When I hear the term anti-lag, I usually think of top-tier rally cars spitting fireballs and the sound of dozens of firecrackers going off in quick succession. If you’re as obsessed with cars as I am, that’s probably what you think of as well.

But not all anti-lag systems are created equal. Ford showed off its new 2026 Mustang RTR today, and one of its selling points over the normal Mustang EcoBoost, aside from the bigger brakes, the extra steering angle, and the Dark Horse suspension, is the addition of an anti-lag system.

But Ford’s system, which has been in use by the company for nearly 10 years, is nothing like traditional anti-lag. Let me explain.

What Is Anti-Lag, Anyway?

When turbocharging became popular in race cars in the ’70s and ’80s, engineers needed a way to solve for the delay between throttle input and engine response. A turbocharger works by using an exhaust-driven turbine to spin a compressor on the other end of the turbine’s shaft — a compressor that builds up pressure in the intake, forcing more air into the engine.

As the turbocharger needs exhaust gases to spin the turbine to develop that pressure, building up that pressure results in a delay between when you press the throttle and when the engine delivers full power. That delay is commonly referred to as turbo lag.

Anti-lag systems, then, are any piece of tech, whether hardware or software, meant to counteract that lag. Here’s how Motor Trend defines it:

In a nutshell, it’s any of several means of eliminating or reducing the delay between opening the throttle and a turbocharger delivering meaningful torque. In other words, an antidote to turbo lag. They were essential in some homologated racing series where restrictor plates greatly exaggerated turbo lag.

This could mean any method of keeping the turbocharger spun while off-throttle, or, in the case of some newer systems, filling in that delay with instant electric torque.

Pick Your Poison

If you’re like me and love watching compilation videos on YouTube from obscure rally events in Eastern Europe, you’re probably most familiar with the traditional type of race-level anti-lag, also referred to as a secondary air system (SAS). This involves using separate plumbing from the intake to the exhaust manifold, directing air around the combustion chamber—i.e., sending fresh air directly into the exhaust pipe. That air now in the exhaust mixes with hot fuel from the engine’s exhaust gases to ignite, causing tiny explosions that keep the turbo spooled.

It’s important not to confuse such a setup with an emissions-based secondary air system, which uses a similar plumbing arrangement to inject air into the exhaust to ignite unburnt fuel before it reaches the atmosphere. From Hewitt Technologies:

It’s no secret that gas-powered engines aren’t 100% efficient. As a result, there is a portion of unburned fuel (hydrocarbons) that doesn’t get converted to engine power. This is particularly true on cold starts for two reasons. First, for more reliable starting, the fuel/air mixture is going richer in fuel. Secondly, it takes a couple of minutes for the engine and catalytic converters to get to operating temperatures.

These two factors combine to increase the amount of unburned fuel after a cold start. Thus, the purpose of the secondary air injection system is reducing hydrocarbon and carbon monoxide emissions that result from cold start conditions.

The always wonderful Engineering Explained has a great video showing how an SAS made for anti-lag works:

This type of anti-lag system is the one that creates all the pops, bangs, and exhaust flames you see on YouTube. It’s only usually found in race cars because it has some pretty significant drawbacks. Those explosions put a lot of extra stress on the exhaust manifold and the turbocharger; you’re essentially creating a combustion chamber inside the exhaust, which is not what exhausts are for. It’s also violently inefficient, as the system has to dump a ton of extra fuel into the engine to get that exhaust mixture to ignite.

A type of anti-lag system you’ll see on production cars involves no extra piping at all. Instead, the system uses the engine’s variable valve timing system to pull off a similar effect. From Motor Trend:

The simplest anti-lag systems require no external plumbing or hardware. Simply holding the throttle-by-wire open to admit excess air, then ordering a bit of late fuel injection, and massively retarding the ignition (to maybe 45 degrees after top-dead-center) does the trick. This causes the air-fuel mixture to ignite as or after the exhaust valve opens.

Now instead of pushing the piston down, the products of combustion expand in the exhaust. This keeps the turbo spooling and delights onlookers with pops and fire-belches. As soon as the driver drops the hammer again, fuel injection and spark timing return to normal and the car charges off with a full head of turbo boost.

A good example of this system in action is Hyundai’s lineup of gas-powered N cars, which uses it to great effect to produce the crackles and pops those cars are known for (and to keep the turbos spooled, of course).

Like I mentioned earlier, more modern interpretations of anti-lag involve electric assistance. Though they don’t act on the turbocharger itself, electric motors have long been used in performance cars to “torque-fill” an engine’s power delivery, using the instant twist that electric power provides to “fill” in the delay from the turbocharger spool (think cars like the McLaren P1 and more recently, the Aston Martin Valhalla). While it’s nothing like the race-bred anti-lag of the ’80s, it’s still considered a type of anti-lag, since it targets the same problem.

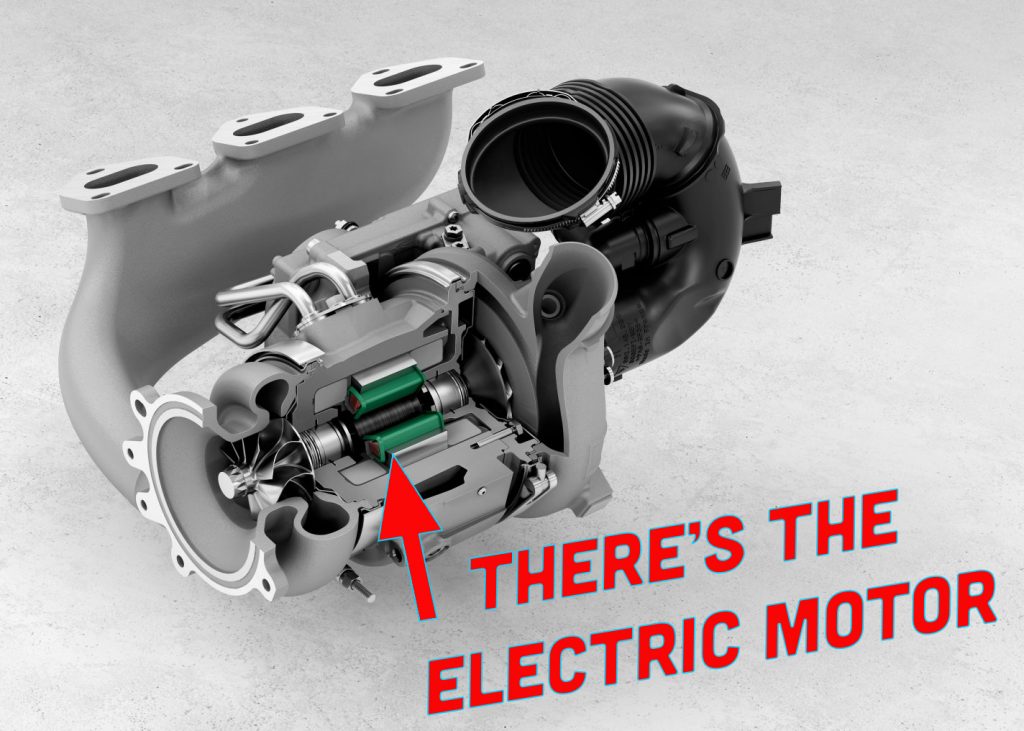

Recently, some brands have taken an even more complex approach by adding electric motors to the insides of the turbos themselves. Commonly referred to as electric turbocharging, brands like Mercedes and Porsche integrate an electric motor between the compressor and exhaust side of the turbocharger, allowing it to spin up on command of the ECU, rather than having to rely on exhaust gases alone. This means the turbos can deliver an essentially instant response when the driver pushes the throttle down, rather than having to wait for the exhaust gases to build up.

How Is Ford’s Different?

Ford’s version of anti-lag doesn’t use any sort of electrical assistance. In fact, the brand’s been using it since before that sort of tech became mainstream. The company’s patent for the system was first filed in 2016, and according to Ford, it first appeared on its Ford GT Le Mans race car. It’s since been implemented in production cars like the GT, the Bronco Raptor, the Ranger Raptor, and now, the RTR.

Ford’s system is a sort of mix between the traditional-style SAS anti-lag and the more modern timing-based anti-lag systems seen in the Hyundais I mentioned earlier. It uses some of the same ideas, but does so in a way that doesn’t absolutely tank the car’s fuel economy or emissions. Here’s how Ford explains it in the Ranger Raptor’s Australian press release:

It works when the driver’s foot comes off the throttle pedal (when the vehicle is in Baja mode) by keeping the throttle open (for up to three seconds) this keeps the turbocharger primed by operating the engine like a big air pump. Because the turbines/compressors are already spinning, the time to boost (provide power) when the throttle pedal is pressed again is minimal.

So basically, the system uses the cylinders to keep compressed air moving through the engine to the turbocharger, resulting in sustained boost pressure, even after the throttle is lifted. It does this by adjusting the engine’s timing so that there’s valve overlap (where the intake and exhaust valves are open at the same time) to let that compressed air pass through. But, being a press release, this only explains about half of what’s going on when the anti-lag system is active.

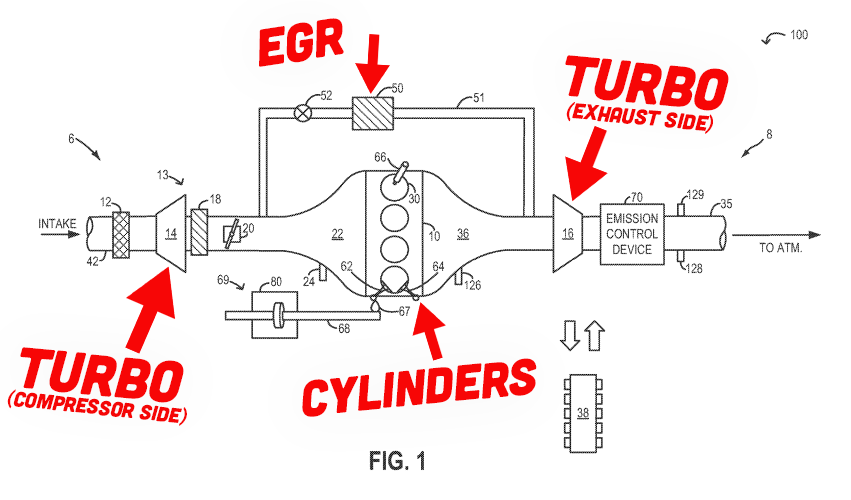

In Ford’s setup, there’s another piece of the engine that’s also directing intake air into the exhaust: the exhaust gas recirculation (EGR) valve. Normally, this valve, a common emissions feature on most modern cars, works in the opposite direction, moving exhaust gases to the intake through a series of pipes in the engine bay to lower the amount of harmful nitrogen oxides and carbon dioxide emissions coming from the tailpipe. [Ed Note: Fun fact: I once heard when I worked as an engineer that one of the main benefits of EGR is that sending inert exhaust gases into the intake allows the throttle to remain farther open for a given amount of intake air/load. A farther-open throttle yields fewer pumping losses, and thus a more efficient engine. How much of a difference this actually makes, I do not know. -DT].

EGR valves are widely hated by the car community because when they fail, they usually cause a check engine light to come on, despite not having a huge impact on engine performance, and they’re usually expensive to replace. But Ford has cleverly realized it can make the EGR act like a secondary air system, pathing the compressed air directly to the exhaust, where it can keep the turbo spooling.

Ford calls the combination a “blow-through air delivery” system, and though it never explicitly mentions the term anti-lag, it does say the system was designed for reducing turbo lag. Here’s how the company explains it in the patent:

[T]he method comprises, directing intake air from an intake manifold, downstream of a compressor, to an exhaust manifold, upstream of a turbine via each of external EGR and positive valve overlap through a cylinder, wherein amounts of air directed via EGR and air directed via positive valve overlap are adjusted based on conditions. In this way, intake air can be directed to the exhaust manifold to rapidly increase exhaust pressure without degrading engine performance.

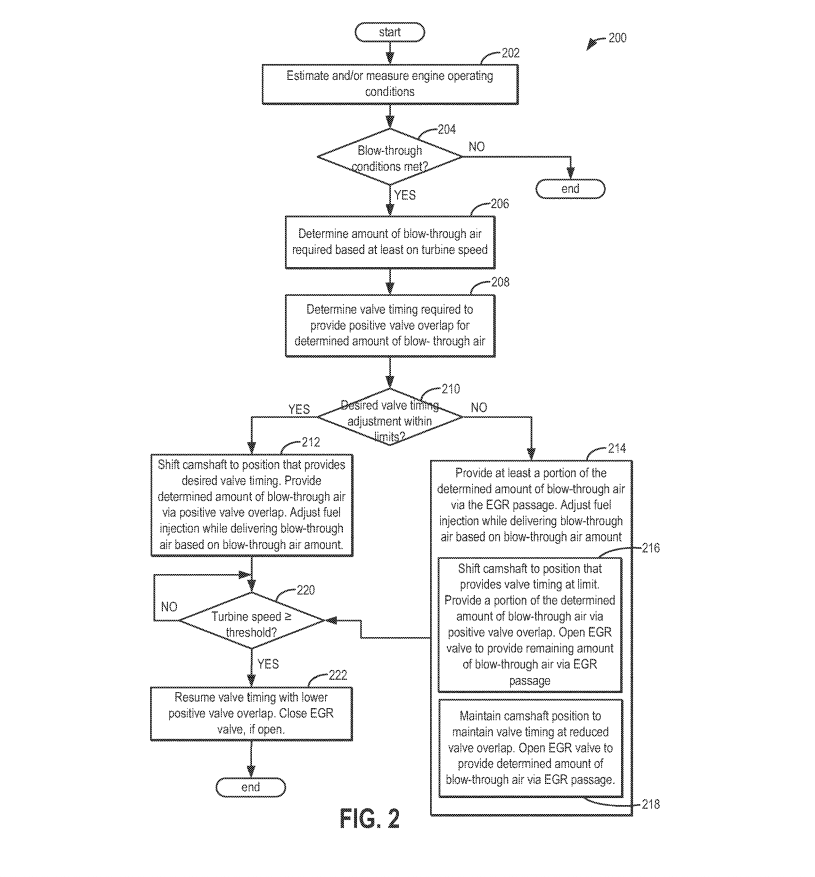

The patent explains that a sensor mounted to the turbocharger measures the speed of the turbine. If the turbine speed is too low (a.k.a., when it’s not spinning quickly enough to provide boost), the computer adjusts timing to activate the system, pumping compressed air through the cylinders. If there’s a scenario in which such an adjustment “degrades engine torque output and combustion stability,” the computer will start using the EGR to feed air into the exhaust as well. Here’s how the car determines when to do what:

Ford’s system uses a similar alternate pathway method as you’d find in race-level anti-lag here with the EGR system, and also pulls a similar strategy from modern anti-lag systems like those found in Hyundais, with regard to its timing-based method. But unlike either of those methods, there’s no extra fueling involved. From that Ranger press release:

While some systems rely on spark and excess fuel to keep the turbochargers spooled this can cause high heat and excess fuel consumption, the Ranger Raptor’s anti-lag system doesn’t. Rather, with Ranger Raptor the fuel injectors are kept idle during the anti-lag process to reduce heat build-up in the turbochargers, and then resume normal operation when the throttle pedal is pressed.

This is what makes Ford’s system viable for use in road cars. If Ford were dumping a bunch of excess fuel to ignite the exhaust gases, it would greatly hamper fuel economy and spike the car’s emissions. Instead, Ford is smartly using some emissions-related gear already onboard—the variable valve timing and the EGR valve—to develop an anti-lag system that makes its cars more fun. That’s clever engineering at work.

Top graphic images: Ford / USPTO

How does Ford reverses flow of EGR at idle, at vacuum that sucks exhaust gassesa into intake, to make its anti Lag work though?

It probably is just marketing

The thing I hated about EGR on my Jetta TDI was that it resulted in a nearly completely carboned/blocked intake manifold.

None of this makes up for not giving a “drift” car a proper manual.

If enough people wanted them, they would get them.

I have a manual V6 Mustang that I bought new, so I put up my money on a base engine manual Mustang and would have again. But if the take rate can’t justify an ecoboost manual then don’t make this poser faux “drift” car that is just going to cause more cars and coffee wrecks. My ID.4 commuter car with a fuse pulled is more of a drift car.

Fun little side track:

The anti-lag system is often offered by tuners here in the lowlands as ‘pops and bangs’. It has nothing to do with performance or gearheads. These sounds are used as the soundtrack of a drug dealing team. (Like the song on an icecream van.)

In major cities like Brussels or Antwerp, mostly exclusively Mercedes A-classe drive around slowly while making obnoxious exhaust noise. This alerts the many drug users on the street. Secret signs are given. Money is secretly exchanged. And moments later, a drug mule, mostly a minor on a share scooter, randomly drops something on the street.

Crucially, the luxurious but obnoxious cars occupants have done nothing against the law. No drugs or money in the car. Just difficulty explaining how they can pay for it (it’s my uncles…). The car is mostly driven slow and careful, to avoid doing anything illegal.

The money system is divers and digital. Difficult to track and impossible to shut down.

The only persons that can be detained were the minors on the share scooters. But these are often kids (like 12yo) and the quantities of drugs per person are minute. So they don’t go to jail.

It’s such a perfect, elegant system. I almost whish to be part of it myself.

But as it stands, not me nor any of my friends want anything to do with this kind of anti-lag system.

So anti lag is stopping you? Not the child exploitation? Ok…

You forgot to make a point.

Kudos on the thorough explanation on the EGR valve.

This explanation, along with the implication of the Ford system, is antidode to the EGR-delete movement.

A correctly working EGR-valve does clean up exhaust, has the potential to lower fuel consumption and, in this case, lower lag.

I still don’t get it how it reverses flow of EXHAUST GAS Recirculation valve to become Fresh Air BYpass valve at idle, while there is vacuum

This is really clever tech and a great write up on it!

“When I hear the term anti-lag, I usually think of top-tier rally cars”

I used to think of the same. Now I live in Vermont, where the ‘ant-lag’ backfires of clapped out Subarus, along with the whine of turbo diesel pickups spooling up, are the soundtrack of every Friday night.

Yeah I have some neighbors whose turbos can be heard inside my house with the windows closed (nevermind the antilag rattles and bangs when they lift off the throttle as they approach the curve in the road)

“EGR valves are widely hated by the car community because when they fail, they usually cause a check engine light to come on, despite not having a huge impact on engine performance, ”

Any emissions system failure has to light the check engine light, it’s a legislation thing.

The EGR and throttle opening thing is partially true. EGR was introduced before drive by wire, and was vacuum-operated. The truth is that intake plenum vacuum is basically a direct measurement of throttle body pumping loss. When the throttle body closes, the engine has to work really hard, and is trying really hard, to squeeze air through that gap. What EGR does is introduce inert gases downstream of the throttle body, reducing that vacuum. That results in lower pumping losses because less air is shoved through the throttle body, not because the throttle body is more open. It effectively behaves as if the T/B was open though, as the volume of air (intake+egr) being ingested on the intake stroke is about the same as you’d get with the throttle plate open. Not only does the intake flow less air through the throttle plate, but the air recirculated from the exhaust also means there’s marginally less air going through the ctalyst, muffler etc, reducing noise and pumping loss on the exhaust side as well (marginally).

Fun fact: There are no pumping losses during the compression and power stroke, because even without a spark, the compressed air just bounces back, pushing the piston back down and effectively returning the energy that was put into compressing it. That’s why engines with piston deactivation close all the valves of the inactive pistons instead of opening them, because with the valves open, air rushing past the valves would be dissipating that energy as noise, causing power and efficiency loss.

How does Ford reverses flow of EGR at idle, when vacuum sucks exhaust in, to make its antiLag work though?

It probably is just marketing

That’s totally possible with modern EGR. Much like other systems that were vacuum-operated at their time of introduction, many modern EGR systems are electronic instead. To operate in reverse, all it takes is an intake manifold that’s under boost of higher pressure than the exhaust manifold.