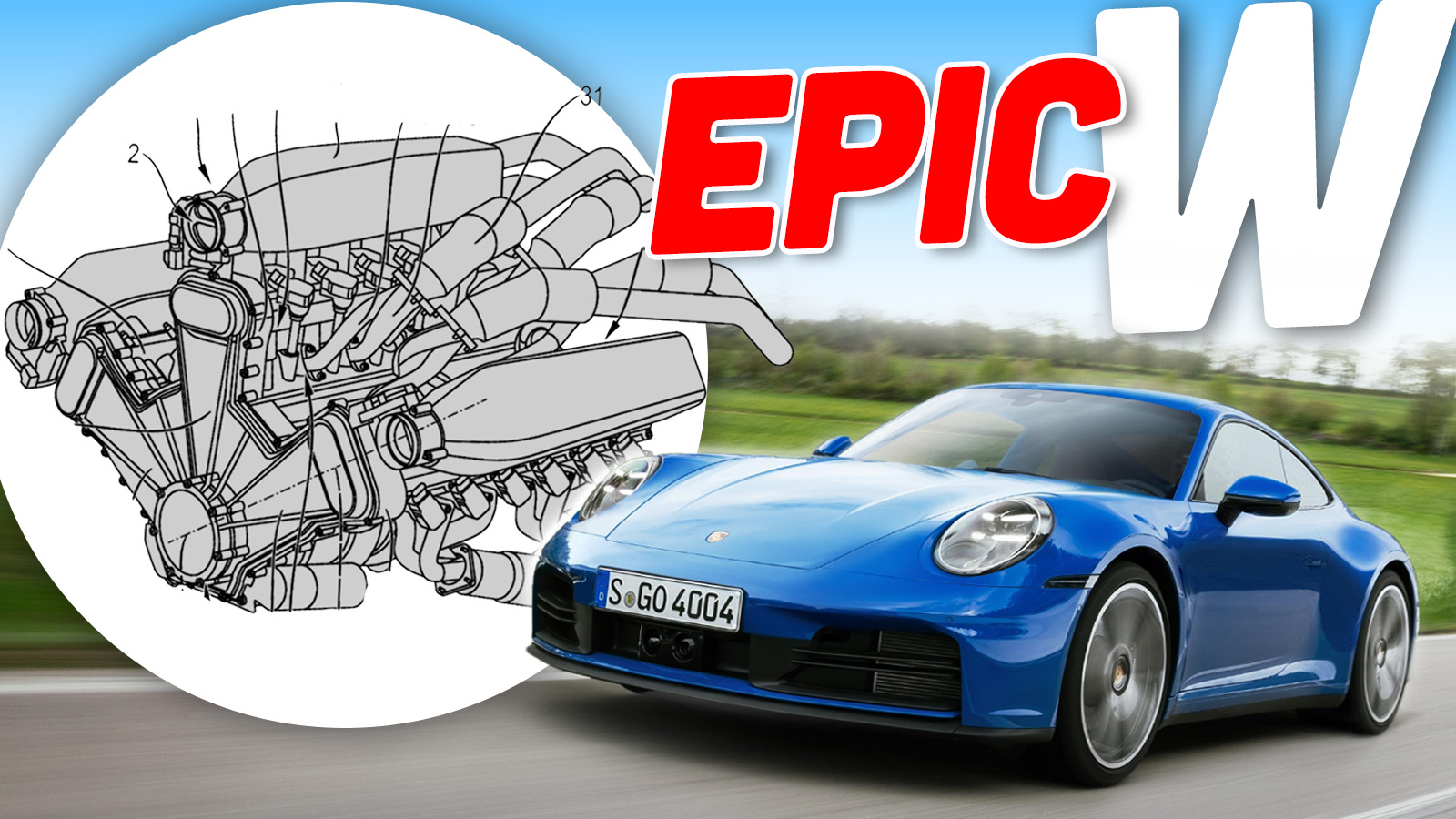

Last week, the car internet was lit ablaze by a patent from Porsche that depicted a design for a W-shaped, turbocharged, 18-cylinder engine. The patent was cool for a lot of reasons: It features a weird engine layout no one really uses anymore. It depicts a huge internal combustion engine with a lot of cylinders at a time when downsizing and electrification are the norm. And it comes from Porsche, a widely loved company responsible for building some of the coolest sports cars around.

The main reason why so many outlets covered this patent was the wacky-looking main drawing, which showed a true W-shaped engine with three distinct cylinder heads. It’s far different than the only “W-shaped” engine in use on production cars today, the W16 found in Bugatti’s lineup of Chiron-based, limited-run specials and one-offs—that engine is more like a squished V16, using only two cylinder heads to cover two banks of eight cylinders. Think of it like a VR6, but with two banks and a lot more cylinders.

I’d argue the engine’s shape isn’t the most interesting part of this engine design. Instead, my interest was piqued by the design of the cylinder heads. It’s a unique approach that redesigns how air travels in and out of the cylinder, lending more practicality to the W-shaped design. Here’s how Porsche explains it in the patent, translated from German:

According to the invention, an air intake is formed starting from the top side, wherein the top side is arranged along a cylinder axis of the cylinder of the cylinder bank facing away from a crankshaft of the internal combustion engine, wherein the air plenum is arranged on the top side, through which the intake ducts can flow, and wherein the exhaust gas discharge device is arranged on the first side and/or the second side. In other words, the air plenum is arranged on the top side, in particular largely covering it, such that air can flow from the air plenum into the intake ducts from above, or can be sucked in directly in a straight line, thus without curvature, by a reciprocating piston of the internal combustion engine, which is arranged in the cylinder to perform a substantially upward and downward movement.

Porsche doesn’t provide a diagram for this setup, so we only have these words to rely on to picture how the cylinder head setup can function. I’m not an engineer, so I thought it best to reach out to someone with real experience to explain how this worked.

If anyone can interpret this patent succinctly, it’s Dr. Andy Randolph. Randolph spent 12 years as an engineer at General Motors before moving to an R&D manager role at Hendrick Motorsports. After that, he spent 17 years at ECR Engines. Then, in 2021, he co-founded M2X Energy, a startup that builds tech to convert methane gas into usable methanol.

Here’s How Cylinder Heads Are Supposed To Work

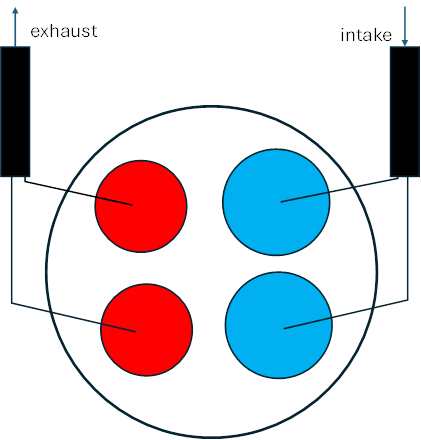

In an email to me, Randolph explained the cylinder head layout in a way a layman like me could appreciate, and even assembled some graphics to help me understand. First, he described the layout of a traditional cylinder head, the design you’d see on pretty much every new car on the road today.

“A normal 4-valve-per-cylinder engine has the intake valves on one side of the head and the exhaust valves on the other,” Randolph told me. “This is convenient because it places the intake plumbing on one side and the exhaust plumbing on the other. It also allows for a pentroof combustion chamber with a centrally-located camshaft running the length of the head using finger followers to actuate the valves.”

Before going any further, it’s important to explain the importance of a pentroof-shaped combustion chamber and why you’d want it in your engine. In short, it makes the air mix better with the fuel and allows that mixture to burn more evenly. Here’s how Randolph describes it:

“The optimal combustion chamber is a sphere with the ignition source in the middle,” he told me. “In a spherical shape flame area increases with the cube of flame front diameter until combustion is complete, when the flame reaches the wall simultaneously in all directions. A spherical shape is virtually impossible in an engine, so developers have gravitated towards a ‘hemispherical” shape which combines a pentroof chamber with a dished piston in pursuit of more optimal flame front growth and propagation, along with slightly larger valve sizes.”

“Further, a pentroof shape naturally creates a tumbling motion as the fresh charge enters, whereas a straight entry from above into a flat chamber will not,” he added. “Tumble in pentroof configurations converts into turbulence as the mixture is compressed, leading to a faster and more repeatable burn process.”

A Simple Change With Big Effects

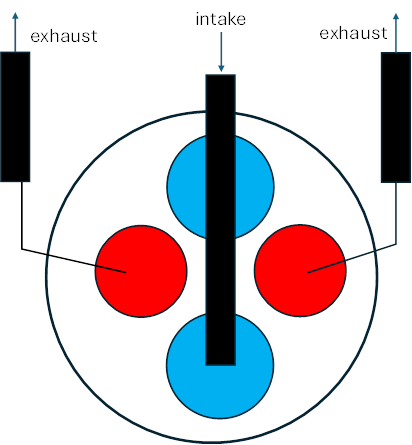

Now, onto Porsche’s cylinder head design. “It appears that in this incarnation the cylinder head is rotated 90 degrees, placing one exhaust valve on each side of the cylinder head and the intake valves inline along the length of the cylinder head,” says Randolph. There are still four ports in the head; they’re just arranged differently, where the intake ports are in the middle, while the exhaust ports are off to either side.

This means the intake plenum can be positioned directly above the cylinder head, giving the air a straighter path towards the cylinder—something Porsche posits as an advantage, saying that “frictional losses in the air flow are minimized.” Randolph doesn’t see it so simply.

“The intake runners are very short, with the intake plenum raised slightly to allow spark plug access from the side,” he says. “The patent applicants portray this as an advantage from a flow efficiency perspective. That is a nice glass-half-full perspective, but intake runners are typically configured—tuned—to provide volumetric efficiency enhancements at the desired speeds. There is no tuning possible with such short runners, although this isn’t nearly as important in turbocharged applications, which they mention as a preferred embodiment. Their example splits each six-cylinder bank into two three-cylinder banks, which are particularly conducive to intake tuning optimization.”

Then there’s the actual shape of the cylinder head. “I don’t see how a pentroof-shaped combustion chamber could be adopted; thus, the cylinder head would have to be flat,” Randolph says. “A flat chamber will suffer a burn rate penalty—a slight efficiency penalty—from less optimal flame propagation.”

There’s also one thing Porsche remains pretty vague about in the patent: How the valvetrain is actually arranged. On a normal cylinder head, the valves are controlled via the camshafts (directly on overhead-cam engines and via pushrods and rocker arms on pushrod-style engines). But because the air intake comes from directly above the cylinder, it’s unclear how Porsche will actuate the valves on its W18.

“The valvetrain will be interesting, likely consisting of finger followers to the outboard exhaust valves and direct acting to the central intake valves,” Randolph says. “This is not necessarily bad, but it makes for an interesting internal geometry.”

Finger-follower-type valvetrains are usually reserved for motorsport applications, as they allow better valve lift and a higher peak RPM. Here, it’d likely be used to figure out the packaging, according to Randolph. Here’s a photo that compares finger-followers to a traditional bucket-tappet-style system:

“I still haven’t figured out valve actuation and runner packaging on the inlet side,” Randolph told me in a follow-up email. “The inlet runners appear to come straight down in their figures, which makes me wonder how the valves are packaged/actuated. The patent application is a little short on details!”

What About The Exhaust?

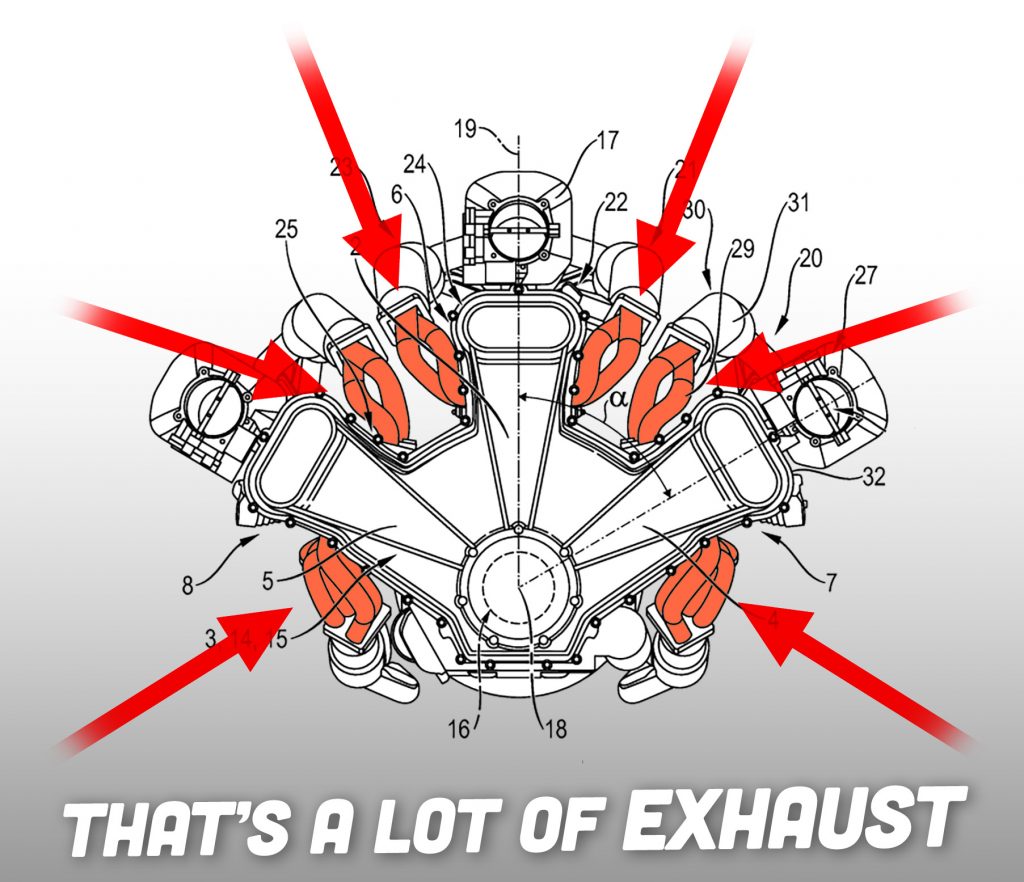

Lastly is the exhaust arrangement. Because there’s exhaust exiting from either side of the cylinder head, that means each cylinder needs double the number of exhaust pipes normally required for an internal combustion engine.

Not only does that mean more materials are needed, but it also means more design work to implement those pipes.

“[The] pipe diameters can be smaller because each exit only carries half the exhaust flow, but it is still more costly than a typical layout,” says Randolph. “Further, turbocharging is less effective because each exhaust runner only carries half the energy. Two smaller turbos would be required to extract energy from both exhaust exits. Their example with two three-cylinder heads per bank—six cylinder heads total—would require twelve turbochargers! Wow, that gets expensive! On the bright side, multiple small turbos are much more responsive than fewer large turbos because of reduced rotating mass.”

Can This Work In The Real World?

In short, Porsche’s W18 could work, but it’d be incredibly cost-inefficient, according to Randolph.

“[T]his is an interesting concept with some nice packaging advantages offset by implementation disadvantages, which will reduce efficiency and increase cost,” he says. “This would be a VERY expensive engine!”

When asked whether such a design would be viable for any sort of real-world use case, Randolph said it could be, but “it would just be expensive and not be as efficient as conventional design. The advantage is packaging with the W configuration; 18 cylinders in a comparable space as an inline 6 (okay, maybe a little longer to fit all the throws on the crank).”

While such a design doesn’t seem viable for anything in Porsche’s production car lineup, I could see it ending up in something much bigger, like an aircraft, a boat, or a tank (variants of the M4 Sherman used a five-bank W-engine with 30 cylinders). Coincidentally, Porsche has been pushing to secure more defense contracts recently to make up for all the profit it’s losing in the car business, so such a proposal isn’t as far-fetched as it sounds.

I’m no defense contractor, but if I were, I’d be pretty excited to hire Porsche to build an 18-cylinder engine for my main battle tank. I feel like that’d be a pretty big selling point. Plus, I get to put Porsche branding on my tank. And that just sounds cool.

Top photo: WIPO / Porsche and LinkedIn

I may be daft and missed it, but not one mention of the triflux? https://www.speedhunters.com/2013/02/the-triflux/

SSIK Any one reminded of an old R&T single cylinder motorcycle diagram (joke) I think from 70s or 80s with the connecting rod attached directly to the rear wheel?

“I’m not an engineer, so I thought it best to reach out to someone with real experience to explain how this worked.”

You don’t need need an engineer, you need an English scholar to explain all those whereins and thuses. Get a professional translator with an automotive background to do the job instead of an AI next time.

I didn’t read the patent, but I’m guessing this would be meant to be used with electric turbochargers. It would make packaging much easier, wouldn’t it?

Also, I’m looking forward to seeing Porsche Cabriolet tanks in the valet lines the next time I’m in Beverly hills.

“This would be a VERY expensive engine!”

Porsche, checks out.

We need to get this engine on a motorcycle. But if we have to put it in a vehicle with more than two wheels, then it goes in the Mitsubishi Mirage.

Looks like spark plugs and throttle bodies: It seems to be spark ignited (gas engine). It makes no sense for military applications. You want compression ignited engines for that, which can run on diesel or jet fuel. Two main reasons: 1. higher fuel efficiency. 2. The fuel supply chain is already set up for these kind of fuels. It would be crazy to have to supply another type of fuel to the battle zone just for your fancy W18 tanks.

This thing is for some kind of über-super car. Meh.

Yep, NATO standardise on diesel for this very reason, which also leads to some of the diesel motorbikes Mercedes likes writing about 🙂

Maybe there are no cams for the intake valves. If the intake valves operate on actuators, the head could still be hemispherical with the intake valves canted towards the front or rear of the engine. You could actually end up with something even more hemispherical than the pent roof design.

That exhaust gives me headaches – especially figuring out how to package turbos in there.

Reminds me of the Life W12 F1 engine

https://daxstreet.com/cars/159813/the-life-w12-engine-a-story-of-high-hopes-and-tough-realities/

It was a total disaster

What’s old is new again. Lancia did the same basic cylinder head idea with the Triflux back in 1986: https://dyler.com/blog/313/the-unique-triflux-engine

Obligatory (for me): this is a published patent application, not a granted patent.

Interesting that they only have two figures. This would be rejected in the US for lack of enablement I would expect.

I’m with Dr. Randolph on all this. A solution for a problem that might not exist.

Still, useless ideas can be important because some lead to useful ideas.

Is there a Maus heritage edition on the way?

Patent writing takes me back. The trick was to cover your invention but not give away the ‘real’ design that makes it work or practical. One described many ways of accomplishing the design and hoped to make it difficult to cost effectively determine the best method. Alternatively, one could try to make the solution broad enough that no matter the method, it was covered within the patent.

For patent portfolios, the number of patents is important for their perceived financial value. However, one just needed a single strong patent to maintain control of the technology. Many years ago, I had the task of evaluating a patent portfolio for a type of optical data storage (magneto-optical) held by Phillips. There were more than 100 patents, but less than 10 were of any significance for a real product. It helped us negotiate a licensing fee that was about 10% of what others had paid. The real reason that they accepted such a small amount is that we would have just terminated the business, if they stood their ground. Turned out that the technology got by-passed pretty quickly and we may have been the last company to take a license.

Sounds like an interesting career.

It was. In the 80s I helped develop and manufacture several stealth coatings. These were used on the Sea Shadow and the B-2. We did some other work for which I never learned the application but suspect it was for some type of military satellite.

After that was a stint of 11 years at a company where we developed and manufactured (on a pilot-scale) the magneto-optic media. I was the salesman for that product for a year for which I was completely unsuited. After that business was closed (not my fault, technology just passed it by), I worked with a world-class scientist to implement a laser-texturing process for hard disks. This was the same scientist that was the driving force for the optical media. Working with him was the equivalent of getting my second PhD.

From 1999 to 2002, it was a rough time with the dot-com bubble bursting and 9/11. I was out of work for 14 months. I started working again at a much lower level (senior engineer vs. director) in 2002 at a company that developed a flexible, transparent ultra-barrier against water vapor and oxygen. It is a necessity for flexible OLED displays. As a result our technology was acquired by Samsung Display. I had worked my way up to VP of Operations and Technology at Vitex Systems being responsible for the design and manufacture of small-scale coating systems.

I spent 3 years in South Korea as VP R&D at Samsung. I wrote an unpublished book about that experience. It was mainly as a cathartic release. In short it was very frustrating. Nonetheless, the Vitex encapsulation technology is used on all mobile OLED displays. After I returned home, I joined a start-up where we developed and manufactured an ultra-barrier coating on thin PET film. Unfortunately, the market did not develop and we closed in 2019. I then retired. It was actually fortunate. If we had been successful in selling the business, it would have been to China and I would have been there at the start of the COVID pandemic.

I’d say I was a lucky man throughout my career.

A life well worked, at the very least.

For today’s U-boat commanders, there is no substitute.

Did anyone else look and think Porsche was just patenting the Napier Lion engine?

I only see a design like this maaaaybe being useful in some sort of racing application where you want a lot of displacement in a relatively short package.

Think outside the box a bit – no cams ala Koeniseggggggggggg, and electric turbochargers. This is Porsche – does cost REALLY matter? Ferraris seems to count costing more for no real useful purpose a benefit. It will probably sound pretty cool – there’s value in that in a world of souless EVs, right?

pneumatic valve actuation…no cams. just like F1.

the complexity of cam actuation is replaced with an air pump.

They would be easier to get around than cams, but I don’t see anything that looks like actuators/space for them for the exhaust valves. Maybe they figured out how to properly seal rotary valves.

It does look like there are timing covers in the diagram.

Maybe the exhaust valves are operated by cams. One cam for each side of the head operating half of that bank’s exhaust valves just to maximize complexity.

I guess that would give full independent timing control of both the intake and exhaust valves.

Good call.

F1 does not use pneumatically actuated valves. There are camshafts and lifters which actuate the valves.

The valve springs are pneumatic instead of steel coils, but the valves are still actuated by a cam and lifters. It’s just like replacing steel spring suspension with air suspension. They do this because air weighs less than steel and thus the reciprocating mass is very low.

When I tried to figure out how the intake would get by the valvetrain, I dismissed it as a patent without intent to build. Cost would be nuts and I can’t imagine there would be any way to distribute it over multiple models. Or maybe it’s intended for Bugatti? They already have a new V16, though. If they actually have a solution to the intake, I would like to know what it is.

Porsche designed (the “Ing.” part) at least 4 armored fighting vehicles, dating back to World War 2. The Leopard 1 Main Battle Tank went into production in 1965, and almost 5,000 were built by Krauss-Maffei.

It is rumored that the ones without air conditioning and door handles were the most expensive of the several variants…

Porsche thinking about building tanks, now?

What timeline are we on?

The worst one. Everything old is new again. Friend, fun, and Der Fürhrer.