A few months ago, a Jeff Bezos-backed newcomer in the car world, Slate Auto, got the world’s attention by debuting a dirt-cheap electric pickup truck. I had my concerns about it, namely, I thought it had too few doors and was too expensive given its lack of features. Well, if the Slate got your blood flowing, it’s time to get even more excited, because an established automaker — one with manufacturing experience and economies of scale that a newcomer lacks — says it’s planning a $30,000 electric four-door pickup truck. And it’s only a small part of a massive $5 billion investment from the Blue Oval brand. Here’s what we know about Ford’s “Model T Moment,” its new “affordable” EV platform.

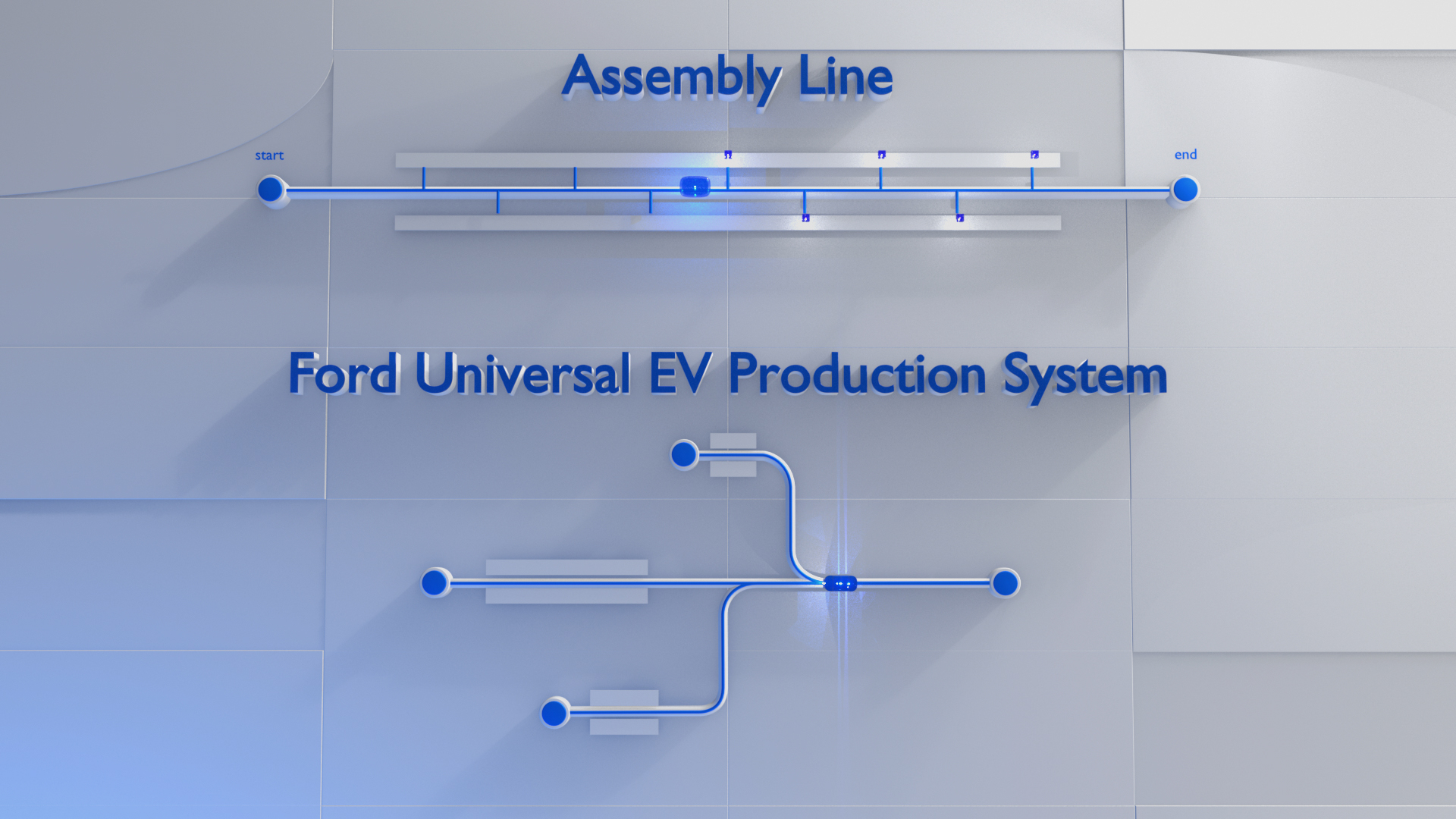

If you’re been “in the loop,” you know Ford Motor Company has had a Skunkworks team working on some kind of “secret” project in the Bay Area. What exactly is it? We never knew for sure, other than that it almost certainly had something to do with electric cars, given that it was happening in California. Well, it turns out, that Skunkworks team was mapping out the future of Ford Motor Company as we know it by developing not just a new platform, but a new production system that is a bit different than the linear assembly line that built Ford in the early 20th century.

In a “bold and difficult undertaking to compete with the best in the world,” i.e. China, Ford has developed the Ford Universal EV Platform, “a simple, efficient, flexible ecosystem [meant] to deliver a family of affordable, electric, software-defined vehicles – the first of which is a midsize, four-door electric pickup that will be assembled at Ford’s Louisville Assembly Plant for U.S. and export markets. Its launch is scheduled for 2027,” as FoMoCo says in its press release.

The company’s CEO, Jim Farley, reiterates the Universal EV Platform’s emphasis on affordability, saying in the press release:

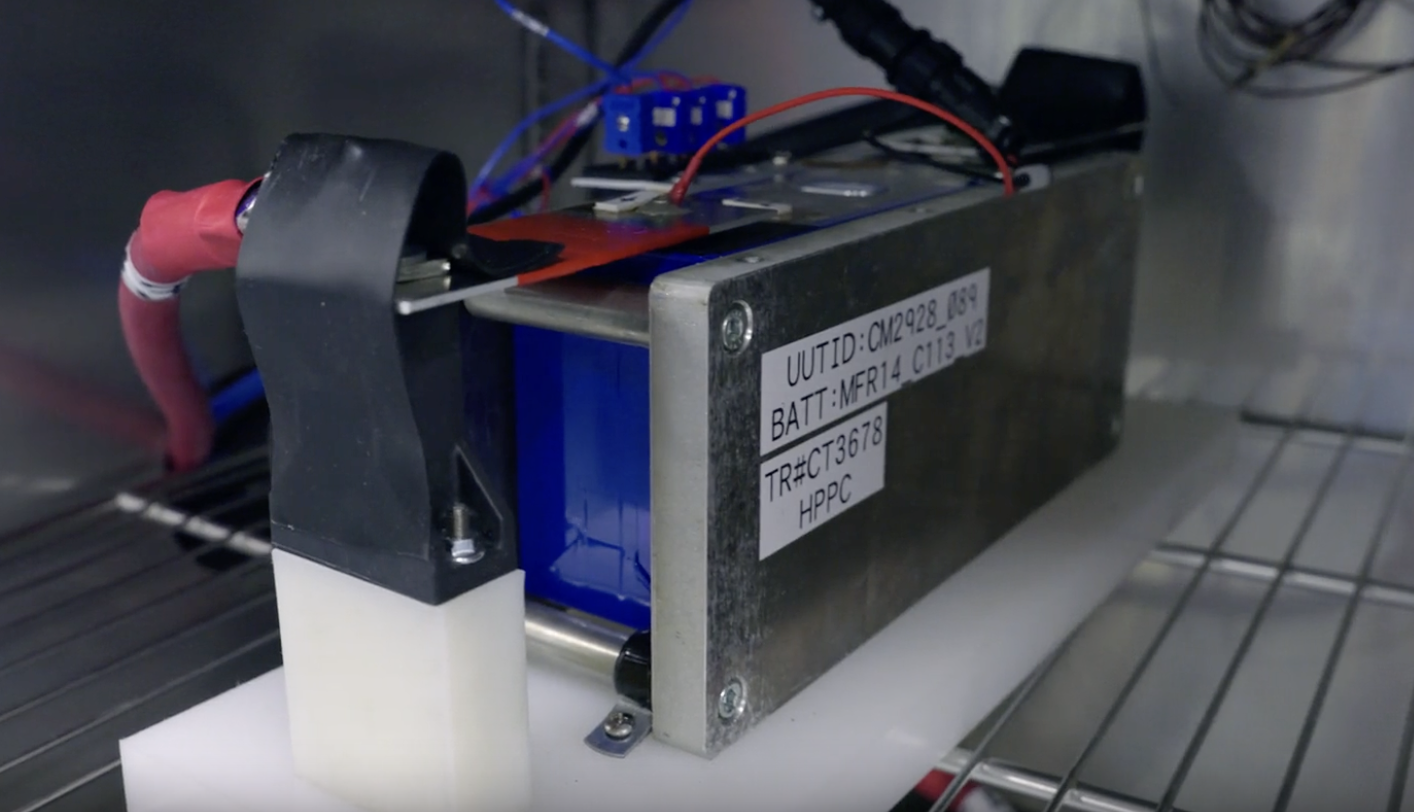

“We took a radical approach to a very hard challenge: Create affordable vehicles that delight customers in every way that matters – design, innovation, flexibility, space, driving pleasure, and cost of ownership – and do it with American workers,” said Ford President and CEO Jim Farley. “We have all lived through far too many ‘good college tries’ by Detroit automakers to make affordable vehicles that ends up with idled plants, layoffs and uncertainty. So, this had to be a strong, sustainable and profitable business. From Day 1, we knew there was no incremental path to success. We empowered a tiny skunkworks team three time zones away from Detroit. We tore up the moving assembly line concept and designed a better one. And we found a path to be the first automaker to make prismatic LFP batteries in the U.S.”

Launching a new modular EV platform is hardly novel, and in fact, Ford has been well behind others like Volkswagen (whose MEB platform debuted roughly seven years ago), GM (whose Ultium architecture underpins a bunch of GM vehicles like the Equinox and Blazer EV, as well as non-GM vehicles like the Honda Prologue and Acura ZDX), Hyundai/Kia (whose e-GMP 800v architecture that underpins the Hyundai Ioniq 5 and Kia EV6 has been out for about five years), and on and on.

But when I asked Ford how its architecture is different, it replied by saying “it really goes beyond a modular architecture,” saying the reduction in wiring and fasteners, plus the use of unicastings, makes this a more modular approach than elsewhere in the industry.

I’m tempted to say “its’ about time,” but Ford’s slow roll-out of EVs — its F-150 Lightning that was largely based on the existing gas truck and thus managed to get to market early, as well as a crossover EV named the Mustang — wasn’t necessarily a bad thing, as the world has clearly been clamoring more for hybrids than for EVs, of late. Still, EVs are the future, and to truly compete long-term, you’ve got to build a modular platform, so that’s what Ford has done. Here are some of the benefits of Ford’s new modular architecture and of its “affordable” in-house LFP prismatic batteries, per the automaker:

The platform reduces parts by 20% versus a typical vehicle, with 25% fewer fasteners, 40% fewer workstations dock-to-dock in the plant and 15% faster assembly time. Lower cost of ownership over five years than a three-year-old used Tesla Model Y.

Take for instance the wiring harness in the new midsize truck; it will be more than 4,000 feet (1.3 kilometers) shorter and 10 kilograms lighter than the one used in our first-gen electric SUV. Lithium iron phosphate (LFP) prismatic batteries also enable space and weight savings, while delivering cost reduction and durability for customers. The platform’s cobalt-free and nickel-free LFP battery pack is a structural sub-assembly that also serves as the vehicle’s floor…The new midsize truck is forecasted to have more passenger room than the latest Toyota RAV4, even before you include the frunk and the truck bed. You can lock your surfboards or other gear in that bed – no roof rack or trailer hitch racks required.

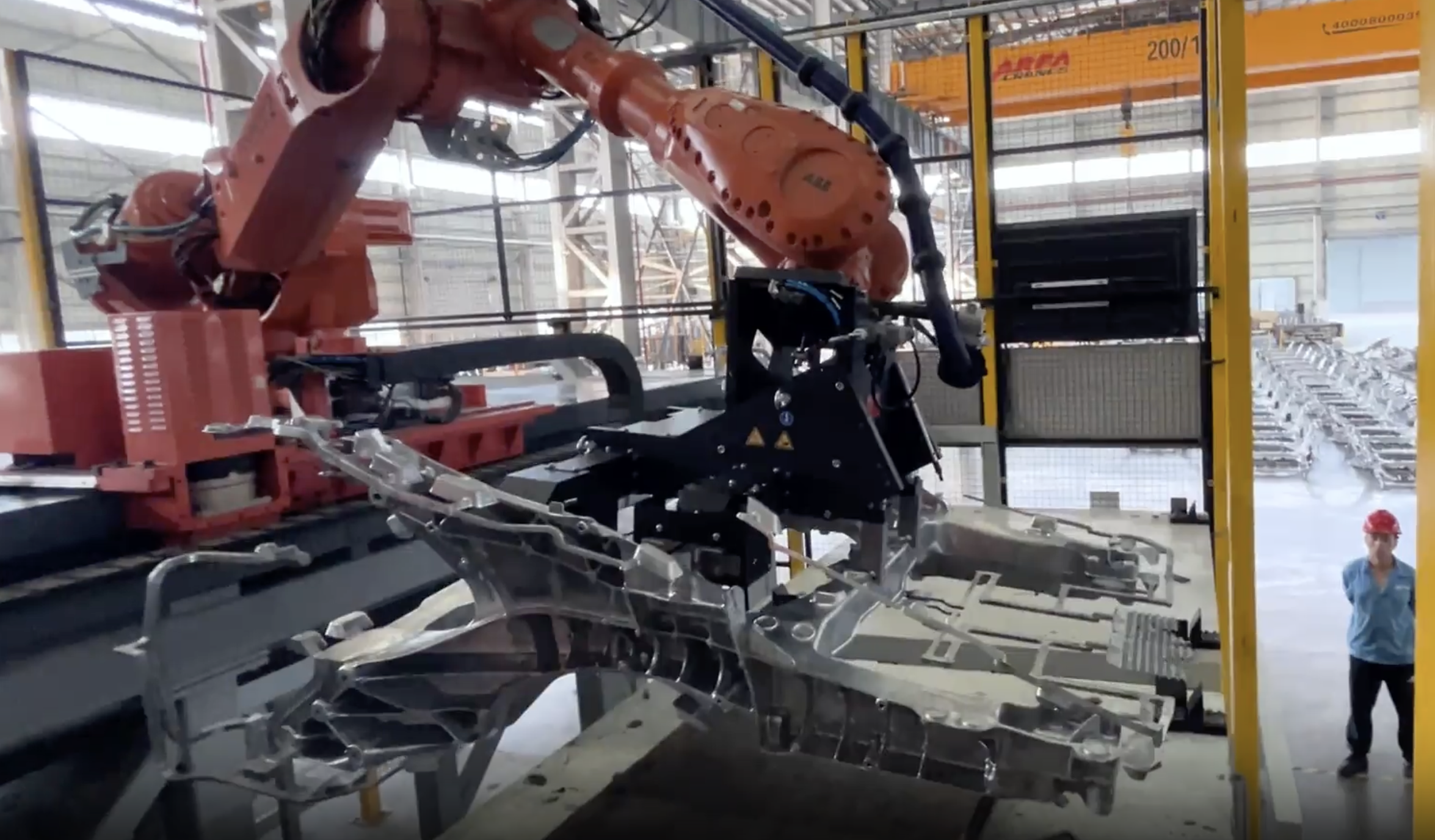

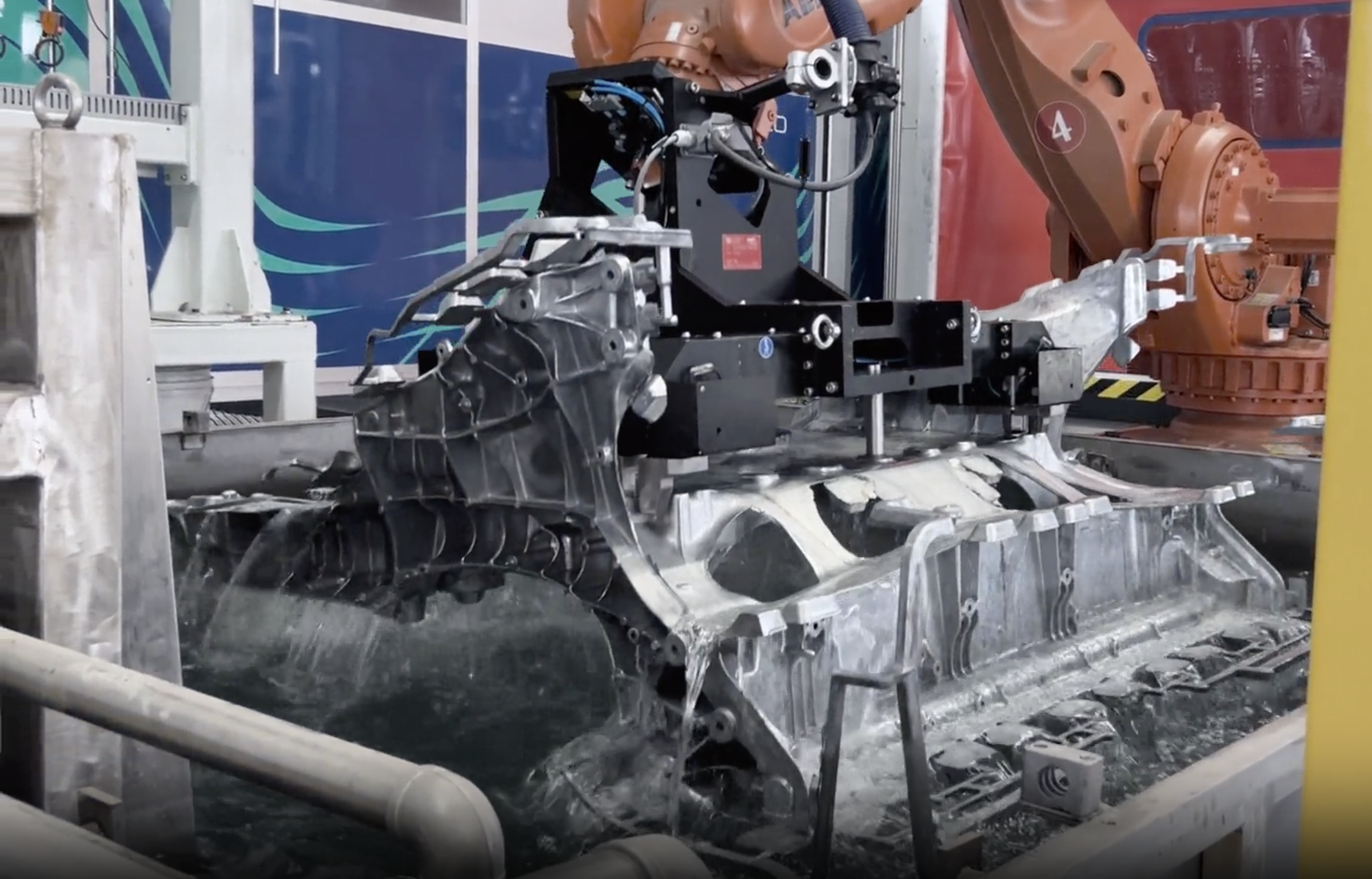

Ford talks about large “unicastings” (like Tesla’s gigacastings), and how its team plans to build sections of its vehicles independently, and then bring those sections together — in much the same way as a front subframe is “decked” with a body on a traditional car, except with three large subassemblies. From Ford:

Large single-piece aluminum unicastings replace dozens of smaller parts, enabling the front and rear of the vehicle to be assembled separately. The front and rear are then combined with the third sub-assembly, the structural battery, which is independently assembled with seats, consoles and carpeting, to form the vehicle.

Parts travel down the assembly tree to operators in a kit. Within that kit, all fasteners, scanners and power tools required for the job are included – and in the correct orientation for use.

The Ford Universal EV Production System dramatically improves ergonomics for employees by reducing twisting, reaching and bending, allowing them to focus on the job at hand. Because of the integration between the Ford Universal EV Production System and Platform, assembly of the midsize electric truck could be up to 40% faster than Louisville Assembly Plant’s current vehicles.

Some of that time will be reinvested into insourcing and automation to improve quality and cost, ultimately netting a 15% speed improvement. “We put our employees at the center and re-created the factory from scratch,” said Bryce Currie, Ford vice president, Americas Manufacturing. “We live and breathe continuous improvement, but sometimes you need a dramatic leap forward. We expect ergonomic breakthroughs and complexity reduction – through elimination of parts, connectors and wire – will flow through to significant quality and cost wins.”

Here’s a look at Ford’s “production tree”:

The architecture is a 400V one, with Ford saying “We think that is absolutely the right choice,” as it enables low cost and access to the existing charging infrastructure. When I asked whether the platform has provisions for a range extender, Ford replied with “We’re not gonna get into specifics.”

As for what more we know about that midsize truck? Not a ton. Ford says it will be aerodynamic to the point where, if the company put its battery into an existing truck of roughly the same size, the range would drop by 50 miles compared to the upcoming vehicle. In addition, Ford says EV will have a 0-60 mph acceleration time similar to a Mustang EcoBoost (~4.5 seconds), and then the press release seems to maybe include a subtle dig at Slate Auto: “We assembled a really brilliant collection of minds across Ford and unleashed them to find new solutions to old problems. We applied first‑principles engineering, pushing to the limits of physics to make it fun to drive and compete on affordability. Our new zonal electric architecture unlocks capabilities the industry has never seen. This isn’t a stripped‑down, old‑school vehicle.”

Maybe that wasn’t a dig, but why mention that this isn’t a stripped-down vehicle? I mean… who would think a modern EV is a stripped-down vehicle if not for the existence of Slate?

Anyway, the mid-size truck is to be built at the Louisville Assembly Plant, which will see a $2 billion investment that, when combined with Ford’s $3 billion investment in its Michigan battery factory, will total $5 billion and allegedly create 4,000 jobs.

Ford says in reference to the Ford Maverick hybrid pickup: “We believe there’s room for both.”

Ford calls this new platform and manufacturing method a “Model T moment,” which is fair to say, as this represents a major shift for the company. At the same time, I’ll be interested in seeing if it’s really that different than what we’ve seen from the competition. GM makes its own batteries, it’s focusing heavily on affordable LFP batteries to bring EV pricing down, and it’s got an architecture malleable enough to build a variety of vehicle types across a variety of brands.

But it doesn’t have a $30,000 four-door pickup truck. Nobody does right now, so if Ford can be first, and if that truck can offer decent range and decent tech, it could be a game-changer in its own right, worthy of Ford’s new “The Universal Vehicle” badge you see above.

All Images: Ford

Auto, truck and motorcycle PR teams have writers breathlessly chasing the laser pointer like a bunch of desperate cats when it comes to anything EV. Nothing but “we’re going to build something sometime maybe maybe maybe…” but please write about it like it’s really going to happen this time. Everyone knows an in-your-driveway 30K electric pickup is totally impossible and that’s why all the important info is not available. Always going but never gone. Meow, meow.

Next week Ford will be recalling its Model T moment announcement.

Well I hope it is a successful project.

In my view, variations of this new BEV platform could be used for ALL Ford vehicles. And essentially Ford can go back to the days where they made a bunch of different vehicles off of one basic chassis and powertrain.

And in theory, this could greatly simplify Ford’s vehicle manufacturing and theoretically, greatly reduce their costs in the long run.

But there are a lot of big ‘IFs’ going on here.

Well…..good luck with that!

No renders, no pictures, a whole lot of “trust us, we’ll do it.” For all the hype I was expecting a lot more from this unveiling, at least give us some renders or something.

At least Slate and Telo have actual running models…

I agree. This is cool news, but if you’re going to call something your “next Model T moment” give us a render or three.

I’d rather have a “VAN DOWN BY THE RIVER!”

RIP SLATE…we hardly knew ye

Ford didn’t even show anything, at least Slate has trucks that sort of drive around. I was hoping for at least some renders.

I agree, they should have shown some kind of rendering at least.

They will repeatedly delay the $30,000 base model, all the early stock that makes it to dealerships will be in the $40,000-$60,000 range before adjusted markup. The base model will eventually start limited production nearly a year after launch, they will build a few thousand of them, then quickly discontinue it due to some unspecified production or supply chain issue, and pressure anyone who ordered one to upgrade to a higher trim

It’s almost like we’ve seen this exact same scenario before! I hope you’re wrong, but I doubt it.

I agree Ranwhenparked is right. I would bet the Ranchero on it.

The buffing is maybe another dig at Slate? Slate is going to rely on wraps, while Ford is going to actually paint?

Remember when the maverick was a 20k hybrid? Pepperidge Farm Remembers.

As much as I applaud this effort there doesn’t really seem to be anything ground breaking about it and at this point it’s vaporware chasing a price point that you can pretty much already hit with a equinox ev.

The slate is a purpose built device for socal surfers that realize they can’t run their pool cleaning business on a super 73 – I don’t think the demand between these two will cross over too much.

USSteel is going to be hard at work trying to re-design those complicated aluminum castings with steel stamped parts, like the Dodge Brothers intended. (first all steel car body: Dodge). swap ’em in, save on expensive aluminum, get money. those california boys don’t understand the glory of modern high strength steel alloys.

“those california boys don’t understand the glory of modern high strength steel alloys.”

– Rust enters the chat

are you wondering how you know legacy automakers are scared of Slate? this is how you know.

per another comment but in the opposite direction: “mount the seats on the battery and bolt into the chassis from the bottom” … this sounds suspiciously like the first era mustang’s idea of “let’s make the bottom of the trunk the same as the top of the gas tank,” which turned out to be not such a good idea.

“per another comment but in the opposite direction: “mount the seats on the battery and bolt into the chassis from the bottom””

To me it sounds more like what Tesla is currently doing with the Model Y and the Y’s structural battery pack.

I’m into this! Currently have a Telo truck reservation. But would likely pull the trigger on this if I can fit a full sheet of plywood in the back with the tailgate closed. Will likely have better warranty and long term support than the Telo.

Sorry Nick. No chance this gets an 8’ bed. The powers that be have decided there will only be 4-door pickups from this point forward, and all us guys who just want a reasonable small standard cab truck with a full size bed don’t count. Good luck with the Telo!

I was thinking it might have the mid-gate, like the Telo. Or that they’d work out some other sort of magic.

Ford and warranty, there is a joke there.

Not a car? I’m done. $30,000? My Aunt Fanny! Dealers will happily pile on a $10,000 + premium and Ford will say, “Oh no. You shouldn’t do that.” Nudge, nudge. Wink, wink. Sorry to be a cynic, but this is everything I hoped it wouldn’t be.

The “mount the seats on the battery and bolt into the chassis from the bottom” trick is the only cool thing about the Cybertruck, and I’m very glad to see Ford adopting it.

Tesla did it first with the Model Y.

And yes, I’m glad Ford is adopting ideas like that too.

Interesting, but besides the possibility Ford is cutting corners too deep somewhere to reach a price point its dealers will happily slap a $10K market adjustment on, what’s unfortunate about that Ford “The Universal Vehicle” video is not once did its modular EV platform video take on a sedan shape. Screw you, Ford!

Can someone please build an “affordable” EV sedan/wagon/coupe with a decent trunk? Maybe we sedan aficionados will be forever stuck in the ICE age, choosing from a dwindling selection of new or used sedans.

Yeah there are (sadly) very few options for an ev car in the US Market.

New there’s the

Tesla Model 3

Hyundai Ioniq 6

Nissan Leaf

And that (I think) is it.

If you are OK with slightly used the Ioniq6 in SE trim and the big battery pack w/363 miles of range and has excellent 800v fast charging, though may be impacted by the iccu defect

Tesla model 3 could be a great choice, though real world range is maybe 240 miles max at 70 mph and of course have their own issues some that I did “not-see” coming

And the Leaf is very limited in recharging making it basically a commuter / city car but that may work for you And a new Leaf based on the Arya is supposed to be coming out for 2026

“World’s attention” is a big exaggeration. In the same space as NFL team that wins a Superbowl is a World Champion. And only America is pick up obsessed.

Cool, but… eye roll… another pickup. Of course it’s a pickup. UGH. Thanks… I guess.

Have we not yet learned that people expect to do, y’know, TRUCK things with a truck, and that EV trucks aren’t great at TRUCK things? Sheesh.

Plus, I’m not sure I trust the Kings of Recalls to do anything right. Ever since quality went from Job 1 to Job 57,852, they’ve botched pretty much every vehicle launch.

Also, let’s see if there’s a non-stopper model available at $30k when it finally hits the streets.

“Have we not yet learned that people expect to do, y’know, TRUCK things with a truck”

Not really:

https://www.ford-trucks.com/articles/study-finds-that-most-light-duty-pickup-owners-dont-tow-heavy-loads/

https://www.insidehook.com/autos/pickup-truck-owners-admit-dont-need-trucks

Ok, but will it come in a 2 door version?

No. It also will not have a manual transmission

Someone’s gonna have to come up with a ute conversion kit. Kinda like how the first crewcabs were coachbuilt, but the opposite.

No, and it will cost $40,000 too. Pray Ford does not alter the deal further.

Ok but if they name it the Ford Vader or Skywalker I’ll buy one.

So they think there’s room for both, when for years they thought there was room for zero small(ish) trucks?

Yikes, they are really fighting to revitalize Henry Ford’s legacy (and Elon’s market share) by incorporating the N*zi eagle into their new* logo.

*apparently not new, its a reworking of the original logo. I still say avoid anything that looks remotely like fascist imagery

Looks nothing like the Nazi war eagle. The eagle is incorporated into many logos including the Great Seal of the United States. Ford’s use of an eagle predates NAZI use by twenty-something years.

That’s a callback to the 1912 emblem: https://www.thehenryford.org/collections-and-research/digital-collections/artifact/100255/

It’s a triangle. Perhaps an Illuminati conspiracy would make more sense here.

This is along the lines of ‘The Nazis drank water therefore everyone who drinks water is a Nazi’ type logic.

It’s a fucking bird. It doesn’t even have the arms necessary to do a Nazi Salute FFS.

Its a bird, its a plane, its a Nazi emblem! Okay, fine, I acknowledge my bad take, I’m wrong. The bird still gives me bad vibes, and when I think of Henry Ford, I think of Nazis for some reason.

Henry Ford was an antisemite, so that’s probably why.

Most American’s were antisemites and believed that America had a “Jewish problem” – Henry Ford was not an anomaly. I think it’s a misdirection to call him out because it allows us to avoid the deeper recognition of the challenges of the time.

Oh.

Ford , when will you learn? I’ve heard this song-and-dance before with a Ford.Maverick pick up truck by the time the dealers get ahold of it.It’s double the promised price. I see a merger with v w in the near future.

The Maverick is selling 3x the original expected volume.

And at over 1.5x the original price.

Which is great for Ford. More sales with at a higher profit.

“stripped down vehicle” could also be in reference to Tesla