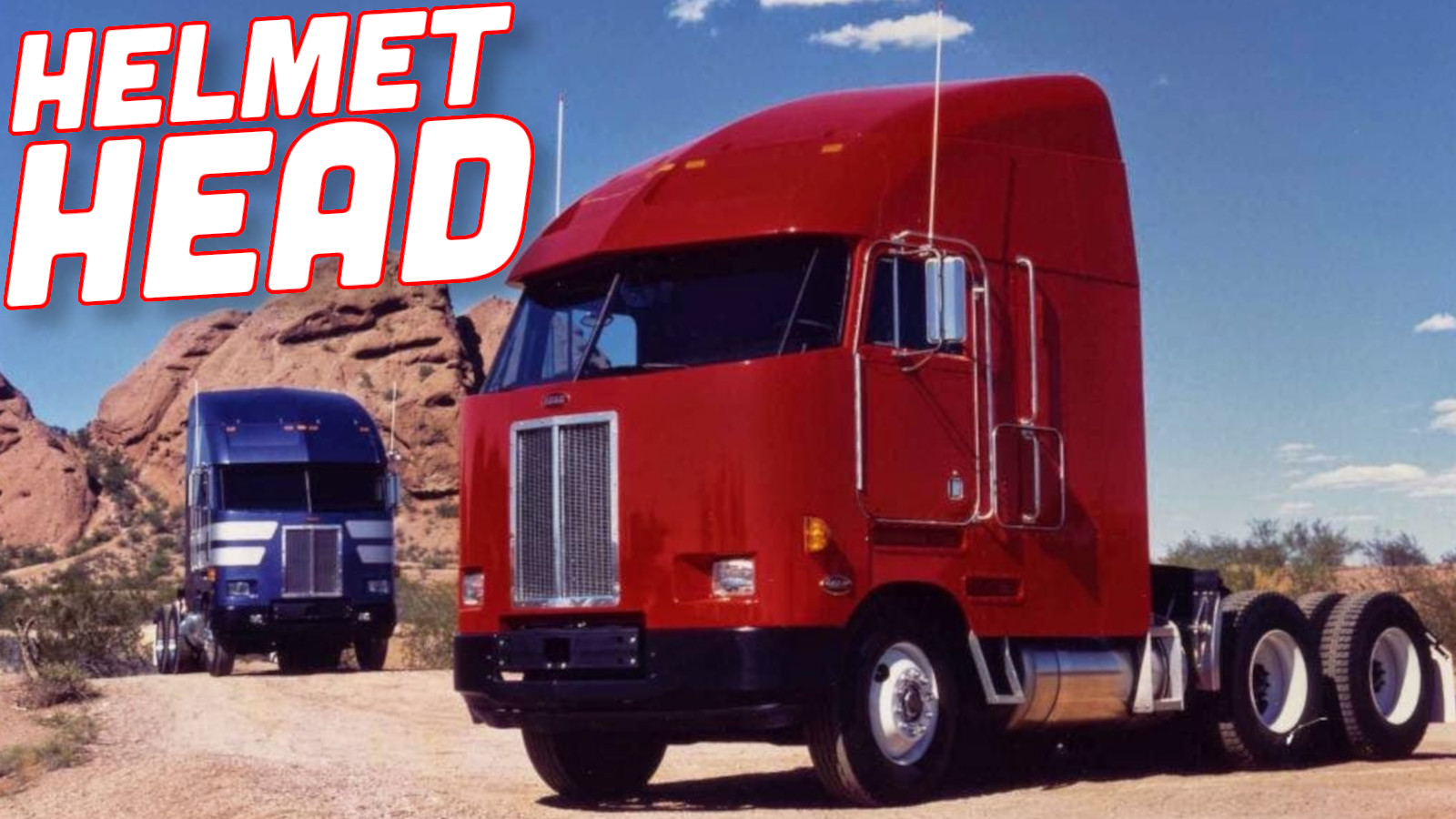

Trucking companies, owner-operators, and semi-tractor producers are always on a relentless quest to save money. Semis move much of America, and tons of money gets shoveled into just fueling rigs. If an operator can spend less money fueling, that’s more money they get to keep. One of the best ways to cut down on semi-tractor fuel consumption is to make the tractor slip through the air as best as possible. A little under four decades ago, Peterbilt tried to change the game for cabover semis with the Model 372. This super slick, helmet-shaped aero truck managed to squeeze out 11 mpg when conventional trucks got 8 mpg.

As with so much of automotive history, the Peterbilt Model 372 technically has its roots in the multiple oil crises of the 1970s. Fuel prices had nearly tripled, which threatened to throw shipping into a spin. As Fleet Owner explains, paying for fuel makes up a quarter of motor carriers’ average operating costs today, and fuel costs are always changing. The publication expands on this by noting that fuel alone is one of the most expensive factors in running a fleet.

To put this into perspective, Fleet Owner notes that, from the period of 2014 to 2023, fuel prices cost carriers on average 55 cents per mile, which was bested only by driver wages, which averaged 78 cents per mile. Now, imagine this fuel cost nearly tripling over less than a decade. The numbers were different, of course, but that’s what happened during the 1970s.

Trucking fleets cannot dictate the prices they’ll pay for fuel, so one of the best ways to fight higher prices is to make the truck itself cheaper to operate. Back in the 1970s, America attempted to cut down on its insatiable thirst for fuel with efforts that included downsizing cars and the 55 mph national speed limit.

This era was also a time of reckoning for semi-tractors. Until then, most semis were not built with aero in mind. Due to total length and weight restrictions, the semis that ruled the road were ultra-blocky cabovers, which maximized loads thanks to their more compact footprints. Conventionals were also on the road, too, and they had about the same attention to aerodynamics as your average K-Mart. Only weird experiments like the Paymaster semi dabbled in high aero.

But it was now time for a change. If the trucking industry were to pull its way into the future, semis just couldn’t get 5 mpg anymore. As I wrote earlier this summer, trucking historians often point to the 1984 Kenworth T600 as being the first mainstream semi to be built from the ground-up to be aerodynamic.

Peterbilt Goes All-In On Aero

The success of the T600 had a ripple effect through Paccar Inc., the successor company to the Pacific Car and Foundry Company and owner of Kenworth, Peterbilt, and other companies. Peterbilt followed the lead set by Kenworth in 1986 with the 377 A/E, which featured an aerodynamic fiberglass hood and sleeper. This was a great start, but Peterbilt had greater ambitions. Like Kenworth, Peterbilt wanted to change the game.

According to the American Truck Historical Society, development on the Model 372 was conducted in Peterbilt’s facility in Denton, Texas. At its core, the Model 372 shares the cab structure and engine of the Model 362, the blocky, but popular cabover pictured below.

By now, America had finally set nationwide standards on length and weight. These regulations meant that truckers could now enjoy the comfort of a conventional semi while still hauling profitable loads. This would eventually spell the end of the cabover’s reign.

However, at this point in time, cabovers were still popular among truckers, and Peterbilt was brewing up something it thought was revolutionary.

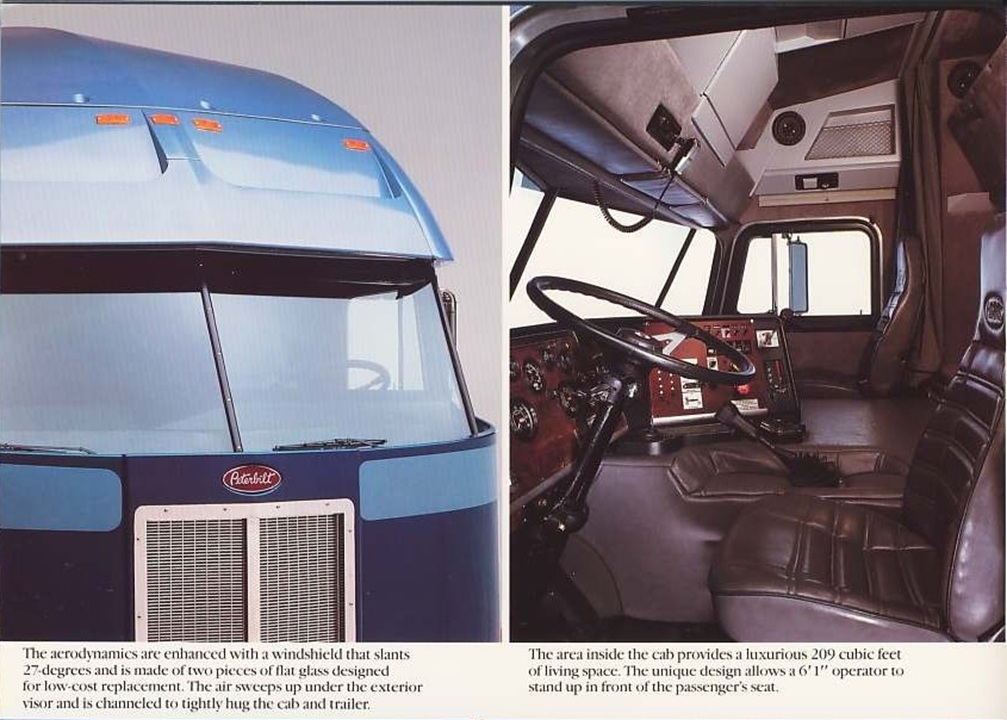

To create the 372, Peterbilt started with the 362 cab, and then smoothed it out to the extreme. The Model 372 features an integrated roof fairing, fiberglass body panels, fiberglass nose, inset lighting, wrap-around bumper, and optional side skirts that were all added to the truck in the name of aerodynamics. Peterbilt says that the 372 spent hours in a wind tunnel and that, ultimately, the final shape was designed by the wind and computer-aided design.

Something a bit weird for the Model 372 of its day was the size of its cab. As I noted earlier, one of the primary advantages of the cabover was that, by piling the cab over the engine and the front axle, you could maximize your trailer length to carry more cargo. Well, this wasn’t a big deal anymore. The Peterbilt Model 372 measured 127 inches from the front bumper to the back of the cab, making the cabover one of the largest of its kind back then.

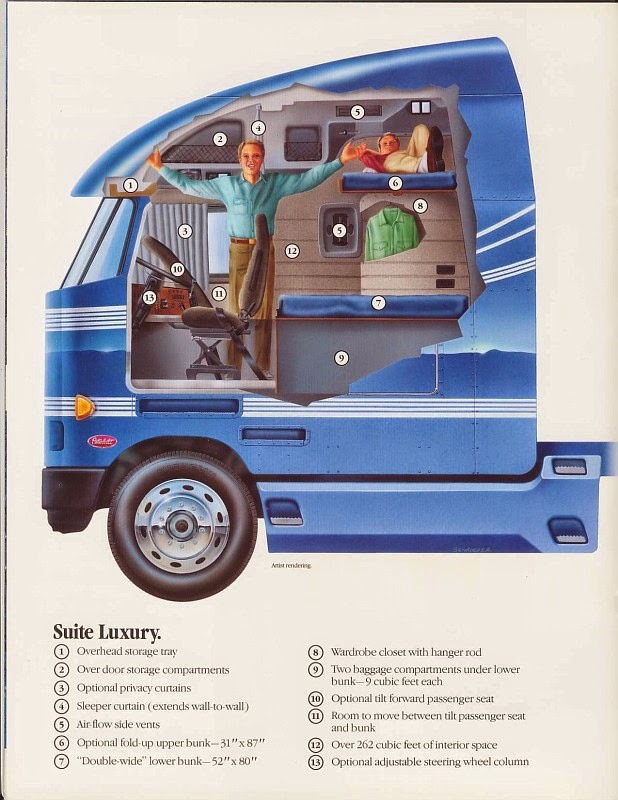

The American Truck Historical Society notes that this was done primarily for aero. However, Peterbilt also used this opportunity to give the Model 372 a spacious and luxurious interior. The cab featured 262 cubic feet of interior volume, which included front seats that slid forward to ease access to the rear, a full-size lower bunk, air-ride seats, privacy curtains, enhanced insulation, and options like a TV stand and a refrigerator. Other neat tricks baked into the truck included enough headroom for a driver to stand in the truck, plus an adjustable steering wheel for increased ergonomics.

The innovations didn’t end there. Peterbilt knew that it had built a monster of a rig, and didn’t want to hamper serving the unit.

The Model 372 was designed to have a nose that opens upward, allowing a mechanic easy access to over 30 system components from the HVAC system to brake valves. For more intense maintenance, both the front end opened and the cab tipped open like a typical cabover.

When the Model 372 started sales in 1988, Peterbilt saw the truck setting the standard for cabovers. Allegedly, the truck had 50 percent lower drag than the Model 362, and the extreme aero, combined with the luxury and what Peterbilt called “elegant” looks, would have the 372 setting the pace.

Peterbilt Proves Its Claims

In 1990, Chris Cavette, product marketing manager at Peterbilt, claimed: “Getting good fuel mileage in a Class 8 vehicle isn’t all that difficult anymore. Pick an aerodynamic tractor, spec it right and drive it right and you’ll get outstanding fuel economy.” Then, he decided to prove it. That year, Peterbilt took one of the Model 372 prototypes, hooked it up to a modified trailer, and decided to haul it across the country. This test was covered in the February 1991 issue of DES, a trucking periodical. In the magazine, Cavette said:

“All we did,” Chris said, “was make some refinements to the test vehicle, such as adding a belly pan, nose and side skirts, gap seals, side extenders and a profiled roof fairing.”

The test Peterbilt Model 372 was equipped with a standard powertrain that was available on production versions. In this case, that meant a Caterpillar 3176 10.3-liter straight-six diesel rated for 325 HP at 1,900 RPM. Peterbilt says it chose this engine because it makes 300 HP from 1,300 RPM and on, while also featuring electronic controls and electronic injection. The big Cat up front was backed by a Fuller RTO-12609B nine-speed transmission and an Eaton DS402 tandem rear axle with a 3.90 ratio. Peterbilt said that the Model 372 shipped with short-throw shifters, and the Fuller transmission provided a wide range of ratios.

DES detailed that Peterbilt got pretty obsessive with this testing:

“The test tractor was also equipped with several premium items,including Eaton automatic slack adjusters, Peterbilt FrontAir suspension and Peterbilt hub-piloted 10-hole wheel system (PHP-10). We also chose Alcoa aluminum wheels for their light weight and fitted them with 275/80R22.5 low-profile Michelin XZA-1 tires for low rolling resistance. In addition, Chevron’s Ultra Gear 68 borate lubricants were used in the transmission and axles to reduce friction.”

To integrate trailer aerodynamics with the tractor, Chris explained further, Peterbilt took a 45-ft smooth-side van and fitted it with a full-height nose cone to close the gap between the trailer and the tractor’s roof fairing and side extenders.

“Box-section side pods formed from aluminum and fiberglass were also added,” he continued, “to assist aerodynamic efficiency and serve as a spray suppressant. And on the rear of the trailer, pressure recovery panels- or boat tails as they are commonly referred to- were designed to be aerodynamically efficient while still allowing a full width door opening for cargo transfer.”

The neat part is that the test truck didn’t look that different from how today’s aero-obsessed rigs look. Anyway, the truck and trailer were loaded up to 71,200 pounds and hit the road.

In the end, the Peterbilt team managed to average 10.49 mpg driving across America at an average speed of 51 mph, and there were many stretches when the truck did better than 11 mpg, including one stretch in Texas where the truck drove 704 miles averaging 11.54 mpg. Sure, 51 mph doesn’t sound very impressive, but remember that there were lower speed limits back then. Peterbilt noted that it was common for a non-aero semi of the late 1980s to get 7 mpg or 8 mpg under similar conditions, and that the Model 372 could hit 11 mpg. A gain of 3 to 4 mpg is incredible for a semi.

Darth Vader’s Helmet Fails To Sell

You’d think, then, that truckers would have been all over the Model 372. For a time, the Model 372 seemed promising. RV companies even took the opportunity to convert some Model 372s into aerodynamic luxury motorhomes.

One of those coaches was the $475,000 Genesis Touring Coach, which weighed up to 33,500 pounds, had a fiberglass body, and was advertised to get up to 12 mpg thanks to the slick Pete front end. Other rigs got turned into car haulers.

Unfortunately, despite Peterbilt’s clever marketing and the stunt back in 1991, the 372 never caught on. Worse, it was actually sort of mocked. The book, Big Rigs: The Complete History Of The Semi Truck, claims that truckers of the day called the Model 372 the “Winnebago,” and that wasn’t in a complimentary way. The American Truck Historical Society says that the Model 372 also gained nicknames like the “Football Helmet” and “Darth Vader.”

The Model 372 also came at about the wrong time. While cabovers might have clung to some popularity in the 1980s, that popularity was quickly fading as truckers purchased conventional semis. Peterbilt says that sales were slow enough that, by 1993, it canceled the Model 372 program. Only 772 examples were ever built, which is a lot more examples than the Paymaster, but still abysmal sales. The Model 362 outsold the 372 despite getting worse fuel economy, and sold well enough to continue its production deeper into the 1990s.

Despite the failure of the 372 to capture an audience, Peterbilt didn’t waste its time. Like the other big truck manufacturers of this day, Peterbilt’s aero experiments of the 1980s would find their way into more modern trucks. Now, basically every truck is built with aero in mind. But these manufacturers all had to start somewhere. For Peterbilt, it just so happened that it dipped into the pool of aero trucks headfirst with a truck that looked like a helmet.

(Topshot: Peterbilt)

My father bought an early 70s Kenworth with a Cummins 350 and a 13-speed Eaton Roadranger to pull bottom dump trailers. Those trailers might be some of the least aerodynamic trailers you could hook up to a truck.

But at least it handled rough non-roads (he was bringing the stuff into places to MAKE roads) including places like north of Yreka to make I-5 in 1979, better than the International he had before with a 8 V71 and a 4×4 transmission.

Dad gave me an opportunity to drive both, and they were a lot more complicated than the Datsun 510 stick I drove back then. Five axles of brakes were particularly spooky.

I don’t know what it’s like to drive modern rigs, but I don’t cut them off and I often give them room to get around a slower rig going up hills. I don’t get paid by the mile and a 30 second delay on my trip is no big deal. I don’t know how those drivers do it.

3 or 4 companies (maybe 5) make the;

engines

trans

axles

frames

That go in your class8. The amount of brand preference stubbornness is very interesting.

Next up: Mushroom head

I somehow missed this one growing up with truckers. Friends had a 362 and a 359 (and later a 387.) I definitely remember the resistance to adopting new models, though, not just because of the newfangled looks, but because of the initial outlay of a new rig.

I do remember that when they dropped from two trucks to one, the 362 was the one to go. Which I was fine with; I hated working on that thing. I was always worried that cab was gonna come down, and when you’re 12, you can make up some pretty grisly situations.

Anyway, neat truck. Too bad it didn’t catch on.

This cabover looks goofy.

There are two Peterbilt 37x trucks in use in Qatar. Both belong to an oil company.

Kenworth seems to be by far more popular in Oman, Kuwait, Saudi Arabia, as an oilfield truck.

I don’t know much about semis really, but of course anything large and diesel and capable of keeping an economy going is going to be of interest to me. 😉 I think the smooth look of the 372 is really easy on the eyes personally, and of course, I’m always partial to cabover anything and I remain sorry it’s so uncommon these days.

Thanks for this Mercedes! 🙂

I think if they had done this with a conventional instead of a cabover it probably would have been a hit. I remember when semis only got about 5 mi to the gallon.

Interesting. Radical improvement in aerodynamics is really hard in a semi, since, obviously, the squared off aft end is where 90% of the loss occurs due to the massive unavoidable shedding of vortices. Nice effort, though.

Their timing was bad, since a,change in the laws to trailer length rather than overall length opened the floodgates for conventional trucks and killed a lot of the cabover market. Peterbilt’s conservative customers didn’t help. They did miss the cool trick of the later Freightliner Argosy with power operated stairs to the cab.

Freightliner Argosy Steps | Mid America Trucking Show 2012 | Flickr https://share.google/8ykwwHEXJ5CxAu5l8

The Argosy was successful, because Freightliner was well known for cabovers and it looked a lot like the older Freightliners. Of course it was a limited success because cabovers were dead in the US

This has been one of the most interesting comment threads to read, and I’d like to thank you all for giving us a glimpse behind the scenes, especially the strangely dressed lizard.

I’m also shocked by how fuel efficient trucks seem to be, even 9MPG blows my mind. if I got that towing a 10K enclosed trailer with a more plebian vehicle I’d be happy, and that’s trivial to what a semi is capable of.

I aim to please. Trucking is a passion and a life

As you say, now, in Europe at least, nearly every lorry (truck) looks like that — Volvo FH16 aero for example. In fact in-depth research of the Volvo site, (20 seconds) shows only the stone movers do not have the smooth front with a spoiler look.

As I understand it in Europe now the big divide is between manual shifters, dual clutch auto boxes or torque converter auto boxes.

For years, manual shifters gave much (20%) better fuel consumption.

But, as with cars, now the advantage is usually 2% better thanks to electronics, and sometimes with idiot drivers, the manuals are thirstier than the automatics.

Even new manuals now typically have electronics between the shifter and the box to smooth things out.

Automatics still cost more, and owners do the sums and relatively few make the change, unless they are owner drivers when nearly all do, because auto boxes are so much easier.

The other bit is that if there is an autobox, it will be easier to replace the driver with a robot,

Which does not please drivers.

All the Europeans immigrant truckers i met seem to love American volvos better that the ones back home because ours have bigger sleepers. But I do have to admit they have better power train options. The American market is dominated by mega carriers, so they drive power train options. So America gets low power cheaper powertrains.

My understanding from European friends is that oddly enough, the much lower speed limits (that are rigorously enforced as well) for trucks in Europe drive the power options. When you can only legally go 90 or 100km/hr, you want to get there right now, and keep that speed up at all times. Not like in the US where on the flats you can belt along at 80mph even if you have to crawl up a hill at 25mph. And most of the US is pretty flat, relatively speaking.

But having driven coaches back in the day, I well know what a difference having an extra 200hp or more can make in a heavy vehicle. We had coaches with 300hp 8v71s, and we had a couple with 500hp 8v92Ts. 300hp could be pretty painful at times, even in the pretty flat upper Midwest. Some of the climbs out of river valleys are no joke, even if nothing like the Rockies.

No joke. Most of our trucks are speced with 500 horse. Mine came with a 525 horse. Same torque. I walk all my coworkers on the hills. That little power bump makes a noticeable difference

The automated manuals save fuel and are easier to drive – win / win. The newer ones will shift ahead of time because all the Interstate highways and US highways have been mapped. The truck know where it is and the grade so it can anticipate and shift into the correct gear (up or down) before an driver can even see the grade around the corner.

Here in the US for on-highway the take rate for the automated manuals is about 95%. It is only very stubborn owner-operators still buying manuals to haul freight on the highway.

Sticking with manuals is sometimes not cause of stubbornness. My company pulls double flatbeds. We found that they have unique pulling characteristics that destroy autos. When you replace $30k transmissions every 3 years, the fuel economy benefits are pointless. Also, my experience with that premapped downshift stuff has been abysmal. It can’t account for changes in loads, wind drag, traffic conditions. And dont you have to pay extra for that feature? Isn’t it a subscription?

I dont belive in what manufacturers say, and salesmen can f off. I know what the reality is.

Volvo is a 9 mpg truck

Freightliner is 9 mpg

Pete and kw 8 mpg.

Gps downshift maps are subscription bs. Dont work

Automatic are great, but unreliable. Manual is better for vocational and flatbed.

And if you want the truth, a cascadia is an excellent choice for making money. But a Pete is best if you wanna feel alive.

No one needs a motorcycle or sportscar. But dammit we love them

The real answer to making shipping more efficient is to repeal the Jones Act.

How would that affect getting freight from Long Beach to Phoenix, for example?

If they ever built the proposed canal from the Gulf of California to build an inland port in the Coachella valley, it *might* work!

There is this for that: https://www.up.com/shipping/intermodal/intmap/phoenix

But also trucks going that route getting 5 mpg would be a drop in the bucket if there was exponentially better shipping between the cities that are not landlocked.

Well, getting freight to Long Beach would cost less, so there would more money to spend getting it to Phoenix. But yes you are both correct and pointless. For shipping between warehouses where most of the people in the United States live, shipping with ships would be more efficient. Phoenix is always the dumb exception.

That would certainly help transportation up and down the East and West coasts. But incentivizing faster rail freight transportation would help a lot more. At the moment, all the incentives are for the railroads to run the longest, slowest trains they can get away with to minimize costs (long and slow saves on crews, fuel, and track maintenance), so anything with priority that is too heavy (or not enough priority) to go by air goes by long-haul truck. Plus we don’t have an actual coast-to-coast single railroad, though there are run-through arrangements for some intermodal (container or truck on rail) trains. The proposed Union Pacific / Norfolk Southern merger would create the first one in history. Given the current administration, I expect it will be approved.

Haven’t even started the article, but I have to say I love this design and I’m already bummed because I’m sure I’ll find a dumb reason why it didn’t stick.

EDIT: so that was it? Just “Other people say it looks like a helmet so I’ll buy the older, thirstier version with less space” bullshit? I fear for humanity’s future (reason #3,924)

Peterbilt is like Harley Davidson. It is an image brand. If it had a Freightliner logo, it would have sold well. The Freightliner Argosy sold quite well and it incorporated many of the same aero tricks. Heck, the most recent Volvo Vnl looks like it was designed by a drunken AI, but it sells extremely well, due to its comfortable sleeper and high fuel efficiency. But Pete guys like their chicken lights and chrome. Yup, it is an ego and lifestyle thing. My belt buckle is a Pete emblem.

In my previous job I bought semis. You could show the drivers that a competing truck was far superior in every conceivable metric, and they’d still demand a Pete. One year I bought some of those International Lonestars, and I was afraid to walk across the yard for months.

Lol. Trucking is a life for some of us. And loanstar is a wannabe plastic Pete that is for guys who can’t afford a Pete. LOL.

But honestly you are completely right.

I think the decline of cabovers is a lot of it, really. Had those Euro-style fully air suspended modern cabs been available, perhaps we’d still see them in regular use today in the US

To much of a climb. Most American truckers are too big to climb 6 ft up. They can barely make it up 4 ft

I haven’t seen a 372 in years. Occasionally I’ll see a late freightliner flb or argosy hauling something. The cab air ride, ride fairly well much better then traditional coe. Kind of shame at least some operators didn’t continue using them. It seems like they would be of some use in New York and new England.

American truckers are a strange breed, driving uncomfortable, outdated, & underpowered trucks like it’s a badge of honor. If fleet owners hadn’t dragged them kicking & screaming into aero rigs, they would all still be driving Kenworth W900s by choice.

(I guess the “underpowered” part is out of the drivers’ control, since American truck engine manufacturers refuse to cross some imaginary line of output.)

The median age of truckers is a lot older then most realize. The last I looked it was around 66. Alot of guys that got into trucking from watching smokey and the bandit and their wants haven’t seen to change from the late 70s. W900 with a big cam or a 379 with a Detroit. The fleet trucking schools don’t train drivers on manuals anymore and apparently they have to go all though the process again if they want a manual endorsement so it’s going to change one way or another soon. Some of the new drivers I’ve over heard yelling they want the newest truck with all the tech available quite the contrast from the old guys.

I started back in 2013, and I can tell you that yes, the old men wanted old tech for a reason. You do not buy a truck made between 2009 and 2014, because emissions would break your account. Heck, my company has 2019s that cost $50k a year to keep running. We have a 2000 with 2 million miles that cost less to operate despite its gargantuan fuel thirst. And yes, old school truckers like old school trucks. I actually straddle that gap. I love my current long nose Pete. It is fun to drive, mostly because it IS a challenge to drive. But I told my boss my next truck is a freightliner cascadia with all the tech, because im getting old. Tthat heavy clutch and long throw shifter is getting hard on the joints.

That being said, these young kids need to learn how to be professional. They walk into a shipping office wearing stained pajamas and wonder why they are treated like trash. I walk in wearing a tie and slacks and I am treated like management.

Even the old time truckers treat me with respect. They say I am a throwback to when trucking was respected.

Maybe they should listen to their own words

The flip-flop wearing “steering wheel holders” that can’t read, speak or understand English are the opposite of a professional trucker. My late uncle drove 2 million miles w/o an accident; an illegal immigrant who couldn’t recognize 3 out of 5 road signs got a CDL in California and killed a family of 3 in Florida. Yea DEI and sanctuary states.

And California broke federal law to allow them to test in foreign languages. Why? Keep them ignorant, pay them a pittance. Cali is the crookedest damn state, and they are using those poor immigrants as slave labor, to save the harbor a few bucks

DEI isn’t about lowering standards so those who are not qualified get approved anyway. Nobody wants unqualified people driving 40 ton semis. Rather, one aspect of DEI is about asking whether the qualifications have been designed, intentionally or not, to exclude certain groups of people when that need not be the case. Truck drivers in Europe safely traverse countries where they don’t speak the language all the time because the road signs and other systems have been designed for universal understanding.

Sorry, but in California, DEI is designed to promote those who are NOT qualified. It is designed for equity of outcomes rather than just equal opportunity; so racism is definitely employed to “overcome racism”, even though the racism occurred 50 years ago. Witness the subject truck driver. California, is also discussing paying reparations to the offspring of enslaved people’s (3-4 generations removed) even though California was never a slave state and virtually none of the residents are even descendants of onetime slave holders. Also see the State Law that says biological boys can play sports with biological girls just because “they feel like a woman”. It’s all naked pandering and virtue signaling.

You may want to develop some self-awareness and look up to see who wrote the article.

I know who wrote the article. They didn’t go into a woman’s locker room as an intact male and beat up on little girls playing a woman’s sport. I worked with a trans woman and our employer went through thousands of dollars of accommodation and indoctrination during the course of their transition. I hold no particular animosity towards them. I do not believe that they should be given preferential treatment when it comes to who gets employed or promoted. Merit should be the only factor considered.

i do get annoyed with leftists liberals who “know better” and try to “educate” anyone who disagrees with them.

Liberals have the unassailable knowledge they are correct

Liberals are sure that they are right, they are the anointed and righteous and enlightened and are compelled to educate you. A differing view couldn’t possibly be entertained because “well, I”m right, of course”. When proved wrong, they will say, “it hasn’t been done properly, yet. We’re going to do it differently”.

Ok

Bud, you know you’re commenting on an article written by a trans woman, right?

Eat shit, bigot.

So what. (S)he is not playing sports with girls in high school or college. What she does in private is none of my (or your) concern. She is writing articles that appeal to car enthusiasts and does a fine job.

I love ad-hominem attacks. You made assumptions about me based on virtually no information. The fact that DEI is racist is beyond doubt.

*says super bigoted things*

“I’m not a bigot!”

Your feelings are all hurt because Harris didn’t win. Too bad a majority of the voting public didn’t agree with you.

im not gonna waste another second rest to you.

Now who’s making assumptions? Still ain’t me. All y’all bigots trying to claim some kind of superiority but get scared the moment something or someone new comes along. Hilarious. Worried about having to compete on merit and not simply by being old and/or white.

But ours isn’t. Unfortunately American roads and driving habits are completely ass backwards from the rest of the world, so the immigrant is thrown into a situation where they are ill equipped to deal with it.

Ah yes the flip flop mafia. For sure on the emissions hopefully that is at least on the way to being fixed. I’ve heard so many horor stories about the x15s and most engines of that era. The tractors doing regen in the middle of a field then starting a fire was always my favorite in dumb ideas. I’ve run into a few younger team drivers the amount of drama they seemed to be able to cause was disturbing to say the least.

Mega carriers used automatics as a way to lower the bar on training standards, instead of using them as a way to reduce workload. New drivers have no clue what all those guages mean, and megas prefer that.

And the x15 is a pile of garbage, and the paccar ain’t much better. Pete went full Harley. After covid, quality dropped so bad this die hard hood man would rather have a Volvo. And dont get me started on the 589. That ain’t a hood. It’s a curbsniffer with a bad nose job.

And I just realized I may confuse our non trucker friends.

Hood: long nose truck

Curbsniffer:aerodynamic truck

Hood man rather have a Volvo Vnl: utter blasphemy

The Navistars they were putting in alot the internationals and the mercs in some of the freightliners are worthless too. You can always find tons of them at old don Baskin for hardly anything. They both bankrupted some carriers and some school districts that got a hold of them in buses. Paccar quality is in the toilet from the latest stuff I’ve seen. Volkswagen taking over international and getting scania involved seems like a step in the right direction. The scania engines seem to be a lot more robust. It seems like Volvo / mack have figured things out. Still a whole lot of plastic

I drove one international and it was horrible. Spent most of my time waiting for it in the shop. Rode like hell and horrible seat. Paccar is sad. Went from multi million mile trucks to disposable. Volvo is ugly as sin, but damn they are moneymakers. And cascadia dashes are still falling apart at a million. Meanwhile an fld is still solid 30 years in. And the hoods are gone. Now we have ‘hoods’ that look like c5 vettes with c1 body kits.

I don’t think I’ve seen a fld on the road with decent paint or a hood in one piece in a decade. Some of the western stars look ok but I haven’t been in a recent one still alot of plastic.

Western star is now just a cascadia with a different hood. No more curved sleeper. No more buttoned leather. No more air cans.

For sure everything is plastic now. Looks a whole lot better then the sea of cascadias and Volvos.

Yup. At least it has chrome. Have ya seen a Cascadia 5th gen? Not a speck of chrome.

Yeah I think they look a little better that way but still terrible. They probably won’t age too well though. The way the cascadias did chrome always looked cheap to me. The new kids seem to hate chrome so I can see why they did it.

Flat black is the new chrome. Look at the escalade. Heck my boss loves the next cascadia, gonna go durablack rims. I’m down for it only cause it took a week for my back to recover this spring after polishing out my 389.

That black chrome and paint match seem to be popular too. I don’t care for the plastic chrome so I’ll take it including the flat black. Its honest. Same with pickups I’ll take the base with black grill over a chrome plastic

Pretty much. Besides, ya dont drive a curbsniffer for looks. Ya drive them cause they are comfy. But I’ll always miss the chicken lights and chrome. I’m already morning the loss off truck stop diners. An 19 has gone silent….

They seem to be dropping like flies. I think it’s part of the new generation too. They seem content in the pilot or ta food court don’t seem to want an independent restaurant I’ve seen a few switch over to chain diners like black bear or Dennys but it’s not the same. The aero clearance lights really don’t have the charm of good ol chicken lights that is a shame.

Yup, the youngsters are missing out. I haven’t been thro7gh baker city oregon in forever. But my spiritual home is at the counter of the restaurant of the truck corral, dodging jabs from those old school waitresses.

And watermelon lights forever

I saw an old timer put watermelon lights on a Volvo years ago it looked weird but also kinda matched the front in a weird way. The truck stop diners I used to frequent along 81 40 and 25 are mainly gone 80 still seems to have theirs intact

I’m from the southwest and the Latinos put watermelons on any truck. I am all for it. I also love it when they go crazy with penny lights. I even know of a yard spotter truck at the hay press in Brawly CA with chicken lights and polished aluminum wheels. I love the rock what ya got mindset and love seeing what they come up with

Ive seen some of those in New Mexico and Colorado. With the sikhs so heavy in trucking now and buying some Petro stations I’ve seen a few turn the restaurants in to Indian with buffets. Sometimes you see a truck decked out with all the little statues and drape things around there.

Lol. I like the Sikhs. They have their own take on customization that is still similar to American tastes. Alot of them will break out the button down shirts for delivery, which I can respect. I might borrow some of their chicken lights installation tricks for my future freightshaker

Everyone I’ve met is decent they are running from quite a big problems and a genocide. Some of them will light up their rig like a Christmas tree like you used to see 30 years ago. A lot of them wear button down and khakis even in truck stops and depots.

Yup. And big supporters of the ag community. I’m in ag, so that is more to like about them.

Yeah we have a couple that cattle haul too and from the sale barn and do some hay hauling

A touch of chrome here and there can be nice. Too much in the right circumstances however can be blinding.

And yet people still pass me with high beams on. Must not be that blinding

I’ll take high beams over having the sun reflected into my eyes any day.

Since you work with it, is there a reason why cab over designs are shunned? I would imagine that using efficiently that space in the nose would be seen as a good thing…

First, riding over the steer axle will make you piss blood. Not a joke. Second, massive blind spot in front. You can hide a escalade in it. (Not as bad in a fishbowl cabover, but still much bigger than the front blindspot in a modern aero truck) third, the floor is six foot up on coe vs 4 foot conventional. That and on a coe you have toe climb up then sideways over the steer tire. Forth, only the freightliner argosy above had a flat floor. The rest you had to climb over the doghouse. Fifth, that sleeper shown on the pete above? The ‘big’ one? That is positively tiny by modern standards. Sixth, lifting the cab ment everything fell on the windshield. Seventh, servicing was a pain. Mechanics did not like them. My mechanic has been delaying fixing our cabover because he has to squeeze into weird places. Eight, the shifter was practically behind you, and the complex shift linkage made finding gears vague. And most importantly, you were the first on the scene of an accident.

Damn these comments are more interesting than the article (no offense, Mercedes)! Really interesting getting the inside stories from you folks. But I’ve got two questions:

1) As a Lizardman, how do you manage your tail? Do you stuff it down one of the legs of your human suit, or what?

2) Why the hate for Volvo? To my eye, they look similar to the Cascadias. Is it because The Grays prefer Volvos (or so I’ve heard)?

How i manage my tail is a trade secret.

As for the Volvo VNL, the hate for it started off simply because it was a foreign name. Nowadays most off the hate for them is the Volvo attracts a certain type of driver. The texting while weaving through traffic while speeding type. Not the trucks fault drivers misuse it’s efficiency and safety aids to be dumb asses.

Oh, and I dont like it because the newest gen looks like it was designed by a drunken AI. But the fuel efficiency and how comfortable it is makes it really easy to overlook the looks.

The easiest way to manage a tail is to not have a tail. They grow back after all kind of like you with your hair.

Ya but that hurts, and takes so much energy. And remember, we have tech that you don’t.

The district where I worked had an old COE Ford 600 (?). (25900 GVW). The crew tilted it up one morning as part of the routine pre-drive check and didn’t get it properly latched before setting off. First stoplight saw them staring at the crosswalk, up real close.

I’ve forgot to latch a hood, which leads to similar embarrassment, but not as thrilling. Betcha those guys needed new underwear after that

They were rather excited about the whole thing. There were 3 of them in the cab.

I never heard of that happening again, and future trucks were NOT cabovers.

The market for higher-horsepower engines in the North American market is significantly tempered by fleet buyers. Fleets will choose the minimum necessary engine output to get the job done, assuming speed is positively limited to 65MPH. (And then they may choose the next engine just under the best specs for that…) It’s all about cutting costs.

Speed is an interesting concept between North America and Europe, though. Typical truck speed limits in North America are between 55 and 65 MPH. Converted to MPH, European truck speed limits are slightly lower with a very large area of Europe standardizing on effectively 50MPH (80Km/H, with some countries allowing up to effectively 55MPH (90Km/H). EU regulations mandate trucks have a speed limiter set to approximately 90Km/H or lower.

On the other hand, European countries generally allow higher loading on highways than most US states, at least. European trucks have powertrains designed to get heavier loads up to slightly lower speeds and then maintain them better on widely varying grade conditions. Depending on the particular county’s road network, speed changes due to curves and grades may be more frequent.

North American trucks operate in a different environment, where highway stretches tend to be longer and flatter except for the notable exceptions in Western and Eastern mountain regions. Loading is more restricted, and acceleration is less of a factor when the bulk of long-distance limited access highways have long acceleration lanes (slip lanes) leading into wide, multiple travel lanes. (Yes, there are plenty of smaller, narrower highways with worse traffic and grade characteristics, but fleets invariably ignore those conditions and focus on major interstate highways where they expect trucks to spend most of their time, statistically. This is where experienced drivers really hate fleet manager’s thinking.)

In the end, it’s fleet buyers dictating engines and drivetrains for both environments. North American fleets are based on long distances at constant speeds on wide, less-congested highways that stay clear of urban traffic, with relatively lower average loading limited by regulations. European fleets are expected to haul heavier loads on routes which tend to face more congestion even on highways around the outer edges of cities, and on highly variable grade conditions across many regions due to continental geography. But speeds are limited to the lowest speeds allowed in North America, and often even lower. The higher horsepower engines are utilized for acceleration and traversing grades with heavier loads, not for speed over long distances.

There’s been a series of YouTube videos on a Scania cabover brought over to the US for testing and promotion. It certainly has more horsepower than typical US trucks and its acceleration was immediately notable. But even with the speed limiter turned off, it was initially slow on US highways until it was re-geared to be better suited to running at higher highway speed limits. I haven’t kept up with the reports, but it would be interesting to see how the performance and fuel economy of an imported EU-spec engine works out with US-style gearing and driving conditions over time. My guess is that it will do well, but not necessarily significantly better than a high-end Volvo conventional which is already using a variation of an internationalized Volvo engine, connected to a drivetrain optimized for US driving. The Scania cabover’s advantages will be in the driver visibility and overall maneuverability of the cabover form factor. Comfort-wise, it will be very similar to a Volvo conventional cab (which is largely an adaptation of Volvo’s European cabover interiors) but will also lose somewhat for its smaller sleeper area inherent with a cabover.

Ya, you are right on everything you said, but drivers will hate them. Slightly smaller sleeper. The most popular sleepers are the biggest a manufacturer offers, which on a Volvo is 80 inches by 89 inches. As for the visibility, I’ve never sat in a European cabover, but I know old school American cab overs had much worse visibility than modern aero trucks. Be interesting to see if they make it to this market. I could see the advantages back east. But then, truck length was never a problem for me, it was the trailer. A set back axle truck can maneuver as tight as a cab over of yore, but the trailer length will get ya.

The smaller sleeper will be a no-go for a lot of drivers if there’s ever serious attempt to bring a standard Scania to the US market.

With that in mind, I think the testing is more of a trial balloon with some nearly-hands-off blessings from Navistar due to their engine partnership with Scania to let somebody else front testing and feedback for what Euro features might be interesting to the US drivers and worth working into US designs. I doubt a new cabover will ever make it here; the smaller sleeper area even in a flat-floor design is just too small, and the need to stow everything before tilting the cab is going to be a major turn-off all over again.

Euro cabover designs have done a lot with mirror placement and multiple auxiliary mirrors (including the front one facing down over the bumper). They also make use of larger windshields and side windows that reach lower, so there’s less of the gun-slit effect of traditional US cabovers. They’re a bit more like driving a bus, but still higher up in the air, if that makes any sense. However, the steering wheel angle is set up more like a conventional’s driving position due to Euro safety and ergonomic requirements. So it’s definitely not the same as a US cabover — more sophisticated and well-suited to European driving needs.

But I can’t see it replacing the US-style conventional cab over here — with the possible exception of East Coast fleets that do runs too long for daycabs, but not so long that drivers are out for more than a day or two such that the small sleeper is useful but they’re not spending weeks in a coffin. Cabover dimensions and turning circle (Euro cabovers are all set-back axle designs) could be useful for runs that force a full-length highway rig to drive into East Coast urban centers and godforsaken tiny docks down awful alleys.

More than anything else, this will probably test out how much of the Scania technology platform they can integrate and re-package into the next generation of International trucks. They’re probably trying to figure out if they want to go the Volvo route — a lot of straight re-packaging their Euro-spec systems into a North American cab and chassis, or go the Paccar-DAF route, which more selectively integrates DAF-based engines and systems or US engines and systems to varying amounts (depending on model and options) in largely North American designs.

International has one brand that they can’t screw up or they’ll end up shooting themselves in the foot. Too much Euro-ization, handled badly, might make technically better trucks but could alienate customers. Expanding their relationship with Scania could help or hurt them; they need to proceed with caution.

Volvo has the advantage of being a well-known European brand, and they built up their own following from the ashes of the awkward WhiteGMC-Volvo mashup that left them at least with a large fleet customer base to build relationships off of. They’ve continued skewing toward tech-forward designs and Euro influence with a focus on fuel efficiency and new-style driver comfort. But — they also own Mack, which buries the Volvo tech under a layer of more traditional North American style, features, and marketing behind a known US branding. They can grab customers on both sides of the traditional vs high-tech fence. International doesn’t have that luxury.

All good points. I see where you are going with this.

Great article I wonder if this multi million dollar investment was ever used for RVs where owners would appreciate the savings and not worry about shaming

Aero designs appeared off-and-on in RVs going back to (Mercedes, correct me on this if I’m off-base…) at least the 1970s. The GMC Motorhome was a clear example.

By the late 1990s/early 2000s Holiday Rambler built a Class A motorhome with aero design and a smooth belly pan underneath to maximize fuel economy. (And I doubt mechanics liked it very much…)

Personally, I’ve owned a Winnebago Adventurer from the mid 90s, which had a fairly standard aero shape. (But no belly pan, thank heavens.) Outside of mountain driving, it could get 10-11 MPG on normal highways if I kept to 60MPH or lower. It had a Chevy 454 (or whatever metric designation passed for a 454 in the 90s), so getting a big gasser over mountains just plain sucked, and destroyed fuel economy. If you can get an improvement to just 8-9 MPG in a heavy truck, it saves money.

I’ve driven other less-aero trucks and motorhomes, and for many, 8 MPG was something to celebrate. 5 – 7 MPG was a lot more common in anything big until aero came along. The look may be controversial even to this day, but managing air resistance has an undeniable effect on economy.

Additionally, while it’s nowhere near a cure-all, having good airflow over a moving slab-sided big vehicle can make crosswinds less horrible. It doesn’t fix the problem, not by a long shot. But it can mitigate the white-knuckle effect in bad crosswinds to some extent, which is still welcome. And sometimes it makes the difference between rolling (carefully) and having to pull over.

So, 11 mpg was considered good for a rig like that in the 80’s, but even now, the average is like 7-8 mpg or something like that, which make this even more impressive. I’m sure the 55 mph speed limit helped, but I’m surprised that newer trucks aren’t surpassing that even with the higher speed limits.

The Freighter Cascadia did 11 mpg in their latest mileage test from Detroit to Portland Loaded to 76,000 lb and cruising at 65 mph.

(Not the most recent 5th gen that just started production)

Interstate 80, 90, and 94 is damn near flat most of that way, almost no towns. Take that truck down I 95 and tell me what it gets. BTW, a buddy of mine team drove a 2010 cascadia with a ten speed and 3.2 rears pulling ABF doubles down that route doing 75 and got 9. 11 at 65 with a direct drive auto, 2.15 rears, and a properly streamlined trailer? Not a good test. My buddy gets 11 doing 75 at 50k on that route. As soon as he took a load down to Arizona and had to go up and down high plains rolling hills, and Arizona mountains (if you can call them that) he dropped to nine.

Why? 95% of Cascadias are sold with the DT12. They are sold with that transmission because it saves fuel.

The route was 80 to 84. Plenty of elevation in Wyoming, Idaho, Eastern Washington. I’ve driven that route myself.

This is the test – they have only become more efficient since.

New Cascadia Fuel Efficiency Tour

That is an extremely fuel efficient route. It avoids steep passes, tail winds most of the way. So as I was trying to say, it gets 11, in the right scenario, the 372 test was also rigged. Truth is, real life milag3 on a cascadia is closer to 9.

Or I-81, though the average speed in the left lane being only about 7 mph all the way through Virginia might offset the fuel economy hit from elevation changes

Assuming the truck can be kept upright for the entire test loop, instead of veering across the center line without looking or signaling, then hitting another vehicle and tipping over into a fireball, which is the I-81 way

There’s a 372 I see weekly hauling logs out of WV. It’s definitely an odd-looking truck, especially as I almost never see any cabovers around here.

This headline reads very differently in the UK.

Appropriately, this is the first post that I’ve seen the Member thing under my name.

Hehehe. Member.

Actually it still works in the UK. Thev372 does look like a helmet. Hooked to a trailer it is very phallic

“Turned the Truck into a Bellend….*

Exactly.

Those things look awesome! Unrelated: that illustration of the guy standing up in the cab seems WAY to happy to just be standing up in the cab.

What a strange industry. Owners and operators obsess over fractions of an MPG, but when manufacturers offer better options, owners say “no thanks”.

TBF the COE were abysmal rides

Huge difference between owner operators where the truck is their identity and large fleets that only car about total cost per mile and uptime.

Saving a penny a mile on one truck ain’t much, on 500, it’s big money

The difference between 8 and 9 mpg is a bit more than 5 cents per mile. 500,000 miles and that is $25K

The crazy thing to me is that people will pay thousands on things that cost them money. Stacks are an excellent example. There is no reason to have stacks on a modern on-highway truck. The vast majority just have an elbow out of the aftertreatment. Chrome stacks hanging out in the breeze is just throwing away money – to throw away more money every mile.

I was on a dealer call and a guy was going on and on about how we needed 8 inch stacks.

Oh I agree. But sometimes it isn’t about the bottom line, but the passion. For some, ‘Prisoner of the Highway’ is a song. For others, it is life.

What was the buy-in cost differential?

11 mpg with a 9 speed and 3.90 gears? I’m waving the bs flag. A modern cascadia might get that doing 55 with a 70k load, but it would be iffy. And conventional trucks of that era averaged 5, not 8. But then, Pete advertises their 579 as a ten mpg truck, but 8 is much more likely.

Okay math guy from 5 to 8 is still an increase of 60%. That is the same as a 30 mpg car going to 48%. If we could do that with cars global climate change would be solved.

Yup. Truck tec came a long way since 2000. Kinda stagnant before that.

Nope. We’ll just find new ways to burn petroleum to make up the difference.

Hello, AI.

See above for what a modern Cascadia will do. (11 mpg)

Oh I know what modern Cascadias can do, I’ve drove them. 11 is possible. A buddy of mine gets that in his, but he is on a contract with light loads, under 50k. At 70k, ya loose almost a mpg, unless you take your foot out and drive slow. Weight and air resistance are a killer.

I thought this looked like an early Transformer before I clicked the article. With the hood open and the cab raised, it really does look like it’s ready to talk in a bass voice and kick some Decepticon tail.

There’s a joke here about wanting to see my new Member badge while repeatedly reading about Helmet. . . Anyway, I’m not that clever.

Wrong generation it should be my new members only badge

I’m glad you showed photos of the “hood” open and cab tilted forward. I recall seeing one of these broken down many years ago with the engine exposed like that and at first I thought the cab had somehow broken in two.