A few months ago, a Jeff Bezos-backed newcomer in the car world, Slate Auto, got the world’s attention by debuting a dirt-cheap electric pickup truck. I had my concerns about it, namely, I thought it had too few doors and was too expensive given its lack of features. Well, if the Slate got your blood flowing, it’s time to get even more excited, because an established automaker — one with manufacturing experience and economies of scale that a newcomer lacks — says it’s planning a $30,000 electric four-door pickup truck. And it’s only a small part of a massive $5 billion investment from the Blue Oval brand. Here’s what we know about Ford’s “Model T Moment,” its new “affordable” EV platform.

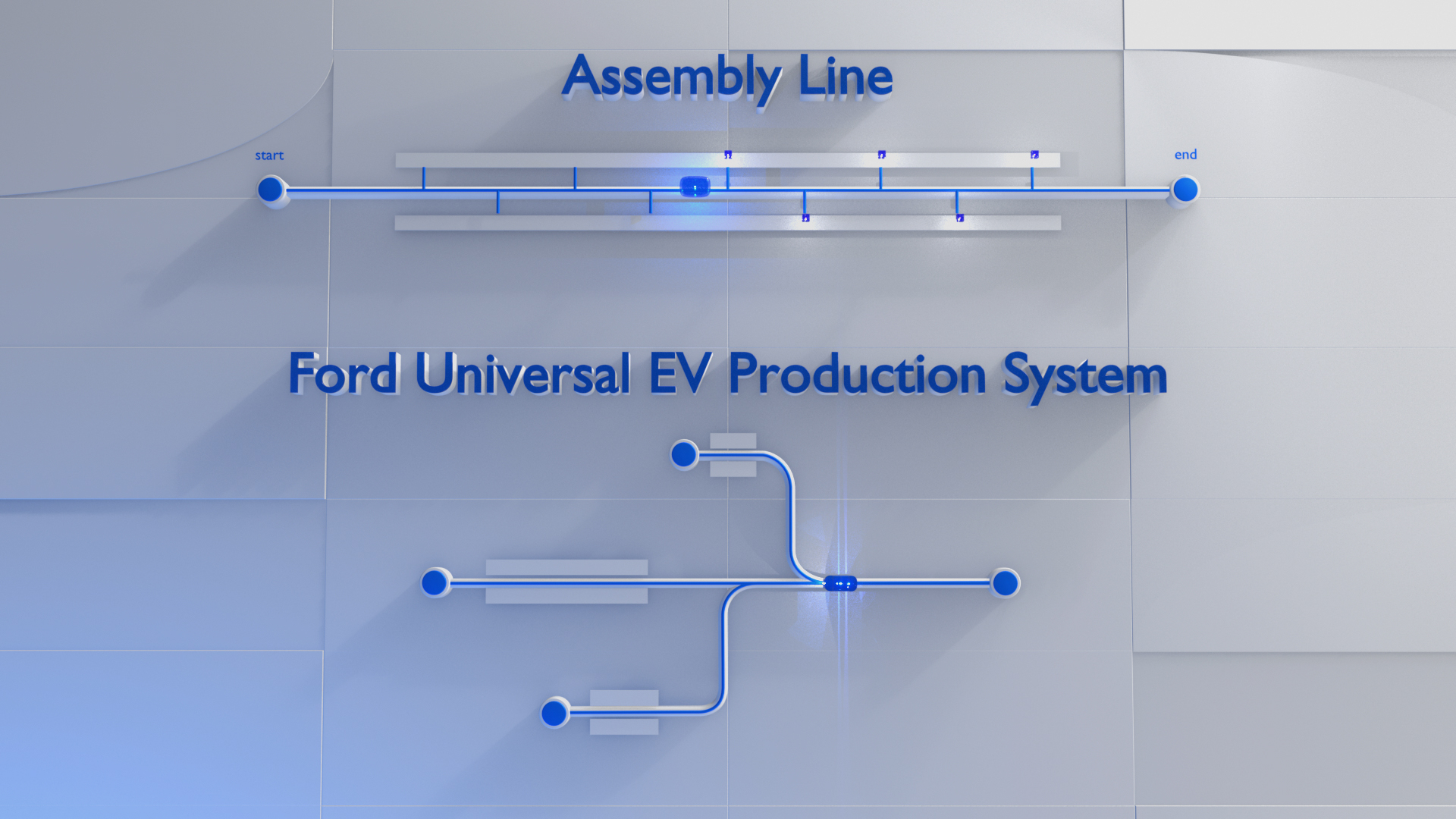

If you’re been “in the loop,” you know Ford Motor Company has had a Skunkworks team working on some kind of “secret” project in the Bay Area. What exactly is it? We never knew for sure, other than that it almost certainly had something to do with electric cars, given that it was happening in California. Well, it turns out, that Skunkworks team was mapping out the future of Ford Motor Company as we know it by developing not just a new platform, but a new production system that is a bit different than the linear assembly line that built Ford in the early 20th century.

In a “bold and difficult undertaking to compete with the best in the world,” i.e. China, Ford has developed the Ford Universal EV Platform, “a simple, efficient, flexible ecosystem [meant] to deliver a family of affordable, electric, software-defined vehicles – the first of which is a midsize, four-door electric pickup that will be assembled at Ford’s Louisville Assembly Plant for U.S. and export markets. Its launch is scheduled for 2027,” as FoMoCo says in its press release.

The company’s CEO, Jim Farley, reiterates the Universal EV Platform’s emphasis on affordability, saying in the press release:

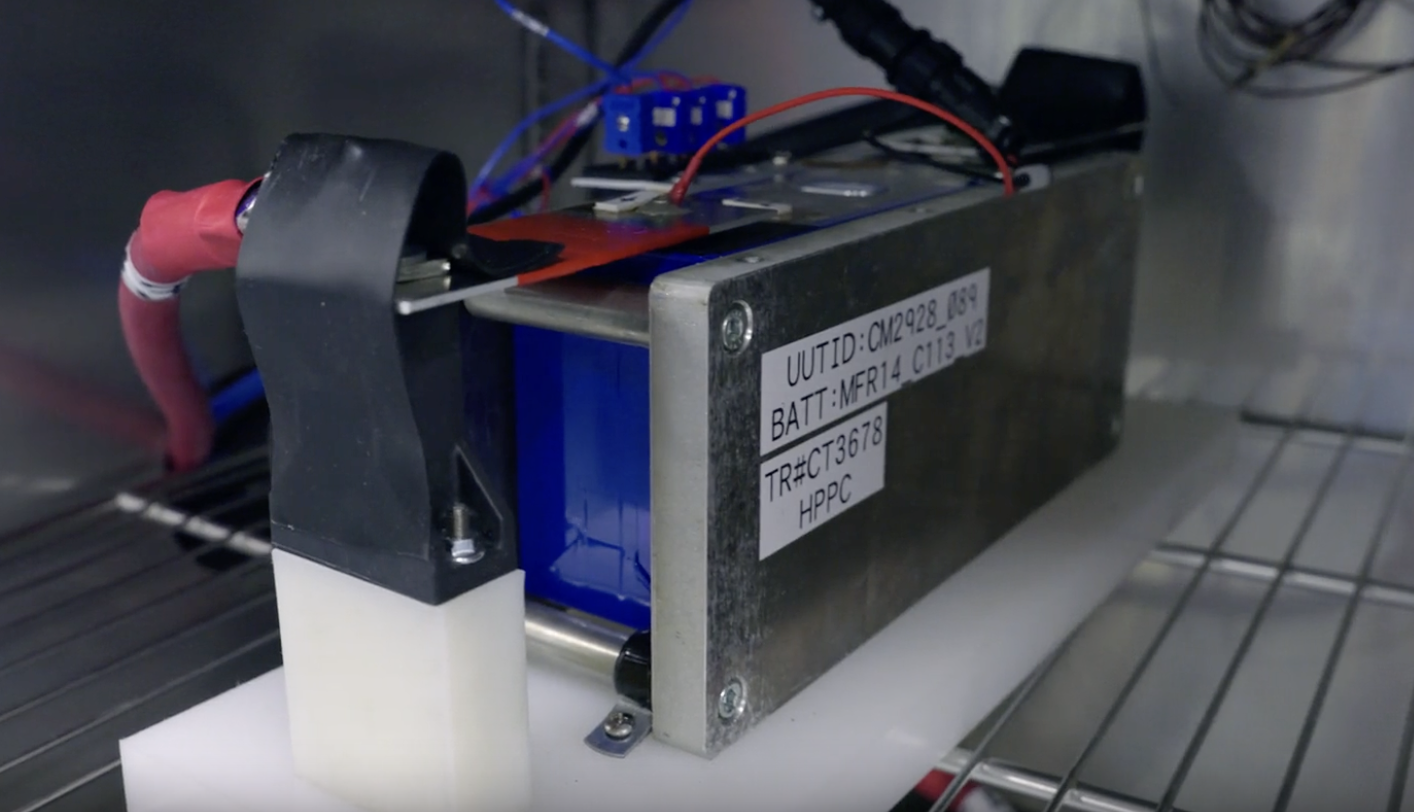

“We took a radical approach to a very hard challenge: Create affordable vehicles that delight customers in every way that matters – design, innovation, flexibility, space, driving pleasure, and cost of ownership – and do it with American workers,” said Ford President and CEO Jim Farley. “We have all lived through far too many ‘good college tries’ by Detroit automakers to make affordable vehicles that ends up with idled plants, layoffs and uncertainty. So, this had to be a strong, sustainable and profitable business. From Day 1, we knew there was no incremental path to success. We empowered a tiny skunkworks team three time zones away from Detroit. We tore up the moving assembly line concept and designed a better one. And we found a path to be the first automaker to make prismatic LFP batteries in the U.S.”

Launching a new modular EV platform is hardly novel, and in fact, Ford has been well behind others like Volkswagen (whose MEB platform debuted roughly seven years ago), GM (whose Ultium architecture underpins a bunch of GM vehicles like the Equinox and Blazer EV, as well as non-GM vehicles like the Honda Prologue and Acura ZDX), Hyundai/Kia (whose e-GMP 800v architecture that underpins the Hyundai Ioniq 5 and Kia EV6 has been out for about five years), and on and on.

But when I asked Ford how its architecture is different, it replied by saying “it really goes beyond a modular architecture,” saying the reduction in wiring and fasteners, plus the use of unicastings, makes this a more modular approach than elsewhere in the industry.

I’m tempted to say “its’ about time,” but Ford’s slow roll-out of EVs — its F-150 Lightning that was largely based on the existing gas truck and thus managed to get to market early, as well as a crossover EV named the Mustang — wasn’t necessarily a bad thing, as the world has clearly been clamoring more for hybrids than for EVs, of late. Still, EVs are the future, and to truly compete long-term, you’ve got to build a modular platform, so that’s what Ford has done. Here are some of the benefits of Ford’s new modular architecture and of its “affordable” in-house LFP prismatic batteries, per the automaker:

The platform reduces parts by 20% versus a typical vehicle, with 25% fewer fasteners, 40% fewer workstations dock-to-dock in the plant and 15% faster assembly time. Lower cost of ownership over five years than a three-year-old used Tesla Model Y.

Take for instance the wiring harness in the new midsize truck; it will be more than 4,000 feet (1.3 kilometers) shorter and 10 kilograms lighter than the one used in our first-gen electric SUV. Lithium iron phosphate (LFP) prismatic batteries also enable space and weight savings, while delivering cost reduction and durability for customers. The platform’s cobalt-free and nickel-free LFP battery pack is a structural sub-assembly that also serves as the vehicle’s floor…The new midsize truck is forecasted to have more passenger room than the latest Toyota RAV4, even before you include the frunk and the truck bed. You can lock your surfboards or other gear in that bed – no roof rack or trailer hitch racks required.

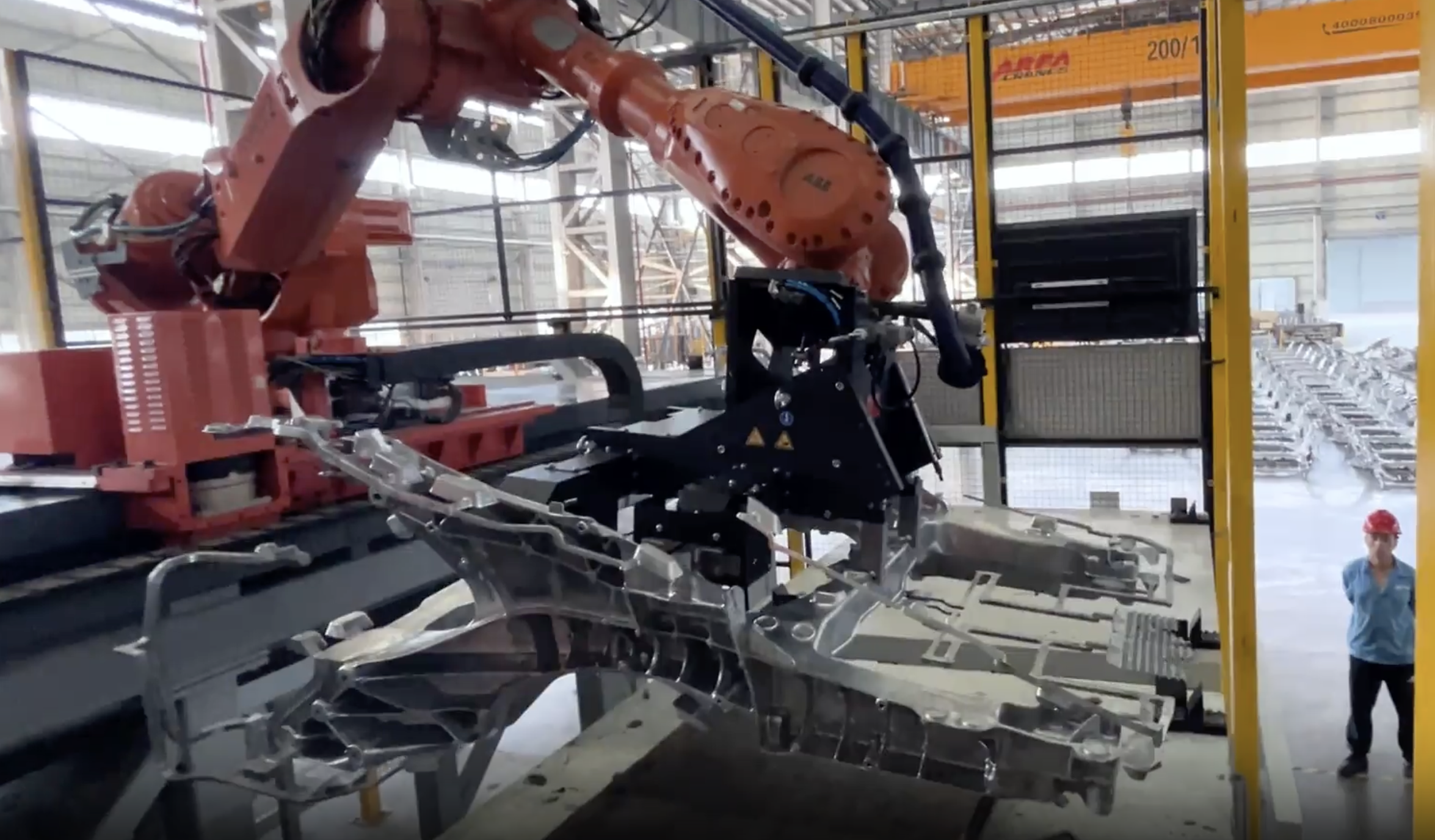

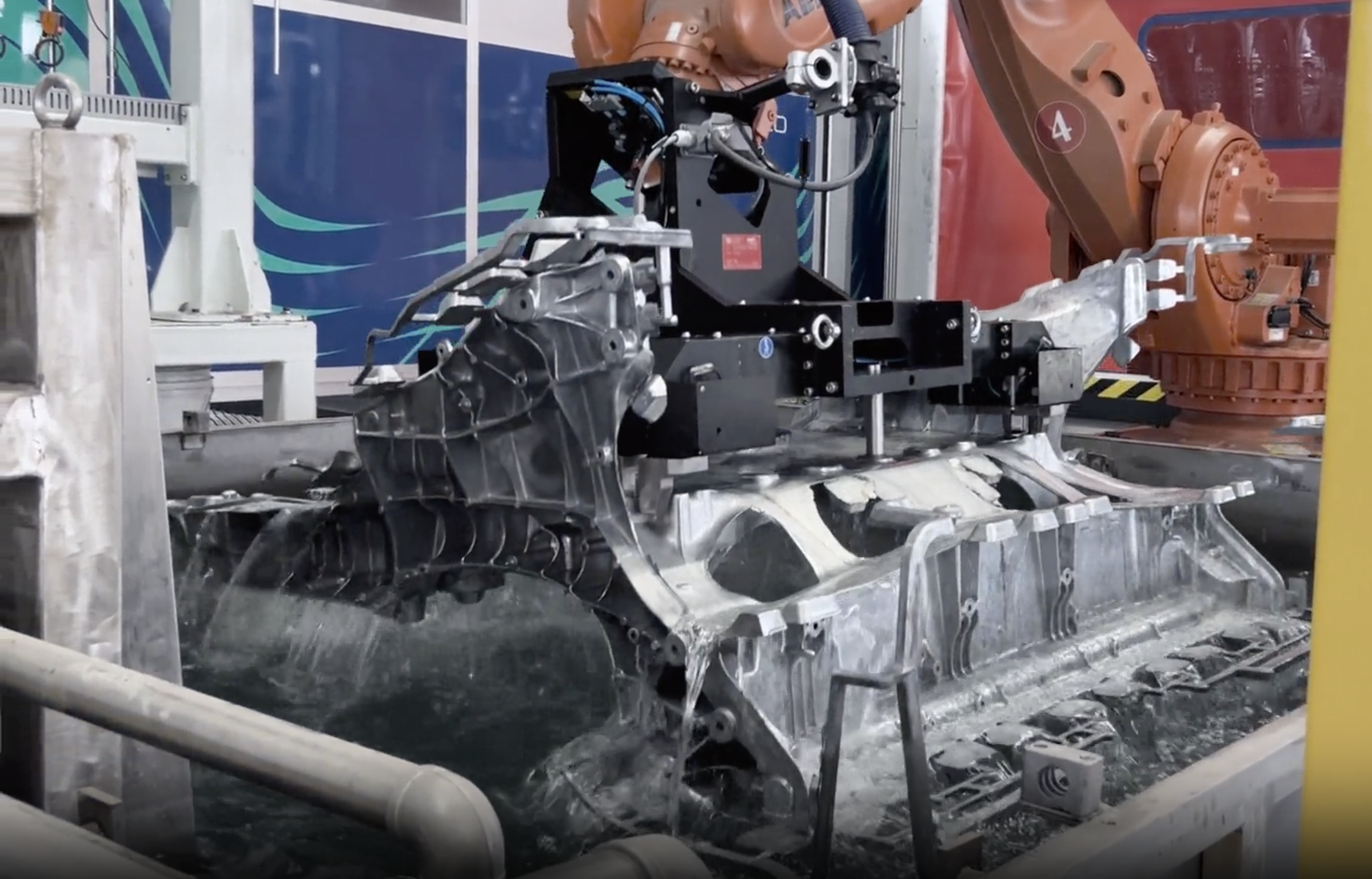

Ford talks about large “unicastings” (like Tesla’s gigacastings), and how its team plans to build sections of its vehicles independently, and then bring those sections together — in much the same way as a front subframe is “decked” with a body on a traditional car, except with three large subassemblies. From Ford:

Large single-piece aluminum unicastings replace dozens of smaller parts, enabling the front and rear of the vehicle to be assembled separately. The front and rear are then combined with the third sub-assembly, the structural battery, which is independently assembled with seats, consoles and carpeting, to form the vehicle.

Parts travel down the assembly tree to operators in a kit. Within that kit, all fasteners, scanners and power tools required for the job are included – and in the correct orientation for use.

The Ford Universal EV Production System dramatically improves ergonomics for employees by reducing twisting, reaching and bending, allowing them to focus on the job at hand. Because of the integration between the Ford Universal EV Production System and Platform, assembly of the midsize electric truck could be up to 40% faster than Louisville Assembly Plant’s current vehicles.

Some of that time will be reinvested into insourcing and automation to improve quality and cost, ultimately netting a 15% speed improvement. “We put our employees at the center and re-created the factory from scratch,” said Bryce Currie, Ford vice president, Americas Manufacturing. “We live and breathe continuous improvement, but sometimes you need a dramatic leap forward. We expect ergonomic breakthroughs and complexity reduction – through elimination of parts, connectors and wire – will flow through to significant quality and cost wins.”

Here’s a look at Ford’s “production tree”:

The architecture is a 400V one, with Ford saying “We think that is absolutely the right choice,” as it enables low cost and access to the existing charging infrastructure. When I asked whether the platform has provisions for a range extender, Ford replied with “We’re not gonna get into specifics.”

As for what more we know about that midsize truck? Not a ton. Ford says it will be aerodynamic to the point where, if the company put its battery into an existing truck of roughly the same size, the range would drop by 50 miles compared to the upcoming vehicle. In addition, Ford says EV will have a 0-60 mph acceleration time similar to a Mustang EcoBoost (~4.5 seconds), and then the press release seems to maybe include a subtle dig at Slate Auto: “We assembled a really brilliant collection of minds across Ford and unleashed them to find new solutions to old problems. We applied first‑principles engineering, pushing to the limits of physics to make it fun to drive and compete on affordability. Our new zonal electric architecture unlocks capabilities the industry has never seen. This isn’t a stripped‑down, old‑school vehicle.”

Maybe that wasn’t a dig, but why mention that this isn’t a stripped-down vehicle? I mean… who would think a modern EV is a stripped-down vehicle if not for the existence of Slate?

Anyway, the mid-size truck is to be built at the Louisville Assembly Plant, which will see a $2 billion investment that, when combined with Ford’s $3 billion investment in its Michigan battery factory, will total $5 billion and allegedly create 4,000 jobs.

Ford says in reference to the Ford Maverick hybrid pickup: “We believe there’s room for both.”

Ford calls this new platform and manufacturing method a “Model T moment,” which is fair to say, as this represents a major shift for the company. At the same time, I’ll be interested in seeing if it’s really that different than what we’ve seen from the competition. GM makes its own batteries, it’s focusing heavily on affordable LFP batteries to bring EV pricing down, and it’s got an architecture malleable enough to build a variety of vehicle types across a variety of brands.

But it doesn’t have a $30,000 four-door pickup truck. Nobody does right now, so if Ford can be first, and if that truck can offer decent range and decent tech, it could be a game-changer in its own right, worthy of Ford’s new “The Universal Vehicle” badge you see above.

All Images: Ford

I honestly hope I’m no longer in the car business when these arrive in showrooms.

I have nothing against EVs – we have a Mach E – but I’m quickly losing faith in Ford to keep their word (see wild price swings of recent models). Does the Blue Oval need yet another truck? Yes, the Maverick exists and is relatively affordable, but Ford (at least in this area) does not support it with rebates or special financing. Furthermore, the margins on the lower-end vehicles are essentially non-existent, making the dealers look like the bad guy when we are unable to discount it to customers’ expectations.

I’ve read enough of your posts about EREVs that I’m now a believer that that is the near future. If Ford doesn’t include that as an option, I’d consider that a huge misstep.

Ford is big on EREVs!

But most likely on larger SUVs/trucks.

My cynical self is waiting with bated breath for the results!

For me, I think Ford sees an open field for BEV commercial Pro trucks, where the lower operating costs for this Maverick-sized truck in limited routes would work well in cities and even semi-rural areas. Ford Pro seems to be making a good profit for Ford, and they’re leaning into this.

Yes, passenger sales of this truck for personal use, too, especially if they can truly sell it for “about $30,000” in two years.

Well, I wish them luck. I personally haven’t sold an E-Transit in over a year due to its incredibly limited range.

That being said, a small EV truck for fleets would be a good option since the range won’t be as negatively affected by excess payloads like the vans can carry.

This feels like Ford making a bet that the auto market will be very different in 3-4 years (politics, Chinese competitors, etc.), they expect to be ramped up on these new EVs when it happens while competitors won’t be able to react to the market shift fast enough.

It will either pay off or get Farley fired, there probably isn’t much room in between.

Well, then he’ll be…”livin…in a…van…

DOWN BY THE RIVER!”

100% a dig at Slate, and a pretty good one too considering the Slate looks A LOT like an old Ranger! LOL

Excited to see what they come up with … and if they will spec a minivan version!

I just want a freaking electric CAR that isn’t all gadgeted out. Normal door handles, a reasonable set of features (the mandated safety equipment, decent stereo, adaptive cruise, heated/ventilated seats, smartphone mirroring), acceptable range and a reasonable price, and decently stylish looks. Keep it relatively simple, keep the costs down, and sell a ton on volume.

Of course, most people have been convinced that they need a crossover, so I am, yet again, doomed to disappointment.

I’m sorry, but a crossover is kind of an ideal form factor. It just is. Sedans are compromised.

“ideal” is doing a lot of heavy lifting there. A crossover is compromised for aerodynamic efficiency and packaging. A sedan has less gross cargo volume, and may not be as easy for mobility-challenged people to get into and out of. It really depends on what the use case is. For 90% of what I do, a sedan or a coupe or small hatchback would be a better choice of form factor. Commuting, grocery runs, road trips with one other person, etc. For things where I need to haul large things, I have an old pickup that I use for pickup things.

Also, I think most crossovers are ugly, or at the very least boring and forgettable, which is entirely subjective, but it’s definitely a thing that impacts the buying decision.

How is it compromised for packaging? You get hatchback utility in a vehicle that takes up roughly the same footprint as a hatchback with a higher field of visibility. I also don’t think aerodynamic efficiency is as important as you think it is when you’re getting roughly 40 mpg combined in a Rav4 Prime.

For 90% of what most people do, a scooter and backpack would probably suffice. Crossovers tick the most boxes most of the time.

Weight and aero matter. Crosovers are heavier than the equivalent hatchback. The RAV4 Prime gets 40 MPG, sure. Great. But look at the Prius Prime – same basic drive train, good cargo space (yes, less, and less tall), significantly better mileage. I don’t personally see the “higher field of visibility” as a worthwhile tradeoff.

You personally don’t, and I don’t, but visibility and ease of ingress/egress are, and I cannot stress enough, massively important elements for a huge amount of the population. Which is why the Rav4 and other crossovers sell the way the way they do.

Agree they’re boring and almost universally ugly, but sales figures don’t lie. It’s the ideal form factor.

Ideal is not the same as “most sold”. It’s just the most sold. Especially when there are such a dearth of other options available. It’s ideal for a manufacturer, as they can charge more for a lifted, porked up version of a hatchback that they already sold (Impreza vs. Crosstrek, Legacy vs. Outback) Profit margins don’t lie.

You are conflating two ideas here. An ideal is defined as “satisfying one’s conception of what is perfect; most suitable”. You can’t tell another person something is ideal like its a fact, as ideal is an opinion.

You may be correct. Crossovers may be ideal to MOST buyers. But once Bearddevil says it is not ideal to him, you can’t tell him he’s wrong. One cannot be wrong about one’s own ideal.

MPG is a bit deceiving as it isn’t a linear relationship. The difference between a 39 mpg AWD RAV4 hybrid and a 54 mpg Prius is 107 gallon of fuel a year or about $350 a year. Lots of people are willing to pay $7 a week for a larger and roomier vehicle. 15 mpg looks huge but when you are starting at almost 40 mpg it doesn’t really add up to a lot – nothing like the savings of going from 20 mpg to 35 mpg.

(I’ve driven the new Prius as a rental for a week and it is severely compromised for that new styling. Greenhouse way too low. I say this as someone that owned a 2005 and 2009 Prius)

Compared to a sedan maybe, but “ideal” is going to mean entirely different things to different people. I tend to agree with you for my needs, but like my buddy with a farm will see differently.

I would say a crossover is the “what you get if you put all the car shapes in a blender” result. Okay at most things, but not really great at anything in particular, other than being so very very marketable.

One could argue that crossovers are intrinsically the most compromised vehicle form factor.

I’m going to come out and say it: minivans are actually the ideal form factor for automobiles.

^This^ – but only for people who need to seat 6+ people

For those of us who don’t – I’d say VW Golf/Polo-shaped “4 door hatchback”.

Then “Station Wagon” in second place.

You aren’t driving a Chevrolet Bolt already, so that’s kind of evidence that most people actually don’t want that. It already existed and it wasn’t even on anyone’s radar.

The Nissan Leaf also kind of fits what you’re asking for.

I’m already driving a Fiat 500e. I really wanted an Ioniq 6, but my local dealers weren’t interested in working up a decent lease deal. The Leaf’s air-cooled battery and funky charging standard made it unappealing. The seats in the Bolt hurt my back after about 30 minutes.

I’d say a CPO EV from basically any brand you like fits that bill, except maybe ventilated seats, which is still relatively uncommon in general. New EVs depreciate like crazy (though the numbers look far better accounting for the $7500 tax credit most of them had on the original purchase price), so you can find excellent low-mileage used ones very affordably.

Depends on where in the country you are. Much easier on the coasts than in the middle. But yes, that’s what I’m going to be looking at when my lease is up. Even if the insurance bump up is going to suck. I still hate the automated doorhandles, though. Totally unnecessary. Same with the touch-sensitive everything controls and freaking enormous screens.

Yeah, I get that.

The pop-out doorhandles especially suck after an Oklahoma ice storm.

FWIW, my Mach-E doesn’t have pop-out doorhandles, but it does have “poppers” that push the door open when you press a glowing button on the door. I have had the car covered in ice in zero degree temps, and the buttons still worked. The popper servos inside the doors that push the door open broke the door free from the ice just fine. I don’t think the funky poppers were necessary, but as far as “weird EV doors” go, the Mach-E is one of the least offensive.

One benefit is my young kids can easily open the doors on their own since the servos that crack the doors open do most of the door opening work and stay extended so that you can’t slam your fingers in the door until it’s most of the way open. Not sure if Ford planned that, but kudos for kid-friendliness if they did.

So the floor is the battery. I guess I won’t worry about cold feet. Also, do I attach the hitch on the trailer to the bed?

The battery is structural on most EVs. Saves weight in the unibody since the battery packs are already well-armored and rigid. FWIW, you don’t feel anything radiating into the floor. Even the totally air-cooled Leaf we have doesn’t transmit any noticeable battery heat into the cabin.

Thanks, and here’s to hoping your cooling fan continues to operate.

Electric fans are literally the simplest machines ever.

Correct. They rely on a motor , like the one providing power to turn the wheels on an EV. As you know the only difference in a fan is that it doesn’t have 4000 things between the motor and the power source.

It’s completely passively cooled with the battery casing acting as a heat sink and dissipating heat from underneath the car. Unless you’re in a very hot climate or are constantly fast-charging (which heats up the batteries a lot), it’s a system that works well. There is no cooling fan or liquid pump for the battery pack to fail, period.

The Leaf does have a liquid cooling system, but it’s just for the charger, inverter, and motor unit. The battery isn’t part of that loop at all.

The passively-cooled battery has gotten a lot of flak, but we’ve had our Leaf in a modern PNW climate for 7 years and 65k miles, and the battery still has 85% capacity with excellent cell health and charge balance across the pack. We haven’t done anything special to preserve the battery other than it only has 25 fast charges, but the car usually lives outside and sees all temperatures.

Trailer hitch? Unless you only need to tow something light a short distance, you won’t need a trailer hitch.

A few years ago Ford was making a huge deal about a $40,000 Large Electric Pickup Truck and a $20,000 Small Hybrid Powered Pickup truck, both with four doors.

Here we are and they are now promising a MidSize Electric four door Pickup truck for $30,000 with the most cost effective (but with caveats) battery technology. It seems…underwhelming, or at most the minimum expectation.

A Model T moment it surely is not. Or maybe it’ll only be offered in black.

Hopefully it’s not a TNT moment!

I don’t think anyone is actually reading this article lol. The Model T moment is the manufacturing process.

Oh I read it. I just don’t see how it’s all that different than how an F150 for example is produced. The engine is assembled in one place/plant and then mated to the frame which is built up while traveling along a completely separate assembly line from the Cab as well as the Bed. At some point all three are mated together and the last bits are put on with the three elements combined. It just seems more like a current body on frame production process.

But nobody normal buying a car or truck really gives a shit HOW it’s produced. If this way somehow is that much more efficient and saves a ton of money then maybe Ford will wait a little longer before jacking up the price this time and having to stop milking the $30k headlines.

Well yeah, but they will care if that manufacturing process means the cars can be sold for cheaper.

Ford needs to worry about assembling them *correctly* first. Quality is no longer Job 1 over there.

The only way that lower production costs lead to lower prices for the customer is if there is market competition that forces them to do so. Ford is hoping to capture every penny of cost savings that come out of a new process and pass zero of it along to the consumer.

No doubt, but if that quoted $30k price for this new truck is accurate, and assuming other models on this architecture cost in that neighborhood, then I honestly can’t complain too much. I’m sure they’ll jack prices up as soon as they possibly can, though, but more affordable EVs is never a bad thing.

I would add that the term “affordable” isn’t really appropriate these days. Maybe “least overpriced” is the best we can hope for. The average new car used to be around 60% of the median yearly income, and now it is about 90%. As the wealth gap increases, there is less and less reason for companies to sell low-cost models. Companies target people based on their disposable income, not need.

Average is misleading. In general you see people comparing the average (mean) new car transaction price to the average {median) house hold income. That is the first problem. The second problem is that the average transaction price is going steadily higher because people are choosing to buy more expensive types of vehicles.

Compare like to like and cars are cheaper today than in the past.

Case in point – the Corolla.

So adjusting for inflation the 2025 Corolla is way cheaper.

We can also look at weeks of median income.

2025 Corolla is still WAY cheaper. (And WAY better)

Notes: 2023 is the most recent officials numbers for median household income

1995 MRSP from KBB

1995 Toyota Corolla Price, Value, Depreciation & Reviews | Kelley Blue Book

Median Incomes from FRED

Median Household Income in the United States (MEHOINUSA646N) | FRED | St. Louis Fed

The issue is that using a base Corolla isn’t representative. In 1992 the average new car transaction was $16k so the base Corolla so the Corolla was only about 16% under the average.

Now the average transaction price is $49k, so the base Corolla is only 47% of the average. That is a massive difference in where the Corolla sits in the market. It went from being the protoypical car to one over the very cheapest models available.

We need to look at the overall market to get a picture of why companies have stopped making cars like the Focus, Fiesta, Malibu, Cruze, etc. They only want to make cars that have great margins. Hence all the trucks.

In today’s dollars, a 1992 Ford F-150 ranged between $ 24,000 and $42,000. It is now between $40-80k. Ford sold three times as many pickups as Toyota did Corollas. Toyota sold over twice as many RAV4s as Corollas, and they didn’t exist in 1992, but have an average transaction price that is likely in the mid $30k range.

The technology has gotten much better so product capabilities have imrpoved but, to my original comment, the car makers have zero interest in selling cars at low margins even though they are perfectly good cars. They are in the business of extracting money from the public as possible. Something that only works if they make things that are expensive for people who can afford to waste money.

A Corolla is available to buy even it has become a lot less popular over the years. Again – apples to apples vehicles are cheaper today than in the past an consume less of a household budget.

Buyers have voluntarily decided to stop buying sedans and start buying more expensive crossovers and crew cab trucks as family vehicles. Of course automakers are going to make them if customers are buying.

The fact remains that the increase in average transaction price is due to a shift in what people buy – not cars getting more expensive.

We can take the most popular crossover in the USA

1996 RAV4 $17,758 ($33,198 in 2025 dollars) 27 weeks of median household income

2025 RAV4 $29,550 19 weeks of median household income.

Cherry picking data is pointless and dishonest. If you want to analysis the market as a whole you need to look at tha market as a whole.

Also, thinking that people “voluntarily” select their vehicle is incredibly niave. Car makers select which models and trims they produce and are highly incentivised to use all available production capacity to produce the highest margin (most expensive) products available. A high margin vehicle can be discounted more and still be profitable while low cost models can’t. People can only buy what is available. People that can’t afford what is availabel aren’t customers the companies care about.

Just consider the fact that GM spends about $400 per vehicle on marketing and $900 on R&D. That $400 per vehicle is 100% dedicated to convinsing people to buy products with the highest margin. If it wasn’t effective they wouldn’t spend it. The price example of the Ford F150 show this impact. More people are buying them and they are also twice the price.

The biggest issue with your framework is that you assume technical advances counter the macroeconmic realities.The vast and quickly growing gaps in wealth are undeniable proof that the value of human advances are benefiting a very small number of people vastly more than most people. The general public doesn’t view their way of living relative to that of their great grandparents. They look at it relative to their contemporaries.

Yes the average price of a F150 has doubled in 3 decades. However, the median household income has gone up by more than double in that same time. So it takes the median household fewer weeks of income to buy that F150 today than in 1992 – which was your metric complaining about the price of cars.

Using your numbers a top sped F150 was $42K in 1992 – that is 64 week of median income. A $80,000 2025 F150 is only 52 weeks of median income. Same for the base F150.

You accuse me of cherry picking data but now we have compared the best selling compact sedan, best selling crossover, and best selling truck. They all cost the average family today fewer weeks of income than they did in the 90’s.

The average transaction price for a new vehicle is going up because people are CHOOSING to buy a more expensive class of vehicle.

There are more than 11,000 Corollas on dealers lots today. It isn’t Toyota’s fault if someone spends $10K more to buy a RAV4 instead of a Corolla. That is the buyer’s choice and people are responsible for their decisions.

Yes, wealth inequality is a problem. That doesn’t change the basic fact that someone buying the same class of car today as 30 years ago is going to spend less of their income to buy that vehicle.

Adjusted for inflation, the 1992 median household income of $30,636 would be roughly $73,042 in 2025 dollars. It is now around $80,000. I don’t know how you figure a F150 that cost $42k in today’s dollars took more weeks of income to purchase than one that costs $80k.

You seem to be under the false impression that people are completely rational beings, always able to make decisions that are free of outside influence. Nothing could be further from the truth. Something that should be obvious these days. If your framework is based on people making rational decisions, your framework is wrong.

Here is some light reading.

Robert Cialdini – Influence: The Psychology of Persuasion

Daniel Kahneman – Thinking, Fast and Slow

Richard Thaler & Cass Sunstein – Nudge

Dan Ariely – Predictably Irrational

As stated, GM’s marketing budget is nearly half its R&D budget. Every part of car sales is designed to shift people from low-cost, low-profit models into high-cost, high-profit models, and it works well.

This is an important factor in why the average transaction price for a new vehicle has risen (20-25% in adjusted dollars) faster than income. Which is especially impressive/depressing given the fact that housing (50% more), food (8% more), healthcare (60% more), technology (500% more) and education (110% more) have all also increased significantly in that time.

The core issue is that the vast majority of the benefits from the work and technological improvements over the last 30 years (that exist due to work and investment by everyone) have only benefited the very few at the top of the oligarch food chain.

Meanwhile, the plebs continue to get poorer on the only scale that matters, which is the one that measures against the current society in which we live. Nobody looks at their lives against those of the 1700s and thinks, “I have a bike and cell phone. I’m rich!”

I missed your “In today’s dollars” before those prices. My bad.

Looking at actual prices the cheapest F-150 costs 4 weeks more pay in 2025 (but you get an auto and Coyote V8) and the top end (of what you could actually buy in 1992) costs 3 weeks more pay today.

I don’t think most car buying choices are rational. I do however hold people (and myself) responsible for making bad and irrational choices.

Yes, wealth inequality is a problem – I absolutely agree with that. Yes, many things cost more today than they did in the past.

However, you can’t lay those problems at the feet of automakers. A family can go out today and buy a quality car for less than it cost them decades ago. Make a smart decision and they can offset some of those other costs that are higher.

You $24k-$42k compared to $40-$80k isn’t 3 weeks of pay for the median household income. Even in the middle of that range represents a $30k increase, which would be 20 weeks. Again, you can’t cherry-pick.

The issue with your framework is that you assume that consumers shouldn’t expect product improvements, which doesn’t really make sense. Consumers are the same people who create those improvements, so they should expect to enjoy the benefits they provide. We shouldn’t assume that only the CEOs, executives, and the non-working investment class should benefit.

Also, while this is even more in-the-weeds, take a look at Chained-CPI vs CPI-U. Chained is what is currently used, but it uses hedonic pricing and substitution. Hedonic integrates product improvements like those you mention into the number, so you are basically double-counting that value when you say that products have improved. Substitution means that if the price of something goes up (say, steak), they expect the consumers to substitute it with something less expensive (say, hamburger). This significantly undercounts the price increases, particularly for people in middle and low-income groups, who have fewer options for substitution and would benefit more from price decreases than product improvements. The change to chained CPI makes inflation look lower, which justifies lower increases to salaries and payments like Social Security. If you use CPI-U measurement, median household income hasn’t increased since 1993.

I absolutely will lay a meaningful amount of the problems at the feet of automakers. I’ve been doing product development and marketing for 30 years. I am very aware of how impactful those massive marketing budgets can be. In order to see this, you have to ignore the idea of any single transaction and look at the full picture. Car makers don’t take actions that manipulate any single consumer. They take actions that will manipulate consumers on a large scale. They shift behavior across large populations, but that manipulation is 100% real.

You, I, and everyone are being manipulated, to some degree, at all times. This manipulation continues to get ever more effective because the thing that fuels it is data and behavior, and now that everyone is almost always connected and providing data on their behavior, the manipulation has gotten very, very effective.

Sure, there is competition for that behavior, but it is all moving people in the same general direction, shifting money into the hands of those who control the marketing. The fact that this is so much a part of our world that it seems normal doesn’t mean it doesn’t exist.

I’m not cherry-picking. I’m comparing the cheapest and most expensive F-150’s available in 1992 to what that truck costs today.

Back in 1992 the cheapest F-150 was a regular cab, SB, 2WD for $13,392. Median household income was $30,640*. That is 23 weeks of income. In 2025 that regular cab, SB, 2WD F-150 will cost $38K, 2023 median household income is $80,610 which equals 25 weeks of pay. The cheapest F-150 today costs the median household 2 weeks more pay than in 1992. Now that F-150 is massively better than the 1992 one – the customer absolutely is getting a better product but they do have to pay an additional week’s income. (Unlike the Corolla or RAV4 where they get a massively better product for fewer weeks of income)

Back in 1992 the most expensive F-150 was an extended cab, SB, 4×4 for $18,007. (There was a step bed for $1k more but step sides are no longer available). That is 31 weeks of pay.

Today that extended cab, SB, 4×4 cost $49,000 which is 32 weeks of pay. That truck is also massively better than the one sold in 1992 – the customer is getting a lot more for their dollar. More HP, payload, towing, MPG, features, ABS, airbags, stability control, etc, etc, – but again paying a bit more.

Now can you buy a truck that cost more than $49K in 2025? Sure you can but that isn’t an apples to apples comparison to what was for sale in 1992. If a customer lets Ford’s marketing department convince them that “need” a F-150 Raptor $80K -that is on the customer not an accurate description of the cost of a vehicle.

I blame the customer for falling for the upsell – you blame the world and assign no personal responsibility on the buyers. That is why we are not going to see eye to eye on the topic

(*I originally used the wrong median income which was higher)

I never claimed zero personal responsibility. I just happen to be far more aware than you seem to be about how the world works.

You might want to try reading up on the linked books provided and learn a little more about how inflation is calculated.

CPI inflation calculations have nothing do with measuring the cost of an item in weeks of median income – which is why I didn’t following you off topic into the weeds

That comment clearly illustrates how limited your understanding of the topic is. The ability to understand the value of today’s dollar against the value of the dollar in 1992. This entire thread is dependent on that understanding.

There is also a tremendous amount of irony in your idea of “personal responsibility” when it comes to consumer behavior. The first step to being a responsible consumer is to understand how the game works. To understand your own structural biases that are simply a part of being a human being, and how others can use those biases to their advantage. You have failed at the first step of being a responsible consumer.

This quote is appropriate.

I understand how CPI works and the difference between Chained-CPI vs CPI-U.

None of that changes the very basic fact that in 1995 a Corolla cost the median household 21 weeks of income and in 2025 a corolla cost the median household 14 weeks of pay. A Corolla buyer in 2025 is getting a MUCH better car for 1/3 less. Which is my point in this thread

I also find it hilarious that you think I don’t understand that in every part of our lives there are marketing people like you trying to get consumers to overspend, buy stuff they don’t need, take stupid amounts of debt to live beyond our means, etc, etc. Yes, that is all real. So is the very simple reality that it is up to us as individuals to navigate through life in that reality because the calvary isn’t coming to save the consumer from the marketing men trying to pick our pockets.

You main point seems to be that the consumer is screwed because nobody could resist a sales pitch to buy more car than they need.

Since we are recommending books – I’ll recommend a book that changed my mindset and approach to money when I read it in my mid 20’s. “The Millionaire Next Door”

TD/DR version: Most of the people you see that look like they have money – are actually broke living paycheck to paycheck with no actual wealth.

This has come full circle because today instead of reading about millionaires living in a middle class neighborhood and driving a used car I am that person.

You have yet to grasp the core issue, which is that when speaking to the market as a whole, your shallow self-help Horatio Alger delusion is 100% pointless. Companies aren’t attempting to change the behavior of any particular individual. They are very effectively shifting the behavior of large populations just a bit each day. You can’t both understand that to be true and promote the idea that “personal responsibility” is an infallible shield.

Your “point” in this thread is a cherry-picked anecdote from a massive and complex market, which, as a whole, makes my point obviously true. To illustrate this, I cherry-picked another example of the F150, which shows the opposite situation of the Corolla. One with higher sales and higher impact on the market. Which is why cherry-picking examples is a pointless endeavor only undertaken by people who have lost the argument.

The irony of you being influenced by a shallow self-help book while denying the scientifically backed understanding of human decision-making theory is stark. As somebody who has zero debt, hasn’t had a car payment for around 20 years, and is partially retired in my early 50s, I don’t think your infomercial book is going to teach me anything I don’t already know.

BTW, I am one of those marketing guys picking your pockets. I’ve got 30 years of product development and marketing experience, and people with your attitude make my job easy. You have a delusional amount of faith in your own ability to make good decisions.

Ah, yes! Unicastings – those things that make vehicles get totaled in the slightest bump because no body / chassis parts are as easily replaceable and insurance companies won’t touch it! :O

I though this too but that video of them gluing the cybertruck back together as the official repair have me pause … if they can build in failure points to the casting, and have premade epoxy repair kits, seems like at least the first crash repair could be manageable? I don’t know!

I’m not sure anything can prevent a car from being totaled anymore. I got a quote last week to fix a dent on the rear quarter panel of a Fiesta and they straight faced said it would be $4,500 and an additional $4,500 for the peeling paint in 2 spots.

For $9,000 you better paint the whole fucking car. Thrice!

This. All the castings do is make the car a truly disposable item. When the slightest bump leads to the car being declared a total loss, that full cost replacement instead of repair has to be spread around. I’m pretty sure this is why insurance rates are just escalating higher and higher. I left USAA after 27yrs due to rate increase that made no logical sense as I have no claims or tickets in the last 10yrs. They basically blamed it on me living in Broward County, FL which has an inordinate amount of claims. These higher costs, whether it’s full cost totaling of a car for a minor fender bender or it’s the amount of claims for injury/personal loss, are spread around to all of us in the form of these new exorbitant insurance rates. Then we can get into the ordeal of actually finding a shop to do a repair if one is even approved. Take Tesla for example, go on Reddit or Tesla FB groups and the amount of owners in SoFlo complaining about not being able to get repairs done is crazy. There just aren’t enough shops or techs to do the work

Fenders were supposed to be the easily-replaceable sacrificial lambs for minor accidents. Now they cost an arm and a leg to replace, partially due to all the sensors in them.

Might have something to do with this. You live on basically a sandbar that now floods regularly at high tides.

Florida Hurricanes Result in Over 17,000 Flood Damaged Cars Filling Auction Lots | The Online Automotive Marketplace | Hemmings, The World’s Largest Collector Car Marketplace

If only I was wealthy enough to “live on a sandbar”. Sadly, I’m one of the plebs that lives inland and out of the flood zones. Guess that’s why I’m not required to have flood insurance on my home.

All of Florida is a sandbar in the ocean. (Wikipedia tells me that the absolutely highest point in Broward County, FL is only 27 feet above sea level)

Plenty of people are finding that flood insurance is good to have even if not required.

How much did you save by moving away from USAA? Personally I’ve found that insurance companies will pretty much always give new customers a lower rate and then rapidly increase it. Similar to the teaser rates for internet or cable. That is why I shop insurance every 3 years. There is no savings for customer loyalty.

I first switched to GEICO, which was half of what USAA quoted. That lasted 18mo at which point they too jacked the rate. I’m now with Progressive and it’s held steady.

And the highest point in Broward County is well over a hundred feet, it just happens to be a landfill. Waste Management calls it “Monarch Hill”, we call it “Mt. Trashmore”

I know they’re going for a modern take on the 50’s/60’s Thunderbird/Thunderbolt logo, but I would have thought a winged pyramid would be the logo for Tesla’s stock

No they are reaching much further back for that logo. The “Universal Car” sign dates back to the 1910’s. https://www.thehenryford.org/collections-and-research/digital-collections/artifact/100255/

There’s a Musky smell in the Ford PR department…

My first vehicle was a Ford, ’85 Ranger 4×4, so I’ve always had a bit of a soft spot for them (right between my ears some would argue) so I really hope they succeed. Kudos to them for taking a fresh look at this, looking at the competition (ie, China) and starting with a clean slate (see what I did there?)

I have my suspicions about how well this will work in practice but time will tell. As others have mentioned, Ford’s dealer network generally sucks and will likely take a good stab at f-ing this all up with markups and required add-ons when the first ones finally arrive, giving everyone a bad taste in their mouths and potentially souring the whole project, killing enthusiasm until the new-ness has worn off and then sales slump.

Also, the $30k is likely a semi-mystical/theoretical/wishful-thinking starting point so most will realistically be $40k+ by the time they roll out the door and that’s getting into much deeper waters as far as competition goes. Ford has a history or starting low on price then jacking them up within a year or two. Maverick, Bronco, etc…

I also have reservations about the 400v architecture when so many others are going much higher. I understand it’s a cost/benefit balance but that seems like a risk when Americans are so obsessed with range (most will never use/need it all 98% of the time but there it is) that now compounding that anxiety with the slower charge times (generally) of the lower architecture may be a misstep.

Then there is the Ford Recallpalooza that’s been going on for the last decade or two… or three… Is a Ford with 25% fewer fasteners really a good thing?

Time will tell.

Electric is not the future. It’s part of it

Unicasting or gigacasting is a bad idea because while it might be cheaper to make, it costs much more to repair. Expect high insurance rates and lots of totalling out in minor accidents

Surprisingly based on teardowns on Tesla and the couple of chinese vehicles, it’s actually NOT more expensive to repair. Munro and Caresoft have done big deep dives on the repairability costs and the casting method is turning out to be cheaper. I haven’t been fully involved with that workflow, but it was surprising to find that out.

It may not be according to them, but most insurance companies still total them anyway.

For now. They used to total out early Teslas (pre-gigacasting) for minor fender benders too until shops got comfortable with them and parts availability scaled up. Now, when my cousin’s Model Y was rear-ended pretty badly, it wasn’t totaled and was fully repaired.

I expect we’ll see insurance claims settle as repair shops get their workflows in order.

I was impressed by the Cybertruck repair video that was reported on here a little while back from the guy that broke his hitch (while measuring the force to do so).

It does seem like repair is easier than I expected. The CT is terrible for lots of other reasons, but that bit of engineering was interesting and impressive.

Of all the things you can claim not needing racks since you can just lock it in the bed, a surfboard is the least believable since the bed on this will be 5′ max.

They could have gone with an inflatable SUP or something or even just point out that locking damp wetsuits in a bed is better than in the passenger cabin, but in the end truck beds just aren’t that useful for replacing racks. Kayaks, canoes, surfboards, fishing rods, etc don’t fit in a truck bed and you need a rack anyway. I even prefer racks for mountain bikes over slinging them over the tailgate.

maybe it’s a hint at a cab passthrough option.

Ah, good call. Hopefully that’s the case, but I’d still be holding out for 3 rows instead. My dog needs somewhere the ride and she doesn’t do well between the kids in the 2nd row.

If you watch the sketch morph you will see a 2 row and 3 row crossover on the same skateboard

That was my first thought. A maverick size truck that has a mid gate! Now add in bidirectional charging and awd (or even 4×4!) and it would be pretty excellent.

You’re asking for too much.

Like the $20k Maverick and the $40k Lightning. This might hit the market with a $30k trim. But it will be low production and quietly disappear. See also: The Base bronco that went away for a bit to come back ~20% more expensive.

Yeah, it turns out everyone like the idea of a low base price, but almost no one actually buys those trims when offered.

Ford limited production for them in all three cases. Wait times were in the range of multiple years. I personally waited 2yrs for my Base Bronco

Was anything else going on in the world at the time that might have affected lead times and trim mix for those particular products?

My statement is much broader. Base models, stripper vehicles, etc are generally hard sells regardless of the specific vehicle or price point.

Yeah. Companies realized they could put all of their limited capacity into higher trims and offlay the issue onto consumers.

Remember how the (original) Mustang was priced, and then promoted? The “unexpected price” of $2,368 fob Detroit. You could even save $10 by deleting seat belts, $31 by deleting the heater. But the option list was as long as your arm: air conditioning, backup lights, emergency flashers, floor mats, fourteen-inch tires and wheels, LH or RH outside mirror, padded sun visors, push-button AM radio, rear seat belts, tinted windshield, two-speed electric wipers and washers, trailer hitch, yes three V-8 engines, and 50 more choices.

I don’t think the current Maverick will still have a base version below $30K in 2027, let alone this new electric Maverick.

Ford is claiming it needs radical changes to be able to compete with China.

You know what would help that?

Stop paying your clueless CEO $25 million/yr when the CEO of SAIC is only $300k/yr and the CEO of BYD is $800k/yr.

Also, I am sick of how these companies like to overstate the amount that labor tacks onto the cost of a new vehicle so they can try to keep labor wages down. While it is hard to pin down a specific number, most agree that labor adds well under 20% to the total cost of a car. Some estimates state as low as 5% to 15%. So even if you found a way to reduce your labor costs in HALF, you aren’t moving the needle all that much.

Executive pay is absolutely absurd but saying labor costs don’t matter because they only make up 5% to 15% of cost falls a little flat if you consider Fords net profit margin was 2.36% for 2024. Cost of labor was at least double what any net profit was for Ford

How are you making that leap of faith that just because X then “clearly” Y must be true? The sources I found stated that assembly labor was 15% or less and I even rounded UP to be fair to Ford. Blaming the cost of vehicles on assembly labor is ultimately bullshit and used as a scare tactic to keep worker pay in check. Part and material costs from the sources I found make up around 3/4 of the total cost of a car.

My point was mainly that 5% is not exactly a small amount and every penny is scrutinized. If you told a chief engineer there was a way to save $0.17 on a part that went on each vehicle they would do a f***ing back flip.

We would backflip for a $0.05 savings on a high volume part.

“But we have to pay this to attract and retain talent!” 🙂

The reality is that boards usually look at CEO median pay among their peers and say “Well we have to pay a little above the median, at least”

And then another car company looks down and says “Wow, the median went up again!”

Not even kidding. IMHO, true corporate governance would be something like a 6-year term limit on a CEO, even one who is doing a good job. There is just far too much risk putting the entire culture of a company (symbolically or literally) in the hands of one person. It should at the very least be a rotation of C-people.

Add to it that it doesn’t cost the board anything. It isn’t coming out of their pocketbook. To them, the salary of these CEOs is just another number, so the fact that many of times these board members are very friendly with the CEOs, makes it isn’t a big deal to the board to inflate the salary a little here or expand the bonus a little there. Its Monopoly money to them.

But I do have to say that I find it quite humorous that when they determine if a new factory will be built in one country or another, labor rates are always looked at. The US labor is 8X more than China. But when determining CEO pay, they never look at what Chinese CEOs get paid. Or honestly, in almost any other country. Even in Japan, automotive CEOs aren’t at the obnoxious level that they are in the US. Toyota’s CEO “only” makes $4m, and no one is going to say that Ford is doing better than Toyota.

This is the same scenario that is causing public utility rates to skyrocket.

Agreed on the CEO compensation part, but the entire article is basically going into detail about how they will be competing with China by streamlining manufacturing.

Let’s not allow topical facts to get in the way of a good classism argument, though. (/s but also not really /s)

I agree, but they are all interconnected. After all, WHY does Ford need to streamline its manufacturing? If they felt that it wasn’t adding cost, then they wouldn’t be spending all this time on it.

I mean, they pretty clearly feel that electric propulsion is going to remain a significant part of the future, and they also want to be able to compete with China on a cost basis, so yeah, they’re going to want to build EVs as quickly and cheaply as possible.

My radical, practical, yet impossible to actually implement is this for CEOs:

You have a 5-year plan? Great, you don’t get anything more than base (lower) pay until and only unless your 5-year plan actually results in the what you forecast/promised. If your plan fails, you get the heave-ho, and nothing else.

Currently, if your plan fails badly, you still get a golden parachute, which is just plain stupid and financially irresponsible.

At the bottom of the pay scale, you fail at your job one day, it is recognized immediately, and you can be tossed out, the further up the pay scale, the longer it takes to recogize that you failed, and so on up to the top.

If it were me, I’d pay Farley whatever he wants.

(Though generally I do think executive pay can get out of hand in the U.S.).

I think it’s more out of hand than not at this point.

Why? Quality, sales, profitability, nor almost any other metric has drastically improved under him. He hasn’t been great for the shareholder, and he’s been at best, middling for the consumer.

“In 2024, Ford CEO Jim Farley’s total compensation was nearly $24.9 million, according to the Detroit News. This includes a base salary of $1.7 million, stock awards, and a reduced bonus due to performance targets not being fully met. Specifically, the bonus was cut by 33% to $1.6 million.The stock awards were valued at $20.6 million, though their actual value depends on future stock performance.”

Even Ford shareholders know he doesn’t deserve whatever he wants.

Maybe you are too close to these executives then.

For comparisons, the total compensation of Toyota’s CEO is $4m. Are you seriously going to argue that Ford, of all companies, is doing BETTER than Toyota?! And doing 6X better, on top of that?! Not a chance. Yet that’s the pay difference between their CEO and Toyota’s CEO. Heck, it is the exact opposite, in fact. Toyota’s net income is almost 6X that of Ford’s, while their CEO makes 1/6th of Farley.

Make that make sense.

I am not close to executives. Yes, CEOs get paid a lot in the U.S.; maybe I’ve just grown used to it covering the industry this long. I’m not saying to literally pay Farley whatever, it’s just me saying he seems to me like one of the good ones.

During his time as executive of the company, he has overseen arguably greatest product lineup in Ford history. Maverick (at the time, a truly outside-the-box stroke of genius — a hybrid unibody pickup!), F-150 Lightning (a brilliant move to get an EV truck to market without spending too much on a dedicated platform), Mach-E (start with an EV crossover, and name it Mustang: Very smart), F-150 hybrid (very smart), Ford Bronco/Bronco Raptor (a perfectly executed design that is about to catch Wrangler in sales), Ford Bronco Sport (a great fun little 4×4 to capitalize on the Bronco brand), Ford F-150 Raptor R (a badass supercharged V8 sport truck), Ford Ranger/Ranger Raptor, Mustang and all its variants including the new Mustang GTD, and on and on.

I’ve been saying this for many years now: Ford’s product strategy is phenomenal — arguably the best in the business. I realize not all of it can be attributed to Farley (and much of it came pre-him becoming CEO, though he has been an exec at Ford much longer), just as not all of the longstanding quality issues can be, which is why, typically, views on him as a CEO are mixed. From Motor Trend’s Person of the Year a few years back to, more recently, New Republic calling him the “Biggest Loser” to Cleantechnica saying he’s “one of the best CEOs in the legacy auto world.”

Obviously a CEO’s job is shareholder value; to me, he seems like a thoughtful enthusiast-CEO, and as someone who runs an enthusiast site, of course that appeals to me. This view is based solely on 1. The products I’ve seen from Ford lately and 2. The way Farley communicates to the media, and how he thinks when it comes to decision-making (including EVs; he’s been studying Chinese EVs and he and I are in agreement on the value of EREVs).

TLDR: From where I stand, he’s a smart car person who’s been around during one of the golden eras for product at Ford, especially for enthusiasts. I understand the challenges with regards to EV strategy (though I contend that Ford has been navigating these incredibly treacherous, unprecedented, and ever-shifting waters better than many others) and with regards to quality; it’ll be interesting to see whether that improves in the coming years.

I literally could not disagree with you more.

First off, he’s been the CEO for 5 yrs and nearly all the products you listed have been around longer than that. We both know the auto industry has long lead times before vehicles are released versus when they are developed. He might have touched some of the products you listed, but how are you attributing the Mach-E to him seeing as how it was released a year before he even became CEO? The Bronco and Maverick came out a year after he become CEO but there’s no way that design wasn’t locked down before he took his first big boy paycheck.

However, he was in charge during the time when the F150 lost the sales crown for the first time in 43 consecutive years. And also during an endless stream of recalls and horrible quality which still continues to today – a 100 year old company can’t even get the basics right. Even the recently restyled ICE Mustang has gotten some rather poor reviews and its sales are in the toilet – down around 50% from when he took the helm.

I see very little to be positive about when it comes to Ford and their direction. They are incredibly vulnerable. They have pulled back from most international markets and heavily rely on US sales. A US recession would badly hurt them – way more than any other company. They are also blindly focused on trucks and SUVs – yes, they are popular now, but the market is fickle which is why most other brands still have some kind of mass market sedan and/or coupe around. They also can’t produce their own vehicles – they have to partner with VW for some terrible vehicles in Europe and elsewhere. If the Scout brand takes off, VW will have little reason to continue the partnership leaving Ford even more vulnerable.

I just don’t see how anyone can claim that Ford is headed in the right direction. Farley might be the type of person you’d want to share a beer with, but I wouldn’t let him look after my house plants, let alone keep him at the helm of Ford. His background is marketing and communications, so that aspect of the company he’s doing a lot better job than other companies, but at the end of the day, product is king in the automotive space, and some slick presentation or good speech isn’t going to fix my neighbor’s transmission or make the new Mustang handle well.

Fire Farley!

I addressed most of your points in my reply (noting he wasn’t ceo but was an exec during development of these vehicles).

The “what happened on his watch/when he was in another executive position and what was going to happen because of inertia anyhow (F-150 losing crown, quality issues)” question is a difficult.

In time we’ll have a better answer. As of today, from where I sit, it seems Ford is in competent hands.

But again, I do want more data before I can say that confidently.

Really? The guy who promised to get the warranty costs/recalls under control, and then watched them go up? He needs to be shown the door.

Executive pay is extremely ridiculous in the United States and you can thank the deregulation squad for that!

Why does a CEO need to make 30 times the salary of a worker when he can make 3000 times what they make?

America needs to get over this whole ‘today is the only day that matters’, and quarterly profits being more important than long term viability. The oldest restaurant in the world has been operational for hundreds of years. I bet they weren’t primarily focused on executive pay.

Executive pay, especially in the US, is obnoxious, but because most Americans are terrible at math, these large numbers we are dealing with, make most people’s eyes gloss over.

Try explaining to Jimbo in Alabama that his CEO makes more on January 1st than he will make working full time ALL YEAR. If you explain it that way, it might sink in. But if you just start talking about millions here and millions there, he can’t relate. The numbers lose meaning. Then sprinkle in the uniquely American idea that just anyone can be a successful millionaire if they work hard enough, and then Jimbo ain’t so sure we should be limiting people’s pay, no matter how laughably unrealistic that idea is. Especially these days.

Soon to be what exec makes on Jan 2 (1 is a Holiday, well for now anyway) could equate to half a decade of Jimbo working at the drive through window. (Remember, execs get weeks off, don’t work weekends, probably have a 4 day week and I day of golf with cronies) So say realistically the Farley get about 136,000 per woking day. at 14/hour with 2000 hours JImbo grosses 28000. 28 x 5 + 140k in 5 years

I was trying to be slightly fair to the auto industry since thanks to collective bargaining, the industry tends to pay rather well. Especially the longer you stay and the higher up the ladder your go.

Good call. I was referencing our potential dystopian future given the present power structure here in America.

The average Ford UAW worker was making $60 / hour in wages and benefits BEFORE the new contract with a 25% bump. How much should they be making?

Labour is between 15 and 25 hours per vehicle.

I think the all in cost of a UAW member is around $60/hour ($28 per hour plus benefits)

Cost per vehicle for labour is $900 to $1500

https://jvis.us/2022/10/17/how-long-does-it-take-to-build-a-car-these-days/

If it doesn’t have at least a 6 foot bed, then what’s the point.

Looking at most trucks I see around here, lots of people have no problem with a 5.5′ bed.

I think the word truck gets overused. One there is more space inside than outside, it becomes a Lifestyle Activity Vehicle. I believe some author on this site came up with the term and I think it’s brilliant. It describes something that looks like it could be useful, but has no real need to actually be useful.

Doesn’t change the fact that lots of people apparently want a 4 door vehicle with a small bed, no matter what you call it. I’d bet a lot more people want that than Slate’s single cab with a longer bed, which was my biggest gripe about the Slate.

The minimum size for a bed should be 1 standardized pallet IMO.

It’s almost like they shouldn’t bother making it a truck at all…

Funny how what were always the stalwarts of economical transportation, small sedans and hatchbacks are all gone. I wonder why that happened?

I am so tired of everything needing to be a damn truck. Great that some people actually use their trucks to do truck stuff, but it shouldn’t be the default bodystyle.

I mean, ford already has a F150 (and bigger), Ranger and Maverick. Does the world really need yet another variety of Ford truck?

If they want electric, economical and kind of butchy, seems like they’d get smart and clone off a Rivian R3. All the Crosstrek owners (and boy are they a dogmatic lot) who think they need offroading ability to drive to work/school will eventually want the the next step up that Ford does not have. I don’t see an electric Crosstrek coming, so why not get ahead of the curve for once?

Because more actual buyers of new vehicles prefer trucks, regardless of blog commenters’ statements on their “needs”.

Once other body styles stopped having a significant fuel economy disadvantage (with hybrids, small turbo engines, and multispeed autos), the rationale for people to compromise with a small hatchback or sedan was gone. Sales figures for every small car since ~2010 bear that out.

Do you truly believe that automakers marketing higher-profit margin vehicles and deleting more economical choices are at all a coincidence? That the changing preferences for people toward trucks and SUVs was not at all cultivated?

I don’t like it, but if I ran a large automaker and I was told to maximize profit, I would create a campaign to market and sell the products that generated the most profit.

That’s all this is, it has nothing to do with our individual preferences, our needs, our desires, it’s about profit. Nothing new here. We are being sold things that drive the bottom line. It’s an easy move for automakers to market things that are tough and butchy and convince us that we need them and that if we buy anything that doesn’t measure up, WE don’t measure up.

Just like the transition to electrics, the automakers would not bother unless they could profit from it. That’s why we’re being sold on the idea that almost every electric car is also a luxury car. There are so few exceptions to this like the Leaf and, yeah, that’s about it.

I have much more belief that people express honest preferences with their dollars than you (and others) seem to.

I think small cars were never truly desirable, except to weirdos online or poverty fetishists and people settled for them because they were cheap to buy and run.

Now that we have a market where:

-Small trucks and SUVs can routinely get 40 mpg

-Something like a Chevy Trax costs as little as $21K

-The same levels of features and equipment are available in trucks as in cars

-People can get 7+ year loans on new cars (because they last so much longer)

It’s simply much easier for people to express their true preferences, which for over 100 years have been for larger, more spacious, better equipped, and more capable vehicles.

For almost all consumers:

The modern crew cab truck is a better version of the BOF full size sedan, which was the most popular vehicle in this country for decades.

The modern SUV is a better version of the midsize FWD sedan, which was the default vehicle in the 80s-90s.

It’s not some nefarious conspiracy that people buy an improved product once it’s offered to them!

I wish we didn’t seem to chase the bloat all of these things bring, but otherwise I can’t argue this line of thought. Growing up, when sedans were “fuel efficient” at around 20-25 mpg, and it was basically impolite to talk about trucks/SUVs mileage, it was “worth it” to go with sedans if you needed to drive economically. That gap has shrunk considerably, so people get to have their cake and eat it, too.

Hell, I was looking to try and get into a Kia Sportage Hybrid a few years ago. It’s definitely too big for my daily driving/life, but when it was EPA rated at 38/38/38 – better than the Optima I was driving at the time – where’s the drawback?

People love to forget about the Bolt, which proves your point also.

Small sedans and hatchbacks are dead – BECAUSE THEY DO NOT SELL. Sorry but the emphasis is needed because this same old tired conspiracy won’t die. Companies are happy to sell people anything that sells. Small cars do not sell in the USA. As V10omous said – you can clearly looks at the sales number of any of the small cars that got the axe and see that.

These cars did not sell – so they were discounted.

Meanwhile the Ford Maverick sold 98K in the first half of 2025

Chevy Trax is at 120K for the first half of 2025.

Lets be real – if your job is to do product planning at GM do you pitch your boss the Sonic or the Trax?

I see people with long bed Tacomas and I always laugh at them for how much they punish their self for the two or three times they will use the extra length.

Americans are size queens!

For a commercial vehicle, maybe a 6’+ bed is needed.

For the vast majority of personal pickup owners, mostly pointless.

Looks like they have just repackaged some different ideas from around the industry. Universal ev platform, that’s similar to the Ultium, E-GMP, or MEB. The “Assembly Tree” sounds similar to Tesla’s proposed “Unboxed Assembly” Zonal architecture sounds like what Rivian and Lucid are using today for their vehicles.

Except that GM’s Ultium Platform isn’t really a platform and is just the battery. Other than cells I doubt much is shared between that Blazer and Silverado EV. Certainly not the suspension and structure which is what is typically considered a platform.

Ford started using Zonal Architecture over 25 years ago, but abandoned it because it was more expensive than the traditional systems. Granted that was when they were cutting it down from a dozen or so computers to 3 or 4.

I was dumbing down GMs setup to what their marketing would have you believe, but still they use 2 architectures to underpin their EVs, the BEV3 for crossovers and the BT1 for trucks and suvs.

Sometimes, all it takes is someone to come along and put all the pieces together to make a killer product that truly is the game-changing thing we need. Easiest example off the top of my head: the original iPhone.

Please don’t take this as me saying this product announcement is Ford’s “iPhone moment”. We will need to see the thing and get all the details of the actual production model. However, IF they can truly deliver on these promises, it could be a good leap forward for EVs.

I’m surprised The Autopian doesn’t have a template for writing posts about vaporware affordable EVs that will never exist. That could be a huge time saver.

Maybe do some kind of MadLibs style thing where readers can fill in the blanks to create their own post about a hypothetical affordable EV? That could be kind of fun.

We all know there is a higher likelyhood of seeing a pig fly an A380 through a blizzard in Hell than there is of seeing a $30k US-built EV pickup truck.

Torch, this is your calling. PLEASE build this MadLibs template.

I would certainly default to thinking a $30,000 vehicle in 2027 is pretty stripped down, and I don’t entirely believe Ford’s assertions that it won’t be.

Forward looking cost projects are a fools errand in this day and age. The past 5-7 years seems like a continual cluster fuck of once-in-a-lifetime disruptions. Trump 1.0 trade war, covid, and now

Oprah‘s Trump’s everyone-gets-a-tarrif trade war on steroids.If Ford can hit $30k in todays dollars, I’ll give them the benefit of the doubt.

I bet it will include some sort of infotainment, power windows and a lot of things that will be optional on the $28k Slate.

The Slate is silly. It likely cost more to make crank windows than motors at this point. I reserved one, but I regret it because I’m not going to be a 4×2 pickup with crank windows and 150-mile range for $35,000. That SUCKS.

I kind of think they will be dead on arrival and then we will see them as Dominos delivery trucks.

I agree that the Slate is likely to be a flop and this announcement only increases the likelihood.

It’ll almost certainly be less stripped down than the Slate.

Now if Ford can just put their quality issues behind them they may have hit on a vehicle that can be built to a cost without feeling cheap- and being constantly recalled.

I have my issues with Ford, but I really do respect them for their response to Chinese EVs. Instead of just stomping their feet and whining and complaining to Daddy Trump about how unfair it is that another country builds better cars than they do, they’ve actually studied those cars, studied their production methods, and are using what they’ve learned to improve their own cars and production methods.

I do believe they’ve got their sh*t together more than anyone else right now, that’s why I’m an investor (but not an owner). Of course, deep pockets and existing economies of scale definitely help you throw your weight around, and they seem to be paying just the right about of lip service to Trump to stay off of his naughty list.

They seem to be the only major domestic automaker who realizes the pendulum is going to swing back the other way someday and maybe it’s not the best idea ever to put all your eggs in one basket. Trump is stupid enough that he’s not going to either realize or care that Ford is still investing so heavily in EVs – just tell him he’s a special boy every so often and continue planning for what things will be like when he finally kicks off.

I’ll believe it when I see it. Unless they don’t use Ford dealers expect massive markups, selling orders out from under the orderers, and ransoming of orders to get more money under the threat of selling them to someone else.

How about a 2-Door pick-up. I am sure I am not the only one that would like to see a return of the 2-door.

I think they’re specifically trying to avoid negative comparisons against Slate’s two-door budget pickup by being able to point to four doors as an advantage.

I like that nostalgically-speaking, but when I look around at other pickups, plus everything from the GTI to the Wrangler, it’s pretty obvious that 4 doors is the best (first) option.

I wish it wasn’t nostalgia, but it is what it is.

You and like 7 other people. Looking at sales, the market has spoken and it wants 4 doors.

Consider the fact that all US automakers have discontinued all things that are not trucks/SUVs. No more sedans, no more hatchbacks, no more wagons.

If you want to buy from one of the US automakers, you’re either getting a truck or SUV. People that might have been perfectly fine in a Fusion or Malibu are now buying a Colorado or a Maverick.

So yeah, go figure that the four door trucks sell better, there aren’t any other choices for US automakers.

True, but in cases where truck manufacturers sold both extended and crew cabs of the same model, the crew cabs always sold way better, so if I’m a manufacturer only going to make one cab version of a truck, damn right it’s going to be a crew cab 4 door. That’s just good business sense.

Nissan is basically the only full line automaker in the United States currently with a car for every purse and purpose. Toyota and Honda abandoned cheap cars long ago.

Not only does the Versa exist, but a loaded Sentra with leather is less than a base Honda Civic.

…and yet they struggle.

The 2025 Toyota Corolla starts at $22,175 MRSP. A cheap but quality car – which explains why it is the best selling compact car in the USA by miles.

“People that might have been perfectly fine in a Fusion or Malibu are now buying a…”

Camry

Corolla

Elantra

K4

Sentra

Accord

Civic

Full size trucks are sold in regular cab, extended cab, and crew cab. Regular cabs make up 3% of sales.

“I mean… who would think a modern EV is a stripped-down vehicle if not for the existence of Slate?”

Anyone whose seen the interior of a Tesla 3.

Crying Woman: It looks like high-end Scandinavian design!

Smug Cat: Soviet austerity.

“As for what more we know about that midsize truck? Not a ton”

So a half ton then? Maybe a 3/4 ton?

Very ton-deaf comment, IMO.

We’ll just have to weight and see.

The new Ford Raven, now with more “quoths” than David’s article about it! 🙂

Hooray. Double-hooray if they can find a way to modularize an EREV generator, too. A single architecture that could handle BEV and EREV is probably a big hurdle, but seems like it would be worth it.