A few months ago, a Jeff Bezos-backed newcomer in the car world, Slate Auto, got the world’s attention by debuting a dirt-cheap electric pickup truck. I had my concerns about it, namely, I thought it had too few doors and was too expensive given its lack of features. Well, if the Slate got your blood flowing, it’s time to get even more excited, because an established automaker — one with manufacturing experience and economies of scale that a newcomer lacks — says it’s planning a $30,000 electric four-door pickup truck. And it’s only a small part of a massive $5 billion investment from the Blue Oval brand. Here’s what we know about Ford’s “Model T Moment,” its new “affordable” EV platform.

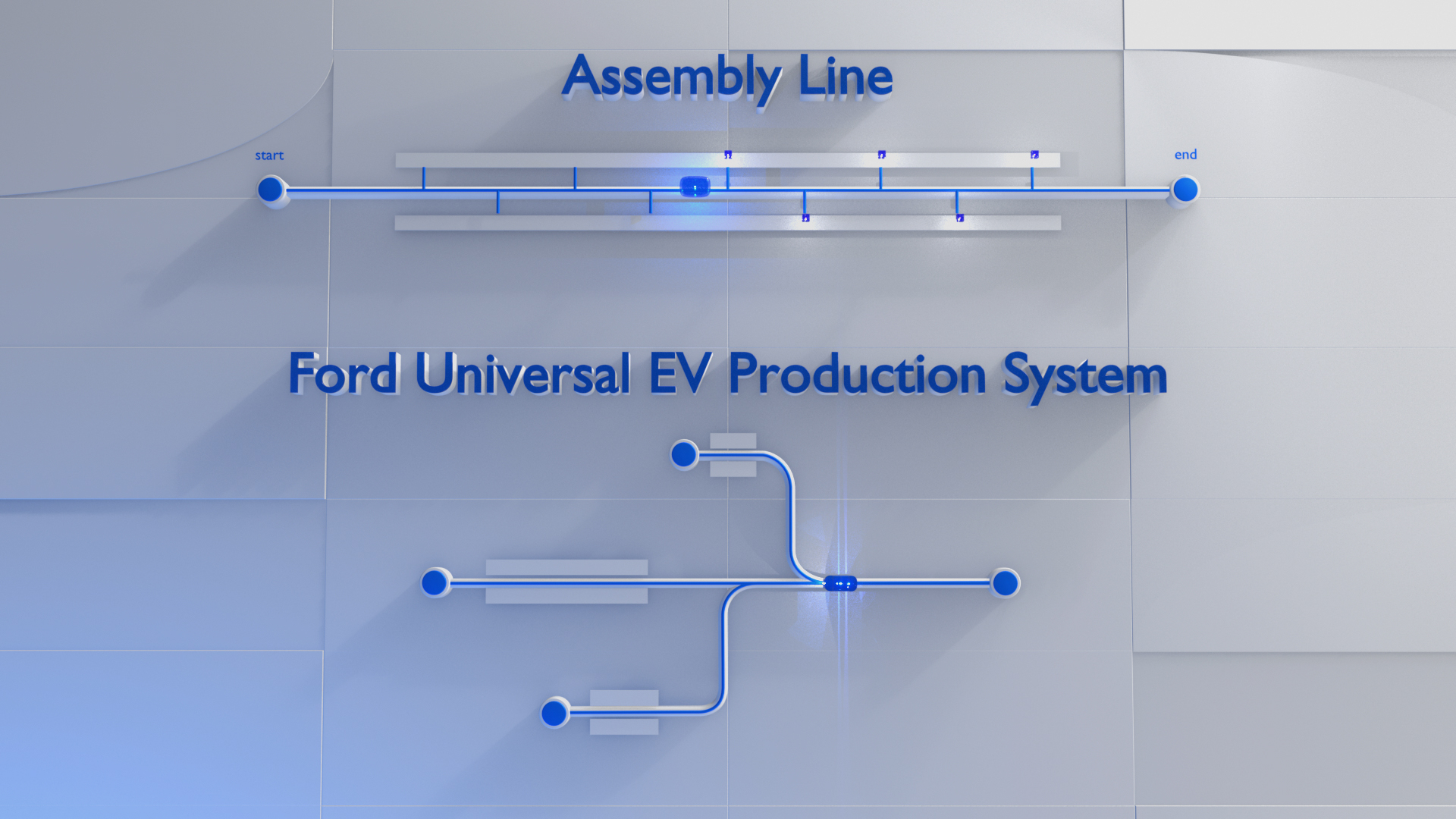

If you’re been “in the loop,” you know Ford Motor Company has had a Skunkworks team working on some kind of “secret” project in the Bay Area. What exactly is it? We never knew for sure, other than that it almost certainly had something to do with electric cars, given that it was happening in California. Well, it turns out, that Skunkworks team was mapping out the future of Ford Motor Company as we know it by developing not just a new platform, but a new production system that is a bit different than the linear assembly line that built Ford in the early 20th century.

In a “bold and difficult undertaking to compete with the best in the world,” i.e. China, Ford has developed the Ford Universal EV Platform, “a simple, efficient, flexible ecosystem [meant] to deliver a family of affordable, electric, software-defined vehicles – the first of which is a midsize, four-door electric pickup that will be assembled at Ford’s Louisville Assembly Plant for U.S. and export markets. Its launch is scheduled for 2027,” as FoMoCo says in its press release.

The company’s CEO, Jim Farley, reiterates the Universal EV Platform’s emphasis on affordability, saying in the press release:

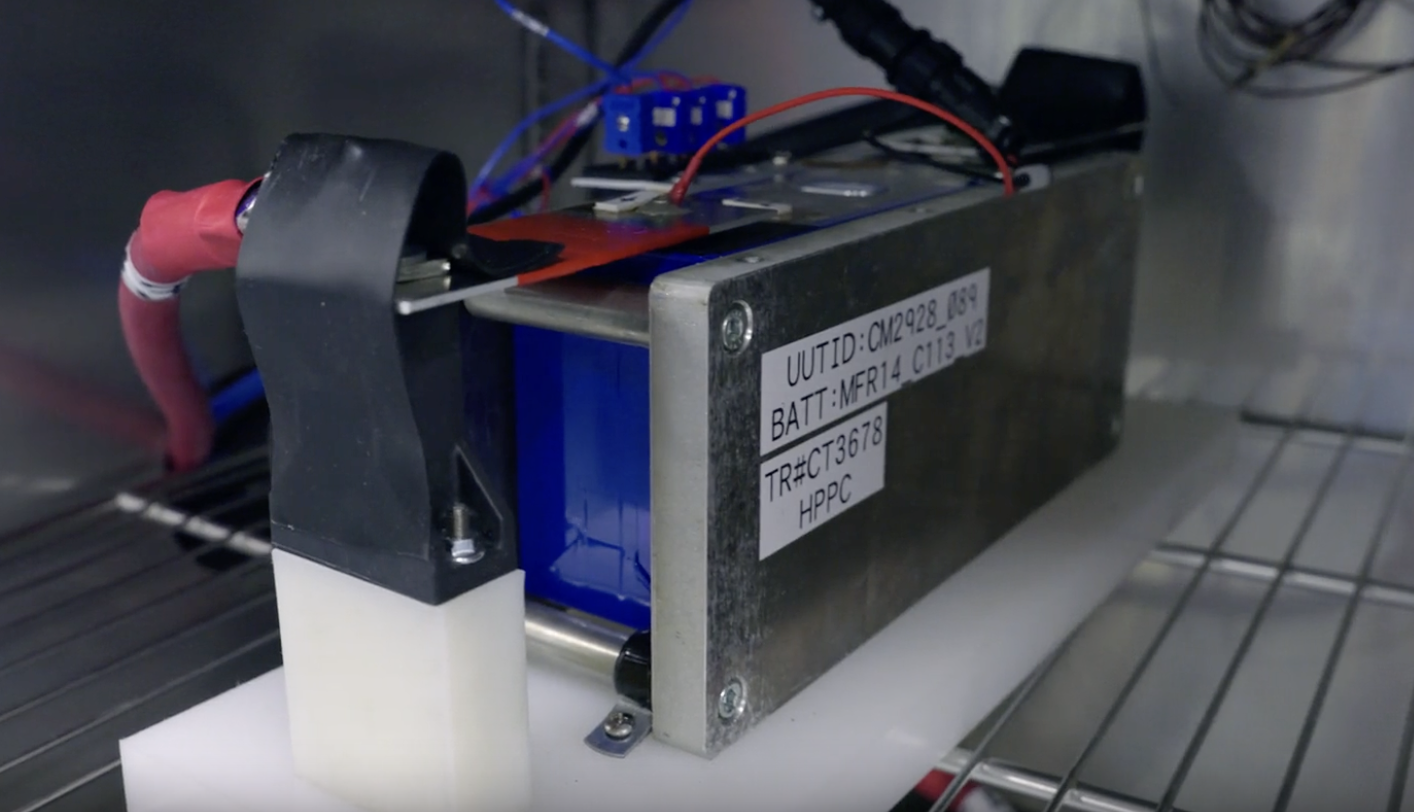

“We took a radical approach to a very hard challenge: Create affordable vehicles that delight customers in every way that matters – design, innovation, flexibility, space, driving pleasure, and cost of ownership – and do it with American workers,” said Ford President and CEO Jim Farley. “We have all lived through far too many ‘good college tries’ by Detroit automakers to make affordable vehicles that ends up with idled plants, layoffs and uncertainty. So, this had to be a strong, sustainable and profitable business. From Day 1, we knew there was no incremental path to success. We empowered a tiny skunkworks team three time zones away from Detroit. We tore up the moving assembly line concept and designed a better one. And we found a path to be the first automaker to make prismatic LFP batteries in the U.S.”

Launching a new modular EV platform is hardly novel, and in fact, Ford has been well behind others like Volkswagen (whose MEB platform debuted roughly seven years ago), GM (whose Ultium architecture underpins a bunch of GM vehicles like the Equinox and Blazer EV, as well as non-GM vehicles like the Honda Prologue and Acura ZDX), Hyundai/Kia (whose e-GMP 800v architecture that underpins the Hyundai Ioniq 5 and Kia EV6 has been out for about five years), and on and on.

But when I asked Ford how its architecture is different, it replied by saying “it really goes beyond a modular architecture,” saying the reduction in wiring and fasteners, plus the use of unicastings, makes this a more modular approach than elsewhere in the industry.

I’m tempted to say “its’ about time,” but Ford’s slow roll-out of EVs — its F-150 Lightning that was largely based on the existing gas truck and thus managed to get to market early, as well as a crossover EV named the Mustang — wasn’t necessarily a bad thing, as the world has clearly been clamoring more for hybrids than for EVs, of late. Still, EVs are the future, and to truly compete long-term, you’ve got to build a modular platform, so that’s what Ford has done. Here are some of the benefits of Ford’s new modular architecture and of its “affordable” in-house LFP prismatic batteries, per the automaker:

The platform reduces parts by 20% versus a typical vehicle, with 25% fewer fasteners, 40% fewer workstations dock-to-dock in the plant and 15% faster assembly time. Lower cost of ownership over five years than a three-year-old used Tesla Model Y.

Take for instance the wiring harness in the new midsize truck; it will be more than 4,000 feet (1.3 kilometers) shorter and 10 kilograms lighter than the one used in our first-gen electric SUV. Lithium iron phosphate (LFP) prismatic batteries also enable space and weight savings, while delivering cost reduction and durability for customers. The platform’s cobalt-free and nickel-free LFP battery pack is a structural sub-assembly that also serves as the vehicle’s floor…The new midsize truck is forecasted to have more passenger room than the latest Toyota RAV4, even before you include the frunk and the truck bed. You can lock your surfboards or other gear in that bed – no roof rack or trailer hitch racks required.

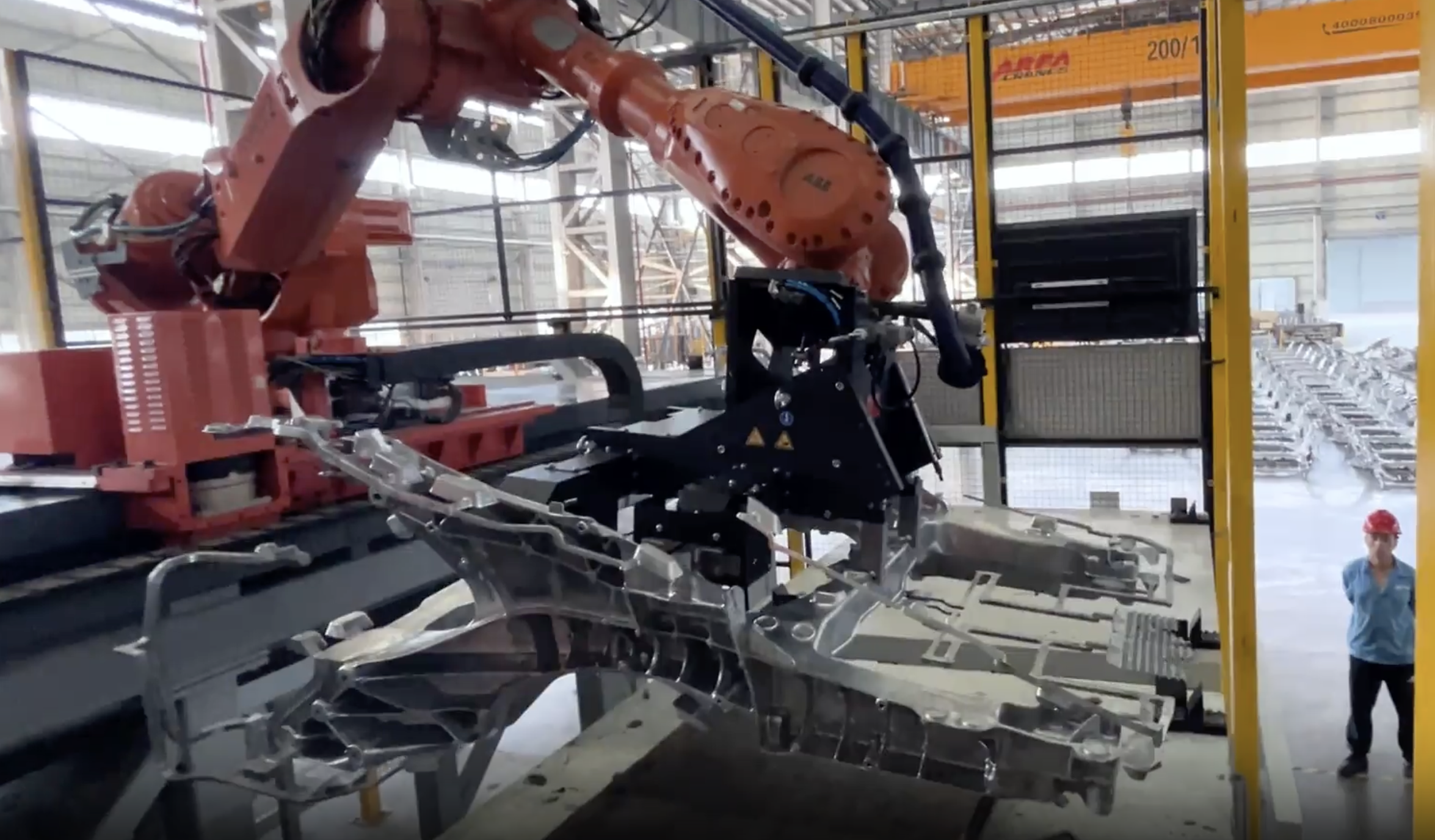

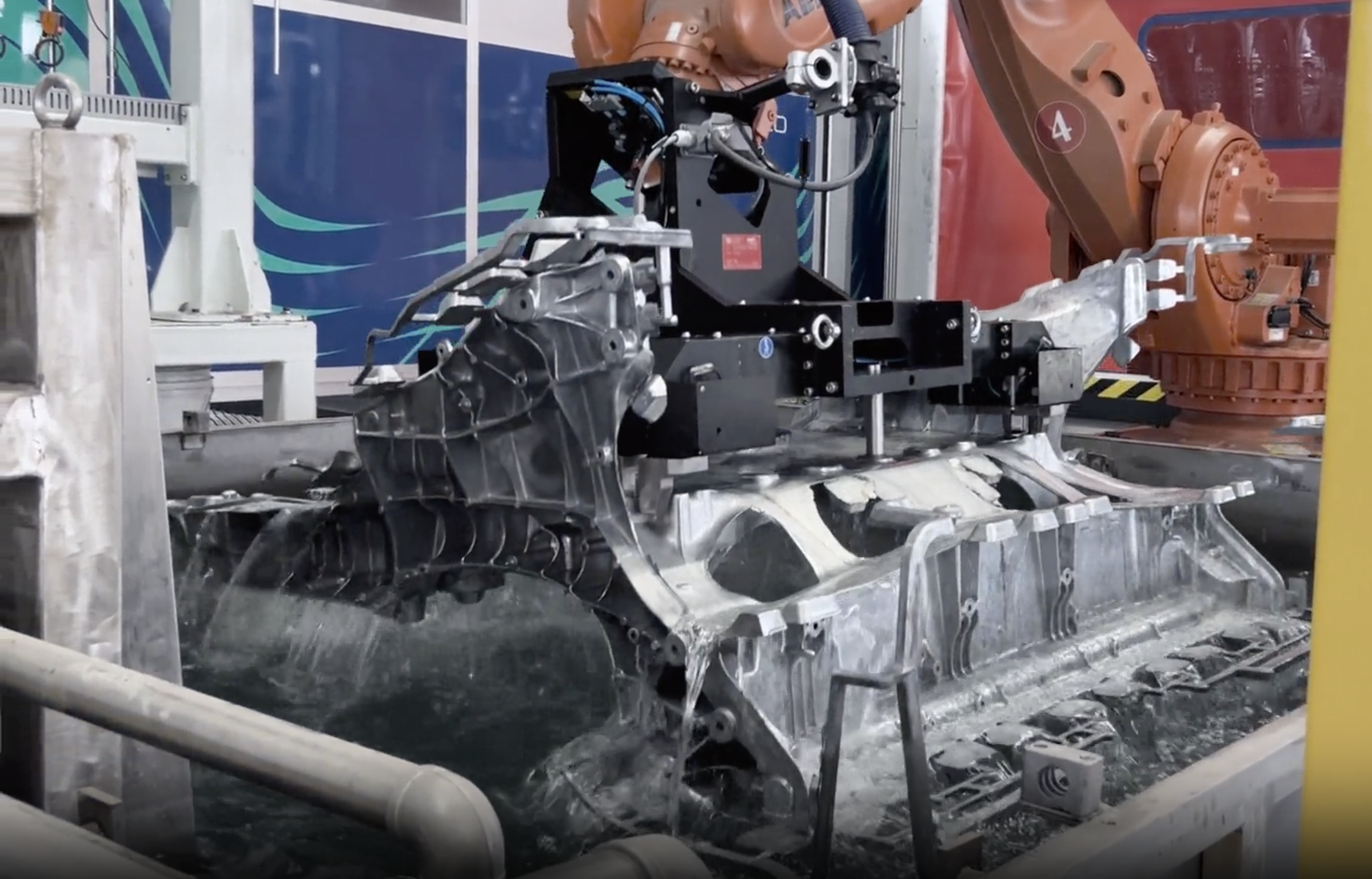

Ford talks about large “unicastings” (like Tesla’s gigacastings), and how its team plans to build sections of its vehicles independently, and then bring those sections together — in much the same way as a front subframe is “decked” with a body on a traditional car, except with three large subassemblies. From Ford:

Large single-piece aluminum unicastings replace dozens of smaller parts, enabling the front and rear of the vehicle to be assembled separately. The front and rear are then combined with the third sub-assembly, the structural battery, which is independently assembled with seats, consoles and carpeting, to form the vehicle.

Parts travel down the assembly tree to operators in a kit. Within that kit, all fasteners, scanners and power tools required for the job are included – and in the correct orientation for use.

The Ford Universal EV Production System dramatically improves ergonomics for employees by reducing twisting, reaching and bending, allowing them to focus on the job at hand. Because of the integration between the Ford Universal EV Production System and Platform, assembly of the midsize electric truck could be up to 40% faster than Louisville Assembly Plant’s current vehicles.

Some of that time will be reinvested into insourcing and automation to improve quality and cost, ultimately netting a 15% speed improvement. “We put our employees at the center and re-created the factory from scratch,” said Bryce Currie, Ford vice president, Americas Manufacturing. “We live and breathe continuous improvement, but sometimes you need a dramatic leap forward. We expect ergonomic breakthroughs and complexity reduction – through elimination of parts, connectors and wire – will flow through to significant quality and cost wins.”

Here’s a look at Ford’s “production tree”:

The architecture is a 400V one, with Ford saying “We think that is absolutely the right choice,” as it enables low cost and access to the existing charging infrastructure. When I asked whether the platform has provisions for a range extender, Ford replied with “We’re not gonna get into specifics.”

As for what more we know about that midsize truck? Not a ton. Ford says it will be aerodynamic to the point where, if the company put its battery into an existing truck of roughly the same size, the range would drop by 50 miles compared to the upcoming vehicle. In addition, Ford says EV will have a 0-60 mph acceleration time similar to a Mustang EcoBoost (~4.5 seconds), and then the press release seems to maybe include a subtle dig at Slate Auto: “We assembled a really brilliant collection of minds across Ford and unleashed them to find new solutions to old problems. We applied first‑principles engineering, pushing to the limits of physics to make it fun to drive and compete on affordability. Our new zonal electric architecture unlocks capabilities the industry has never seen. This isn’t a stripped‑down, old‑school vehicle.”

Maybe that wasn’t a dig, but why mention that this isn’t a stripped-down vehicle? I mean… who would think a modern EV is a stripped-down vehicle if not for the existence of Slate?

Anyway, the mid-size truck is to be built at the Louisville Assembly Plant, which will see a $2 billion investment that, when combined with Ford’s $3 billion investment in its Michigan battery factory, will total $5 billion and allegedly create 4,000 jobs.

Ford says in reference to the Ford Maverick hybrid pickup: “We believe there’s room for both.”

Ford calls this new platform and manufacturing method a “Model T moment,” which is fair to say, as this represents a major shift for the company. At the same time, I’ll be interested in seeing if it’s really that different than what we’ve seen from the competition. GM makes its own batteries, it’s focusing heavily on affordable LFP batteries to bring EV pricing down, and it’s got an architecture malleable enough to build a variety of vehicle types across a variety of brands.

But it doesn’t have a $30,000 four-door pickup truck. Nobody does right now, so if Ford can be first, and if that truck can offer decent range and decent tech, it could be a game-changer in its own right, worthy of Ford’s new “The Universal Vehicle” badge you see above.

All Images: Ford

Those front seatbacks will need to be wafer thin to fit that rear-seat passenger’s legs in.

This sounds like a continuation of the 3T(trust the truck) project not the ‘skunkworks’ cheap EV. I was thinking more of a Focus/Escort sized compact cheap EV for the skunkworks, priced around $20k, and the 3T was put on hold. I swear Farley said in one interview that large big batteried EV trucks weren’t sustainable or cost effective or some such.

Comparing Ford vs the Slate, I think the Slate has gone more hardcore cost reduction, and keeping costs low in actual development, buying an existing factory to refurbish, outsourcing the chassis and battery, every model produced is identical except battery spec.

Ford may have done a ‘skunkworks’ but it’s still a giant legacy manufacturer, I don’t think they know how to truly cost reduce, it will still be built in a giant factory, it’s using gigacasting instead of welded steel frame, it’s still going to be painted, it still looks to have tons of proprietary molded panels, it’s still being built by UAW, it’s still going to have an integrated infotainment which I’m sure will be connected and collecting all the datas, it’s still going to be sold by dealerships that can upcharge. I mean they’ve spent $5 billion already, that’s a small elite project?

Also for it to truly be a model T, after the initial cost of $30k, once it ramps up, it’s price should go DOWN, like the Model T’s did. But as we saw with the Maverick, that’s not going to happen.

I feel slightly flimmed by their flam.

“Large single-piece aluminum unicastings replace dozens of smaller parts, enabling the front and rear of the vehicle to be assembled separately. “

You mean like Toyota and Elon announced about a year or so ago?

It’s like someone woke up and discovered large subframes.

“the wiring harness … will be more than 4,000 feet (1.3 kilometers) shorter and 10 kilograms lighter than the one used in our first-gen electric SUV.”

It’s amazing how optimizing the use of 1990’s fiber-optic/CAN-bus tech can do that.

This is not a breakthrough – just another progression of existing tech.

“…a family of affordable, electric, software-defined vehicles”

Ie: Get ready for more apps, ads and subscription services.

Ford’s dealers will fuck this up with “market adjustments,” unwanted accessory add-ons, and outrageous documentation fees.

I have a deposit on a Slate but would consider this instead.

Had a Lightning and loved it. It fit my use case very well and the best part about it is that is just a run of the mill F150 that is electric, and smooth and quiet and fast and cheap to operate. Bonus was all accessories that fit 2015 + would fit a Lightning.

I was really excited when he started calling it a Model T moment, unfortunately the projected vase price is about $10k to high for them to call this a Model T moment.

The first major manufacturer to truly make a modern equivalent to the Model T or Beetle will dominate the EV market in the long run.

Does a “structural battery” means it’s non-replaceable? If so, once the battery degrades past a certain point is the only answer to scrap the whole car?

It doesn’t have to be. Only the frame of the battery case really needs to be structural, the actual batteries inside can be as plug and play as Ford wants them to be.

We aren’t talking about first-gen Nissan Leafs anymore. The reality is that modern batteries (especially LFP for low cost EVs) will be serviceable long past the rest of the chassis. It is much more likely recyclers will be cutting apart the scrapped shell to extract the usable cells.

We have friends with an aging Tesla Model 3. The vehicle still drives like a rocket, with over 90% of its range. The same cannot be said for the body. The paint is coming off in chunks around the wheel wells, exposing rusty metal. All of the bumpers, trim, underbody cladding and the interior are falling apart.

Unless manufacturers drastically improve the resilience, corrosion protection, and longevity of their vehicle’s surface-level components, EVs will not be seeing battery replacements at any scale.

Ford math:

Add 3 years, multiply price by 1.6 and add $2700 for destination and “acquisition”.

And plan for at least 5 recalls.

I can’t wait for the Ford Gran Torino Elite IV-e

Where were the skunkworks? Three time zones from Detroit is pretty far east or west.

California, Silicon Valley workers. Sooo, potentially ex-Apple, Facebook, Meta, Tesla employees.

Doh! I misread something and thought Detroit was CDT, not EDT.

No! I want a truck with a usable bed, not 4 doors. You know what carries a bunch of people much more efficiently than a truck? A car! You know what carries a lot of stuff better than an oversized car with an open-air trunk? A truck with a real bed!

You know what fills the needs of many people in one vehicle – a 4 door truck

You know which truck cab configuration has 3% market share – the regular cab.

If GM tried this, I’d simply laugh. Of all the domestic manufacturers, I honestly do believe that Ford has what it takes to make this work. HOWEVER, Ford has historically had a high number of recalls. If, just perhaps once, this “skunkworks” methodology means that the engineers had all of the appropriate time to create and test their systems to the extent that say, Toyota, does, then – and only then, could I see this platform as a truly Global platform that is both cost-effective, reliable and a big sales hit. That’s alot of if’s that Ford has to sort out though. Can they do it? Only time will tell.

GM EVs are performing really well right now. I would not be surprised if they could pull it off first.

It is all BS. Nobody made a 2nd EV after a “Global platform” debuted.

THey only made crappy pickups from F150 Lighting platform and no other EV at all.

Same with Mustang Mockery platform – only a crappy crossover.

GM’s “global platforms” only made the same vehicles since debut. Blazer platform only makes crossovers, same with Equinox. Bolt platform makes only Bolts.

Not a single different kind of EV. 1 Global plaform = 1 EV type.

VW made wagon, hatchback, coupe, convertible, crossover and sedan out of its

platform and it could do 0-60 in 4 seconds, or get a diesel engine, or hybrid. And you could buy from at least 4 different brands across the world

Hyundai/Kia is making a sedan, two-row crossovers, and three-row crossovers on their E-GMP platform.

The GM Ultium BEV3 platform underpins the vehicles you mentioned, their counterparts in Cadillac, and the Honda Prologue, which are all far too similar, but still…it’s possible to milk the global platforms.

That said, I don’t know as I trust Ford to do this right. Time will tell.

Ford will sell the first ten units at that price, then double it. How many times have Ford done this?

Not to mention what the dealerships will do with them.

The good news is that there are still dealerships that will sell in-demand models at, or even below, retail. There’s not much you can do once Ford hikes the price, themselves.

A swing and a miss. Damn a wanted a low cost erev, not this.

a true model T moment would be a modular erev capable drivetrain with a revolutionary (omega one?) rotary ICE generator combo option + a small battery for 100 mile battery / 500 mile battery + ice range. Add 48v low voltage architecture and plastic body panels and you’re revolutionary.

theres nothing I see that ford is doing that the other companies aren’t already have going on. The bolt, slate, Kia ev4 and other low cost EVs are on the way. I guess if you really want a small ev pickup the ford may be an option other that the slate, but Toyota, dodge and GM are sure to bring some small pickup ev to market soon too.

I don’t know why the automakers cannot realize that all we need is EREV, they just need to build it and learn how to articulate in their marketing why it’s the best platform for most people.

Just put the Escape PHEV powertrain in the Maverick

Apparently that drivetrain can no longer be 50-state certified, which is one of the reasons the Escape is getting discontinued after ’26.

That may not be a problem with the EPA standards being rolled back and CA losing its authority to set its own emissions standards

When it was introduced, the Maverick Hybrid was a sub-$20k truck – excluding destination. Now it’s $28k+. I don’t think this will be a $30k truck in 3 years.

Breaking News Ford has announced multiple recalls on their new “affordable electric car.”

I think they just recalled the recall.

Qualty is Job Onne.

And 7 “stop sales.”

Seriously. I’ve got a bunch of ’24 Transits collecting dust with recalls (latest ETA for a fix: October), so I’m selling ’25s with smaller incentives. Same thing happened with the ’24 and ’25 Mavericks a few months ago.

Whoever’s idea it was to reference the model t re: this announcement…yikes.

Pretty underwhelming. It’ll be lucky to be $35 by the time it’s out in 2028-29, and more likely 40.

400v? Idiotic.

Basically this “skunkworks” they’ve been tripping all over themselves to reference for a year or whatever came up with stuff that half the Industry is already doing.

I don’t get Ford at all lately.

me neither, but they only make vehicles for farmers now so I’m not seeing anything interesting to look at interior or test drive

That is what struck me as odd. Committing to a 400V system for production later this decade seems like kneecapping yourself before you even start.

Farley is getting a talking to at the next Illuminati meeting about that logo.

Is it going to be called Thunderbird? I mean… I feel like it’s going to be called Thunderbird.

with 5 doors, all wheel drive, 7 inches of ground clearance and extended unpainted fenders like Mustang Mockery

Imagine if it’s called Aerostar.

ThunderCougarFalconBird

Falcon

brother that is what i specifically want, best be careful or i’ll strip it down myself

I mean… cool stuff, but given the price trajectory of the maverick… its hard to actually take any of these statements seriously.

I just want some van PHEV’s besides the Pacifica. It’s crazy that only one manufacturer has done it so far.

Doubt.

(Presses “X”)

See this is still far less exciting than slate to me. A normal 4 door pickup is boring. The slate is fun due to the convertible nature. My plan is to get the fastback SUV kit, then buy a soft top that the aftermarket is probably already developing, and have a modern EV RAV4 convertible. I know the price comparison won’t make sense as at that point I’ll likely be paying more for the slate than for this, but that’s nothing new. Cool and unique cars almost always cost more than the mainstream ones, and both can coexist. Y’all can have this, I’m still in for the slate

You get to see one in person yet? I checked it out in a nearby city a few weeks ago. It’s actually a little bigger than I expected (which isn’t a bad thing).

Unfortunately not. I’m stalking their events page waiting for one to pop up nearby me, but so far they haven’t been anywhere within 300 miles.

The slate is definitely fun, but it’s more niche.

Oh for sure. I know this truck will be more useful and hence more appealing to most people, but I want the weird, so I want the Slate, and this is just yawn inducing to me.

Watching this, the Slate, and the TELO (which is admittedly the least likely to make it to market), this one is the least exciting. I’m definitely willing to pay more for one that makes me happier.

100%. I haven’t followed the Telo much because yeah it just screams vaporware, but it would be an interesting one if the stars align for them.