Two days have passed since I ordered just about everything I need to make the hideous Ssangyong Rodius — a vehicle The Autopian purchased as a joke for its beloved, picky designer, Adrian, who opted to wear a paper bag while driving it — road-worthy again. Sadly, the parts needed to keep the ugly diesel van out of the junkyard have yet to leave the warehouse and begin the journey. All I really need is the springs. If the substitute springs are good, then we can make some headway, but if my gamble doesn’t pay off, then I’m stuck in customs import hell waiting for them to arrive. Not to mention, these Rodius-correct springs would end up about three or four times more expensive than using the Rexton nearly-right ones.

Parts For The Beloved Rhodius Are…Not Easy To Find. So I Bought Springs For A Different Model

In case you’ve forgotten or missed my last article or PedalBox Garage episode, our particular early-model Rodius has two possible suspension spring set-ups up front. A short 325mm for the 2.0L diesel, and a longer 375mm for the 2.7 diesel. The short ones aren’t exactly common, but they’re not too hard to find in stock. The longer ones are pure unobtanium, at least in the UK. There’s no stock of them anywhere, and ordering through what’s left of the Ssangyong Dealer network has a lead time of at least nine weeks.

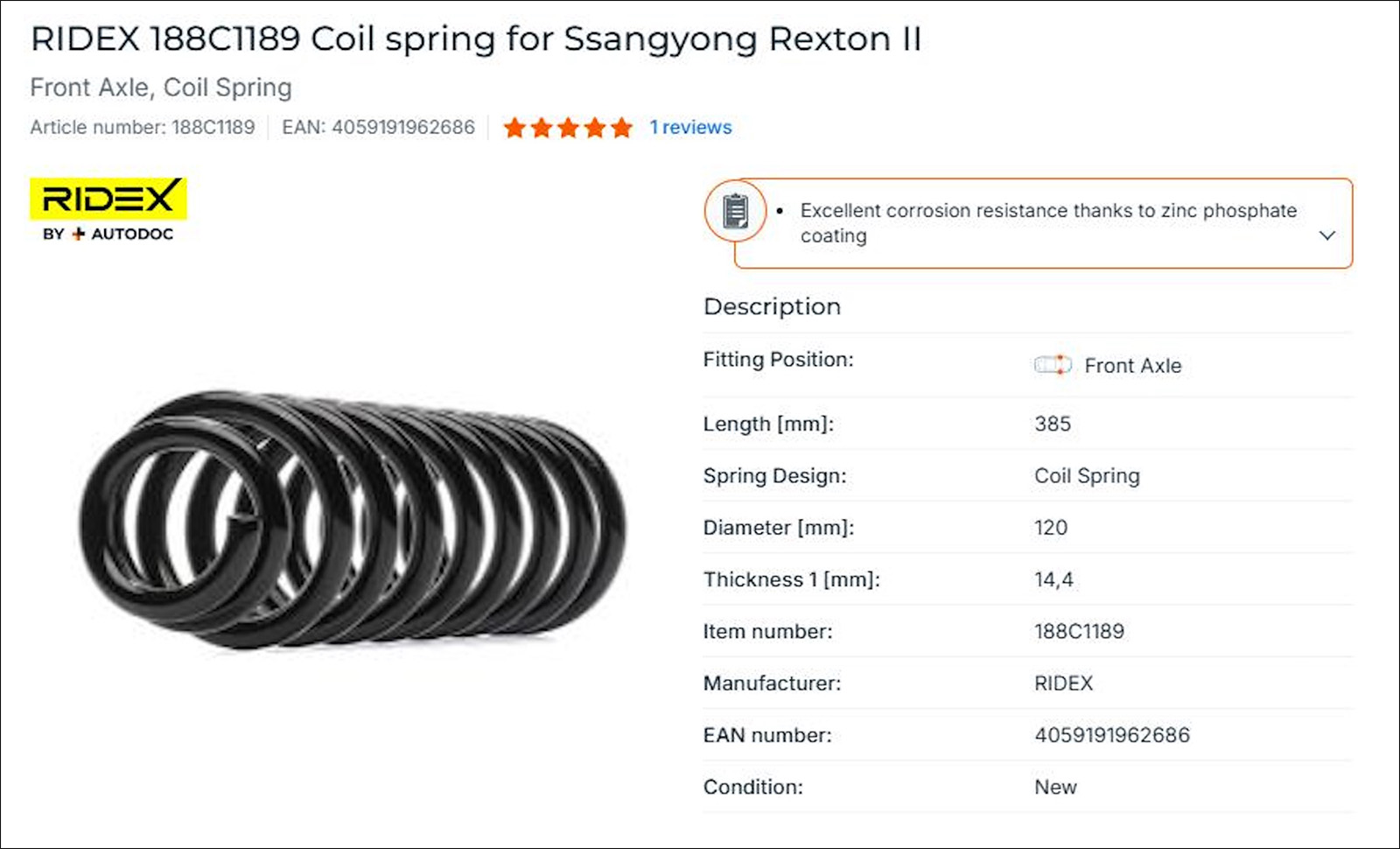

So with those two equally long and unappealing options, I crossed my fingers and ordered the Ssangyong Rexton II springs, which are 10mm longer but for the same 2.7l drivetrain as the Rodius. I pray I’ll get away with it.

As convenient as it would be to just order the one spring and put the left strut back together and move on, convention and good practice mean both sides should be replaced to ensure even and equal performance and no odd driving characteristics. There’s no way a brand new spring and a potentially 20-year-old spring will ride right together, so best to just do both, even if it might be a tiny bit hacky. At least it should be equally hacky on both sides, and whoever ends up the lucky owner of this fine steed doesn’t have to worry about the other side snapping any time soon, and they can’t use it as an excuse to rid the world of its glory.

Back to parts. My hope was to get all of this done in a weekend: strut off, swap the springs and reinstall Saturday, chuck the new discs and pads in on Sunday, and there’s a slim chance we might have this thing MOT’d before it even expires. Of course, I’ve scuppered that already by forgetting to order a CV boot, but maybe I can find one of those locally, since it’s all just Mercedes running gear …

[Ed Note: I’d just like to point out that our plan was to actually scrap the Rhodius. Adrian (Clarke) couldn’t just hold onto it, it failed MOT, and nobody — I mean nobody — wanted to buy it. At the last second, I found this Adrian, who volunteered to take the car off our hands and fix it. Yes, we literally had to pay someone to buy our Rhodius. But hey, we’re getting content! – DT]

Apparently, no, just another unobtanium part, meaning this won’t be the rapid, one-weekend turnaround I’d hoped for. Moreover, this isn’t the last of the problems that will befall this plan. Perhaps this is a sign? A foreshadowing that every attempt to keep this car functioning will be beset on all sides with looming uncertainty, caught betwixt seized fasteners and a maddening hunt for what will inevitably turn out to be ill-fitting parts and broken tools.

Or it’s just unpopular, and with the demise of the dealer network, domestic stock is non-existent. It would certainly explain the high demand for second-hand parts, which caught me out and denied me an easy swap for a complete used strut to slot in without having to risk life and limb disassembling one.

A Greasy Job

I’ve been mentally going over how to pull the strut out while removing as few parts as possible. Not that it matters much on this side, as I’ve also got to take the hub out to do the wheel bearing and get to the CV boot. But establishing the minimal cut-set of removal will pay dividends, as on the other side I hope to get away with disturbing as little as possible.

Were this a McPherson strut, as every other car I’ve had to replace springs and shocks on has been before, this would be fairly easy; pop the whole assembly off the top of the hub, drop out the top mount, and it’s free.

But free is a relative term; I don’t think I’ve ever been lucky enough to actually “just” (as I’m sure a Haynes manual would judgingly put it) remove the strut from the hub in situ. I’ve had to cut away a pinch bolt one sliver at a time with a grinder, eating it away bit by bit through the pinch gap as it’s tapped into the fresh void, all to release a multilink control arm from the hub. Fortunately, this doesn’t appear to be anywhere near as bad, either in condition or access to fasteners.

The Rodius upper control arm pins the top of the strut in place, and the tie-rod, sway bar, drive shaft, and hub, along with the chassis itself, constrain it in all directions at the base. Removing the upper control arm will probably be the quickest option for the non-broken-spring side. But for this side, that’s actually the only piece I can leave in place.

Every bolt released and every piece removed opens more doorways to another potentially catastrophic episode of “while I’m here, I might as well just…” It would be so easy to fall down the pathway of engine out, powder coat the subframes, and have someone come to do some paintless dent repair while I meticulously try and blend in the rattle-canned areas to the rest of the 20-year-old paint…

No. This car cannot become another driveway ornament. Not least because it’s blocking the Thunderbird’s triumphant return (which might yet be on a truck due to its lack of compression on at least one cylinder)

Either way, three boxes of parts will be here by 2pm, and ignoring the fact that it’s already 3 pm with no sign of them, it’s time to get as far as I can through disassembly. With this courier it seems, every delivery is a gamble.

Despite having a plan to try the minimal disturbance approach as a test for the other side, I gave up on it pretty quickly. Be it a subconscious decision that the upper control arm is by far the easiest way to do it, or just plain old distraction in the process, we’ll never know. The top mounts looked easy, so they went first.

Three bolts and ample clear space above them. If these go badly, I might just go weep into the tools for a moment, curse some bloodlines, and consider burning the whole thing to the ground. Fortunately, they put up little to no fight and now that they’re loose, I can move down. I’m relieved but still suspicious of what problems are ahead.

Next up: brakes. They’re coming off to replace the discs and pads anyway, so no point leaving them on the hub and making that more awkward to work around than it needs to be. Two bolts on the carrier and that should be all that’s nee … WHY AM I COVERED IN GREASE?!

Oh yeah. The CV boot is leaking. It’s been ejecting its contents like an overfed child on a carousel for what could be all 5000 miles since the last test, and as a result, the inside of the hub, carrier, caliper, and the bolts are covered in nearly a quarter inch of grease mixed with every possible speck of dirt imaginable along the way.

Fan. Tastic.

There is an upside, though; while every bolt is covered in this thick goo, every bolt is covered in this thick water-repelling goo! Maybe this won’t be so bad after all. Although the bolts are tight — tight enough that I had to employ the trolley jack on the ratchet handle to get them loosened at the start — there’s no evidence of corrosion. For an assembly at the business end of the salty roads’ abuse, it’s a pleasant surprise.

The Right Tool For The Job

Removing the caliper from the disc was itself a challenge I should have foreseen, knowing as I did that the discs were pretty badly lipped. With no easy way to push the pistons back in effectively, this meant prying the calipers off. Good job, these pads were already destined to be replaced, and if they hadn’t, they’d need to be now after being chewed up going over the lip.

Were I a smart man, I’d have released the disc retainer screw while the caliper was still in place and stopped it rotating with some help on the brakes. However, I am not a smart man and instead I had to brace it with the crow bar thanks to some genius over tightening it.

Releasing the hub nut was delightfully uneventful, although I probably need to source a new one per the instructions. Freeing the lower ball joint was equally simple, or at least it should have been had I not forgotten to actually remove the bolts after taking the three nuts off before trying to pry it free.

I really wish I were making this up for some klutzy, “oh look how silly I am forgetting to do things, deary me!” schtick. But no, I am simply not a smart man.

One slip of the hammer later, the tie rod is out of the hub, and finally the lack of CV grease on a bolt has come back to haunt me. The half-inch of stickout from the nylock nut corroded just enough to make its entire run out a fight from start to finish. Perhaps I should have just stuck the impact on and sent it, but I was trying to avoid melting the nylon, the very same nylon that is probably trashed as a result of the corrosion. Instead, I spent 10 minutes going one-sixth of a turn at a time with the breaker bar the whole way out. I should get a T-shirt made up with “I am not a smart man” on it.

Eventually, after releasing the top mount fully, disconnecting the drop link from the sway bar, and prying the lower arm down further, the strut is free. It’s only taken three hours, but in the meantime, there’s been a delivery!

One box out of three. And it wasn’t the springs.

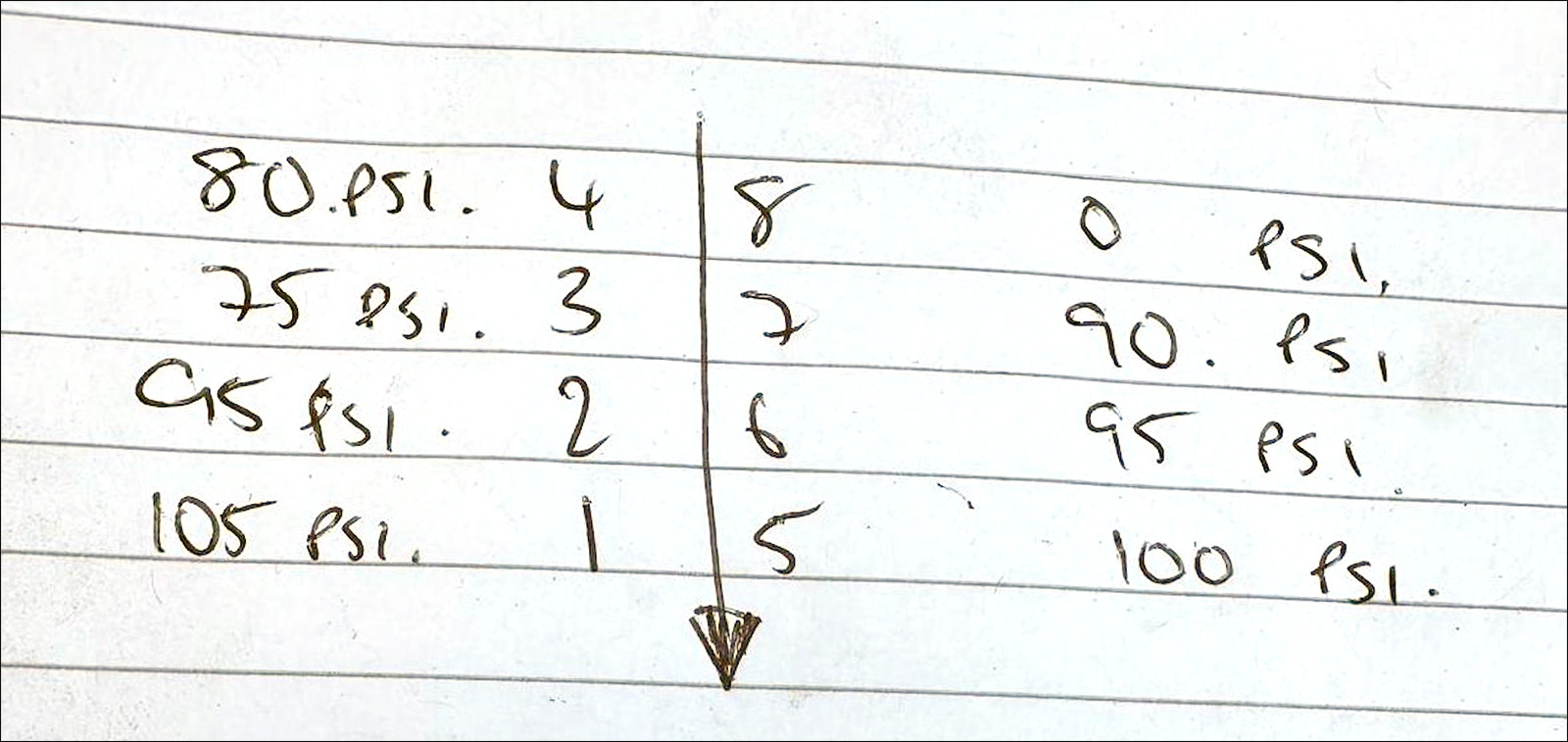

Skip forward a few more days and the springs have arrived, but there’s a fresh new problem to deal with. While trying to take the old spring apart using my trusty widowmaker spring compressors, I found they don’t actually fit between the coils. I could just throw an impact on the top nut and burst the whole thing across the drive to release the old one, but there’s no guarantee I’ll be able to get them off again once the new spring is in.

Furthermore, not only is the new spring longer by 10mm at rest, but the installed length of the spring on the strut is heavily compressed by at least 50-60mm. My clamps need to pull down at least three inches (75mm) on the new ones to get close to fitting, probably more – and there’s just no way they’ll manage that.

Fortunately, on hearing what I was doing, a friend with a commercial garage offered to help with the spring swap. Although I assured him I’d probably be fine, it was at this point that I gleefully accepted his offer and went down to CMC workshop to use their beefy 12,000N spring compressor to get the job done with far less peril.

You may wonder why we used such an antiquated (in reality, only 30-or-so-year-old) looking tool. Despite being perfectly good and capable for the job, surely any garage would have a hydraulic or pneumatic compressor these days. And you’d be right, but Geoff had thought one more step ahead than I. Once we swapped the springs over, there was a chance the top mount alignment and the lower shock bolt alignment would no longer be the same as they were, and I’d have to adjust the alignment on the car. So he planned to loan me this much-easier-to-transport set, just in case.

Sure enough, the old spring was very much done for.

I have a healthy respect for springs under compression like this (above), which I don’t ever want to lose lest I next lose a tooth, an eye, or worse.

The new spring went on with little to no drama. It’s amazing how having the Right Tool™ (even when you thought you already had it) makes the job so much easier. We got the top mount aligned as closely as we could and I went on my merry way, tools and all.

I Have No Idea How This Thing Is Going To Drive

It turns out the alignment was extremely close, just a few degrees of tweaking was enough, and that was done with a chunky screwdriver before slotting the bolt home. Just one more to do now, or so I thought.

While I may not be a smart man, I am clearly a very lucky one. As much as convention would be to replace both springs when one snaps, some previous owner down the line obviously didn’t think so.

The driver’s side spring is almost brand new. The coloured marks are still visible under what is a very thin layer of dirt clinging to an absolutely pristine powder coat. Incidentally, are these coloured marks alignment? QA? Someone enlighten me, please.

This can’t have been done all that long ago. Perhaps I shouldn’t be surprised that when an almost impossible to find spring needed replacing on a cheap runabout, they didn’t go the extra mile and order a pair and spend more than the car was worth on labour for both sides.

I won’t send the other spring back yet; there’s a not insignificant chance that the springs are mismatched since one is Rodius and one is Rexton. If that’s the case, then it’ll have to come apart again, either to fit a Rodius spring to the side I’ve just done, or to fit the Rexton spring to match the other side. But I won’t know that until I can get it back down on its wheels and ideally drive it around to settle everything in.

I could make a start on the brakes, but I have to fix a bolt I broke in the hub that holds the ABS sensor and source a suitable CV boot. At this point, it’ll likely be a generic stretch fit since I don’t want to remove the knuckle from the end of the shaft and disturb something that is functioning perfectly fine. That’ll be in another episode on the channel, but in the meantime, you can watch me struggle in the second episode of Saving the Ssangyong for your entertainment.

While I was hunting down the brake rotors, I found out the Rodius is a 5×130 fitment, which happens to be the same as the car we’re building. With the front in the air, it’d be rude not to throw on the 18” wheels for a laugh!

Alas, the centre bore is much bigger on the Rodius, so they’re just propped on a brick. But that means I have to deliver the disappointing news to what must be a fairly niche group of enthusiasts who stable both Ssangyong and Porsche. Sadly, no, you can’t just swap wheels if you need to in a pinch. Sorry.

All photos by the author unless noted.

Top graphic images: Adrian Gordon

“Rodius” sounds like the vehicle GWAR drive around in.

Considering it’s a portmanteau of Road and Zeus since it’s the “road king/god”, that would be fitting

Don’t they have spring shops that can make springs to orderwhere you live? Here in California they’re all over the place.

I remember a driving school that had a car set up with mismatched front springs so that it would oversteer when turning One Direction and understeer turning the other. Sounded like a great teaching tool. I don’t know if I would want to actually drive it in traffic that way.

Fair point, I’ve not encountered one before or seen them advertised but i’ve also not looked either. Just had a quick search, 2-3 week lead time from that supplier and all POA. Given the size of the Rodius ones I’d wager they won’t be cheaper than the Rexton units.

It’ll be interesting to get a quote for one of the other projects though once we find out what rate we need

Ahhhhh compressed springs! Run!

I hope the Rodius lives on so it can stalk Adrian (Clarke) when he drives the Mondial like a Top Gear special backup car.

This can be arranged! Whether he want it or not 😀

Wait, are you Ssaying there’s something yong with it?

Thats good, thats damn good.

Clearly the Rodius is going to stick around just to spite everyone involved with this.

😀

This is my assumption.

Don’t they sell Dremels with wire brush attachments on that side of the pond? When I did the suspension on my 17 year old Midwest car I Dremeled the rust off the exposed part of the bolt. Otherwise there’s no way that nut was coming off, even with PB Blaster.

Oh absolutely, and I have one too! Which is better than the copper hammer I only got after I’d mashed a rod end thread. Good old “well how hard can it be” and then once you’ve started “might as well just finish it this way”. Did I mention i’m not a smart man…

I file a couple of grooves in the threads of a nut and chase the threads in that situation. Of you could go buy a thread die and ruin it but what’s the fun in that.

I’ve made improvised taps and dies on many occasions. They last about 8 turns usually, but that’s enough.

Castellated nuts sometimes work too.

Thats a good shout. I might give that a go

It’s good to see that the Rodius will live on to torture Adrian Clarke… LOL

One day I’ll just park it back outside he front door 😀

Methinks this is the avenue to madness.

It’s teste me a few times so far. Part three has begun though! hub is ready to go back on.

My first thought was why is Dr Mark Greene (ER ~1998) fixing that car?

Well shit. Theres something I can’t unsee.

Oof. I think every time (but the 1st time*) I’ve had to replace front struts and springs the vehicles all had Macphersons and bc the make/models were common I could get order new struts/springs already assembled.

*the 1st time I was much, much younger and I wanted to try sport eibach springs with sport bilstein struts. It lowered the ride height 30mm and combined with 195/50 R15 summer tires on original BBS rims (some kind of Yokohamas all around + matching set up of new sport springs and sport shocks in the rear), made for a very tidy handling daily driver.

Being the 1st time I had to change suspension components I did thankfully make a smart move and get some help from some more experienced wrenching friends and I’m glad I did bc I was smart enough (thankfully again) to have a healthy respect for the forces involved in compressing the springs. Fortunately all components were successfully replaced in a long weekend of wrenching. Which was possible bc I ordered all the parts in advance including top mounts, wheel bearings, front struts/springs, new brake discs and pads

Yeah, i’ve never had a spring explode out on me in an uncontrolled/unexpected way. I’ve popped a long spring out from the rear of an A2 before but that was fairly uneventful being a very light weight spring and already broken at a lower coil, so it wasn’t much to pop it out.

I wish I’d managed to get the fully assembled strut for the Rodius when I saw it, I just figured it wasn’t going to be that high demand

The look on Adrian’s face in the top photo is priceless – haven’t we all had a moment like that? Fantastic article, here’s hoping we’ll see more from him soon.

Thanks very much for the kind words! And yes, that does sum up so much of that day.

Woof! The spring under compression scared the bejesus out of me. I automatically turned my head and squinted. Terrific article!

Seriously, I HATE those crummy amazon-grade spring compressors. I used one with a friend many years ago, the amount of puckering my ass did probably aged it 20 years. I would not want one of those cheap pieces of crap to let go anywhere near a human being. They all seem so crummy, just bottom-dollar junk for something that should NOT be built to a price point.

I found a Branick wall-mounted spring compressor on craigslist a few years ago for cheap. It’s big, it takes up a lot of space, and I only use it maybe 2x a year, but it’s so nice to just hang the strut in there, set the hooks and spin the thing down, safely, drama free while I can work on it.

I know they’re not for everyone, but if you can find one and have the space, I can’t recommend it enough. If you own a few cars, it pays for itself in time. I’ve done three sets of struts with it so far, so I’m pretty happy with my choice.

Having the freedom to buy struts at my leisure when they go on sale is also a benefit. If they suck and I don’t like them, changing them out isn’t a huge deal either.

I need to keep an eye out for one of those wall mounted ones, this one I borrowed was so much better than the cheap set I’ve got and I still felt uncomfortable around it

I made very sure, despite this being a proper workshop compressor to say behind the escape velocity side of the spring. That one actually has nubs which you can’t really see from the outside which hold the spring onto the top and bottom compression plates. So theres NO way its going anywhere… and I was STILL deeply unhappy being near it.

Potentially dumb question: can you trim the spring so it’s not quite as long as it is?

Yes. Although it not ideal to do so as the way springs are typically engineered means that the compression/rebound forces are not usually strictly leanier, meaning some coils of the springs are intentionally designed to be a biteasier to compress than others.

That said hot rodders have been cutting springs for +70 years.

And this is particular ride is not exactly ever going to be a canyon carver so if Adrian finds the ride with the full too long springs too bouncy he could try cutting them, that has the added bonus of another article too and then possibly a 3rd bcnhe decides if he doesn’t like the cut springs to replace them with the closest springs he can find from another vehicle based on similar weight (of the other vehicle) and spring height

Pretty much, I suspect these from the Rexton (same engine/similar weight/etc) should be ok. Assuming the one on the Otherside isn’t wildly different and gives a horrible lean. If thats the case I’ll put both Rexton ones on and see what that’s like, at least it’ll be rolling while I wait for proper ones to arrive. I’m hopeful it’ll all be fine though

This is a cracking tale, and makes me thank my lucky stars I live in Central Oregon where low humidity and no road salt means brakes and suspension come apart with only mild profanity. I still spent Saturday under our Fiat cursing in 3 languages as I wrestled with rubber exhaust hangers. (our Fiat 500 was built in Mexico so I yell at it in Italian and Spanish). Exhaust hanger pliers are,the greatest thing since the cordless impact driver.

That’s really smart to yell at it in both Spanish and Italian 😉

I try to address cars in their native language so I had some Japanese insults for our Mazdas

Haha just to be prepared I also better learn some Japanese curse words ( best place to start with a new language anyway) for the next time my Toyotas need some work 🙂

Baka des is my go to

Thanks, it’s certainly not been the worst suspension journey. I mentioned about the pinch bolt I had to remove slice by slice. That was on a ~’98 Passat which I bought cheap and seemed fine but rapidly (I mean within 50 miles) sounded like hammers hanging from ever strut, swinging in every corner. That needed 7 out of 8 front suspension links replacing and one upper was responsible for the most miserable day of work in a long time. Blow torch, hammer, slitting disc on a grinder and it STILL wouldn’t go easy. Had to drill the other half of the bolt out to the head.

Definitely approve of the multi language cursing though!

The paint marks could mean just about anything but for many cars it denotes the spring rate and/or length so it is easier on the assembly line to pick the right ones for the given vehicle’s configuration. Aftermarket mfgs may replicate the OE markings or just do their own. It could also mean that it passed the QC check.

Makes sense, cheers!

This is just so delightfully British in all aspects! Now I almost want to go buy some shitbox to torture myself with. Almost.

Do it! You certainly wont ever regret it. Nooo, no once…

“tight enough that I had to employ the trolley jack on the ratchet handle to get them loosened at the start”

This is where bolts go to die. Just yesterday I snapped a probably-never-previously-moved camber eccentric on an E46 with my 26″ breaker bar. At least in the shop setting, I’m still learning the boundary between discretion and valor.

I was both surprised and relived that it worked without snapping the bolt clean through. Those adjustable camber bolts are horrific. I was pretty resigned to snapping something so this just felt like the right accelerant. In the end just the one snapped bolt for the ABS sensor

I really enjoy Adrian’s perfectly British expression of droll weariness as he wrestles with all this. I feel the Rhodius could be on fire in his driveway or other Adrian could be unloading a tirade at high volume nearby, and he’d look exactly the same.

Thanks very much, Theres a glimpse of what happens when the fire starts in episode 4 of PedalBox, working on my Golf and I was less experienced and a bit more panic-y.

I’ve set my clothes on fire a few times with grinding and welding sparks and become perhaps al little too calm about it for some onlookers taste

There’s a 2006 Actyon for sale on FB Marketplace in Mississauga (Toronto area). How and why it got imported. I haven’t a clue lol

Thats amazing. I choose to believe it’s a loved cast off from the Actyon Racing Series in New Zealand which someone couldn’t bare not to bring home.

also TIL: There’s an Actyon Racing Series. The southern hemisphere is a wild and lawless land.

I am here for this. I was saddened by that ugly beast going to the scrap yard after all the blissful suffering it put Adrian C. through, so it brings me joy to see it bring suffering to someone else.

I was thinking that if ever a car deserved to have a piano dropped on it, the Ssangyong Rodius would be that car.

Kudos to those who are putting in massive effort just to prove that it actually CAN pass the MOT inspection.

After that, find a needy family that does not have a car…

…or a piano.

It’s actually becoming a shockingly sensible option for a bit of a workhorse for us. So it might yet be around a bit longer than originally planned… for our sins.

IT’s has plenty to offer, fortunately!

“I should get a T-shirt made up with “I am not a smart man” on it.”

Oh, I think the fact that you’re going to be driving around in a Rhodius that you spent all this time repairing probably serves that purpose 😀

Seriously, though, your efforts are emblematic of the soul of this website. You and SWG are saints for working so hard to bring objectively minimally valuable vehicles back to a state of usefulness. (and you’re both damn good writers too)

Thanks very much! I was very nearly going to hop on a plane to come to the Galpin Auto Show (among a couple other bits of work-y related stuff in LA area) with a t-shirt saying “Ask me about their Rodius”. Alas the cheap flight disappeared so it wasn’t to be. I think a Rodius shirt needs to be made though.

Something about CV Boots I never understood is why since they are basically a rubber container open on both sides meant to hold grease in so parts stay lubed, why are so many different boots needed? I’d think like a muffler if the openings on both sides were the correct diameter they would work with any car. Heck the cars could be designed to use an off the rack boot instead of a different one for every car.

He did mention using a stretch to fit boot which is pretty much a one size fits most deal. I still have the tool to install them and the boots are available from several sources. You can install them while leaving the other end in the transaxle as he mentioned.

I might have to pixelate out the cone tool the new boot came with. it’s almost obscene.

They’re very much meant to be a close fit to the shaft and otter joint diameter, and they just clamp in place so they don’t pop off when flexing. This one just has such a perfectly placed hole that it’s like spinning a piping bag full of icing around. You can get generic ones, fortunately (which is what i’ve ordered) since the OEM ones aren’t easy to find. It’ll all do the same job.

I give zero shits about the Rhodius and yet I read the whole damn article. Well done.

Heck I was planning to fly out to Merry Old England, by way of whatever country had the springs in stock pick them up, assist in the repairs and purchase the Rodius just as soon as I won the Powerball.

Quite a few people made that offer it’s extremely kind and appreciated! I’ve flow to the US to buy parts for the T-Bird more than once (and maybe some holiday stuff too…) and taken parts the other way for obscure English things that found their way stateside.

Hopefully these Rexton springs will do the trick and maybe save someone else from a 2-3month wait on parts for their Rodius.

We should do some kind of UK meet up for it once it’s fixed and MOT’d (though i’m guessing that might be difficult for you to attend at short notice!)

SAME!

The cult status this car has I may never be able to pass it on!

Yeah. I love your prose, love your sarcasm, and also the suffering. Love the quiet mockery in your face in the portrait by the wheel well. You’re a worthy foil to Adrian (Clarke). Onward to the T-bird!

Thanks very much! I really can’t wait to drive the T-bird, one thing after another just knocking back making progress on it down at the garage it’s living at for the moment. But it’s time will come!

Please write about it for the Autopian. Are you hearing this, editors??

So long as they keep letting me I’ll keep going! There’s the whole history of that and the various other cars on YouTube too, scope creep and all!

I was the same. I lamented how terrible they looked when they first debuted. Much like the Fiat Multipla, the best place is actually inside one because it’s one less you have to risk looking at the outside of. Now it’s under my skin, I’m not entirely sure Stokholm syndrome hasn’t taken hold at this point.

The real problem is how shockingly well suited it is to my needs for a tow/support vehicle for doing events. I’ve moved the Tbird behind my daily (Audi A6) and it was… dicey. This would have been fine (were it not overweight on a properly spec’d trailer) since it weigh almost 50% more.