The wind power industry has long faced a bit of a frustrating problem. Gigantic blades are more efficient, but they’re also hard to ship. A single blade can be more than a few hundred feet long, and they’re a logistical nightmare to haul down roads and load onto barges to get to their destination turbines. Startup company Radia thinks it has the answer. For the past decade, it has been developing an aircraft of mammoth proportions that would dwarf even the iconic Antonov An-225 Mriya. The WindRunner is huge, goofy, and I hope it becomes a reality.

The world of super-large aircraft has been a much sadder one since 2022. Early that year, Russia’s invasion of Ukraine resulted in the destruction of the sole operational Antonov An-225 in the world. The distinctive Antonov and its sextet of engines had wowed the public for decades and carried the biggest loads that no other plane could haul. Antonov has vowed to rebuild the world’s largest plane, but when it does, the An-225 may no longer hold the crown.

Since then, other planes have been wrangling for the coveted position of “biggest flying object on the planet.” The dual fuselage Scaled Composites 351 Stratolaunch is shorter than a Boeing 747-800 at 238 feet, but its 385-foot wings make it the largest plane in the world by wingspan. Of course, there are also legends like the Airbus A380, the world’s largest passenger aircraft, and the Boeing 747, the Queen of big passenger jets until the A380 arrived at the terminal.

Here’s the Antonov if you’ve forgotten what that beauty looks like:

If the folks at Radia succeed in the construction of the WindRunner, they’ll take the record of the world’s largest aircraft. This beast would be about 100 feet longer than a Boeing 747-800 and still 81 feet longer than the late Antonov An-225. Supposedly, the absolute unit of a plane will also have 12 times the cargo volume of a 747 and the ability to operate at unpaved airstrips.

So, is this thing the real deal? The New York Times recently covered the plane, and that’s how it got my attention. Seemingly, everyone’s been talking about the WindRunner, regardless of whether their publication has a transportation angle or not.

Aviation For Wind Energy

Radia is the brainchild of aerospace engineer and serial entrepreneur Mark Lundstrom. He founded Radia in Colorado in 2016 to explore the intersection of aerospace and energy to find a profitable way to reduce carbon emissions. Here’s the story of Radia from Lundstrom:

Shortly after Radia was founded, a press release came out from two wind turbine manufacturers that compete for every deal globally. They were frustrated that the energy industry knows how to make offshore-sized turbines and deploy them in places like the North Sea but can’t take that knowledge to deploy them onshore where the market is an order of magnitude larger. Their release asked if an aerospace company, engineer, or entrepreneur could help them figure out how to airlift an object that weighs 45 tons and is over 100 meters in length, and land it on a piece of dirt in the middle of a wind farm. I showed up within a week and started working with them. Our massive cargo aircraft WindRunner is our solution to the problem as it can deliver offshore-sized blades onshore and enable what we call GigaWind.

Lundstrom is joined by a large team of aircraft engineers and other engineers from the energy sector.

Radia has a pretty huge marketing push behind its business. The United States Department of Energy projects that by 2050, wind power will have a capacity of 404.25 GW across 48 states. This is compared to a capacity of 113.43 GW in 36 states in 2020. Wind turbine production is only expected to grow.

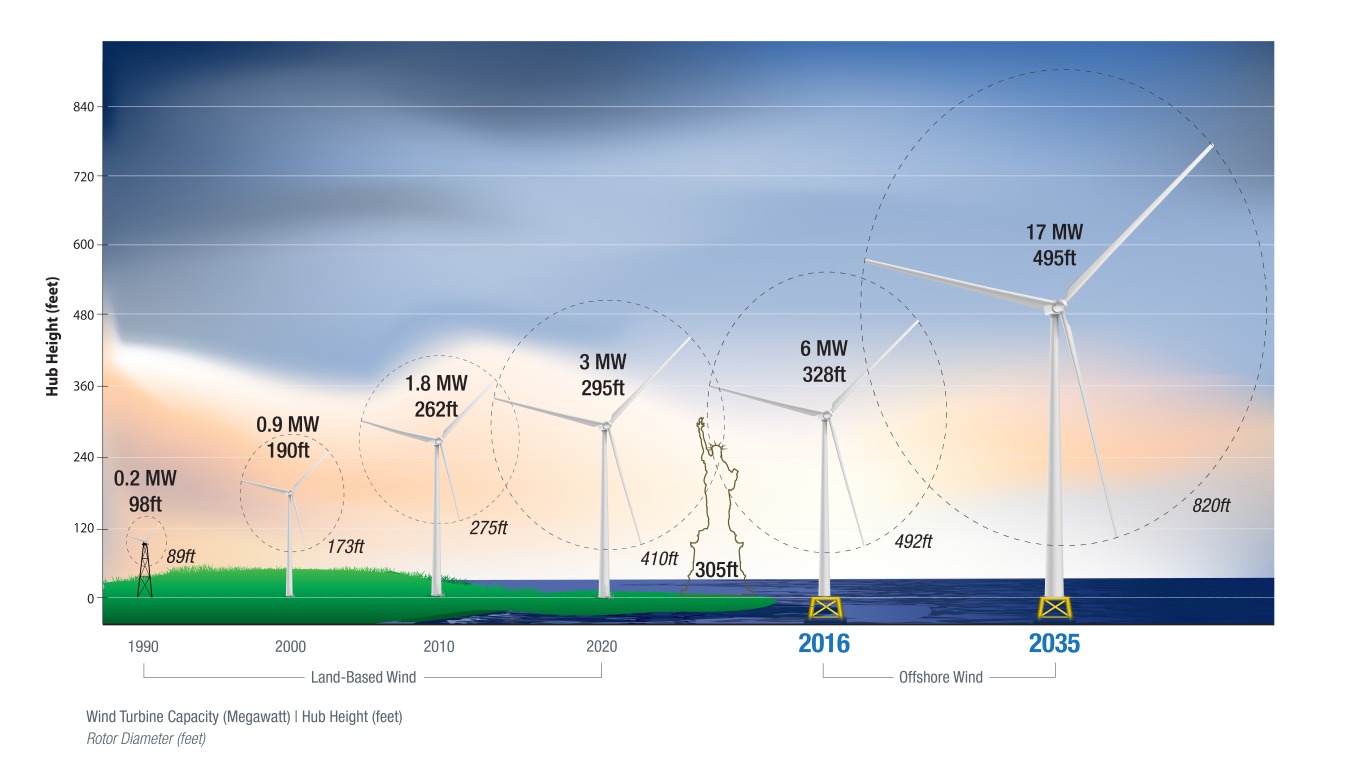

Generally speaking, larger wind turbines with longer blades are more efficient turbines. In short, this is because longer blades have larger swept areas and can capture more wind. So companies are constructing absolute monsters of turbines with blades over 200 feet long. As of 2024, the world’s largest onshore turbine blade, for the SANY SY1310A, is 430 feet long.

Radia claims that infrastructure is limiting the size of most other turbine blades for onshore applications. The company claims that most road infrastructure struggles with blades stretching 230 feet long. Further, the company says, super large blades have quite a huge diameter, which means that shipping a blade by road would require some clever navigation to avoid obstacles like overpasses. This is why some of the biggest wind turbines that you’ll find will be offshore.

As NewScientist reports, the general idea is that the larger you can make a turbine, the fewer of them you’ll need to reach a given capacity. However, as the publication reports, there are tradeoffs. Consider that, when it’s running, the SANY SY1310A’s blades cover an area of over 800 feet. Of course, then you have to figure out what to do with the structure after its service life ends. All of that aside, NewScientist notes, you still have to figure out how the heck you’re getting those giant blades to a wind farm in the first place.

So, to repeat myself here, Radia’s logic is that land transportation limits the size of onshore turbines, so what if the company took the hassle out of shipping turbine blades? Instead of navigating a blade through tight streets, you just load it onto a plane and fly it directly to a farm. Radia’s plane would permit the shipping of larger blades for onshore developments and thus pave the way for the creation of the biggest turbines and wind farms. This concept is what Radia calls GigaWind.

To be clear, Radia will not build turbines or even blades. The whole idea is that the plane will allow other companies to install the biggest wind farms. The GigaWind thing, which is included in the marketing of the WindRunner, is somewhat confusing since it’s not a product or service that will be offered by Radia.

The WindRunner

Radia’s project is the WindRunner plane. In 2024, here’s what Radia said about the aircraft:

Radia’s WindRunner aircraft, capable of landing on short, semi-prepared runways including those made of packed dirt, will be purpose-built to deliver these large blades and other components directly to onshore wind farm sites – greatly expanding the number of locations available for large turbines and enabling onshore wind to scale. Opportunities include reducing transmission costs and increasing reliability by building wind energy sites closer to demand, creating hybrid wind/solar sites to produce clean power around the clock and throughout the year, and generating the large amounts of clean electricity needed to produce green hydrogen.

The innovative design of WindRunner only requires a 6,000-foot semi-prepared dirt or gravel landing strip at a wind farm to deliver its payload. This also enables it to land at almost any commercial airport around the world. WindRunner will be 356 feet long and its volume is 12 times that of a 747, and an overall length of 356 feet to carry the largest payloads ever moved by air.

Radia plans to produce a fleet of certified aircraft at Radia’s U.S. assembly site. WindRunner is more than halfway through the time required to design, build and certify an aircraft.

Radia says that the WindRunner will have a range of 1,200 miles and cruise at 41,000 feet at Mach 0.6. Further, Radia says that the fuselage, which is designed like a Boeing 747 where the flight deck sits in a pod above the main deck, will have 272,000 cubic feet of cargo volume and a payload capacity of 160,000 pounds. The cargo inside could be as long as 344 long, 24 feet tall, and 24 feet wide. Those wings look sort of stubby because they sort of are compared to the fuselage length. The fuselage is 356 feet, and the wingspan is 261 feet.

The WindRunner is projected to be a big bird for sure, but what about that claim of having 12 times the cargo volume of a Boeing 747? Well, cargo airline Cargolux says that its 747-800F aircraft, the final edition of the 747 Freighter, has a main deck with 24,462 cubic feet of space. Times that by 12 and you get 293,544 cubic feet, or more space than the 272,000 cubic feet claimed by Radia.

Cargolux also runs the older and smaller 747-400F, which has a main hold carrying 21,645 cubic feet of cargo. Times that by 12 and you get 259,740 cubic feet, or less than what Radia claims.

In case you’re curious, the Boeing 747-400 Large Cargo Freighter, also known as the Dreamlifter, has a hold carrying 65,000 cubic feet of Dreamliner parts. Cargo volume goes up significantly as you make a fuselage taller, wider, and longer.

Another massive aircraft is the Lockheed C-5 Galaxy, and the Radia would dwarf its 31,000 cubic foot capacity:

Regardless of whatever Radia used as a base unit for the 12 times claim, Radia’s claim of getting 272,000 cubic feet out of a giant 344-foot hold seems to be achievable. What’s interesting is the specification that the gigantic WindRunner will carry only 160,000 pounds. A Boeing 747-400F can carry around 249,000 pounds, and the bigger -800F hauls 295,000 pounds. The Antonov An-225 carried a whopping 550,000 pounds when it was still in one piece.

However, the low carrying capacity of the WindRunner is probably because of its specific mission to carry wind turbine blades. Still, one of Radia’s goals is to make a ton of money, so it seems like a missed opportunity that the WindRunner won’t be able to carry cargo as heavy as existing freighters can haul. The U.S. military is looking into the feasibility of using WindRunners to carry fighter jets, so maybe that whole money thing won’t be a problem.

At the same time, the projected lighter weight of the aircraft may help it with its other statistic: The takeoff roll. A fully loaded Boeing 747-800F may take 10,465 feet or so to take off. The Radia, which will be significantly longer than the 747-800, is said to be able to lift off the ground from an unpaved airstrip in only 6,000 feet. I would pay money to see something the length of this thing manage to leave terra firma in just over a mile.

Presumably, this also means that the Radia will have some sort of hot rod engines under its high wings. Unfortunately, Radia hasn’t said anything about installed power. As you’ve probably already noticed by now, Radia has also issued only renders of the aircraft. That being said, Radia said that it’s not trying to reinvent the wheel here. It’s said that the plane will be built with conventional methods and technologies. The “innovation” is just that the plane will be extraordinarily huge.

Maybe You’ll See One Someday?

Radia sees a market for a whole fleet of WindRunners. These won’t be flying regular cargo, but the expectation is that the wind turbine industry will become so huge that just one aircraft won’t do.

Radia says that it’ll officially unveil the WindRunner at the Paris Air Show next week. Then, the company hopes to have at least one of these birds in the sky by the end of the decade.

It seems like what Radia is proposing here is theoretically possible. It sounds like something this huge has no business getting off the ground, but that’s also what some people said about greats like the Airbus A380 and the Boeing 747. I’m skeptical, but maybe I’ll be proven wrong. Will Radia go into the history books as a record-breaker? It’s too early to tell, but you bet I’m going to be watching.

OR OR, we stop this stupid idea and focus these engineers time on making nuclear power as safe as humanly possible so we don’t NEED to burn a bunch of fuel flying the worlds largest plane to deliver gigantic wind turbine blades, which seems a little counter productive.

IDK who needs to or even can do it, but we need to step back from capitalism a little bit and focus on the right problem. This is a problem stemming from capitalistic competition, AKA greed, when that doesn’t need to exist because the answer is obviously nuclear, not wind. But someone wants to make a bunch of money on wind power and now someone wants to make a bunch of money from the wind power guys because they have a problem of big blades.

Concrete. Oh so very much concrete and steel is required for nuclear. Spent fuel is also still an absolute nightmare. Just transporting it takes massive infrastructure. Storage is even worse.

For the record, I like nuclear, but what we really need is efficient storage capacity for electrons for approximately seventy-two hours or more.

Ideally we would have both. Offshore wind is much more efficient than on shore from my brief studies in college, but the movement of the power to shore is the big factor.

Hear me out–those giant blades are shaped to turn wind pressure into rotational energy. Any Physics 001 student knows energy can be converted both ways.

Why don’t we bolt these giant rotors to a center hub, attach it to a heli fuselage, and just fly the blades to the project site?

Hell if you make them contra-rotating you don’t even need a tail boom.

My God, the gearbox that would require, not to mention the hub and control hardware. I can’t even begin to imagine the rear rotor.

It’s a fun idea, but not practical.

I just discovered a problem that would likely sink the idea.

The rotor head speed of heli is roughly inversely proportional to the heli size. A micro RC heli (30cm rotor diameter) runs at about 4000RPM. A large, .90 class RC heli (1.6m rotor diameter) is between 1400-2000RPM. (Source: me, as I fly these things.) A civilian heli runs at 400-500RPM (source: Google.)

I have no idea how it scales up to something with a 500FT rotor diameter, but let’s, say, 60RPM because it translates to 1 rotation per second.

At that speed, the blade tip would be at 1570 ft/sec, or Mach 1.4.

I guess we can crank up the blade pitch to bring down the head speed, but I have no idea what the actual numbers are.

And the what that supersonic shock wave would do to those tips…

This may work on other planets/moons though, where gravity is low and winds high.

Especially in places with limited sunlight (e.g. Titan) just use the blades as wind turbines to charge up the batteries. When ready flip the blades around and use them as rotors for flight.

We already have an autonomous heli on Mars. This doesn’t seem too big a stretch.

There’s a three-letter company that’s pretty good with drones. Too bad NASA can’t call them up.

Living in Oklahoma and being very aware of the sheer scale of not only the wind generators but the “wind farms” in general, I have to wonder what the CBA really looks like in regard to carrying capacity. Specifically, it looks like even at this size, these planes can only accommodate 2-3 blades per flight? That being said, as a layperson, I really struggle with comprehending how the cost of land and material resources, along with ongoing maintenance and replacement costs, make wind generation a net positive financial prospect.

I would think that, like with dams and solar, most of the cost is frontloaded in the infrastructure. Most of the cost of other power generation methods are buying and transporting fuel.

maybe i watch too much sci-fi, but if something is too large for a plane (Optimus Prime, Jaeger Gipsy Danger) wouldn’t it make sense to use one helicopter at each end?

looking at the cutaway of the Radia seems like ‘attaching flying mechanism to fan blade’ is more efficient than ‘building airplane big enough to fit giant fan blade inside’

The plane would allow for much safer transport over much longer distances.

Coordinating the flights of two helicopters tied together with a relatively flexible blade sounds very dangerous even with favorable conditions over short distances.

youre probably not wrong. i dont know the first thing about helicopters really

It does seem like a lighter than air vessel would be a good choice.

a dirigible, perhaps?

For those who mentioned vertical axis wind turbines, here is an article on the most successful VAWT in terms of installed watts at the time of publication.

https://wind-works.org/wind/vertical-axis-wind-turbines/flowind/

I worked in the Altamonte pass where they were installed, and they were truly mesmerizing.

I can’t help but wonder if aesthetics plays a roll in some of it. VAWTs are a bit ugly by comparison to the somewhat graceful 3 blade designs.

Mezmerizing is a great word for it. My parents used to shuttle me from Tracy to Livermore for grade school in the late 90’s – I used to love looking out the window at all the different types of wind turbines. It’s been interesting to watch it transform over the years as the old, inefficient units were phased out for the new big ones.

This just seems like a guy determined to force airplanes into wind energy by whatever mental acrobatics necessary.

It would make a lot more sense to develop a modular production facility that could be deployed on-site at the wind farm. Then pack it up and move it to the next project.

Nobody is building these turbine blades in 300 foot long clean rooms. They’re manufactured at boat factories, which vary widely in their sophistication but all fall very short of even the most basic automotive production plant.

Serial Entrepreneur.

Isn’t that just a sci-fi writer who focuses on press releases?

Is there a reason the blades can’t be assembled from pieces?

I keep wondering the same thing. It seems like developing a segmented blade would solve so many of the problems associated with the current design(s).

I think that has been done, or at least looked into starting 10ish years ago. It’s certainly doable. Just a question of whether it’s deemed worth it.

The joints tend to be a lot heavier and more expensive than just doing a continuous composite layup. Weight isn’t the end of the world for wind turbines, but more weight will mean more material support the extra weight. That whole rocket equation kind of thing where weight begets more weight.

But cost is a big driver. Utilities are wanting to make money after all.

Landing on a barely improved air strip with the compromised visibility from where the cockpit appears to be situated would make me pop my (so far non-existent) hemorrhoids.

Back in 2012, I flew from LAX to SYD in a Quantas 747 and then back a couple of weeks later in an A380. It was profound how much quieter the A380 was. And they had a camera mounted in the vertical stabilizer that allowed me to watch the sun rising over the Pacific on the little screen in front of me. Pretty cool.

The A380 feels like a building that happens to fly. I’ve never been on something that was so smooth in the air.

The last picture of that proposed plane reminds me of Jabba The Hut…

It is an interesting concept, and a great idea, but I think it has pretty limited usage, unless the blades are manufactured somewhat locally given the 1200 mile range. Additionally, from the windfarms I’ve looked at, you’re lucky to find enough space to put the site offices and concrete batch plant, much less enough flat space to put an airstrip in. You’ still then need the same trucks and cranage to move the blades about site. You still need to move the tower segments, the narcelles (the actual generator), and numerous substation bits, so the roads from port to site still typically need a level of upgrade. Sure it is 3x less loads per tower, which is significant. To put perspective on Australia though and specifically Queensland. You would need to do the following:

Benefits, oversize load check, and road upgrades reduced, but at this point most things can get out of port to most places, it is just small town upgrades local to the wind farm that require upgrade. Shorter truck movements, but twice as many…

For the narrow use case, this will be game changing, but I see that case as being a very narrow.

99% of the use case would be flying a blade to a small regional airport somewhere near the farm and trucking it the rest of the way – much better to only have to truck 100km through a regional area, than 600km from a seaport, through a metro area.

It can also carry lots of pillows, and pre-filled Mylar balloons. That sounds mocking, but I really like the idea of an enormous airplane filled with pillows, and am in general in favor of anything that more or less sustainably helps humans convert to sustainable, renewable energy sources

Rapid fire thoughts:

In plan view it looks like an Ekranoplan. It just needs powered canards/forewings.

It doesn’t need huge wings. It’s not a heavy lift design. Bigger wings would just cause extra drag for no needed extra lift. It’s a purpose built machine.

It doesn’t need very powerful engines for the same reasons as above.

Ground effects from that huge fuselage pushing air out of the way must be wicked. A huge wing would exacerbate that. Flaring would be exciting? Watch out for crosswinds with that ginormous fuselage.

It might make for some of the most epic crab walk landings ever.

No picture of the Baluga?

Great article. I’m guessing since they only need to carry blades, they can engineer it for a payload of exactly that and that solves a whole host of problems.

Looms more like Jabba The Hutt than a Baluga.

Putting aside the fact that I think wind farms are a pretty dumb idea nowadays, when developing solar pane tech seems like the actual practical solution…

I don’t see why they can’t build collapsable blades. Think antennas from those old-school cordless phones, or retractable antennas on cars. The force of them spinning is gonna keep it extended, and if the aerodynamics of the design is a concern, one could just make a semi-pliable “condom”/semi-rigid “air cast” over the exterior of the blade to make it seamless.

This would solve transportation completely, and then you wouldn’t need a gigantic constipated flying turd of a plane at all.

The heavier you make the blades, the less efficient the whole turbine is, especially in low wind speeds. I’m guessing that in any situation where it might make sense to use collapsing blades it works out cheaper to just build more, smaller, turbines.

I love big planes for some reason unknown to me… but when I see how they dwarf the folks inside or outside, I can’t help but chuckle. Globemasters, and Starlifters, and Galaxys, and whatnot… if it’s super-big, has as much empty space inside as a good-sized barn, and rolls on at least a couple dozen wheels and tires, then I’m hooked.

But if someone asked me how to transport giant wind turbine blades from place to place, I’d have explored dirigibles first. They’re not fast of course, but they could conceivably pick up the blades AT the factory and deliver them TO the job site, with zero ground transport required.

Yes, I know post-Hindenburg, large lighter-than-air craft are suspect, but I keep seeing videos about new ones all over my Youtube feed. Even allowing that half or even two thirds of those are AI fluff, some new ones must actually exist, and presumably, some more/bigger/better ones must be on the drawing boards (as if anyone actually used drawing boards anymore).

I’m not saying it’d work, or be practical, or even possible, but designing/building/certifying/making a solid/profitable business case for an all-new supergiant cargo jet can’t be a simple undertaking either.

https://en.wikipedia.org/wiki/Hybrid_airship

Edited later to note that apparently, many Autopians thought the exact same thing. 😉

Do dirigibles use less fuel overall than fixed wing ones? Does the lower transport speed cost more time (which as we know is money)? Landing dirigibles often requires large staff. As others will no doubt point out, wind is the enemy of safe landings and airships are easily the most sensitive to it.

The answers to these issues probably push the equation towards fixed wings making most sense.

Of course I presume/assume that the folks at Radia also thought of dirigibles (as many of us did) and perhaps they ruled them out for any number of reasons (having to transport the turbine blades long distances might be a factor… obviously fixed wing aircraft move at much higher speeds than dirigibles). But the fact remains that unless there’s a suitably long airstrip at the factory and jobsite (unlikely) then even if the WindRunner becomes real, it’s still going to require large trucks moving blades on public roads at both ends of the trip. The potential for point-to-point transport is what makes dirigibles so initially appealing, especially if the distances to be traversed aren’t intercontinental.

Flying Whale has been saying it is about to build a helium airship to lift turbine blades — and things like great billets of tree trunks, for at least a decade, with nothing flying yet.

Truth is it is cheaper to design a 100 individually and computer controlled, wheel road trailer, and hire engineers to plan routes, deconstruct and rebuild bridges and things, than it is to fly.

And the great flaw in the short take off and landing part of the blurb, is that wind turbines need power lines, and power lines are almost always built on the flattest and easiest way in, just where the airstrip would have to go.

In practice I think you’d be flying it to the nearest small local airport and then trucking it the remaining 20km.

That’s still a big improvement from having to truck it 1000km from the nearest seaport.

Wind farms are typically built in places where it’s windy most of the year, which would complicate airship operations.

Airships/blimps/zepplins/etc. are cool though.

“At the same time, the projected lighter weight of the aircraft may help it with its other statistic: The takeoff roll.”

Weight is the most significant factor in balanced field length since it’s proportional to wing loading (weight over wing reference area–hence the untapered wings here, probably to increase S_ref with a manageable span, among other reasons) and inversely proportional to thrust-to-weight ratio. That simplifies to a balanced field length proportional to weight squared. Any reduction in MTOW has an outsize influence on reducing BFL because of that proportionality.

I’ve heard flaps and slats can have effects on such things as well.

I forsee countless issues with jets running onto and off of unfinished airfields. Better a turboprop in this application. You need volume, not weight or speed.

The real likely use case is flying into the nearest small regional airport (possibly with a dirt extension) and then trucking the blade 50-100km through a regional area. That is much preferable to trucking the blade 500-1000km from the nearest seaport (which are usually in metro areas…)

The people demand dirigibles!

I agree. As I was reading this I thought have a dirigible carry the blade to the wind farm. Drop it off and. do it again. No airfield err lad required at all.

You’d have to design some type of huge carrier mounted on enormous casters for when the wind blew the ship around while dropping the load. Otherwise, your multi-million dollar blade will get trashed.

Wind farm…