Maintaining traction on grades is a huge deal in trucking. If a driver makes what seems like a small mistake, it can snowball into a dangerous situation with the rig running out of control. Truckers may also have to battle snow and ice with their loads as well. Back in the late 1960s, International Harvester developed what it called the “Universal Highway Tractor.” The International Unistar was a beast featuring an innovative automatic 4×4 system and a weird detachable third axle that let the truck haul basically any load to any destination.

If you’ve taken a road trip through America’s mountainous regions, you’ve almost certainly seen semis chugging their way up long and steep grades. Semi-tractors are some seriously robust machines built to haul tens of thousands of pounds day and day out for a frankly astonishing number of miles. Mountains are usually only a speedbump to these marvels.

When it comes to climbing a grade with a load, a truck will lose momentum. In response, its driver downshifts through multiple gears until their truck reaches a point where it can maintain speed at roughly 1,500 RPM or so. Remember, semi-tractor engines are some seriously huge mills with real meaty, heavy parts. This results in a situation where the rig slows down to perhaps 30 mph or 45 mph on some grades.

These same grades can become especially challenging with the addition of rain, snow, or ice. Now, not only do truckers have to concern themselves with making it to the top of the grade, but doing so with as little wheelspin as possible and, ideally, not sliding off of the road. The career truckers over at hauling publication Smart Trucking talk about engaging your axle interlock, limiting gear shifts, driving at a high RPM, and not following in the tracks of the truck ahead of you. A driver also has to engage in a delicate dance of maintaining momentum, but not going so fast that it becomes dangerous.

All of this is to say that if you pass by a truck that’s surging its way up a snowy grade, know that the driver behind the wheel is probably exercising some skill in keeping that rig on the road.

But what if your truck did some of the work for you? What if your rig had a cheat code to extra traction when the going gets slippery? Back in the 1960s, International Harvester developed what it thought was the ultimate highway tractor. This was a truck designed to haul just about any load anywhere in America, no matter what the weather report said. The International Unistar was innovative and promising, but short-lived.

A Shining Star

The story of the Unistar starts with another truck, the International TranStar. As Heavy Duty Trucking magazine writes, International Harvester spent much of the 20th century at the top of the pile of heavy truck producers. The company had been building trucks since 1907 and captured lightning in a bottle with its ‘Emeryville’ trucks. From logistics publication Freightwaves:

In the years after World War II, International Harvester worked to design, build and sell new models of trucks. The company re-introduced cab forward and cab-over-engine highway trucks. The IHC Model L was a full line of trucks – from a pickup model to a highway tractor. The cab of the heavy-duty tractor had “Comfo-Vision” – the first heavy-duty truck to feature a one-piece, wrap-around windshield. The truck also offered more head and leg room for the driver, as well as a heating and ventilating system.

The cab-over-engine model DCOF-405 (known as the “Emeryville”) was a very popular IHC model. It was built by International Harvester specifically to enable truckers to haul more freight while meeting the overall length laws of the period. During the 1960s, the Emeryville was “the best-selling truck on American highways for four consecutive years.”

From 1965 to 1968 International produced and sold the cab-over-engine CO-4000. It was the first cab-over-engine heavy-duty highway tractor completely designed by the company. It replaced a generation of tilt-cab tractors that were based on a Diamond T truck design. However, the CO-4000 was only in production for four years; it was replaced by the TranStar-series of cab-over-engine models in 1968. The major redesign was undertaken to accommodate larger-displacement diesel engines that came on-line. The TranStar model was produced from 1968 until 1981. In 1974 the TranStar II was introduced; it had an even larger displacement engine than the TranStar. The TranStar conventional tractor was introduced in 1971. Designed for regional and over-the-road shipping, the TranStar was available in two hood lengths, depending on engine specifications.

The TranStar is such a cool truck in itself that there have been times I contemplated buying one from an old farmer on Facebook. These rigs had aluminum cabs, IHC, Cummins, or Detroit Diesel engines, and a timeless design. Owner-operators and fleets loved the TranStar when it was new, and its success was so great that International developed a couple of unique variants of the TranStar.

One of the variants of the TranStar was the Super TranStar, which launched in 1970. This absolute unit featured a 14.0-liter Detroit Diesel 12V-71 V12 two-cycle diesel, which was good for an astounding 434 horses and over 1,200 lb-ft of torque. International said that a Super TranStar could haul a huge 144,000-pound load.

If frankly silly amounts of power didn’t tickle your fancy, International introduced one more wild TranStar variant in 1970, and this one swung for the fences.

The First Automatic 4×4 Highway Semi

Sadly, despite a deep search through my usual sources, I could not figure out exactly how International came up with the idea to make the first automatic-activating four-wheel-drive heavy-duty highway semi. But I can tell you that the father of the Unistar project was IH’s manager of western new product development, Jack Zimmerman. In period reports, International claimed that a 4×4 over-the-road semi just did not exist in factory-built production form, so it decided to engineer a truck that would have unparalleled hauling capability. International set its sights on building the so-called “Universal Highway Tractor.”

To be clear, International did not make the first-ever 4×4 semi. There were 4×4 trucks in World War II, like the Mack Model NJU. The FWD Model B was another 4×4 truck from all the way back in the 1910s. However, these were not Class 8 highway tractors. Freightliner did offer a 4×4 variant of its highway tractor in the 1950s, but it wasn’t an automatic 4×4 like the International.

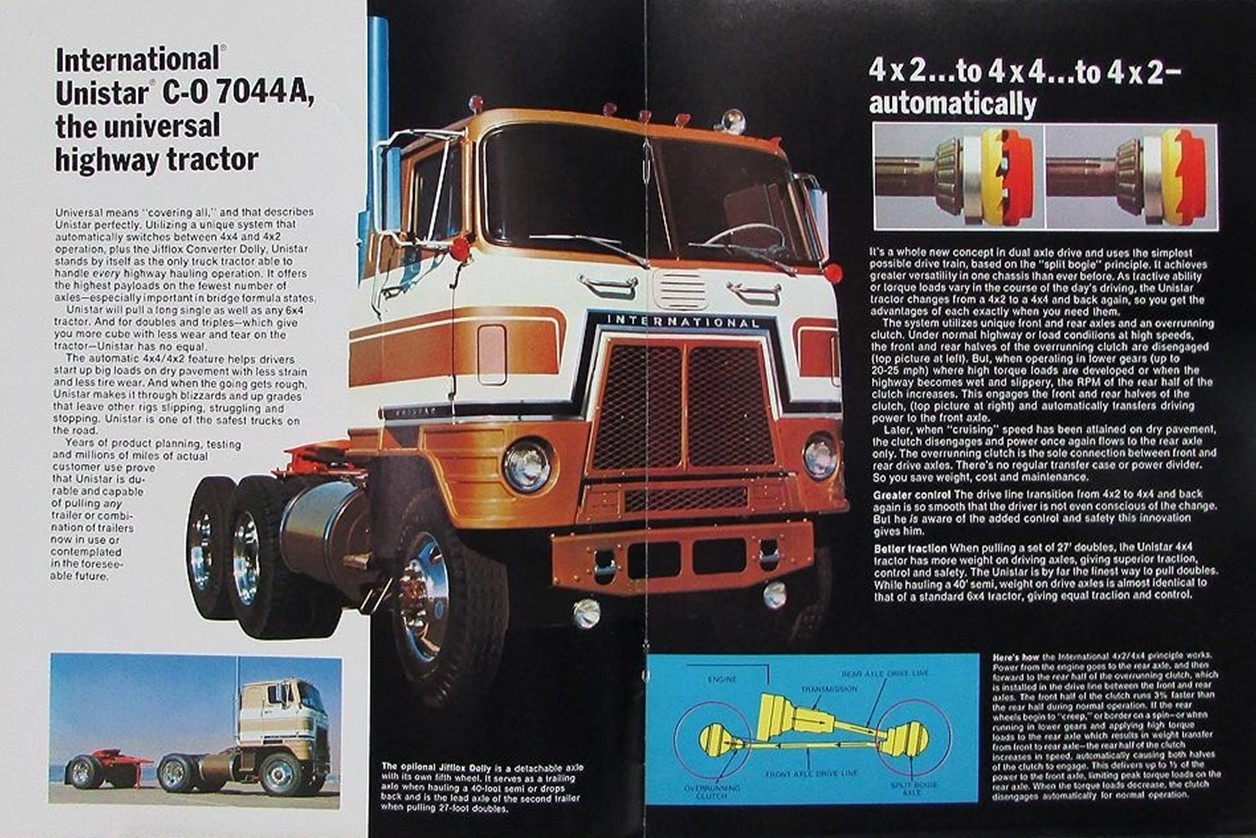

According to Overdrive Magazine, to create the Unistar, which had the code of C-O 7044A, International started with a TranStar. Most of the TranStar parts were unchanged, including the cab, engine, transmission, driveshaft, rear axle, and front differential are all standard TranStar gear. Yep, attached to the forward axle is a TranStar differential, which now connects with a second standard driveshaft headed to the rear. Smaller changes included a slightly revised front end and space to fit a larger cooling system.

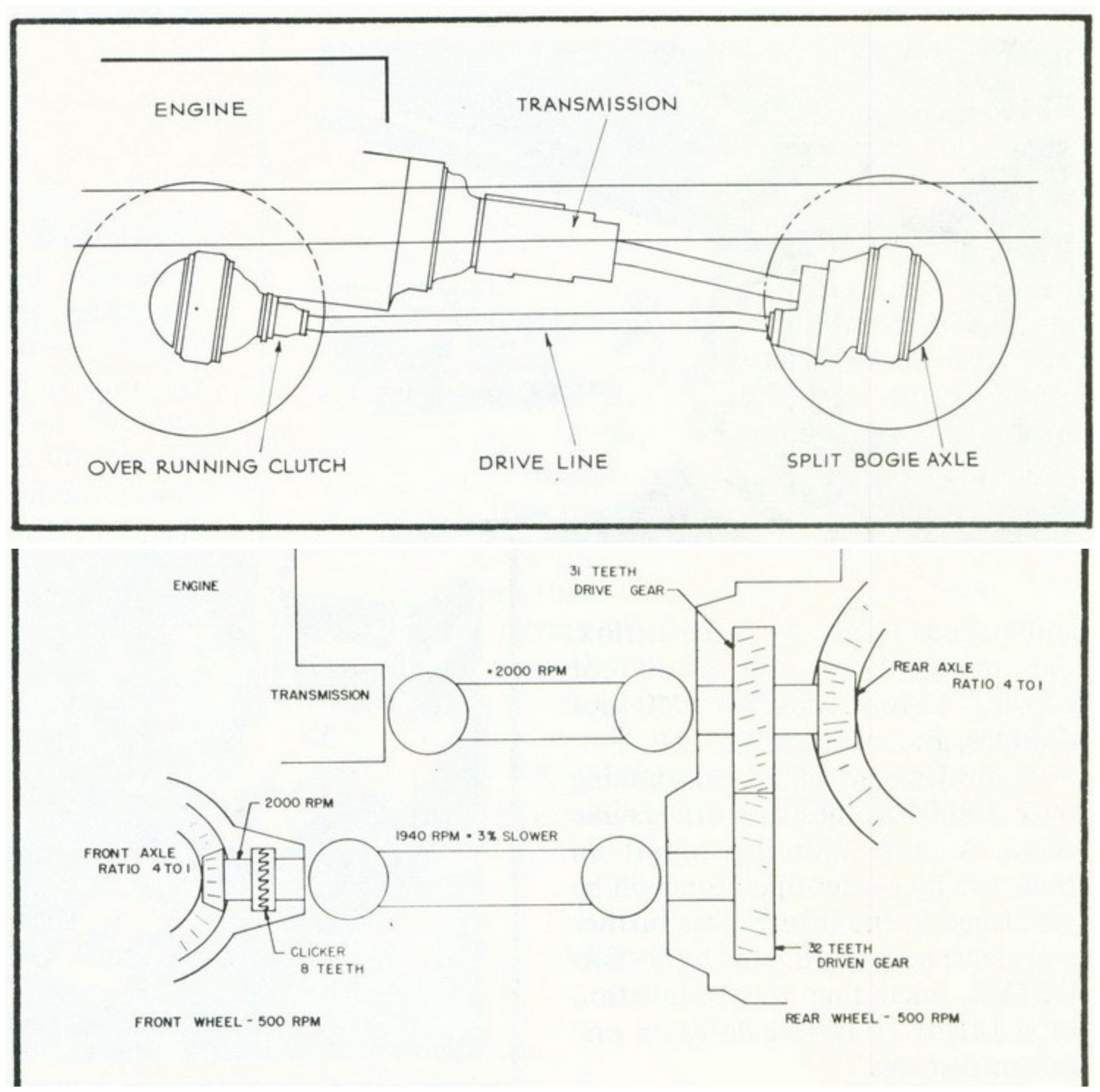

International made two major revisions to the TranStar design to drive that front axle. The first is an automatic overrunning clutch in place of a typical transfer case and found just behind the front axle. The second change was that, since the front wheels were now powered, the steering gear now had U-joints. The second driveshaft meets the first driveshaft at a split bogie axle in the rear. Check out this illustration to help you wrap your head around it:

This 4×4 system was not driver-controlled. How it worked was that there was a clutch behind the front axle. This “clutch” was really what International called a “clicker” that had 8 teeth. The rear axle had two sets of gears, one with 32 teeth and one with 31 teeth. The second driveshaft was connected to the gear with 32 teeth and ran at speeds three percent slower than the rear driveshaft. During normal operation, the differing speeds meant that the clicker was open, and the truck operated as a 4×2. If the rear axle slipped enough to cause the rear driveshaft speed to match or exceed the speed of the front driveshaft, the clicker automatically closed, clamping down and driving the front wheels.

The clicker will then stay closed until the axle difference of three percent returns. After which, the truck automatically reverts back to 4×2. The process was entirely automatic and mechanical. All the trucker had to do was drive.

International said that, to make this, it didn’t just convert a rear-wheel-drive semi, and that the chassis was designed specifically to accommodate 4×4 power. This truck was a true 4×4, too, as it had just two axles.

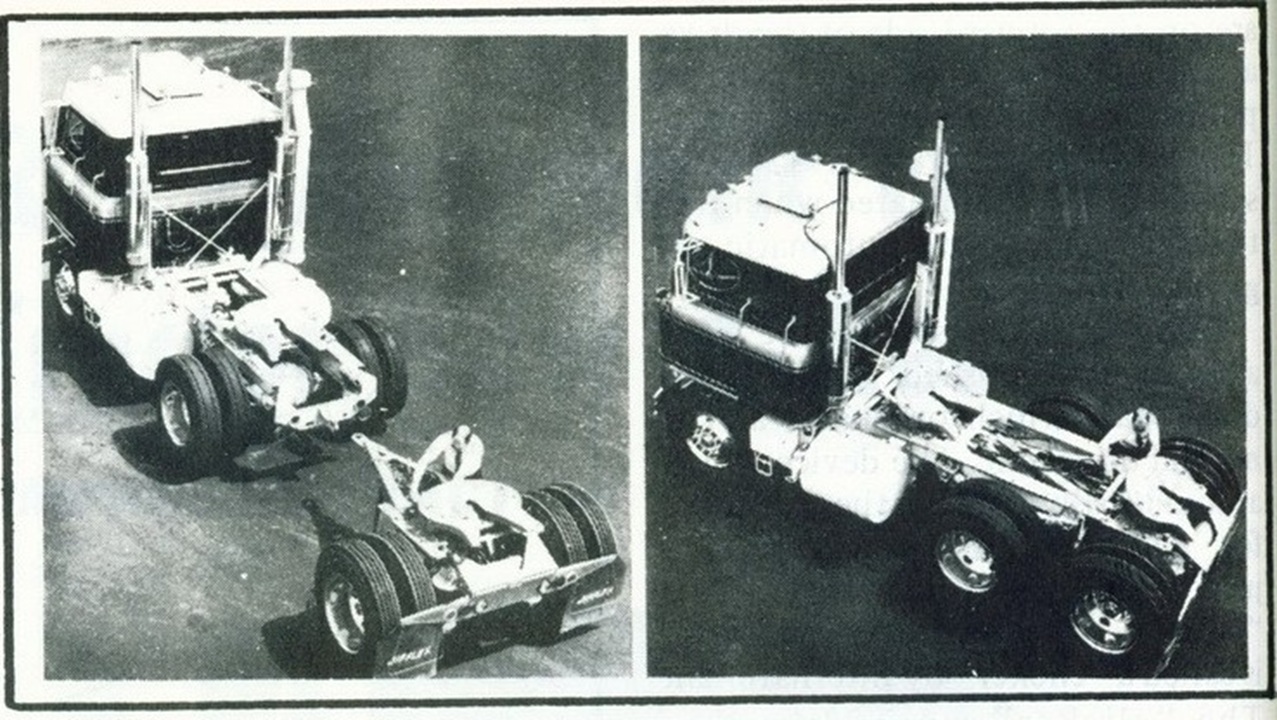

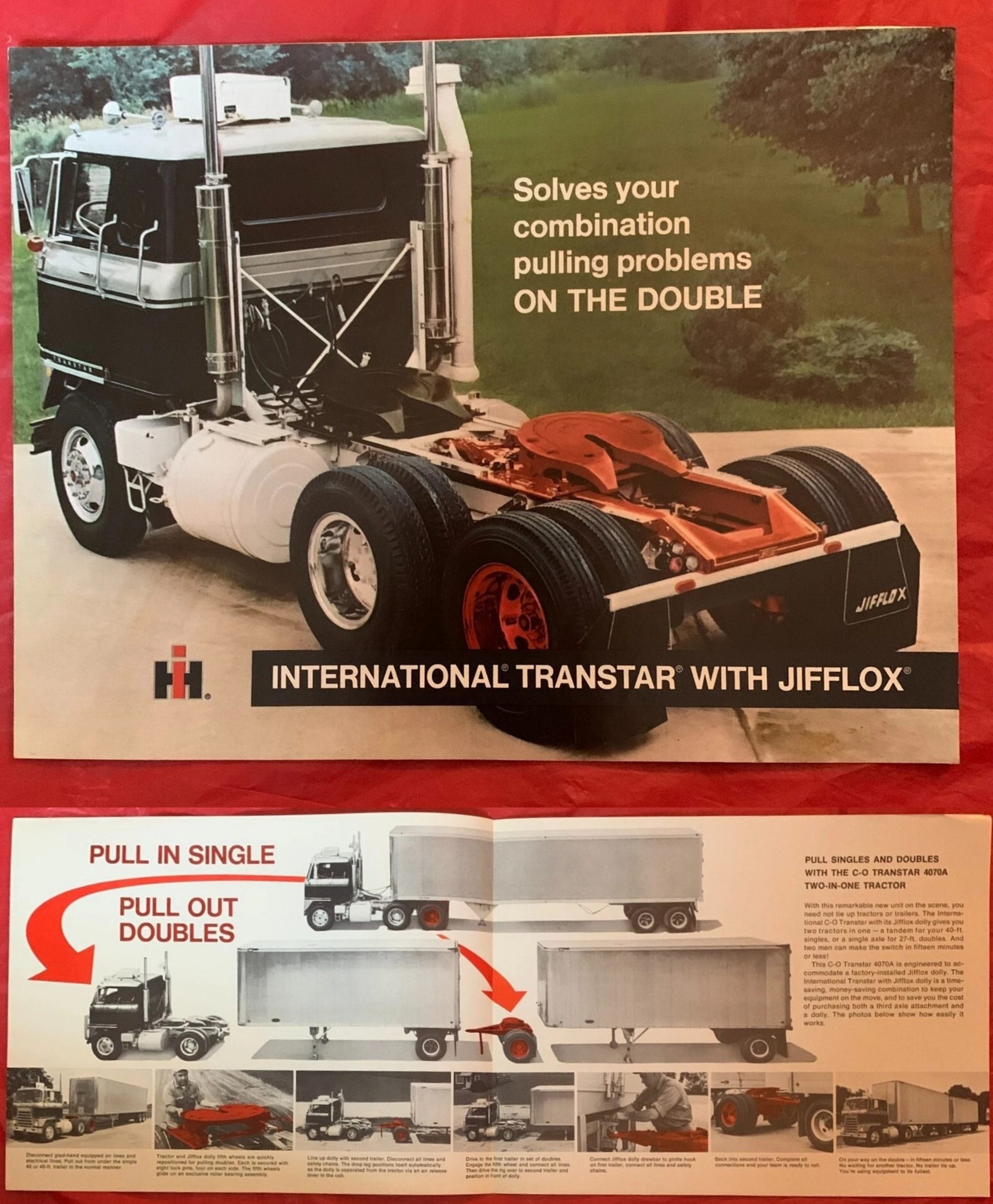

But hold on, what’s with the photos showing the truck with three axles? Well, International baked in one more trick. In addition to the 4×4 system, International also added a product called a Jifflox Converter Dolly to the back of the truck. This is an unpowered and removable axle that changes the truck from a 4×2 and 4×4 to a 4×6.

Here’s another look at the Jifflox:

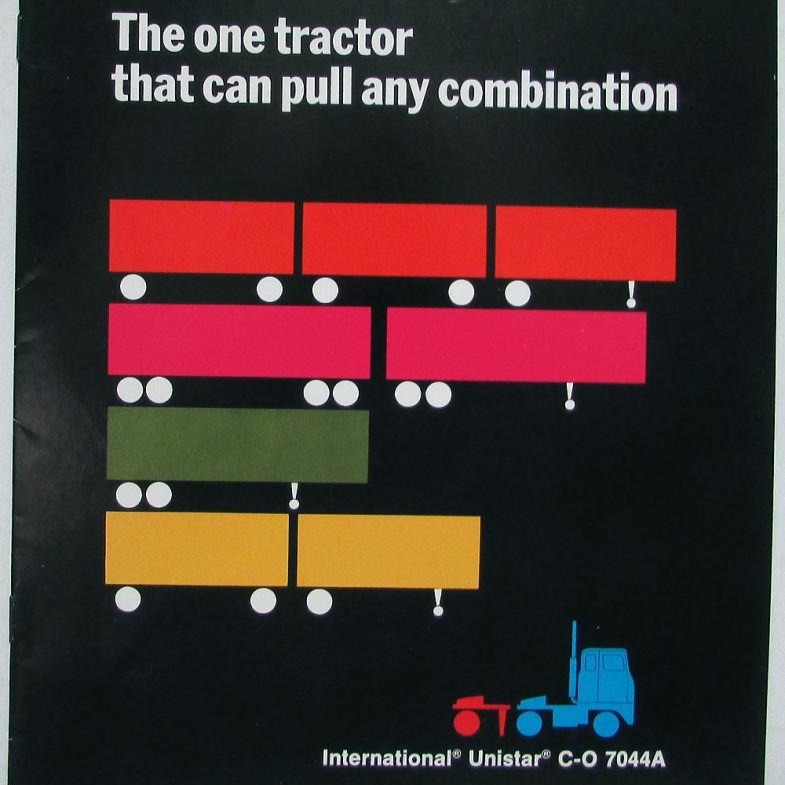

International said that the flexibility added by the Jifflox meant that a trucker could have the Jifflox attached to their truck and haul a 27-foot or 40-foot single trailer, or hook the trailer up directly to the truck, put the Jifflox behind the trailer, and then tow a double or even a triple. Further, International said, you could even use the Jifflox to tow two 40-foot trailers if you wanted to.

It was because of the 4×4 system and the Jifflox that International marketed the Unistar as the ultimate truck that could pull any combination anywhere. The company was so confident that it said that the Unistar could handle “every highway hauling operation.” International then accidentally proved its point while demonstrating the truck.

The Unistar Flexes Its Muscles

When the Unistar launched, International gathered representatives from 53 major trucking fleets at Berthoud Pass outside of Denver, Colorado. It was a cold day in March, and the mountain pass was covered in a foot of snow. The pass also got beaten down further by an avalanche. According to a period report, trucks and cars that couldn’t make it littered the pass.

First, International hooked up a 40-foot trailer to the back of a TranStar, and loaded up to 71,000 pounds, the truck climbed to the top of the pass. Next came the Unistar, which was hauling doubles and was loaded up to 70,000 pounds. Its performance was just as good as the TranStar.

With the baseline set, International then hooked the TranStar to the doubles, and the truck required chains to reach the top of the climb. International explained that the drag and dynamics of towing doubles meant that the TranStar had to use chains to reach the top of the pass, but the 4×4 Unistar, which had better traction, did not.

Apparently, the better demonstration happened on the way to the test site. To get to the demonstration site, International arranged a convoy of a TranStar, an Unistar, some SUVs, and a bus. The convoy had to stop because a trucker trying to climb the pass in a 6×4 rig got stuck in the snow. Apparently, that trucker mounted chains to their tractor, and it still didn’t move.

This was also a sticky situation for International, as its trucks lost all momentum when they stopped. Yet, despite stopping right next to the stuck truck, the International Unistar took off and climbed the grade without the use of chains. The TranStar behind it needed chains to get moving again. This perhaps impressed the trucking company reps more than the actual demonstration did.

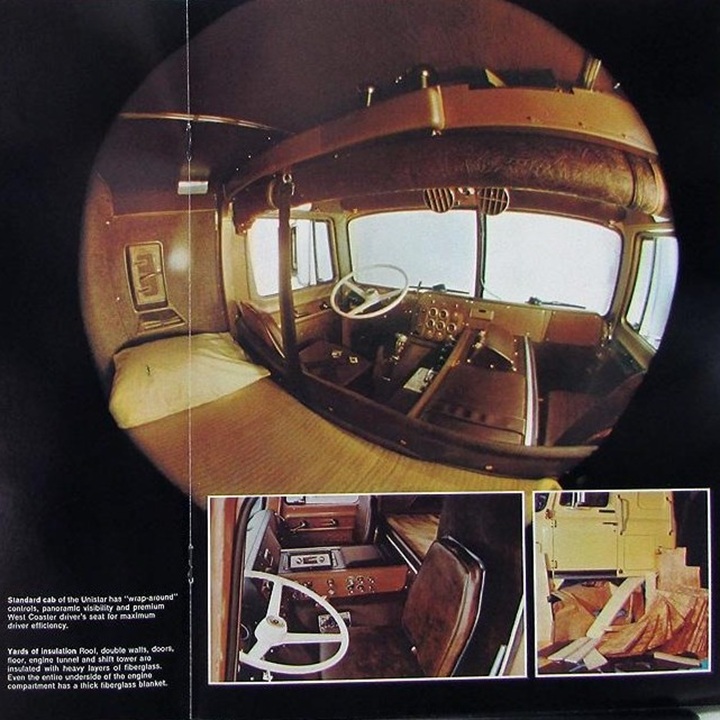

The Unistar C-O 7044A went on sale in 1970, and International pitched it as not just revolutionary, but luxurious. Marketing materials touted the Unistar as being “both beautiful and masculine” with metal interior trim, a walnut-grain instrument panel, and saddle brown Naugahyde upholstery. International also noted a leaf spring suspension and a soft ride, thanks to rubber rear cab mounts. Other luxuries included full carpeting and fiberglass insulation in the sleeper.

The Unistar has a gross vehicle weight of 36,000 pounds and a gross combination weight of 130,000 pounds. This meant that it couldn’t carry as much as a Super TranStar, but, technically, it was more flexible. Power options were vast, and International sold the truck with 12 different engines and tunes, ranging from a 255 HP Cummins NTC-270 CT diesel to a Cummins NTA-370 rated for 370 HP. Transmissions ranged from a Fuller RTF-9509A nine-speed to a RTOF-12513 13-speed Roadranger.

A Short-Lived Oddity

Despite the promise of the Unistar, it didn’t stay in production for long. Press materials indicated that International Harvester really wanted to attract Canadian drivers with the new rig, but it’s unclear what happened. I couldn’t even find pricing information or production numbers. International canned the model in 1972. As for the Jifflox, International just started marketing it for the TranStar:

One thing I can tell you is that the 4×4 semi didn’t take over the world of highway tractors. Sure, 4×4 trucks exist, but those are usually in the vocational space. The semis climbing the mountain passes around America are that old-school 4×6 configuration with chains when necessary.

So far as I could find, one of the downsides to a truck like the Unistar was the fact that, while the truck was a wintertime beast, you were carrying around an entire four-wheel-drive system the rest of the time. Of course, then there was the extra cost of maintaining that four-wheel-drive system.

So, it would seem that the Unistar was ambitious, but a sort of dead end. International thought it would revolutionize trucking with a semi that had four-wheel-drive and a third dolly axle. The Unistar then demonstrated that it had the guts to be a good truck. But for whatever reason, be it cost or complexity, the world of trucking continued unbothered. Still, I think the Unistar is worth remembering. Like so many other trucks of the 1960s and 1970s, it tried to change the industry with a wild and wacky idea, and it’s sort of just plain cool.

If you happen to know more about the Unistar, send me an email at mercedes@theautopian.com.

“The TranStar is such a cool truck in itself that there have been times I contemplated buying one from an old farmer on Facebook”

It was here where I said “ah this just be a Mercedes article” ????

Turned my smiley face into a bunch of question marks lol.

The M35A2 Deuce and a Half used a spray operated transfer case in some models, which sounds similar to this setup. Wikipedia says it was a Rockwell 136-21. Other M35’s had an air operated Rockwell 136-27. The first truck I was assigned was a 1967 M35A2 with the air operated transfer case. And the “whistler” turbo.

Slight correction on the Jifflox configuration — The base truck could operate as a 4×2 or 4×4, and with the Jifflox attached it would be a 6×2 or 6×4. The Jifflox axle would always be an un-powered tag axle.

Thank you for clarifying down here, I was pretty sure while reading that this was the case, but I had myself second-guessing again.

I wonder how many of these ended up in the logging industry? Seems like PNW loggers would have gotten along well with this.

And for the past 20 years you have had Nissan Rav4s, and others who borrowed or stole the idea where a viscous coupling system and electronics automatically turns the 2×4 into a 4×4 with no driver input. Except that it goes the other way round, when the front wheel slips the back kicks in…

Perfect truck for a SnowRunner mod.

I used to haul tanks in the snow belts of western New York. I would not have been interested in this system for two reasons. First, it is automatic. Frequently the only thing that will get you out of trouble is steering, and an automatic system could kick in at exactly the wrong moment and wreck you. If it were manual, or at least had a cut out, I’d be OK with it except for the extra weight.

When dinosaurs roamed and I started driving, the first rig I drove, a 1961 White, had a lever on the dash to cut off the steer axle brakes partially or completely. I could stop that truck in the snow better than any of the later “safer” models. The company I hauled tanks for ordered their trucks without any steer axle brakes until the government mandated their installation. I agree with the government that front brakes should be mandatory – but the driver should also be able to cut them off on snow covered roads. Understeer in a tractor trailer is very dangerous.

Weight is a problem. For a lot of loads – like tankers – you want the lowest weight possible. You get paid by the amount of the payload. You might not think almost 1,000# of extra weight makes that much difference, but 5-6 days a week, 2 loads a day, adds up to close to a quarter million pounds of weight that you could have been paid to haul.

I loved my Ford Louisville 9000 when I hauled motorcycles, I liked the comfort and the fact that the bank of gauges were set so that 3 o’clock when the gauge was normal, making it simple to scan them quickly. But it was heavy – to haul tanks the Peterbilt 359 can be built to be as lightweight as possible. Lighter is always more lucrative, even for hauling freight. Shippers like to put as much as possible in one truck.

What did you haul in Western NY? My dad hauled propane for AR Gundry in the late ’60’s – early ’70’s, and then paper and glass for into the early ’90’s for Cumberland Transport and JCD.

He tells stories about having a Brockway with a big Cat (at least I think it was a cat, I know it wasn’t a Detroit) so he could haul doubles on the Thruway and not get pulled over for going too slow.

Fuel Oil for a company that would not appreciate it if I mentioned them here. They were good to me, so I won’t.

No worries, I was just curious.

I knew I’d seen this concept explored somewhere before.

Is this real? Or is Coca-Cola doing some post-hoc astroturfing for damage control…

My dad used to tow for the International dealership in the 70s and 80s ill have to ask him about this.

What may have killed the Unistar was that if you had the front wheels turned and the rear drive axle lost traction, the front drive would kick in, get traction, and send you quicker than you wanted in the desired direction. As for the Jifflox, good idea but in practice it was hard to work and caused a lot of injuries to drivers who were trying to couple it and move the 5th wheels. Delta trucking in the Southwest was the major user of the Unistar, IIRC they also had some IH ConCos (another story for you) with the Unistart’s drive train.

Interesting read – but the irony of these lines does not escape me:

“…one of the downsides to a truck like the Unistar was the fact that, while the truck was a wintertime beast, you were carrying around an entire four-wheel-drive system the rest of the time. Of course, then there was the extra cost of maintaining that four-wheel-drive system”

Just like today’s CUVs and AWD cars – which cost too much to purchase and maintain?

the thing was compared to consumer vehicles commercial vehicles like this put on a lot more miles. More miles more cost less profit.

Yeah, not really an apples to apples comparison.

It’s the same issue, just magnified. AWD costs 3X – you pay more upfront, you pay more to maintain and fix it, and you pay more in fuel. The miles and usage of a commercial vehicle just makes it worse, so unless you need it pretty frequently, it doesn’t pay.

At this point, many if not most three axle highway tractors are only single-axle drive because it’s cheaper and more efficient. Only heavy haul, and trucks expected to spend a lot of time in the mountains or off-pavement even have both rear axles powered. There is no more rational buyer of a vehicle than a fleet manager.

Most trucks we build today are 4×6 but with the rear drive axle clutched so it only drives when the one in front slips.

You are correct that large fleet managers are very performance oriented. They only spend money things that save money. On the other hand the large margins are made on the individual buyers and small fleets that load their trucks up with chrome and larger than required engines.

The difference is people buy cars with their own money based on emotions, and will happily spend more for AWD systems that they don’t actually need because marketing told them to. Truckers, and especially truck companies, are mostly businesses that have to watch the bottom line, and have more incentive to not pay extra for something unless there’s a real benefit. The head-to-head test in article indirectly points out that the fancy 4×4 system didn’t actually do anything the ordinary truck couldn’t also do after installing much cheaper tire chains.