The wind power industry has long faced a bit of a frustrating problem. Gigantic blades are more efficient, but they’re also hard to ship. A single blade can be more than a few hundred feet long, and they’re a logistical nightmare to haul down roads and load onto barges to get to their destination turbines. Startup company Radia thinks it has the answer. For the past decade, it has been developing an aircraft of mammoth proportions that would dwarf even the iconic Antonov An-225 Mriya. The WindRunner is huge, goofy, and I hope it becomes a reality.

The world of super-large aircraft has been a much sadder one since 2022. Early that year, Russia’s invasion of Ukraine resulted in the destruction of the sole operational Antonov An-225 in the world. The distinctive Antonov and its sextet of engines had wowed the public for decades and carried the biggest loads that no other plane could haul. Antonov has vowed to rebuild the world’s largest plane, but when it does, the An-225 may no longer hold the crown.

Since then, other planes have been wrangling for the coveted position of “biggest flying object on the planet.” The dual fuselage Scaled Composites 351 Stratolaunch is shorter than a Boeing 747-800 at 238 feet, but its 385-foot wings make it the largest plane in the world by wingspan. Of course, there are also legends like the Airbus A380, the world’s largest passenger aircraft, and the Boeing 747, the Queen of big passenger jets until the A380 arrived at the terminal.

Here’s the Antonov if you’ve forgotten what that beauty looks like:

If the folks at Radia succeed in the construction of the WindRunner, they’ll take the record of the world’s largest aircraft. This beast would be about 100 feet longer than a Boeing 747-800 and still 81 feet longer than the late Antonov An-225. Supposedly, the absolute unit of a plane will also have 12 times the cargo volume of a 747 and the ability to operate at unpaved airstrips.

So, is this thing the real deal? The New York Times recently covered the plane, and that’s how it got my attention. Seemingly, everyone’s been talking about the WindRunner, regardless of whether their publication has a transportation angle or not.

Aviation For Wind Energy

Radia is the brainchild of aerospace engineer and serial entrepreneur Mark Lundstrom. He founded Radia in Colorado in 2016 to explore the intersection of aerospace and energy to find a profitable way to reduce carbon emissions. Here’s the story of Radia from Lundstrom:

Shortly after Radia was founded, a press release came out from two wind turbine manufacturers that compete for every deal globally. They were frustrated that the energy industry knows how to make offshore-sized turbines and deploy them in places like the North Sea but can’t take that knowledge to deploy them onshore where the market is an order of magnitude larger. Their release asked if an aerospace company, engineer, or entrepreneur could help them figure out how to airlift an object that weighs 45 tons and is over 100 meters in length, and land it on a piece of dirt in the middle of a wind farm. I showed up within a week and started working with them. Our massive cargo aircraft WindRunner is our solution to the problem as it can deliver offshore-sized blades onshore and enable what we call GigaWind.

Lundstrom is joined by a large team of aircraft engineers and other engineers from the energy sector.

Radia has a pretty huge marketing push behind its business. The United States Department of Energy projects that by 2050, wind power will have a capacity of 404.25 GW across 48 states. This is compared to a capacity of 113.43 GW in 36 states in 2020. Wind turbine production is only expected to grow.

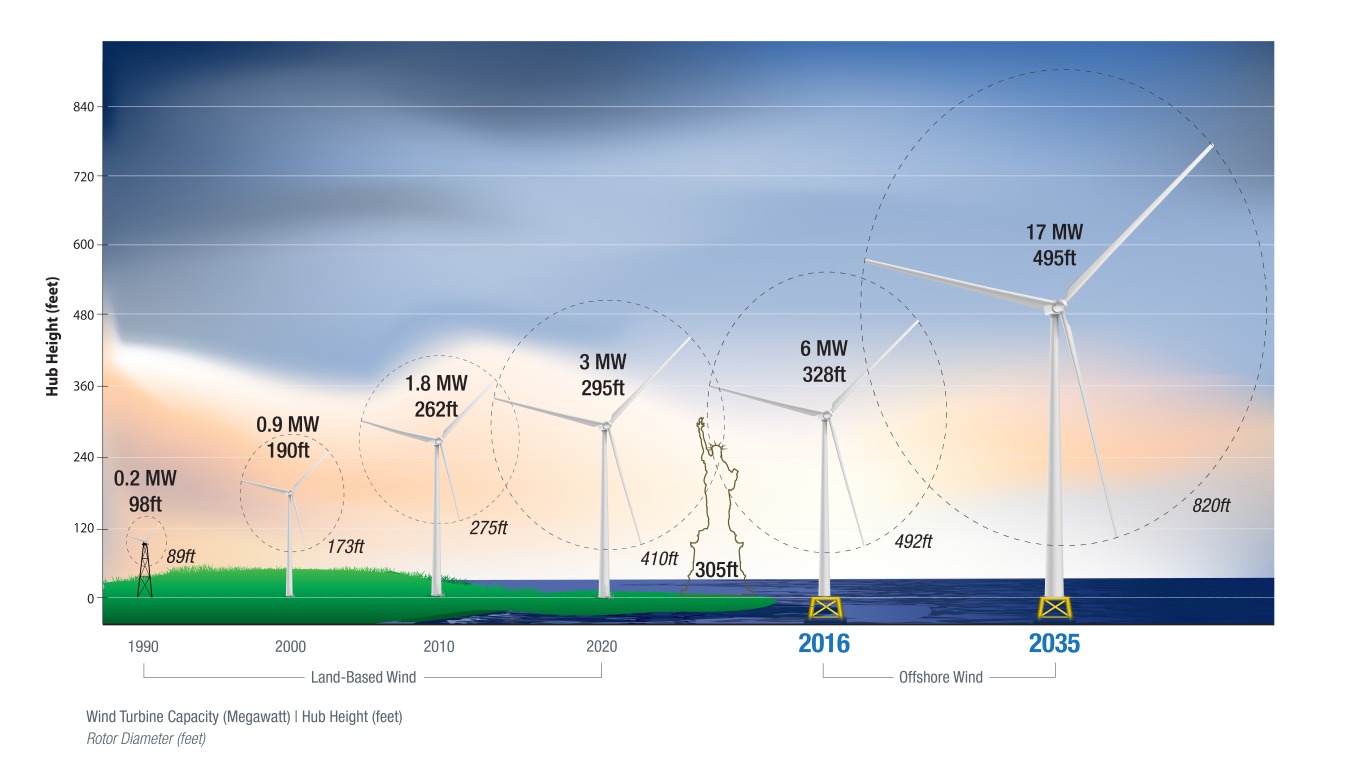

Generally speaking, larger wind turbines with longer blades are more efficient turbines. In short, this is because longer blades have larger swept areas and can capture more wind. So companies are constructing absolute monsters of turbines with blades over 200 feet long. As of 2024, the world’s largest onshore turbine blade, for the SANY SY1310A, is 430 feet long.

Radia claims that infrastructure is limiting the size of most other turbine blades for onshore applications. The company claims that most road infrastructure struggles with blades stretching 230 feet long. Further, the company says, super large blades have quite a huge diameter, which means that shipping a blade by road would require some clever navigation to avoid obstacles like overpasses. This is why some of the biggest wind turbines that you’ll find will be offshore.

As NewScientist reports, the general idea is that the larger you can make a turbine, the fewer of them you’ll need to reach a given capacity. However, as the publication reports, there are tradeoffs. Consider that, when it’s running, the SANY SY1310A’s blades cover an area of over 800 feet. Of course, then you have to figure out what to do with the structure after its service life ends. All of that aside, NewScientist notes, you still have to figure out how the heck you’re getting those giant blades to a wind farm in the first place.

So, to repeat myself here, Radia’s logic is that land transportation limits the size of onshore turbines, so what if the company took the hassle out of shipping turbine blades? Instead of navigating a blade through tight streets, you just load it onto a plane and fly it directly to a farm. Radia’s plane would permit the shipping of larger blades for onshore developments and thus pave the way for the creation of the biggest turbines and wind farms. This concept is what Radia calls GigaWind.

To be clear, Radia will not build turbines or even blades. The whole idea is that the plane will allow other companies to install the biggest wind farms. The GigaWind thing, which is included in the marketing of the WindRunner, is somewhat confusing since it’s not a product or service that will be offered by Radia.

The WindRunner

Radia’s project is the WindRunner plane. In 2024, here’s what Radia said about the aircraft:

Radia’s WindRunner aircraft, capable of landing on short, semi-prepared runways including those made of packed dirt, will be purpose-built to deliver these large blades and other components directly to onshore wind farm sites – greatly expanding the number of locations available for large turbines and enabling onshore wind to scale. Opportunities include reducing transmission costs and increasing reliability by building wind energy sites closer to demand, creating hybrid wind/solar sites to produce clean power around the clock and throughout the year, and generating the large amounts of clean electricity needed to produce green hydrogen.

The innovative design of WindRunner only requires a 6,000-foot semi-prepared dirt or gravel landing strip at a wind farm to deliver its payload. This also enables it to land at almost any commercial airport around the world. WindRunner will be 356 feet long and its volume is 12 times that of a 747, and an overall length of 356 feet to carry the largest payloads ever moved by air.

Radia plans to produce a fleet of certified aircraft at Radia’s U.S. assembly site. WindRunner is more than halfway through the time required to design, build and certify an aircraft.

Radia says that the WindRunner will have a range of 1,200 miles and cruise at 41,000 feet at Mach 0.6. Further, Radia says that the fuselage, which is designed like a Boeing 747 where the flight deck sits in a pod above the main deck, will have 272,000 cubic feet of cargo volume and a payload capacity of 160,000 pounds. The cargo inside could be as long as 344 long, 24 feet tall, and 24 feet wide. Those wings look sort of stubby because they sort of are compared to the fuselage length. The fuselage is 356 feet, and the wingspan is 261 feet.

The WindRunner is projected to be a big bird for sure, but what about that claim of having 12 times the cargo volume of a Boeing 747? Well, cargo airline Cargolux says that its 747-800F aircraft, the final edition of the 747 Freighter, has a main deck with 24,462 cubic feet of space. Times that by 12 and you get 293,544 cubic feet, or more space than the 272,000 cubic feet claimed by Radia.

Cargolux also runs the older and smaller 747-400F, which has a main hold carrying 21,645 cubic feet of cargo. Times that by 12 and you get 259,740 cubic feet, or less than what Radia claims.

In case you’re curious, the Boeing 747-400 Large Cargo Freighter, also known as the Dreamlifter, has a hold carrying 65,000 cubic feet of Dreamliner parts. Cargo volume goes up significantly as you make a fuselage taller, wider, and longer.

Another massive aircraft is the Lockheed C-5 Galaxy, and the Radia would dwarf its 31,000 cubic foot capacity:

Regardless of whatever Radia used as a base unit for the 12 times claim, Radia’s claim of getting 272,000 cubic feet out of a giant 344-foot hold seems to be achievable. What’s interesting is the specification that the gigantic WindRunner will carry only 160,000 pounds. A Boeing 747-400F can carry around 249,000 pounds, and the bigger -800F hauls 295,000 pounds. The Antonov An-225 carried a whopping 550,000 pounds when it was still in one piece.

However, the low carrying capacity of the WindRunner is probably because of its specific mission to carry wind turbine blades. Still, one of Radia’s goals is to make a ton of money, so it seems like a missed opportunity that the WindRunner won’t be able to carry cargo as heavy as existing freighters can haul. The U.S. military is looking into the feasibility of using WindRunners to carry fighter jets, so maybe that whole money thing won’t be a problem.

At the same time, the projected lighter weight of the aircraft may help it with its other statistic: The takeoff roll. A fully loaded Boeing 747-800F may take 10,465 feet or so to take off. The Radia, which will be significantly longer than the 747-800, is said to be able to lift off the ground from an unpaved airstrip in only 6,000 feet. I would pay money to see something the length of this thing manage to leave terra firma in just over a mile.

Presumably, this also means that the Radia will have some sort of hot rod engines under its high wings. Unfortunately, Radia hasn’t said anything about installed power. As you’ve probably already noticed by now, Radia has also issued only renders of the aircraft. That being said, Radia said that it’s not trying to reinvent the wheel here. It’s said that the plane will be built with conventional methods and technologies. The “innovation” is just that the plane will be extraordinarily huge.

Maybe You’ll See One Someday?

Radia sees a market for a whole fleet of WindRunners. These won’t be flying regular cargo, but the expectation is that the wind turbine industry will become so huge that just one aircraft won’t do.

Radia says that it’ll officially unveil the WindRunner at the Paris Air Show next week. Then, the company hopes to have at least one of these birds in the sky by the end of the decade.

It seems like what Radia is proposing here is theoretically possible. It sounds like something this huge has no business getting off the ground, but that’s also what some people said about greats like the Airbus A380 and the Boeing 747. I’m skeptical, but maybe I’ll be proven wrong. Will Radia go into the history books as a record-breaker? It’s too early to tell, but you bet I’m going to be watching.

This raises a few questions according to the article the blades are a few hundred feet long. Now I’m not an expert but if you call up a shipping company and tell them the load is a few hundred feet long they are asking for specific measurements. I seem to recall larger loads being shipped with wheels instead of beds for bridge spans longer than this. I also see the wings being labeled at over 300 feet could they use the blades as wings or store blades in the wings? If you have the front or the rear open up like a cargo plane the length should not be necessary much longer than the blades. I also think if you get the Rubicks Cube people involved you can design a package platform that the blades provided the structure and stability of the body and easily loaded and removed.

I’m wondering at this point whther they can strap a cockpit, wings and engines to a blade and use the blade as the fuselage.

What about the Pregnant Guppy and Super Guppy?

If we could build planes during WWII that had wings that folded up, why can’t we build a windmill blade in two pieces and assemble it on site?

Because then we wouldn’t have the need to build humongous aircraft to carry them

I reckon weight and complexity has something to do with it. They would ideally want light, zero-maintenance stuff that’ll be durable.

As a former employee of a wind turbine manufacturer and wind farm developer in the US, I can tell you that wind turbine blades have tremendous bending forces put upon them, and the hub rotor design benefits from lighter blades. And the three blades on a wind turbine need to be in the same weight class for better balance of the large rotating mass. These requirements make it difficult to make a multi-piece or folding blade, but maybe someday.

Damn, to think we used to call the C-5 the “aluminum overcast.”

Finally a replacement for the An-124 and An-225 (RIP)? The European military will love it since they didn’t have access to the C-5 and depended on the Russian (well not anymore) and Ukrainian civilian Antonovs for some deployments.

Here is a totally stupid idea. Use the blades as wings. Have them hang out like that pixie stick you with marbles that was like Jenga. With multiple wings the plane could take off quicker and then remove them and fly back with the regular wings and empty plane. When do I get my nobel, or more important nobel million dollar honorarium?

Oh good, it can take-off from dirt runways. Because a road paver was the limiting factor, not the impossibility of finding 60+ acres of level ground on the side of a mountain where wind turbines are normally installed. (I guessed 6500ft x 400ft, which is still way less than the required safety area for a real runway)

And you’ll only have to cut down a couple hundred trees for the runway too, because we really need to give the NIMBYs more reasons to be upset about wind turbines.

Maybe this can be re-purposed as a place to land my flying car that will also totally happen in 10 years

There are tons of places in the state of Nevada U.S.A where this could work. It’s endless landscapes of basins and ranges almost every mountian slope has a flat dry lake bed or alluvial fan to land on nearby.

I still don’t know if it’s a good idea.

Any place without trees, solar is going to be a lot easier and infinitely more scalable.

Lots of places in Australia too

Realistically, landing on a new dirt runway *at* the windfarm isn’t going to happen. What we’d likely see is landing at a small regional airport 50-100km away which may have had a dirt extension grafted on, and then trucking the remaining distance.

This is a *big* improvement over having to truck the blade 500-1000km (or more) from the nearest seaport (which is usually going to be in a metro area)

Almost seems like it would be cheaper and easier to mount a couple blades to the roof of a 747 Cargo – A-la-Space Shuttle?

I was just thinking that the Scaled composites Roc would be perfect for this but these blades are so much longer than either that or the 747 that I suspect it would be impossible for the aircraft to pitch up during takeoff without the blades scraping the runway.

I was thinking putting the pointy ends forward and the blunt ends to the rear – one to each side of the upper fuselage- – because the blades could only go so far back before the rudder and stabilizers. Of course depending on how they’re mounted, the blade pitch would require the jet to counter steer to compensate.

I’d probably do the opposite – put some sort of a reusable dome shaped shroud on the base and have that be the front while in transit.

I wonder what the aerodynamic effects of mounting a couple gigantic airfoils to a 747 would be? The space shuttle was as aerodynamic as a brick wall in comparison.

I’m a little surprised the Airbus Beluga wasn’t mentioned here. Carries A350 wings, and the fuselage has an even crazier design.

This seems like a play to get purchased by airbus or lockheed (Boeing’s in no position to be blowing money on startups these days), otherwise I don’t see how you just build a plane this big without ever having built a plane… seems like a $50-100 billion project.

I can see a whole fleet of these aircraft getting built just in time for the wind power industry to shift to vertical windmills with new and improved sectional blades that can be transported by truck.

Ah, sounds like the makings of a good future Unholy Fails. 🙂

Has anyone considered if it would be easier to transport the equipment to make the blades on sight?

Yes, several. It’s not just the equipment but the labor as well.

There was a company called Flowind in California many years ago that designed and built Darius (“eggbeater”) wind turbines. A guy I worked with was the director of engineering. Their idea was to make blades onsite using pull-truded fiberglass. They had some success, but as I understood at the time, they ran out of money before they perfected the process.

Lets face it…This is the answer to “Too fat to fly”.

Given enough thrust you can make anything fly.

We can do this, Sancho. My dear friend, we must only try HARDER than before! The answer is obvious. Brute force. Shut the f*ck up, Rocinante, the men are speaking.

Wit and humor do not reside in slow minds.

Current helium blimps can carry up to 200 tons, so why are they not being used for such cargo runs? No runway issues at all.

Maybe that could be a solution for final mile delivery to wind farms in rough terrain. But remember, wind farms are located in windy places, not good for balloons.

Yep, and an active wind farm has the potential to burst the bubble of a helium blimp.

We’re not talking circus balloons but blimps or derigables than can fly across continents and oceans and since they can land anywhere the middle of nowhere makes it better than airplanes. Especially with airplanes you have large airports in cities trying to deliver to Barren spots miles away.unless you build an airstrip at every windmill farm. Come on people drink, yes I mean that think don’t work new ideas drink does.

Only in good weather. They don’t handle storms well and they may not be able to get to the altitudes needed to avoid them while ladden.

My comment is just for the imaginary comic effect, of course. A blimp pilot would obviously stay clear of the spinning blades.

If they can fly from Berlin to New York I think that is not an issue. The open landing spaces make it easier.

Those were filled with hydrogen which in hindsight may not have been ideal. Helium is about twice as dense so lifting capacity will be much lower than those old German benchmarks.

One of the difficulties that was explained to me by an engineer that was working on making something like that is that of weight transfer. If I understood correctly blimps are more unstable than heavier than air aircraft when transferring large weights from the vehicle to the ground and vice versa.

Not saying it would be imposible, simply that it could be more challenging to implement.

Of course lighter than air vehicles are more unstable than heavier than air vehicles. That is not the question. It is how stable/unstable are lighter than air vehicles? Even then until they are unloaded they are heavier than air that is why blimps aren’t landed and they are strapped in before unloading.

why not attach 2 blades on some kind of vehicle/fuselage and use it as wing to fly and then when it arrives at its destination you just dismantle it and assemble it on wind turbine?

As much as I would love to see a crazy-looking bird with a pair of turbine blades for wings, their design isn’t well optimized for flight.

And since all blades are designed to only go one way, you would have one wing lifting, the other diving.

Do a barrel roll, Fox!

The obvious solution is to build half of the wind turbines clockwise and the other half counterclockwise.

Have you met the guys who assemble wind turbines in the field? I have. Former oilfield roughnecks. Good men for rough and ready work, but clockwise and counterclockwise is a bit to hard on the brain. And I went to a rural high school in oilfield country. I know these folks well. Then again, I’m a trucker, so a bit of the pot calling the kettle black.

blue blades on the left ones; red blades on the right ones.

My thought exactly. It worked on corvette wheels after all.

Then how about we give power to the turbine and make it to somekind of giant propeller or helicopter because if it is a electric generator, it means that if we give it power it becomes electric motor, right?

Attach a tail rotor on the shaft? Now this might actually work!

800 foot wide helicopter!

Assemble while laying down, complete with mast, and put some power in the generator. Only need to add a tail rotor.

Conceptually simpler to attach four together and make a quadcopter.

Of course you would need a 60 some acre spot to land it. And an emergency landing would be quite the emergency.

Also I think the strength needed to make a flying rotor that size might be beyond current materials science, or at least prohibitively expensive for a windmill.

Sure it is. As the world’s biggest – and worst – helicopter.

I read that in Clarkson’s voice.

You’ve been watching too much Dune.

No, wait, you’re onto something. But not two wings. Three. The Triebflügel!

I feel like there has to be a much simpler solution than this. Maybe about 50 industrial drones that ride with a wide load truck, and when they get to a spot that’s an issue the drones just hop over and the truck meets them on the other side.

How exactly is that simpler? Sounds like something from a cartoon.

I’ll get the ACME catalog.

The largest haul trucks at open pit mines, with the largest tires: those tires have to be manufactured nearby, one at a time, because they are too large to be transported. They won’t fit on roads or trains, you tire manufacturing is literally at the mine. They don’t need to be air dropped by giant helicopters. It would simply be easier to manufacture the blades on site in a temporary factory with all materials pre-fabricated as much as possible. Building this stupid plane is not the answer. It’s not rocket surgery.

So build thousands of multimillion dollar ovens to bake the blades, instead of one? Then transport them everywhere? And housing for the specialist workers? There is a huge difference in making one tire at a time vs thousands of blades a year.

You’re exaggerating and it can be done, and done simply. And those windmills are erected one at a time. I live in Texas, I pass by large wind farms all the time and I know people to maintain and install them. “Thousands of blades”. Well, 1000 blades would be 333 windmills, how big do you think a wind farm could be with 17MW windmills? Do the math.

And by the way, these very large windmills may not be welcome on land – too tall.

Too tall? In TEXAS? Whose motto is “EVERYTHING is bigger in Texas!”

Why I’ll bet you could hide one of those very large windmills under the average Texan’s 10,000,000,000 gallon hat.

It would require an entire rethinking of construction, which is likely not possible or practical for such large scale turbines that they want to deploy in the somewhat near future, but I think that’s a valid question to ponder and I find these kinds of exercises to be fun. A massive, redeployable curing oven and the power station it would require is not practical and set up would be a huge undertaking if there’s even suitable space near these offshore sites where they would also need some kind of port to get completed blades onto barges for transport and installation on potentially rocky shores in possibly environmentally protected areas. Then there’s housing and supplying personnel, even just QA issues and possible scrappage while they get it up to snuff . . . Forget that. What’s another route? Air cure resins? I would imagine that would be too heavy and inconsistent. Let’s say they used some kind of UV cure resin. UV doesn’t penetrate very far, so it would have to be built in thin layers, but that might make it more controllable (still something of a task on hundreds of feet of blade). Bonding the layers to each other is an issue, then controlling for weight, dimension, and balance over a huge surface without a vacuum is still an issue. I think it would require a new kind of resin or something I never heard of (I’m not an expert on composites, so there very well could be something out there that could help in this theoretical scenario). All and all, this is a massive undertaking seemingly requiring complete rethink and development of new materials and techniques beyond the still-extant logistical hurdles. I think pursuing a completely different turbine design would be more cost effective and people have been doing that all along, but since they’re sticking with this design, I imagine it has the better stack of compromises of anything else so far.

EDIT: I just realized they’re talking onshore . . WTF, IDK who’d want these beasts anywhere near them, but that only relieves some of the logistical hurdles with the transport and environment.

Wind turbine blades are not cured in giant “ovens”. They’re built up in layers of fiberglass and/or carbon fiber inside two halves of a giant mold, then joined together. Again – no oven. Those molds are certainly made, or could be made, in pieces. It is true that carbon fiber airplane wings are cured inside giant auto-claves. I know this because I’ve seen them at Boeing. But not windmill blades, which I know first hand are made mostly of fiberglass – and fiberglass is not cured in ovens. It’s a two-part epoxy like resin that cures all by itself. This notion that you need some super plane to make this possible, a plane that has imaginary specs but that hasn’t been designed and does not exist, is just absurd. Land the largest plane ever built on a 6000 foot dirt runway to deliver turbine blades…. come on. And those blades fatigue and are replaced regularly. I’ve come across more than one windmill blade graveyard. They saw them in two or three pieces and stack them up. Hundreds of them sitting in fields in west Texas. Better maintain the runway because you’re going to need replacement blades.

Fly over the texas panhandle at night. Then tell me windmill farms are small. As for size, it’s all background at a certain point.

I don’t think either idea sounds especially practical.

Sorry, but thats not true. They get transported to the mine by semi with an oversized load permit. No possible way they could be manufactured onsite.

I figured this was made just to haul around all of Mercedes cars and motorcycles, right?

Huh. Low cargo weight rating to keep the wing loading low despite the hilariously huge cabin. Low cruise speed to reduce the skin friction drag component from the cabin size. I assume the cabin is unpressurized given the flat walls, so the cockpit is most likely its own mini-pressure vessel. Squared off wings to keep wingspan under control and allow operation at regular airports.

It definitely seems less stupid than I thought at first glance. It’ll still need a lot of thrust to get anywhere, but I’m sure GE will happily sell them 4x GE90’s or similar- 115K lbs of thrust x 4 will definitely move a lot of airplane.

This is a big deal. Driving a blade through towns, getting a shitload of permits, escort vehicles, and admin to coordinate it all costs huge money. Add even more if they need the electric company to move wires out of the way.

Putting more farms in the interior without all the disruption, it’s a win-win.

Dumb question:

Why not put the manufacturing site of the blades on the coast and transport by boat/barge for offshore wind farms?

Seems easier than designing a bespoke cargo airliner.

Edit: article said onshore wind farms. Never mind.

Because electricity customers generally live on land, not offshore.

Yeah, I failed the reading comprehension portion of the test today.

Tell that to the folks in Copenhagen – where there’s a massive offshore windfarm near the port serving the city.

That whole country is a postage stamp and is basically ALL coast. apples and oranges.

Well generally electricity customers live near the shore.

Fifty percent of the U.S. population lives within 50 miles of the coast and about 80% within 200 miles

If you count the Great Lakes the percentage is even greater.

Globally 40% of the world’s population lives within 100 kilometers of the coast.

Yes, but infrastructure in the water is a whole lot more expensive, and coasts are linear, which limits space. Are you going to build a line of them along the beach, or a field of them out at depth?

$$$$$$$$$$$$ compared to a cornfield in Iowa.

The power grid is a limiting factor, so putting the power source near the power customers makes a lot of sense. Underwater cables generally don’t catch fire which is a huge deal, and there are some promising underwater power storage systems that are promising.

I don’t know the relative costs, but if it were more profitable to put the generating capacity in Iowa and not offshore I am sure that would happen.

“Iowa is a national leader in wind energy, ranking second in the nation for installed wind capacity. In 2023, wind power generated 59% of Iowa’s electricity net generation, the highest share of any state.”

-the google

Oh I don’t doubt that at all, and I’m glad to hear it. I was just pointing out that putting the power source near the consumer makes a lot of sense.

Sometimes you have a lot of cheap power far away from the customer like Quebec Hydro. Or there are historical anomalies like the railroad system in the US where owning several layers of energy production infrastructure and getting a guaranteed return on investment and a markup for each layer distorts the market in favor of big grids. Of course big grid redundancy leads to reliability, but in the name of efficiency, companies get rid of the redundancy, and make more money off of exploiting the unreliability of the system. See Texas when it gets cold and the gas pipelines stop working, the electricity stops because no gas, and it takes quite a long time to get everything running again. The whole debacle was stunning in its stupidity, but that’s ok because prices went through the the roof.

Anyway, good for Iowa!

Two questions: How many blades will normally be carried at a time, it it only one? How many years of energy production will it take to make up for the amount of jet fuel it takes to deliver the blades? What is the cost/energy comparison to the existing delivery methods, like trucks, trains, ships?

I actually saw a trainload of wind turbines pass through downtown Oakland once, the blades were about 2.5 cars long a bit over 200 feet each, supported by the two middle cars, with the root and tip free floating partway over the neighboring cars. It was clear that was about the limit of what could go by rail, on the west coast at that.

I’m sure there’s a very good reason why turbine blades can’t be constructed in sections and assembled on-site. There must be, or none of these conversations would be happening.

First thing I wondered too. At some point the logistics of transporting these blades would seem to outweigh whatever tradeoffs come with sectional assembly, at least to my untrained mind.

At this point some of the largest blades are almost literally wound in one piece out of resin soaked carbon fiber on spindles, a few more layers of resin sprayed on, then the whole thing is shoved into a 500 foot long oven for curing. The masts are made in sections, the blades aren’t, I suspect to maximize some combination of strength, weight, and efficiency.

I would guess centrifugal forces coupled with bending stress.

However I do think the solution might be to go with vertical windmills. To my eye since its possible to add support spars mid length vertical windmills look like they can use sectionally assembled blades:

https://www.rpnation.com/gallery/vertical-axis-wind-turbine.31796/full?d=1509783849

As I understand these windmills current designs are somewhat less efficient than horizontal windmills but that efficiency is projected to catch up soon. Vertical windmills also work better as a group, boosting the efficiency of the whole windfarm. They also have the heavy motor and gearbox in the base so they are more stable and they do not need to be turned into the wind, any direction works the same.

Thanks for posting this, how interesting. I’ve never seen that kind of design before. I wonder if it’s also safer for birds?

Good question. That I don’t know. I imagine not, they are basically giant mixers reaching into the sky.

Perhaps reflective/illuminated sections on the blades could deter birds from getting too close like the reflective strips used to keep birds out of crops.

And now I’m wondering how best to keep rodents out of windfarms if raptors are excluded. Rats could do a lot of damage to the wiring. Maybe host a colony of feral cats. Pretty sure cats are compatible with windmills.

Painting one blade of a windmill black and two white seems to make birds avoid them because they are more visually stimulating.

There’s some sort of problem that needs to be to be worked out that is keeping them from painting them. I’m guessing that asymmetrical thermal expansion would be a big deal that could tear a one apart at speed.

I think that would be less of a problem for vertical windmills as the centrifugal tidal forces on the blades should be considerably lower. Also they can be reinforced with spars which AFAIK isn’t practical with large horizontal windmills.

As far as I know, the egg beater windmills don’t have the bird strike problem.

There were a hundred or so here in two designs for a few years, but they replaced them with the big three blade ones, I have not seen one for at least ten years.

How a while, there were dozens of designs at any given time, but now they are all pretty similar.

Now I’m picturing a field of vertical windmills lit with multicolored LED’s, looking like the world’s largest rave.

That does sound pretty amazing.

Generally lighting something up at night caused birds to fly into it and get killed. So don’t do that. That’s one of the reasons office building owners are encouraged to not leave the lights on all night.

The world trade towers memorial in light attracted tens of thousands of birds that didn’t collide with anything, but many died of exhaustion. It was actually quite horrific the first year that they did it.

I did not know that. Short of owls how many birds fly at night?

“That’s one of the reasons office building owners are encouraged to not leave the lights on all night”

But they MUST! Otherwise people will think their employees go home at night instead of joyfully being productive 24/7/365.25 at their desks until they are replaced by newer, cheaper ones.

Because the joint weakens the blade, which would need to be stronger, and heavier, which would mean the joint would need to be strengthened, etc.

Also putting the joint half way out on a spinning arm is the worst possible place to put something that is both the heaviest and weakest part.

These blades are at the limit of economics and engineering already.

I’d trust this guy to build the plane more if he were wearing Kleenex boxes as shoes and collecting his own urine in jars.

He didn’t start doing that until a bit after the Hercules. Well, at least the Kleenex box thing, the urine jars may have started right after the XF-11 crash

We’ll take the Spruce Moose! Hop in!

Dont forget to buy a casino to prevent spies

And to give the President a briefcase full of cash to stop nuclear weapons testing, to protect the foundations of your casino

Given the weight distribution of the blades, I’m guessing they will have to carry a fair amount of ballast either when empty (my guess based on the pictured) or loaded, to keep the CG where it needs to be.

As for the rough field capability, that shouldn’t be a problem given the (relatively) light weight.

A better option might be to just air drop the blade out the back, like military aircraft do with palletized loads. They would probably need some sort of air bag system to lessen the impact forces – something that could be packed up and trucked out to get it back to an airport.

Given the cargo, I’m wondering why they’re going with an enclosed cargo bay. Something more akin to the Sikorsky Sky Crane might work better here, so the blade length isn’t limited by fuselage length.

Seems like some odd design choices to me.

A sky crane/chinook style solution could be workable for shorter distances without the runway space.

Inflatable water tanks to manage ballast? Wouldn’t need to be space efficient when deployed, just stowable.

Enclosed for aerodynamics, of course. The fuselage doesn’t weigh very much. The Sky Crane didn’t have one because, well, it was literally used as a crane, vertical lifting and sling-loading it’s cargo most of the time, and at very slow speeds <100kts. A turbine blade is probably too fragile to have hanging out in the breeze at the sort of speeds you would want to go. I expect this thing to be “slow”, but in this context I slow is 350-400kts cruising speed. On par with the straight-wing business jets.

I don’t see how you could possibly air-drop something that long.

My bet is that the CoG of a blade is actually pretty close that of the airplane itself -because when you only plan to carry ONE cargo, you design the thing around your cargo. I bet they are fairly even in weight distribution from root to tip. So not much of a problem

Given the long, tapering shape of the blades, parasitic drag could be lower with the blade than the full fuselage. The benefit of the enclosed cargo bay is it would allow for carrying other types of freight.

As for the weight distribution, the blades are definitely heavier towards the base. There’s just more material there. I’d guess it’s much closer to 30% than 50%. Maybe even closer to 25%. I’ve got a cousin that worked at a place that made them, and as he described it, not only are the walls much thicker at the base and tapering to much thinner towards the tips, the base also has a significant diameter. The longer the blade, the thicker the base has to be to support the centrifugal forces at play. Definitely not a 50-50 weight distribution.

I assume it’s enclosed to ensure the aerodynamics. Don’t want the blade to react to 100mph wind mid flight. Plus it’s easier to keep the engines out of the dirt if you have a complete plane vs wheels on long sticks.

Parasitic drag is hardly the only consideration. They don’t seem to have any plans to carry anything else with these highly specialized aircraft. And I would bet that compared to conventional aircraft, they would be wildly inefficient doing it.

The CoG of the blade will closely match the CoG or the airplane – given this airplane is purpose built to carry these blades. It would be completely nonsensical to design it such that it needed ballast – though shifting fuel around to trim tanks ala Concorde is certainly a possibility, but I doubt it. That’s a lot of added complexity when you can just design the thing for your specific use case in the first place. These are only going to make sense if they are relatively simple and cheap. And of course, I will believe it when they have a prototype flying. Not holding my breath.

And given where the wings are on this thing, I am going to say you are rather wrong about the weight distribution of these gigantic blades. If all the weight was at the root, the wings would need to be far closer to the nose of the airplane. CoG may not be at half-span, but it’s not going to be THAT far from it based on the layout of this airplane.

No, most of the mass is at the root of the blade, as that’s where the forces are highest.

Which is why a two piece blade isn’t going to happen.

But I assume that in the worst case scenario case they will be carrying a single set of three blades with two one way, and one the other. Six blades would be balanced, nine would be unbalanced by one. And of course a single blade would be the worst. Enough ballast to balance a single blade would be enough for all scenarios.

The renders show the tip of the blade extending right back into the narrow tail of the fuselage. I don’t see how they could carry them other than pointing in one direction.

Sorry, I missed that picture earlier on my phone, and yes the plane does indeed seem nose heavy between what I assume is the heavy part of the rotor and the wing looking pretty far back. A mystery so far.

Nose heavy flies. Tail heavy flies….once. Enough deflection on the control surfaces and a good automatic stabilization system will get stuff into the air that has no business being there.

Yes, between computers flying aircraft, and computers designing aircraft, the saying “what looks aerodynamic usually usually is” has pretty much fallen out of fashion.

I’d put canards on the nose if I were designing airplanes instead of paying attention to Beowulf in high school English class, but I am sure that with 20 minutes and a laptop this is fine.

The biggest constraint on designing airliners is they have to convince passengers that they look like something that would fly. Presumably that’s not a problem if the designer is also the customer,

I think the obvious explanation is that the weight distribution of these blades is simply not as biased towards the root as people seem to think. This airplane is literally designed around this one cargo.

But I will still believe this thing when there is a prototype actually flying.

The wing of the plane seems too far forward on it, so I’m gonna guess you are right on the cg of this thing

The blades are really strong in the direction they need to be, not so much where they don’t need to be. A stress concentrating chip or crack could be catastrophic. The blades wear out from fatigue anyway. Dropping them would make predicting their service life impossibleif it didn’t ruin then immediately.

Yah no.

Let’s make a plane ignoring modern aerodynamics and do so while landing in a 1930s airport.

I’m curious, how does it ignore modern aerodynamics? Looks kinda like a scaled-up Predator, and I imagine it’s not designed for high Mach numbers, just efficiency and STOL.

Yeah, that’s why they aren’t promising huge weight capacity either, not sweeping the wings, and have a relatively short wingspan. They probably don’t need to break new ground in terms of engine power or efficiency either. Something based off one of the A380 engines should be fine. It’s designed for a very specific use case, and they seem to have a pretty decent justification for that market supporting several of these.

Also fighter aircraft make sense. Those are compact and light. This will not be carrying tanks.

I doubt they will need anywhere near that much power. This thing is going to be LIGHT. And it’s going to be SLOW too. They are going to get it off the ground the way 727s did – a clever wing that can generate a huge amount of lift at relatively low speeds with not a whole lot of power. Four CFM 56s ala a 737/A320 will probably do just fine (and they are cheap and readily available) – in fact that is what powered the original versions of the A340. In fact, an A340-200 has 2X the cargo weight capacity this is being designed for. And this thing won’t need THAT much range.

I’m not as familiar with engine performance as I should be. Would make perfect sense if they are targeting that engine class. 737/A320 is the compact crossover of airliners. Lots of competitive options for engines, and parts/service should be much easier.

They actually all use the SAME engine, just in different thrust ratings. But CFM has built 30K+ of the things, they are absolutely ubiquitous. Which is why all kinds of other stuff uses them too, like the re-engined KC-135s and DC-8s. The newest get into the 30Klb+ thrust range, but those are a lot more expensive. If I was designing this thing, I’d want to use the older, cheaper ones. This doesn’t need the last % of efficiency and range for this very specific mission.

The CFM56 is not in regular production anymore, and while cheaper than current GE designs, it does not match the efficiency of the newer engines. The cost difference of the newer engines is small vs. fuel cost and allows carrying less fuel for the same range, and more carrying capacity.

The LEAP engines are still a derivation and evolution of the CFM56.

Regardless, the main point is that it is highly unlikely that this thing is going to have 80-110Klb of thrust engines on it.

PW1000G is in this class too. Doesn’t fit on the 737MAX because the wings are too low. I’m sure Rolls Royce has something too (those crazy triple spool engines).

Mistake here – I misread the intended cargo capacity. The A340 had ~100Kbls of cargo – but it could lift about that of fuel as well. I doubt this is going to carry anything like the fuel load, and of course it doesn’t need seats and galleys and all the other crap an airliner needs to lift. So I still think that 80-100klbs of thrust is likely to be where they end up.

0.0% of the current cargo jets look like this.

If i wanted to replace a 737, it would look like a 737, because 50+ years proved a tube with wings is correct.

This looks wrong because it’s a pile of nope no one has ever voted for with thier wallet.

When was the most recent cargo specific (not converted passenger jet) made? Make and Model please.

Perhaps the Embraer C-390 Millennium, introduced in 2019?

Probably, though it is exclusively a military jet. My logic is that there hasn’t been a purpose built civilian cargo jet for years, and never one to this size, nor one specifically for hauling wind turbine blades, so ofc it’s going to look different from every other tangentially related cargo jet

This thinking is what got us to the 737 MAX. Its wings are too low for modern efficient jet engines.

Sigh

https://www.airport-technology.com/wp-content/uploads/sites/14/2024/11/5l-Image-Beluga-XL.jpg

Better comparisons:

C-17

V-22

C-130J

Aircraft designed for specific mission profiles, just like this one.

I agree. This plane is like the 4stratolaunch, in that it is made to do only one thing. And the stratolaunch is one weird plane, much like this one.

Hell, this plane is just a Super Guppy took to the extreme. So the precedent is there.

Beluga might be the best comparison. Latest version is designed to carry 2 A350 wings.

But in this case, we’re not retrofitting a passenger jet for cargo (which is why the 747 beat the A380)…building a cargo plane for one specific job is going to look a lot different.

I don’t see it as any more crazy than all the strange North Sea platforms and ships the Dutch have built over the years with one specific mission.

Only question is whether the market is big enough.

Looks normal to me, form follows function.

https://www.airport-technology.com/wp-content/uploads/sites/14/2024/11/5l-Image-Beluga-XL.jpg