An RV might be the second-most expensive piece of property you ever purchase, right behind a home. In theory, a camper is supposed to be built to handle years of use. It’s reasonable to expect something that you pay so much money for to be built well. For years, owners of Grand Design trailers have complained about the frames of their trailers flexing and completely failing. The frame failure issue is so serious that it sparked a National Highway Traffic Safety Administration investigation and a class action lawsuit. Now, Grand Design is finally responding with what it calls its new Omega frame. This new frame is supposed to be stronger and is supposed to prevent frame failures. But existing Grand Design owners are still upset.

I first reported on this issue nearly a year ago. Back then, Grand Design fifth wheel RV owners had been complaining about frame failure in their units, and these stories eventually became viral, national news within the RV world. These owners weren’t dealing with the typical RV problems like leaky roofs or questionable quality, but something more dangerous. Their RVs’ frames were allegedly experiencing slow structural failure.

The so-called “frame flex” saga hit a fever pitch when the National Highway Traffic Safety Administration opened an investigation into ‘excessive frame flex.’ This was after the agency received 23 reports of Grand Design Momentum and Solitude fifth-wheel trailers that allegedly exhibited frame deterioration conditions that led to, per NHTSA, potentially dangerous events on the road and one injury.

Now, Grand Design, a brand owned by Winnebago Industries, says it has a new fifth wheel frame that is stonger and better than before. Maybe the company can finally start looking at its frame issue saga in the rearview. But what’s going on with this issue as a whole right now? Let’s dig in.

It’s Been A Long Road

Let’s start with how we got to this point.

When a typical camper trailer is built, the box containing the living environment is bolted on top of a steel or aluminum frame. You might expect the finished product to be as rigid as your car. After all, you’d think a bunch of flexing and moving around would be bad for what’s more or less a rolling hotel room.

Yet, the reality is somewhat different. Both the RV’s frame and the living space are designed to flex a little to respond to outside forces such as potholes, speed bumps, unpaved roads, and changing weather conditions. This flex — which is normal for body-on-frame vehicles — is considered to be healthy for your camper. The RV manufacturers operate under the belief that if the typical RV were as rigid as a bank vault, the frames would eventually suffer from metal fatigue failure, and the RV’s walls could be damaged from stress. So a very small amount of flex is expected.

The problem is when that flex exceeds “small” and closer resembles the noodles of the past spaghetti you had for dinner. Here’s a primer on so-called frame flex from my previous reporting:

Before I continue, let’s really talk about what the heck people are talking about when they mention “frame flex” because, honestly, the term is sort of vague and doesn’t really cover what appears to be happening in some of these cases. It’s also sort of misleading because, as we established earlier, some flex is perfectly normal.

When some consumers talk about frame flex, they’re talking about the structure on the front portion of their trailers, typically fifth wheels. The area of concern tends to be right around where the trailer’s landing gear meets the trailer’s lower frame plus the upper deck, as well as the pin box (the hitch). As I said earlier, the structure of an RV is supposed to be able to flex. However, a failure in the frame, such as metal fatigue or broken welds, can lead too much stress on the rest of the RV superstructure (it’s like a domino effect).

Calling it “frame flex” is also understating in some cases. Some people also call it frame failure. While a perfect term for this might not be out there, the end result is the same. If your RV suffers from this, it’s a big deal that’s expensive to fix and, allegedly in one case thus far, has led to an injury. So, it’s not something you want to ignore.

For the purposes of this article, I will continue to say “frame flex,” because that’s also what RV owners and most of the RV media call it. Frame flex has become a recognizable term even though it is technically incorrect. Some RV advocates, like the ones in a private Grand Design issues group that I’m a member of, say that this is more properly called “frame failure” due to the failure modes of these RVs.

Anyway, the consequences of frame flex escalate dramatically. If your fifth wheel trailer is experiencing frame flex, you might notice doors that you can’t open, doors that open by themselves, sagging floors, broken seals, water leaks, wall damage, slides that deploy on their own on the highway, and, in a potential worst-case scenario, a total frame metal failure. Prior to a total failure, you may also find stressed or fatigue-cracked areas on your RV’s frame.

Sadly, frame flex issues are not at all new, and are not limited to Grand Design trailers. When I conducted research for the frame flex story that I wrote last year, I identified several complaints about structural issues in fifth wheel trailers going back to at least 2010. Reported damage in those reports included frame cracks, broken frame crossmembers, wall cracks, and more. These RVs were made by brands owned by RV industry giants Forest River, Thor Industries, and Winnebago. To be fair, these are forum posts, and I have not been able to independently verify the stories or their causes. However, the fact that seemingly countless people have complained about the same problems for more than a decade is not a good sign.

Thankfully, you can identify the signs of frame flex goes too far, from my story:

Bish’s RV notes that you can check for the signs of frame flex when you hitch up your fifth wheel. If you’re hitching up or driving down the road and notice that the pin box moves somewhat independently from the rest of the trailer (shown in a gif below), that’s a problem. Remember, the pin box is connected to the trailer’s chassis. A minimal amount of flex from the pin box is expected, often 0.25″ to 0.50″. If it’s flexing more than this, it can be indicative of the signs of the so-called frame flex problem.

However, we are talking about movements in less than an inch here, so this isn’t something you’re going to easily measure with your eyeballs. If you can see that much movement easily with your eyes then you’re likely past looking for signs by that point.

Bish’s RV notes that there are other clear signs of frame flex. You might notice material separation at the riser, the vertical junction between the upper deck and the lower frame. You might also find stress cracks in the fiberglass outer walls of your unit, especially in high-stress areas such as next to a slide or near the pin box. Once your structure problem advances, you’ll likely begin to notice such issues as bowing walls, popped seals, trim falling off, and water leaks. In extreme cases, you might have issues closing or opening doors or experience the un-commanded opening of a slide while going down a highway.

Structural Complaints For Years

While frame flex has been suspected across brands, Grand Design’s fifth wheel units in particular have come under scrutiny from owners, from RV media, and from the U.S. government. Just punch “RV frame flex” into your favorite search engine, and you will fall down a rabbit hole.

A common denominator in frame flex reports is that the affected RVs have frames built by Lippert, one of the largest suppliers to the RV industry. Lippert frames are used across RV brands, and not just at Grand Design. While an RV manufacturer like Grand Design and Forest River may construct the body of your RV and fill it with the goodies you want, these manufacturers rely heavily on suppliers like Lippert. If you own an RV, it’s extremely likely that your tongue jack, frame, and other major components were made by Lippert.

That has made the whole frame flex deal an even larger headache. Grand Design might have provided the specs to Lippert, but Lippert actually built the frame. Who do you point the finger at when your frame doesn’t work like it should? Remember this, because I’ll get back to it.

Last year, Lippert’s lead engineer and VP of OE Engineering, Tim Schultz, explained to YouTube channel Big Truck Big RV (above) about how Lippert’s frames work. Here’s what I wrote:

Early in the interviews, Tim tells J.D. that Lippert designs frames in two main ways. In some instances, a manufacturer will demand that Lippert designs a frame to their exact specifications. In some other instances, a manufacturer will hand Lippert a floor plan and have Lippert’s own engineers create a frame for it. To give you an idea of the scale here, Lippert says it makes somewhere around 1,000 frames a day. Tim explains how the chassis and the body work together. He explains that the RV body’s superstructure is secured to the chassis through lag bolts. Take a look at the example render below:

These are installed at the RV factory after Lippert builds the frame at its own factory. These lag bolts, as well as other bolts, secure the superstructure to the frame, creating one whole structure. Tim stresses that it’s critical that both the superstructure and Lippert’s frame work in unison.

Tim notes that this structure works as one right until a part of the system takes damage. It could be from a bolt loosening, an undetected water leak, or an impact that, to the RV’s owner, might have seemed to be minor. Or, it could even be from user error such as overloading or unapproved aftermarket pin box modifications. Unfortunately, every flex situation is different, so Lippert can’t point to any single cause.

In the video, Tim said that some RV manufacturers make changes to their designs without consulting Lippert on how that may impact structural integrity. Either way, Tim said, once the structure is compromised, there is a sort of domino effect. The walls are no longer properly supporting weight, and the load gets shifted to a high-stress area, like the joint where the upper deck area of the frame connects to the trailer’s lower frame.

The NHTSA Investigation

On October 10, NHTSA’s Office of Defects Investigation launched an inquiry into frame issues. According to NHTSA Action Number PE24029, the organization is now investigating these possible frame issues. As of publishing, the regulator has specifically targeted the 2017 through 2023 Grand Design Momentum and Grand Design Solitude models. NHTSA believes the population of these RVs includes 55,887 units. I won’t include the complaints here (click here to read my previous story), but the short version is that NHTSA received 23 complaints. Many of them include stories of doors opening or slides deploying while the camper is being towed. One report included an injury.

What I found interesting about the NHTSA investigation paperwork is that Grand Design and Lippert don’t even agree about where the issues are even happening, from NHTSA:

The Office of Defects Investigation (ODI) has received twenty-three complaints alleging excessive frame flex on model year 2017-2023 Grand Design fifth wheel recreational trailers, models Momentum and Solitude. Twenty-two of the complaints allege that excessive frame flex resulted in a cargo or entry door opening while in transit, some with objects lost on roadways, while six complaints also state that slideouts extended out partially.

ODI has been in contact with both Grand Design and Lippert, the frame manufacturer. Grand Design believes that some frame flex, generally considered to be vertical movement in the upper deck area of the fifth wheel, is normal. However, Grand Design has developed a technical service bulletin (TSB), to evaluate concerns of excessive frame flex, defined as vertical movement greater than 3/8 inch. Per Grand Design, the frame ex is only occurring in the upper deck area of the fifth wheel and is resulting in cosmetic defects such as moving sidewalls, damage to cabinets, binding doors, etc.

However, Lippert believes that the effects of frame flex may also extend back to the front axle of the trailer. While Lippert provides frames for multiple trailer manufacturers, the majority of complaints are for these Grand Design products.

Cargo and entry doors that open and slideouts that extend while in transit increase the risk of injury or a crash. ODI is opening this Preliminary Evaluation (PE) to evaluate the severity of the potential problem and to determine whether an unreasonable risk to motor vehicle safety exists. To review the ODI reports cited in the Opening Resume ODI Report Identification Number document, go to NHTSA.gov.

As of publishing, there has not been a ton of progress in the investigation. Click here to go to the NHTSA site, where you can enter the investigation ID “PE24029” and see the current docket. The last action on the investigation was in February 2025, and the investigation appears to still be in its fact-finding period.

The Lawsuit

In response to the whirlwind of a scandal, Grand Design announced a five-year frame warranty, and then applied it retroactively to models going back to 2020. Considering that the NHTSA investigation covers models going back to 2017, this isn’t a full fix. Not all owners were satisfied, either. In April 2025, law firm Weitz & Luxenberg filed a class-action lawsuit against Grand Design, alleging:

Winnebago and Grand Design knowingly sold defective RVs and prioritized profits over safety.

Instead of fixing the underlying frame failure issue, they covered it up using nondisclosure agreements (NDAs), misleading marketing, and censoring online reviews and information.

Frame flex leads to serious structural damage, including walls separating, welds cracking, and even slide-outs opening while in motion.

The National Highway Traffic Safety Administration is investigating Grand Design RVs after receiving numerous consumer complaints.

The law firm then doubles down, saying:

One of the worst things Grand Design did was to cover up the frame defect in its RVs. They knew because they were making larger and heavier designs of their living quarters. However, Grand Design didn’t modify the frame. The underlying frame wasn’t built to accommodate these newer models.

The company aggressively marketed these heavier RV models. The company made false statements and misled customers.

The company promoted their RV models as full-time living quarters. The company:

Knew about the defects but refused to recall the affected RVs.

Silenced customers by forcing them to sign NDAs in exchange for repairs.

Deleted negative reviews and complaints online to keep new buyers unaware.

In addition, Winnebago’s CEO publicly dismissed complaints as “misinformation” even though more and more purchasers were using their Grand Design RV warranty to make claims. All of this was taking place along with an ongoing, active federal investigation.

In the past months, I was in contact with an RV advocate named Pete, who has shown me some of the non-disclosure agreements (NDAs) Grand Design owners have allegedly signed. We also had an hour-long conversation about what Grand Design owners have been going through. Sadly, from what I have seen in the NDAs, the law firm’s claim that the NDAs exchanged non-disclosures for buybacks or repairs does appear to be accurate.

Due to the sensitive nature of these NDAs, I cannot share one. However, here is a YouTube video of an attorney reviewing one of the NDAs that a Grand Design owner signed (skip to 41:24 if the video doesn’t automatically go there):

The class action lawsuit covers Reflection, Influence, Solitude, and Momentum models. This is because while NHTSA is focusing its investigation on Momentum and Solitude models, the Reflection and Influence owners have also complained about experiencing the same structural issues. In addition to money damages, Weitz & Luxenberg is demanding a recall and a full buyback for affected Grand Design models.

The class action also calls Grand Design’s new warranty “close to worthless,” stating, from Weitz & Luxenberg:

“Customers attempting to exercise the Warranty have faced a series of practical challenges, citing red-tape restrictions from the company that make it difficult to obtain the repairs within a reasonable time. Because consumers often must take their RV to Grand Design’s facility in Indiana to address frame failure, consumers who are unable to haul their towable to that destination are foreclosed from exercising their Warranty rights.”

Grand Design Announces A New Frame

This month, Grand Design announced its next-generation frame, the Omega. This frame, which is still made by Lippert, promises greater strength than the outgoing frame.

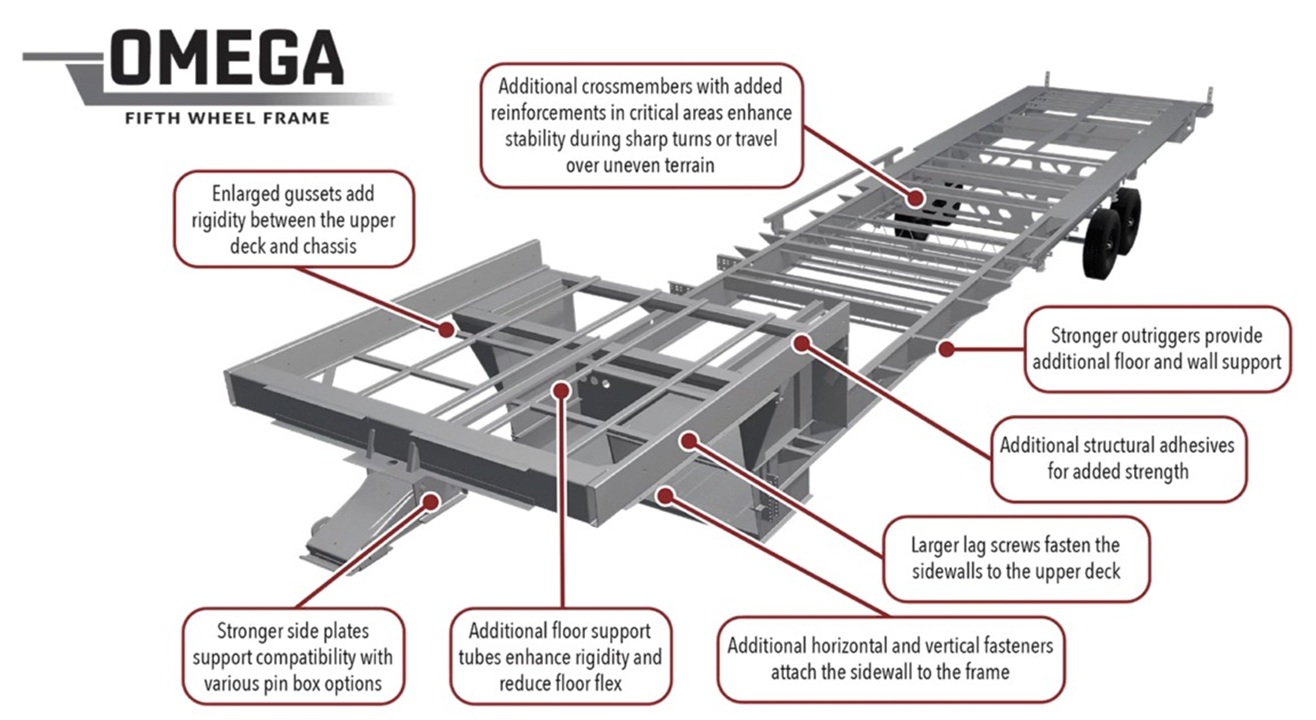

Here’s what Grand Design says are the major upgrades to the new frame, aside from what you can see in the promotional image:

A stronger, sturdier ride: The frame is manufactured with thicker steel, more fasteners, larger lag screws, and added adhesives, exceeding industry standards to give you extra strength and peace of mind.

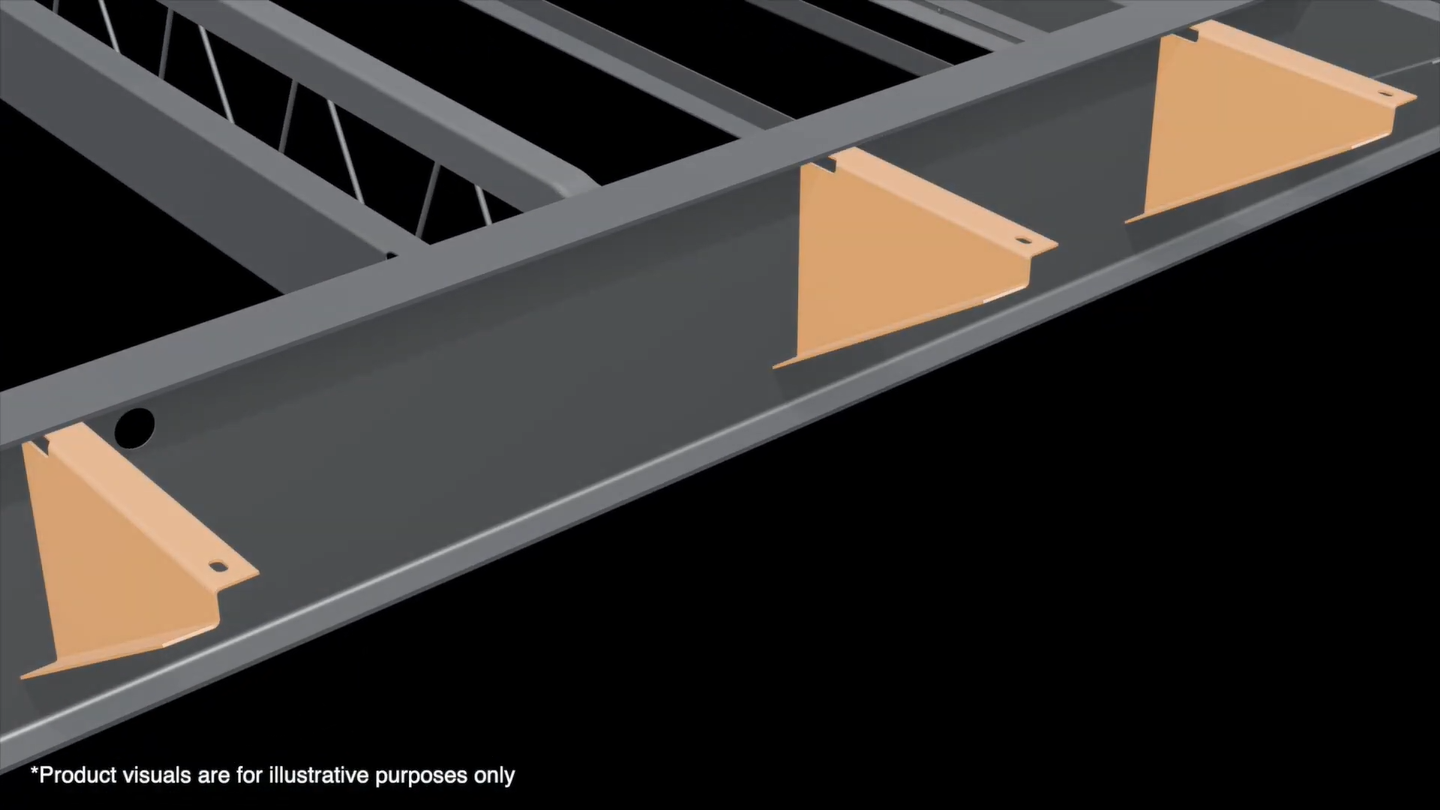

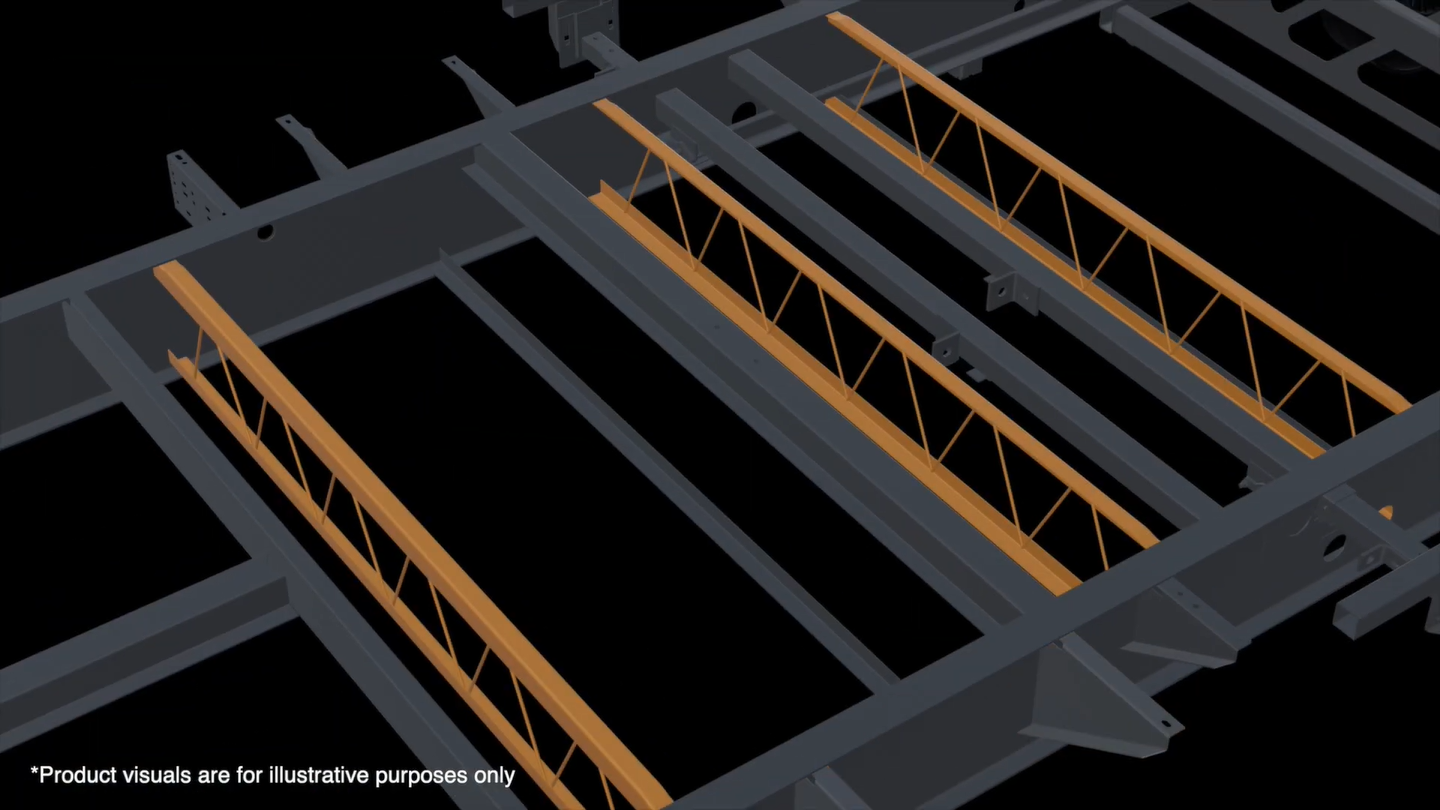

Better support where it counts: Working with Lippert Components and a trusted third-party automotive engineering company, key stress points throughout the frame were identified and parts to provide even more structural integrity were added. This includes stronger outriggers for added floor support, larger gussets for extra rigidity between the upper deck and chassis, and additional crossmembers in critical areas to reinforce the chassis, and so your fifth-wheel maintains stability—even on sharp turns or rough terrain.

Increased reliability for heavy-duty hauling: With stronger side plates that support compatibility with various pin box options, the upgraded frame design offers more options depending on your preferences.

Larger gussets and lag screws.

Additional crossmembers, floor support tubes, horizontal and vertical fasteners, and structural adhesive.

Stronger side plates and rivets.

The Omega’s design is targeted at rectifying the problems that caused frame woes in the past. Grand Design claims that this frame has been extensively tested for durability. However, I must note that there haven’t been any third-party tests done yet, and while Grand Design is confident in its new frame’s longevity, time will ultimately find the truth.

The bigger problem, at least in the eyes of many Grand Design owners, is that, as of publishing, Grand Design is marketing the new frame for new RVs. It does nothing for their current nightmare. As of right now, there are few options. They could try to get the RV fixed or bought back. However, as we established earlier, the warranty doesn’t even cover models older than 2020, and owners with theoretically covered units don’t believe that it’s easy to use the warranty. Of course, then there’s the issue with the NDAs and Grand Design owners feeling like they’re being silenced.

Grand Design Technical Service Bulletin 24-001 for Momentum and Solitude fifth wheels tries to help. RV repair technicians are to check for the signs of frame flex, including taking measurements of the deflection of the pin box. If the signs of flex are present, technicians are to install replacement lag bolts, which are larger and more numerous than originally installed at the Grand Design factory.

However, owners believe that Grand Design has not gone far enough in pretty much every step of this saga, and so, now there’s a whole class action lawsuit about it. The NHTSA investigation is also still ongoing.

I have reached out to Grand Design, Winnebago, and Lippert. I held this story for a little bit for a response. I asked about the NDAs, if the Omega could one day be used on older models, and what Grand Design is doing for existing owners to finally put this issue to bed.

I will update this story when I hear back. Until then, here’s Grand Design’s public-facing statement:

Since our beginning in 2012, we have had the mission to build a better RV and a better RV company. Everything we do and every product we build revolves around our customers with the goal to create a superior RV experience. We back up this commitment to quality with first-class service and the industry’s most comprehensive and trusted warranties.

Simply put, we stand behind every RV we make.

In the spirit of our commitment to our customers, we would like to provide information around frame flex. Frame flex is a normal movement of the chassis in specific areas to absorb shock and stress. Our data indicates that a small number of larger Solitude and Momentum fifth wheels may have experienced excessive frame flex. If you think you are experiencing something irregular with your frame, please see the FAQ below, and reach out to our customer service department at customerservice@granddesignrv.com or (574) 825-9679.

If you’re like me and you’re an avid RVer, it always pays to have an RV purchase inspected by a professional. That applies to brand-new RVs, too. Flaws and defects can cost you a ton of money very quickly, and potentially severe ones like frame failure can even leave you with a paperweight. If you cannot confirm an RV’s condition, don’t be afraid to walk away. Buying used from a brand known for quality is also a good option.

As always, I want to note that I don’t write stories like this to beat up the RV industry. I’ve been a lifelong RV camper and will probably prefer a cool trailer over a hotel until I pass on this love to someone else. But my love for RVs is also why I can be so disappointed in the industry. I don’t hate the RV brands; I just want an RV buyer to be able to walk into a dealership with confidence. These companies are building vehicles for building memories, so let’s make sure those memories are good, not ones of anger and hopelessness.

If you’re an RV engineer or RV technician and you’re familiar with this frame flex issue, I want to talk. Message me at mercedes@theautopian.com.

Update: Winnebago responded to my questions as follows:

1. It has come to our attention that some Grand Design owners have had to sign an NDA before a buyback for frame flex. Can Winnebago or Grand Design elaborate on this practice?

It is standard practice to include a confidentiality clause in settlement agreements. This is not unique to this situation.

2. What is currently being done for current owners who are experiencing frame issues?

If someone is having a frame issue we will be happy to assist. We continue to stand behind our products.

We also offer an industry leading 5 year frame warranty that is retroactive and transferable to subsequent owners, offering added confidence for both current owners and secondhand buyers. Under this warranty, any owner of a Grand Design RV model year 2020 or later experiencing frame concerns can receive a complimentary inspection and repair if it’s needed.

3. Are there any future plans to retrofit the Omega to older models?

We offer an industry leading 5 year frame warranty that is retroactive and transferable to subsequent owners, offering added confidence for both current owners and secondhand buyers. Anyone experiencing frame concerns can receive a complimentary inspection and repair if it’s needed.

Top graphic image: Grand Design

One factor I don’t see mentioned is loading/payload. There’s a good chance a lot of these trailers with frame damage were over their payload rating while being towed. Not because the owner did anything particularly crazy like bring their lead brick collection along, but because they’re barely below the limit as-sold even before you actually pack anything.

Grand Design and Lippert definitely aren’t the only ones with the problem – Lance actually had frame cracking issues for a while when they used BAL, and they actually ended up switching *to* Lippert.

You just hit the nail on the head. People don’t realize how quickly the weight of the things you bring into the RV add up. I can see this as being more of an issue with folks that live in their RV’s full time, as many owners of the huge units do. All of those dishes, canned goods, cleaning supplies, bottles of water, clothes, tools, etc, add more weight than folks realize.

It’s so variable, too. I’ve seen smaller trailers with 2500lbs of payload, and bigger ones that have more like 500lbs that drops to near zero once you add batteries, propane, and a full tank of water. I definitely ended up narrowing my search some by eliminating those, even when it was only for weekend trips.

I assume you mean 2nd most expensive expense if you don’t include plastic surgery?

Thanks for your continued (and very in-depth) coverage! This is an issue that doesn’t just impact RV owners, it has the potential to affect other people sharing the road with these.

And the industry’s treatment of you is very unprofessional and cringe-worthy, IMO.

Thank you for continuing to cover this kind of thing, even though it probably cost you an invite to the big industry events. Hopefully this reporting will force them to improve their standards and then you won’t have to write so much negative press about them.

In the cases where the manufacturer gives the specs to the frame builder I wonder if there’s anyone in the chain of command, like a structural engineer, that actually looks at the frame specs and says whether or not it’s a good idea to actually make it. I would assume there is when a frame is more mass produced but who knows.

Exceeding industry standards in the RV industry doesn’t seem like it would be hard to do. I’m surprised there are actually standards.

From reading these articles from Mercedes I’ve come to the conclusion that Airstream is the only brand worth buying.

I think the basic standard is ‘not currently on fire or full of water’ anything in between is fine

I’d definitely add basically all the molded fiberglass models (like Bigfoot, Escape, Oliver, and Casita) to that list. They’re not as stylish as Airstream and don’t have as many bells and whistles, but the base build quality’s probably better. Oliver in particular is probably the best-built option out there, even though I take some issues with their claims around their insulation strategy.

People buy with their eyes. If you want to sell a $100k travel trailer, the buyers want to see marble and granite and solid countertops and etc, and these things cost money. So they’re going to cut costs in the places that buyers can’t see.

Around 10 years ago, I built my own travel trailer. I got quite a few parts from salvage RV in junkyards. If you ever see a motorhome or travel trailer that’s been gutted, you’d never buy one.

Is this actually surprising, to anyone? The poor overall quality of the products coming from the RV industry as a whole has already been covered here (in a brilliantly interesting group of articles by Mercedes).

Triangulation is key to strength in a frame that is mostly right angles. The frames I see above are lacking basically any of that. Ever take a coat hanger and bend it repeatedly until it breaks? That’s what un-gusseted steel frames are going to do. Claiming that enough frame flex that if left unchecked, causes frame failure is ‘normal’ is bullshit.

I’ve been to RV shows and the over-arching theme every time I leave is the abhorrent quality standards that these manufacturers adhere to. I have honestly seen kit cars put together better than some of these trailers.

I had a mid 90’s Coleman mini-pop-up trailer for a while and that thing was about as rigid as a plastic butterknife.

Another thing that stands out is that the ‘quality’ that the manufacturers showcase is barely even skin-deep. Everything that ‘wows’ you about an RV is quite literally what you see. Pull back that stainless mini fridge and the wall squareness and outlet cutouts look like something you’d find in a tree fort built by a handful of pre-teens.

“Triangulation is key to strength in a frame that is mostly right angles”

I was thinking the same thing. And it’s something so basic and known for such a long time in Automotive as well in other areas like building construction.

It makes me question the competence of the people doing the design work at these RV manufacturers.

On top of that their “redesigned new frame” basically looks like the same one except they point out things like “better glue” and “longer screws” rather than “things you learned in high school playing one of the bridge building games”

So is this a unique problem to fifth wheel designs? Or the lawyers just haven’t gotten around to all the other camper types yet?

Frame fatigue and failure could be a problem on any conventional-frame trailer. But fifth wheel trailers are special because they’re typically the largest and heaviest of RV trailers, plus they have the added complexity of the raised upper deck section where the pin box attaches. It takes the structural engineering problem up to a new level.

This is straight up laziness and cost cutting on the frame designers part. For reference, I’m a mechanical engineer. Just look at the automotive industry and their press releases on BOF trucks and SUVs to see that this is utter BS. Torsional stiffness is what is generally desired, all materials have a modulus of elasticity, infinite stiffness ie zero deformation is impossible. There are two very important figures to understand for structural loadings, Stress Vs Strain curves, and Fatigue loadings/limits. The stress vs strain curve is a way to correlate loads (ie stress, psi, MPa, etc) to stress (flex, deformation), which is to say if the frame at X point undergoes Y pounds of force it will deform Z inches.

The importance of the fatigue loadings comes in to play with the failures. Every metal has a point where if loaded (and therefore strained, aka deformed) a certain number of times, it will fail. Steel has an infinite fatigue limit, which if stressed a small amount, it can be done infinite times. Steel also has obvious finite limits, where if is is strained a greater amount, after a certain, often small number of cycles, it WILL fail. That appears to be what is happening here.

These RV frames appear to be very simple in their construction, lots and lots of flat plates cut to squared shape and welded together. It’s super easy to make a large number of variants out of a small range of stock materials. The downside to this is you end up with a very large number of flat plates welded flush or at 90 degree angles. These abrupt points of contact result in localized stress concentrations, causing more deformation at the welds, which results in cracks and failures. Take a look at any David Tracy engineering deep dive on modern BOF frames, take note how the frames are not straight boxed sections, but shockingly interesting stamped pieces that have subtle curvature, ribs scattered about for stiffness, and few if any hard angles. These frames undergo millions of dollars of research to make them as rigid as possible with the fewest number of stress concentrations that lead to failures while using the least amount of steel possible.

Now take a look at these RV frames. They are boxed sections, and the solution has largely been to add more boxed sections. They are likely more rigid in a couple of very basic loading cases, ie basic vertical and lateral loads, but are still going to be absolute shit in torsion because the weld points will be stressed heavily. I suspect they will do much better overall due to the most common modes of flexure being reduced in magnitude by a lot, but ultimately they are still fairly simple things, and with the poor rustproofing of the industry, are probably still going to be failing in 10-15 years time.

Very interesting, thank you for posting this.

Yeah I am not an engineer, but even I can look at these illustrations and see a complete lack of triangulation and see the problems here. I also don’t buy the notion that an RV frame should flex, all that’s going to do is make the entire house built on top of it flex, eventually damaging or breaking loose everything attached to it. Aren’t these the problems the RV industry continues to face?

All this just reinforces why I’m happy to keep paying for hotel rooms.

Yep you’re pretty much spot on. SOME deformation is inevitable, but minimizing it is a great goal, but making it deform at prescribed locations and amounts is the key to good engineering for structures. Think of these sort of like a box spring for a mattress, sure you can’t get them to fold like a book or a taco because that’s where the most structure is, but you sure as hell can twist them by torquing the ends in opposite directions. What happens when you do that? they snap at the corners.

Also why you see cracks in between two structural beams in the pictures is because those beams deform and flex at different rates and amounts, causing the plates bolted/welded to them at a 1-3″ spacing guaranteed to fail. Those flat plates of steel are not meant to be put in shear like that, of course they fail. At a minimum they flex a bit, crack the power or gel coat rust proofing, start to rust at 3 years, and then get weak and snap on a medium sized pothole.

It’s just bad design, because making them more structurally sound requires more material, which makes them heavier and harder to sell. the incentive structures for these manufacturers with short warranties is entirely geared towards shifting units and not making them last. Needless to say, your beliefs in paying for hotels is far more reinforced than these RV frames.

My assumption on triangulation is they are assuming the sheeting from the walls is going to provide additional strength and rigidity. Similar to building a house, where temporary diagonal supports are necessary until the exterior sheeting is put on, at which point the sheeting takes over the load. Very minimal triangulation is used in the vertical walls in a house typically. Of course, a house also typically moves very little over the course of it’s life…

This image really makes it clear:

https://images-stag.jazelc.com/uploads/theautopian-m2en/gd-frame.jpg

It really is built like a house, with no triangulation to take the load, but if they used sufficiently sized and adhered wall material it could take a fair bit of the “triangulation” load.

The more I read about various travel trailers, the more I’m confident in my decision to just buy a fiberglass unit when it comes time to invest in a long-term unit. Like a Bigfoot or an Escape.

I am so glad I get to read thing like this here. I like to be informed. I also like my Gazelle T4 tent with a cot, table, and chair. The RV industry makes me happy sleeping in a tent.

Two things I find insane in this story:

I also find it insane that even if Grand Design approves your warranty claim, the only way to get it fixed is to get it to their plant in Indiana, but towing it will likely result in further damage.

While I was reading this, I was assuming lag screws was just a misnomer for lag bolts. If it’s really lag screws, then wow.

We really are trying to kill off America’s senior citizens, aren’t we?

I thought that too but looking the photos of the “Upper Deck” it is rectangular steel tube with no holes. I bet they are dropping the body panels on, drilling a pilot hole, then banging in a lag screw.

That way there is no need to keep a real tight tolerance to make sure the holes on the body and frame line up.

Pilot hole, schmilot hole. That takes two separate tools and operations. Self tapping screws for the win!

Some quick searching shows “diy” fixes using carriage bolts through the aluminum body structure members. Seems like the walls of RVs are often just a laminate of aluminum/wood/insulation layers with some extrusion members here and there. Lag screws into aluminum just seems like a bad idea for something so important. They loosen up and wallow out the hole in the aluminum, de-coupling the body stiffness from the frame, now the frame is experiencing more load on its own without the body to help stiffen it.

When I worked as a design engineer for a major RV manufacturer almost 10 years ago, the bottom member of the aluminum sidewall frame was stuffed with 1×1 wood filler strips to give the lag screws something more to bite into than just the thin-wall square tube.

The more stories like this I read, the happier I am to be out of the RV industry.

This is yet another reason I’m building my own RV from an ambulance body. It is all welded aluminum.

Hi! Phil Swift here! Does your RV suffer from frame FLEX?

If it does, I have the answer for you! Introducing new FLEX SEAL RV!

I PUT A HOLE IN THIS FRAME

Yee-doggy! Just cut, peel, stick and seal!