gas, then cover the car in like 2 inches of modeling clay so they can dimple it like a golf ball, and then try again and see if it is more fuel efficient with the dimples than it was without? Definitely one of my favorite Mythbuster episodes. If I remember correctly, the car got better mileage with the dimples even though it added hundreds of pounds of clay. I think they had also tested the dirty car gets better mpg theory on that episode.

One of my favorite episodes as well.

This sounds like the old classic of “we took a beat up old engine that ran like absolute garbage, baselined it, and then fully rebuilt it with our pistons, as well as other parts that were severely worn” and the benefits were all from the rebuild, not the new pistons.

“Our upgraded component, when paired with a tune, yields almost as many gains as just the tune”

Everything old and forgotten is new again. I SWEAR I read about people taking grinders to the tops of their pistons and scoring all these random scallops on 2 stroke dirt bike engines in the 70s… probably Jawa/CZ guys. I remember it because it seemed like BS, since no OEM was doing it.

Alas, I spent a few minutes looking and the sheer volume of content on the internet has prevented me from finding it. But it did happen already.

Yeah some of my dirt bike buddies have mentioned this being a thing in some form-

https://vintagedirtbikeforums.alp-sys.com/viewtopic.php?f=21&t=3971

I dimpled a set of pistons once.

Unfortunately, the dimples were the exact shape and size of my valves.

I did that too. Killed my Feroza.

Interesting how in the graphs for the BWM testing, the magical pistons increased torque and HP below ~3300 rpm, but were detrimental above that. And at least per the graph, the top rotation was 500 rpm lower.

peak torque in the M57 is between 1800-3000rpm, and redline is 4750.

that data looks like something Fisher Motor Works presented in the BMW Diesels facebook group a year or so ago. I think it hasnt quite taken off yet for obvious reasons, but SOA will get traction and funding from curious buyers who can afford to waste the money on pistons when they just happen to have their engines apart and see this kind of news

Why stop there. I’m gonna dimple my crankshaft journals, cylinder walls, cams, and forehead.

John Lee Hooker appreciates dimples on jaws.

My Occam’s Razor reaction is that if this were a major innovation, you’d see a LOT more dimpling on the exteriors of cars, aircraft, etc.

My layman’s understanding of golf ball dimpling was always that it’s reliant on spin. Since a golf ball is inherently backspinning, the dimples are there to selectively create drag to increase lift. A dimple-free ball would fly a much more traditional arc. Just like the stitching on a baseball, just taken to the next level.

It’s what I like to call “The Pharmaceutical Fallacy”.

Pharmaceutical companies are just as greedy as any other for-profit company. And drug development is FUCKING EXPENSIVE. Reagents are expensive. People are expensive. Equipment is expensive. Quality control and compliance is stricter than in the aerospace industry. Clinical trials can cost billions. So why would they waste all of that money if a thousandth of a cent worth of St. John’s Wort does the same thing?

You can apply this principle to things like quantum computing as well. I’ll believe it works when someone uses it to make a boatload of cash. Right now it just appears to be an extremely efficient machine at converting money to hype.

In addition to all the points raised by your anon contact, also: a diesel piston in a combustion chamber isn’t a golf ball moving through the air? Like before you even get into the mechanics of engine efficiency and the like, they are wildly different aerodynamic conditions and I don’t see how they are in any way related. You’re not trying to keep airflow attached to a sphere during travel. Preferably the air in a combustion chamber does NOT go around the piston.

I think it starts wth the actual, real need for turbulence/swirl in the intake air on a diesel engine for a quicker and more complete combustion, which is why all modern diesels have something akin to a throttle-body and electronically-controlled intake flaps.. and then add the snake oil and wildly fantastic claims to it.

Best lies always start with a kernel of truth 🙂

True enough! Makes it that much more fun to try and combat the misinformation when they start with that grain of truth.

I like to dimple the cylinder walls also.

Dimple the valves too!

Dimple the dimples, then smaller dimples in those, ‘til it’s dimples all the way down!

Drill right down to the origin: dimple the fuel.

In addition to the surface area argument that dimples will hurt performance, there are plenty of other reasons too.

For a modern diesel engine, their argument falls flat on its face because the FUEL IS NOT PRE-MIXED, therefore it is not “trapped” in a stagnant boundary layer near the wall (especially in the “squish” region at the top of the piston) just waiting for some turbulence to move it away from the wall or bring the flame closer. Diesel piston design includes a large bowl as the predominant volume in the cylinder when the piston is at TDC; only a very small fraction (<5%) of the volume is up in the “squish” region. Fuel is injected down into the bowl at incredibly high pressures (200X atmospheric pressure or more), and mixes with the compressed air as it evaporates until it has heated enough and has enough O2 around it to combust. You’ll see a premixed “spike” in combustion as this happens for the first bit of fuel injected, but once that first bit has lit off then the rest of the fuel is easier to ignite since there is not only already an ignition source, more heat, and more cylinder pressure – the limiting factor is mixing with air in the chamber in order to find enough O2 molecules to combust completely and not create soot, CO, or unburned hydrocarbons. To help mixing between the fuel jet and the compressed air, you can inject at higher pressure (better fuel droplet atomization, but go too far and you can get fuel spray impingement on the bowl wall), you can create more air motion in the chamber (typically swirl for a diesel as this flow pattern tends to circulate more air into the path of the 6 or 8 discrete fuel injector spray jets), and you can increase the compression ratio (higher air density at TDC, limited by NOx generation and peak component strength as peak cylinder pressures & temperatures go up).

Adding dimples to the bowl of the piston will create turbulence near the wall surface, but in this location it’ll only slow down the existing swirl, hurting mixing and thus slowing down combustion and increasing unburned HCs, both of which will hurt performance. Turbulence near the wall isn’t a good thing since there is no flow separation as in a golf ball – a cylinder has moving air trapped inside a volume, not a solid object moving through unconstrained air. Turbulence near the wall will increase heat losses to the piston by bringing hot gasses closer to the wall (in addition to increasing the wall surface area as pointed out), heating the piston surface up while removing that energy from the gas where it could do some useful work.

Adding dimples to the squish region of the piston will incrementally increase the volume contained up there where the fuel is NOT injected, reducing the amount of air in the bowl where it can mix with the fuel spray and combust. It will also increase heat transfer in the squish region for the same reasons outlined above. All of these will hurt performance.

Basically, it sounds like they’re doing really poor science, not holding variables constant that need to be, and comparing old, tired engines to newly rebuilt ones with fresh injectors, rings etc, and probably modified to different extents in other ways as well (EGR delete, more boost, more fuel etc), then counting on uninformed customers who are replacing their pistons as a part of a much larger overhaul and set of their own modifications to not be able to differentiate the sources of changes in performance.

How did I not think of that! Of course it’s not pre-mixed!

They forgot to add the marketing claim that AI was used to develop this product.

Gosh, with 20% better fuel economy (koff, koff), it’s a wonder every jet plane and racecar doesn’t have dimpled body panels!

I can’t get “turbo-encabulator” out of my head everytime I read “Turbulator” – it’s like their engineers were joking when they came up with the name

Strangely, that’s the only part of this bullshit stew that is actually legit. “Turbulator” is the correct name for a structure designed to generate turbulence in a flow, and it’s a term in general use, not one these yahoos made up.

Welp there ya go, I’d never heard that term before, thanks for the info