The straight truck is a critical component of logistics. These trucks are champions at hauling short-haul freight, moving families across the town or the country, and doing any kind of work that you don’t need a big tractor-trailer for. But these trucks also tend to be smaller than their heavy hauler counterparts. In 1950, the Fageol Twin Coach company tried to create the best of both worlds with the CargoLiner. This weird vehicle was essentially a self-propelled semi-truck trailer, offering the high capacity of a highway truck with the maneuverability and potential cost savings of a straight truck.

A straight truck is generally defined as a truck where the cargo area and cab are a single unit. A U-Haul box truck is a straight truck, as is a concrete mixer truck, a fire engine, a flatbed truck, a refrigerated truck, and more. Straight trucks are great for short-haul freight loads, moving companies, furniture delivery, utility services, construction, or really any other situation where having a tractor and a trailer would either be overkill or implausible. The smallest straight trucks are also great for maneuvering around a city.

Today’s largest straight trucks also get pretty wild. You can buy semis like the Freightliner Cascadia as a big and beefy straight truck. FedEx Custom Critical trucks are often Class 8 tractors complete with sleepers and the capability that comes with a heavy-duty platform. These trucks are sometimes called Expeditor Trucks as they’re often used by operators who may need to haul a time-sensitive load long distance.

The major downside to the straight truck is that jurisdictions limit how long they can be. For example, my home state of Illinois says that the maximum overall length of a straight truck cannot be longer than 42 feet. That’s the total length, including cab and box.

Back in 1950, Twin Coach produced something wild. The CargoLiner wanted to be the best of both worlds. This was a commercial vehicle with the capacity of a tractor-trailer, but with the length, maneuverability, and single-unit construction of a straight truck.

Decades Of Innovation

Twin Coach was known for inventive ideas like this. This was the company that built a bread van that replicated how a horse worked. Twin Coach was also famous for its buses, which achieved higher passenger capacities than the competition through a clever use of two engines. The Twin Coach story started with a different company, the Fageol Motor Company, and here’s what you need to know from a previous piece:

The Twin Coach concern begins with brothers William B. and Frank R. Fageol, which you would pronounce as “fadjl.” Per coachbuilt.com, they were born in the Midwest in the late 19th century and apparently took a liking to buses early on. William was only 19 when in 1899 he joined forces with one of his other brothers, Rollie, in owning and operating a steam-powered bus at a fairground. Later that same year, the two brothers would build their first gas-powered car.

[…]

Fageol Motors claim to fame was the 1922 Safety Coach, a vehicle sometimes credited as being the first purpose-built bus. Most buses in the early days of motoring were coach bodies on top of a truck chassis. The Fageol brothers saw this as a bad thing as trucks rode high and had particularly jarring suspensions. The Fageol had a custom frame and an aluminum body with a low floor, which was optimized for use as a bus. The Safety Coach had wide all-weather tires, air brakes, and interior heating via water heated by the engine. The Safety Coach was so advanced for its day that some in the bus world claim that it changed the bus technology forever.

Eventually, Fageol Motor was sold to the American Car and Foundry Company of Ohio in 1925, but the Fageol brothers weren’t done yet. In 1927, William and Frank split off on their own adventure as they came up with their next big idea, the Twin Coach, and formed a company of the same name to produce it.

The Twin Coach was a huge deal. Not only did this transit bus feature a body and chassis integrated into one, but the dual-engine buses were instrumental in helping urban transit operations fill out practical bus fleets. Twin Coach was so proficient at building great buses that it spent two lucrative decades as America’s second-largest producer of transit buses.

Unfortunately, as the Old Motor writes, Twin Coach became a victim of the dominance of General Motors. As transit authorities overwhelmingly purchased GM buses, players like Twin Coach and Flxible were left fighting for the scraps, leading to sales declines. But this is Twin Coach and the Fageols we’re talking about here. Twin Coach decided to diversify and grab the attention of truckers.

In late 1950, Twin Coach announced the Fageol Super Freighter, a truck that was unlike anything else. The Super Freighter was pretty much just a trailer with its own drivetrain and a small cab plastered onto its front end. In November 1950, Louis J. Fageol, Frank’s son, had filed for a design patent on the Fageol TC CargoLiner. At the time, Louis had been at the helm of the family company since 1943. Louis had that Fageol family spirit in him and was known for being a successful speedboat racer and racecar builder.

Louis is credited as the inventor and designer of the CargoLiner in both the patent and period reporting. What’s wild is that one demonstrator was built and was used in an effort to score a U.S. Army contract for 1,650 vehicles. However, as a patent filing in 1953 shows, Louis had ambitions beyond military use, from the patent:

Heretofore a long-felt unfilled need and demand has existed in the trucking industry for low-cost high-capacity single unit vehicles. However, this need has not been met by prior vehicle designs, except for specially designed and manufactured units which high costs have rendered commercially impractical. Hence, this unfilled need of the trucking industry has continued to exist largely because of the fact that the potential commercial market for such vehicles is too limited to achieve sufficiently low production costs.

As a result of the failure of heavy-duty truck manufacturers to furnish vehicles to meet this need, the trucking industry has turned to extensive use of tractor-drawn semi-trailers and uses them in applications where straight, single unit vehicles of sufficient capacity are better adapted. The reason for this is that the practical market for semitrailers is very broad as compared to markets for straight trucks. Semi-trailers are therefore produced in large volume at low unit production cost thereby giving them a competitive advantage over straight trucks of comparable capacity, prior to the present novel method of manufacture disclosed herein.

Due to high volume manufacture of trailers, trailer manufacturers have been able to devote considerable development work to improvement of trailer bodies. As a result, they have succeeded in engineering a considerable amount of weight out of trailer body units, thereby increasing pay load without sacrificing strength. However, this increased pay load capacity is largely offset by the weight of the tractor required to pull the trailer. Moreover, the use of such trailers results in lower payload capacity under most state laws regulating total gross.

Louis goes on to note that the semi-trailers of the 1950s were prone to jackknifing during sudden stops, a problem Twin Coach’s design was said to fix – and more. The TC CargoLiner starts with a body, and if you think that this thing looks like a converted truck trailer, you aren’t far off. The Fruehauf Trailer Corporation built a stainless steel body for the rig. According to the Canadian Transportation magazine in December 1950, the CargoLiner, which was still being called the Super Freighter then, was built around Fruehauf’s standard trailer design. The truck looks and functions like a typical trailer, too, until you get to the front. That’s where you’ll find the cab.

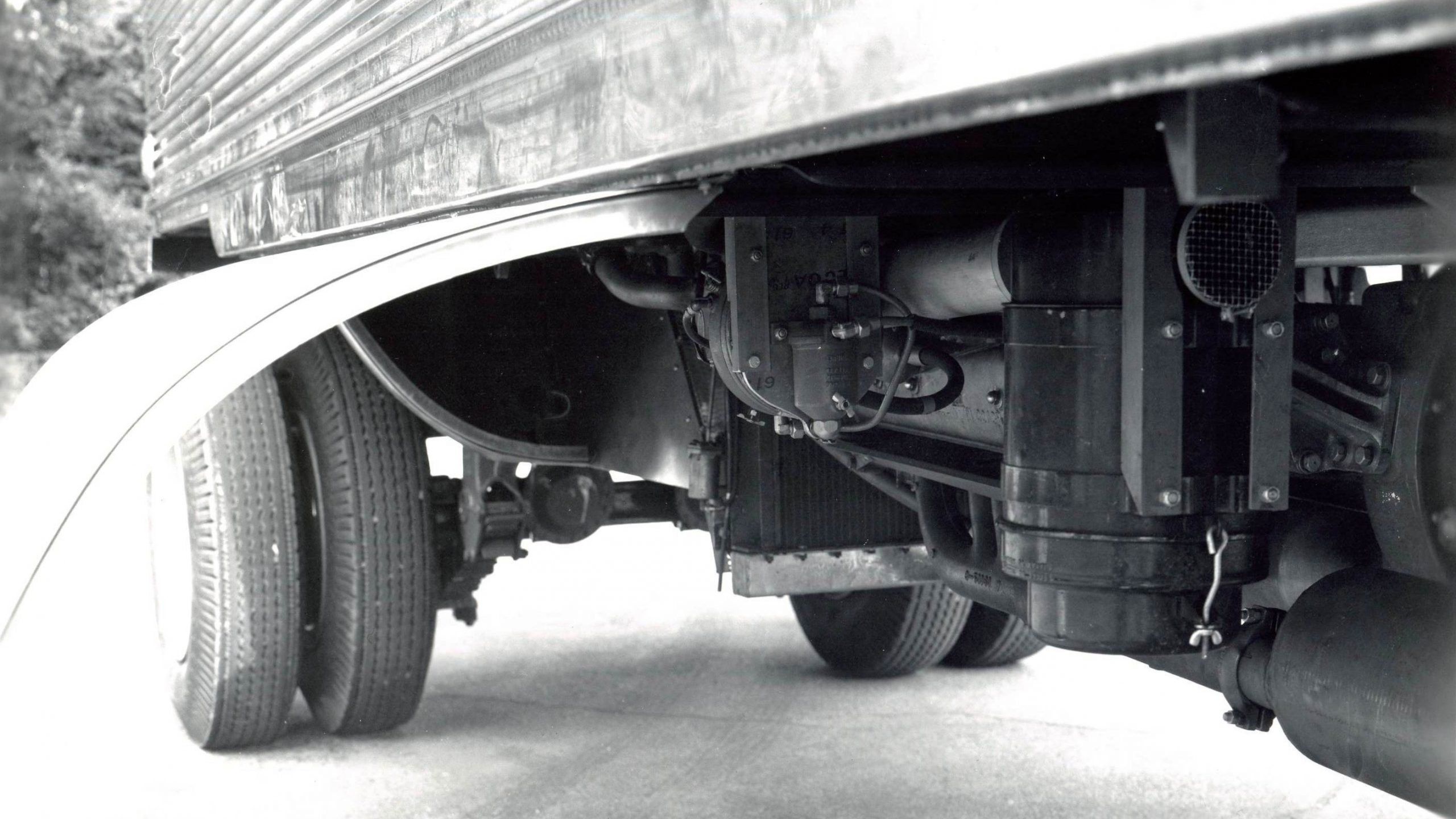

Under the body sat a unique chassis. According to a 1950 issue of Commercial Car Journal, the Super Freighter was supposed to use Fageol underfloor inline engines, making between 162 HP and 250 HP. These would have been the same engines found in Twin Coach buses. In this application, they could have been made to run on gasoline or propane.

The demonstrator used a propane engine from a Twin Coach bus, and a later version was supposed to use a Leyland diesel engine. The truck was to be stopped using Bendix-Westinghouse air brakes and shifted through a choice of Brownies, Clark, and Spicer transmissions. The production truck was supposed to have a rear axle from either Clark, Eaton, or Timken.

The Commercial Car Journal article went pretty deep, noting that the production truck would have used an Exide battery, a 106-gallon fuel tank, and either a 25-amp Delco generator or a Leece-Neville alternator. Up front, the driver got an extremely basic cab with only the basics needed to safely command the rig. The controls were hydraulically actuated and what was unique up front was the dual wheel steer axle, which sat on a bogie they used Vickers power steering and Gemmer steering gear.

In most vehicles, steering is achieved through turning the front wheels. The TC CargoLiner worked like a more complicated version of the red Radio Flyer wagon you had as a kid, and the hydraulics actually turned the entire bogey rather than the wheels.

This was great for maneuverability as a driver could technically jackknife the CargoLiner into a dock or space with greater ease than any typical truck.

According to Fleet Owner magazine, using the rigid front axle and steering bogie meant that the Super Freighter, which measured 35 feet, had a turn radius of just 39 feet and 6 inches. Period newspaper articles also claimed that going with the bogey meant that Twin Coach could go with a burly dual front wheel setup. Twin Coach was also said to offer a typical front axle in the proposed production version.

Put it all together, and Twin Coach said that buying a Super Freighter/TC CargoLiner meant getting a truck that had the same payload as a typical tractor-trailer setup, but was on average 8 feet to 10 feet shorter, thanks to not having a tractor up front. Twin Coach also noted that you’d save about 8,000 pounds of weight compared to a typical tractor-trailer, too. As Business Week noted in 1950, states were also restricting the total length of trucks, so the Super Freighter was also supposed to be a bit of a cheat code there, too. The best part is that according to the patent, a truck like this could be sold for 20 percent cheaper than a typical semi.

According to Bus Transportation magazine in 1951, Twin Coach delayed the production of the TC CargoLiner due to the Korean War. This idea did not die with the sole Super Freighter that was built. Twin Coach also introduced the Fageol Twin Coach Convertible during the same time period. This looked somewhat similar to a Twin Coach bus, but had the Fruehauf body of the Super Freighter, a 477 Fageol gasoline bus engine, and an interior that could be quickly converted between passenger and freight roles. The Army liked this idea and ordered nearly 1,600 “F-32-F” coaches for over $20 million. Other examples of this design became highway post offices.

As for the Super Freighter, Twin Coach took the patent from that and created the Fageol Van, which entered production in the early 1950s. These trucks followed the same formula of being almost all cargo body with only a tiny cab slapped on the front. Twin Coach sold them in 20-foot to 35-foot lengths. Like the Super Freighter, the Fageol Van was marketed with the promise of providing more cargo volume in the same space that you’d get in other trucks.

Advertisements for the Fageol Van showed a 20-foot Fageol Van next to a typical 20-foot cabover truck. The marketing claimed that a 20-foot Fageol Van had 16 feet of cargo room compared to just 14 feet of cargo room for the typical cabover truck with the same overall length. Twin Coach also said that a Fageol Van, which carried up to 33,000 pounds, had a better payload rating than the competition. In case you’re curious, these things had top speeds of around just 45 mph.

Notably missing from Fageol Vans was the weird steering bogie from the demonstrator. But the production trucks did come with drivetrains and chassis from International Harvester. Advertisements said that the IH running gear meant that Fageol Vans technically had a service network of over 7,000 dealers, which is where the Fageol Vans were also sold.

In 1952, Flxible purchased Twin Coach’s bus business, and Twin Coach continued to march forward on the sales of Fageol Vans and Pony Express postal trucks. The Fageol Vans turned out to be especially popular with moving companies. Sadly, in 1956, production of the Fageol Van and the Pony Express ceased when the factory in Kent, Ohio, closed.

Twin Coach would then see its subsidiaries closed and sold off, with the company itself changing its name to Twin Industries in 1962, only to get absorbed into Bell Aircraft in 1963. Flxible stopped using the Twin Coach name on buses in 1962 and the last time the Twin Coach name was used on a vehicle was on some light-duty buses built by an unrelated company operating out of Twin Coach’s old Kent factory.

Ultimately, the idea of an all-in-one integrated truck and trailer never really caught on in the long run. Today, straight trucks are still largely conventional trucks with cubes bolted to them. If you need a truck that’s smaller, you’ll get something like an Isuzu NPR, and if you need the full capability of a highway tractor, then you’ll just go that route.

The TC CargoLiner was properly wild. It was little more than a trailer with a seat, a couple of windows, and an engine, but this weird design had a lot of promise. But it’s also a bit of a product of its day when truckers had fewer choices in the marketplace. There’s not really anyone racing to make a modern Super Freighter. Still, it’s such an awesome part of trucking history that, sadly, might be forgotten if it weren’t for the enthusiasts trying to keep Twin Coach documentation alive. It’s a shame, because I’d love to know how this thing drove.

honey we are going to see the front end collision from the first row seats.

Thanks for getting back to 1920s busses, do you think Ford or anyone ever made a crew-cab smallish truck (lorry)? My Call of Cthulhu rpg characters would like to see a pic of one.

A straight truck that could take a 40′ ISO box would be pretty useful.

In the 1980s? There was a semi tractor (I’m guessing prototype only) that was entirely sat below the trailer

Ah found it, the Drive did an article on it 8 years ago…

https://www.thedrive.com/article/12603/the-forgotten-steinwinter-supercargo-is-unlike-anything-on-the-road-today

Are these the guys that also came up with the Italian soup-like pasta

Lou Fageol was an incredible driver of various classes of race boats in the 1930’s to 50’s. His career unfortunately ended when he flipped the Slo-Mo-Shun V while trying to qualify for the 1955 Gold Cup in Seattle. He is quite famous in racing circles:

https://youtu.be/MTvFX7zDJro?si=1eHMH6EH8fBzFY-T

That dual axle steering is something else! It makes me wonder if any other vehicles have dually steering? The only one I can think of is the Futurliner.

I find it jarring to see the images of the truck with no mirrors.

The illustrations are inconsistent. A right hand-side mirror is visible in the patent drawing and the interior photo of the cab. I didn’t see one on the left side which is perplexing. I don’t know what the regulations were then, but I can’t believe that would be legal now.

Surprisingly side mirror laws in the US appear to be at the state level and therefore vary by state…

In general at least 1 side mirror (usually the drivers side) is required…

EcoModder appears to have a complete list of requirements by state

https://www.ecomodder.com/wiki/Mirror_Laws_by_State_%28U.S.%29#Mississippi

That IS weird. What happens when a car that was compliant in a lax state gets operated in a more stringent state? Probably nothing because as things for LEOs to deal with, this is pretty low on the list.

I’m pretty sure there is a Fageol Van (or something similar) in a field by !-29 in Iowa! I remember passing by it frequently and trying to figure out what it was. But my (admittedly faulty) memory seems to think it was a livestock/horse van setup?

If they ever get that pesky self-driving thing figured out this is how I imagine they’ll look.

Why could I honestly see Ms. Mercedes buy one of these and a pair of ramps to be able to transport her own Smart cars around in. Mercedes, if you do that, you will have some serious respect from the peanut gallery here (myself included).

I’m all for inclusion, but June is our month.

Well played!

Well, it is a trailer that identifies as a truck.

As someone whose family owns a trucking company, this design severely kneecaps the ability to simply drop a trailer to be loaded, hook to another and go.

Speaking of kneecaps, there is not much in front of the driver and passenger in case of a collision. I doubt the screwed-on wood panels below the windshield would protect much, especially with several tons of cargo carrying the momentum forward.

The best thing about a cab-over truck? You’re always the first one to the accident.

Given how old this design is and the fact there appears to be zero thought in the design to frontal crash space I’m sure it would be a death trap in a crash.

That said modern COE trucks in Europe are reported to be exceedingly refined for example there are really 3 suspension systems. 1) regular suspension 2) whole cab suspension 3) of course seat suspension system too. And their crash performance is supposed to be at least on par with American semi tractors if not better.

I’m not saying they’re unsafe. I’m saying in terms of arrival, you’re always there first due to linear distance covered. I bet you even beat EMS by at least 15 mins.

Add a tuft of red hair on top and the styling of the CargoLiner bears a strong resemblance to Beaker the Muppet.

The horn better go meep meep

I kinda like the wicker basket trim on the cab. Otherwise, it doesn’t seem that different than the medium duty delivery vehicles that are common now. Definitiely better looking though. At least in this version.

Sorry! I wrote that before I actually read the article. The steerable bogey on that thing is incredible! I’ve never seen anything like that since, as you said, my red Radio Flyer. And it’s wild to see dual wheels up front too.

Neat idea. I’ve seen kinda similar what I assume are home built units abandoned. Similar to the people use who old blue bird buses with the coe design to haul things like bails or even silage.

This seems like a wild idea here in the USA, given how our commercial vehicles evolved, but I have seen trucks quite similar to these in design in other parts of the world – especially Africa and Asia. They were always fascinating to see, because even with what seemed like a more purpose-built design than semi-trucks here, they were used in a far more multi-purpose, Swiss Army knife-fashion than I ever expected.

That was really fascinating. I am wondering if the technology existed to create a hybrid type steering system? Standard rack and pinion for highway speeds and the locked off and radio-flyer style for tight quarters and lower speed?

I remember when I tried to build my first “car” at around 10 years old, I used that style of steering- just a bolt through the wooden frame (that was previously a picnic table) the the plastic wheels (I got from a discarded grill- this was the early 90’s) snapped off the hub the first time I turned (foot steering, friend pushing).

I can see those forces doing some damage to the wheels and boogie and imagine that it would have much stability, though the low speed maneuverability would be impressive.

Yes! Much better than my half-cock AI idea in my previous comment.

Haha, I just read your comment. AI controlled steering… that’s putting too much trust in the system! However, now I feel the need to dig out some old Lego and see if I can prototype that dual steering set up to see if it’s possible. In my head I am not sure where the steering shaft should go when it is in bogie mode. I’d love to see AI try to design that actually.

Steer-by-wire: the entire steering mechanism, including the motor, mounted on the bogie.

I guess, to keep unsprung weight down, you’d need to mount the suspension entirely on the bogie, too. I’m not sure how truck suspension works: would a compact wishbone set-up be too fragile?

After seeing AI thinks I should try to make this work. I’ll take human advice from now on.

I’m not surprised. I guess hybrid steering mechanisms are still in the “unknown unknowns” category for AI.

Same here, though it was plywood and 2×4, steered with feet pushing on the rotating 2×4 that the axle was mounted underneath of, and used old baby carriage wheels. One had to firmly and evenly press on the axle to keep it straight with only slight let up to steer. Anything less and you were flipped off sideways. I think I eventually used a piece of clothesline to act as a limit stop on the steering, but it might have just been that I intended to.

Nice! Unfortunately mine never made it past the first trials as shortly after that, through lego technic, I started to understand steering better and realized that would never be able to make anything that complex from objects found on the mornings of trash day… and the friend who I built it with also acquired and actual go kart.

Similar. I used to get a lot of parts from trash. Made several bikes that way. It ended up largely abandoned after winning a gocart from a retailer. It had a fiberglass body of Earnhardt’s Wrangler sponsored NASCAR, except they used a T-Bird instead of a Monte Carlo. Today, I could have ordered all manner of solutions off Amazon for next to nothing. Or at least until recently (not sure how the tariffs have changed that yet).

Wonderful article and wonderful trucks and buses. Thank you, Mercedes!

With modern detailing, the Super Freighter could become a futuristic design student’s project. Maybe AI-controlled active steering could even make that front bogey system something less than petrifying.

I’ve been thinking about this, if the steering is electric- like cybertruck, it may be possible to have bogie and standard steering. I am asking AI to help design this system… can’t wait for the results.

Man those are some wild trucks. The metrics make me wonder why someone else didn’t take it further. I was concerned about visibility and steering. I didn’t understand it but apparently turn radiance was great but does that translate into turning in tight city roads? I remember back in the day semi’s always needed people to back up and move over to let them by. Since People back then were nicer and more polite it was not an issue. However that little slap on cab smaller than the trailer I don’t see any visibility past 90 degrees on each side. A front axle set further back would give better turns and a better weight distribution.IMHO

I agree, a setback conventional steering arrangement would be a better solution, but I suspect they mounted it where the reinforced area of the kingpin was and went with a bogie system to use as much of the existing structure as possible.

It looks amazing but that front axle steering = boom boom in the panties at high speed.

Sorry 45mph was top speed.

I see some similar thinking in the very high volume truck and trailer rigs used in Europe. These have a very short cab with a roof top sleeper and often an underfloor engine to get maximum cargo for things like empty cans, Styrofoam packaging and automotive body parts.

There was also a European truck prototype that stuck the cab and engine under a shipping container

You can Coach if you want to

It hauls all your friends and mine

‘Cause that truck-based bus with the high spring rates

Leaves bruises on my behind

C C, O O, T T, D D. Comment comment of the day day!

Can imagine you wouldn’t need a hospital when your knees are the crush zone and 40ft of cargo comes to join in your fun.

Methinks a crash at walking speed would be fatal.

“In McCarthyist America, YOU are the crumple zone.”

Trucks really don’t crush whether they are conventionals or cabovers, then or now. The frame necessary to support the weight and transfer the power of 350-500+hp and 1000-2000+lbs-ft of torque to many, many many tons of cargo is not particularly amenable to crumpling in a crash. What they hit is the crumple zone – something to keep in mind when around them. Hopefully there was a sufficiently sturdy wall between the cargo and your tender self. Though that can be an issue today as well – there are plenty of horrifying load shift videos on the Interwebs. Steel coils especially are a good time when they come loose.

Really cool, simple idea and the corrugated skin reminds me of a Ford Trimotor, but that “Beautiful Beds” van is awesome from the style with the wrap around wings to the colors, graphics, and typeface—I love it!

The Minnesota Teamsters had a bus version that was used as a mobile office into the late 1980s at least. Minneapolis Public Library had one set up as a bookmobile driven by a great gent who was a librarian with a CDL! It survived into the 1990s at least, but was scrapped when he was on leave and he was pissed!