The new 2026 Toyota RAV4 is just about here, and while developing a new generation of the world’s best-selling car is a gargantuan undertaking, the process of actually assembling the thing is arguably even more impressive. See, Toyota Motor Manufacturing Canada’s West plant in Woodstock, Ont. is running at full-tilt with maxed-out overtime. Demand for the outgoing RAV4 remains so strong, you can’t just shut down a major assembly plant willy-nilly. So how do you gear up for a new RAV4 while still quenching the public’s thirst? By building two different generations of RAV4 on the same line at the same time, of course.

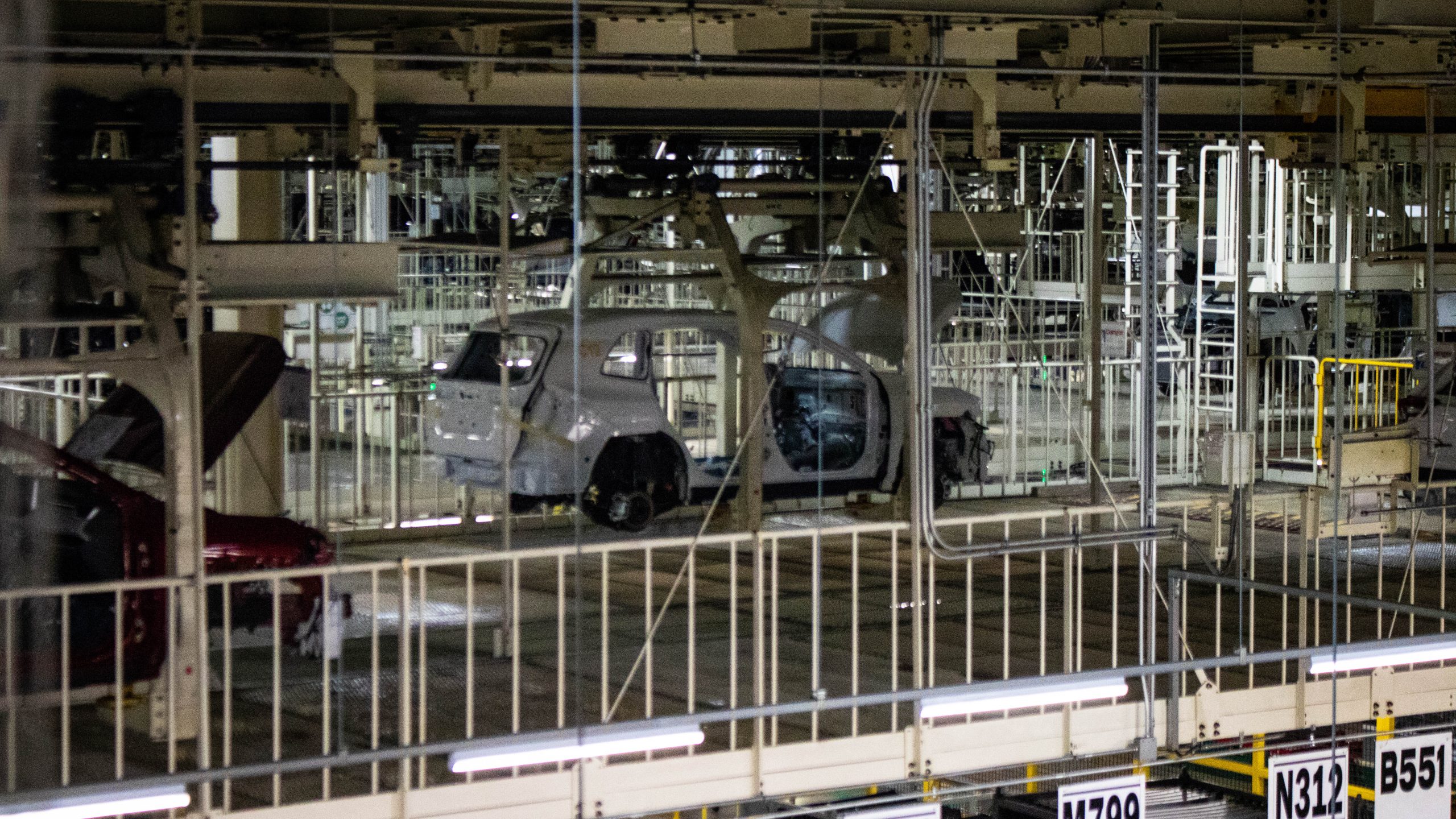

If someone tells you that the 2026 RAV4 is all-new, feel free to correct them. It’s really a heavy evolution of the previous model. While 60 percent of its parts aren’t shared with the old RAV4, it still rides on the same platform and wheelbase, meaning we’re not looking at a complete retool here. Sure, it requires new dies in stamping and new molds in the plastics department that makes stuff like the bumpers and the dashboards, but a certain level of commonality means Toyota is running a production pilot concurrent to fifth-generation RAV4 production. This means that a handful of new RAV4s and a whole bunch of old RAV4s run down the same assembly line, with machines like crane systems and pallet systems permitting workers to take these pre-production 2026 models, stop them, pull them aside, inspect them, and then put them back on the assembly line to continue both its path and employee training.

While the short-lived third-generation RAV4 EV was built in Woodstock, Toyota Motor Manufacturing Canada’s West Plant previously hadn’t assembled the RAV4 Hybrid at all. Now it’s gearing up for the all-hybrid sixth-generation model, and that includes assembling battery packs. Not plug-in hybrid packs, but the 1.1 kWh packs found in all non-plug-in models. It’s a big change, so here’s an overview of how that crucial process works.

It all starts in Toyota’s North Carolina battery plant, where individual cells are assembled into the modules that make up a battery pack. Those modules are then shipped all the way up to Woodstock, Ont. where five new bay doors have been installed in the side of the plant just to keep modules flowing into the facility. At the same time, stamping takes care of pressing out the actual battery pack casing, and the components that make up individual battery packs are shuttled from holding locations to the battery pack assembly line using in-plant autonomous vehicles.

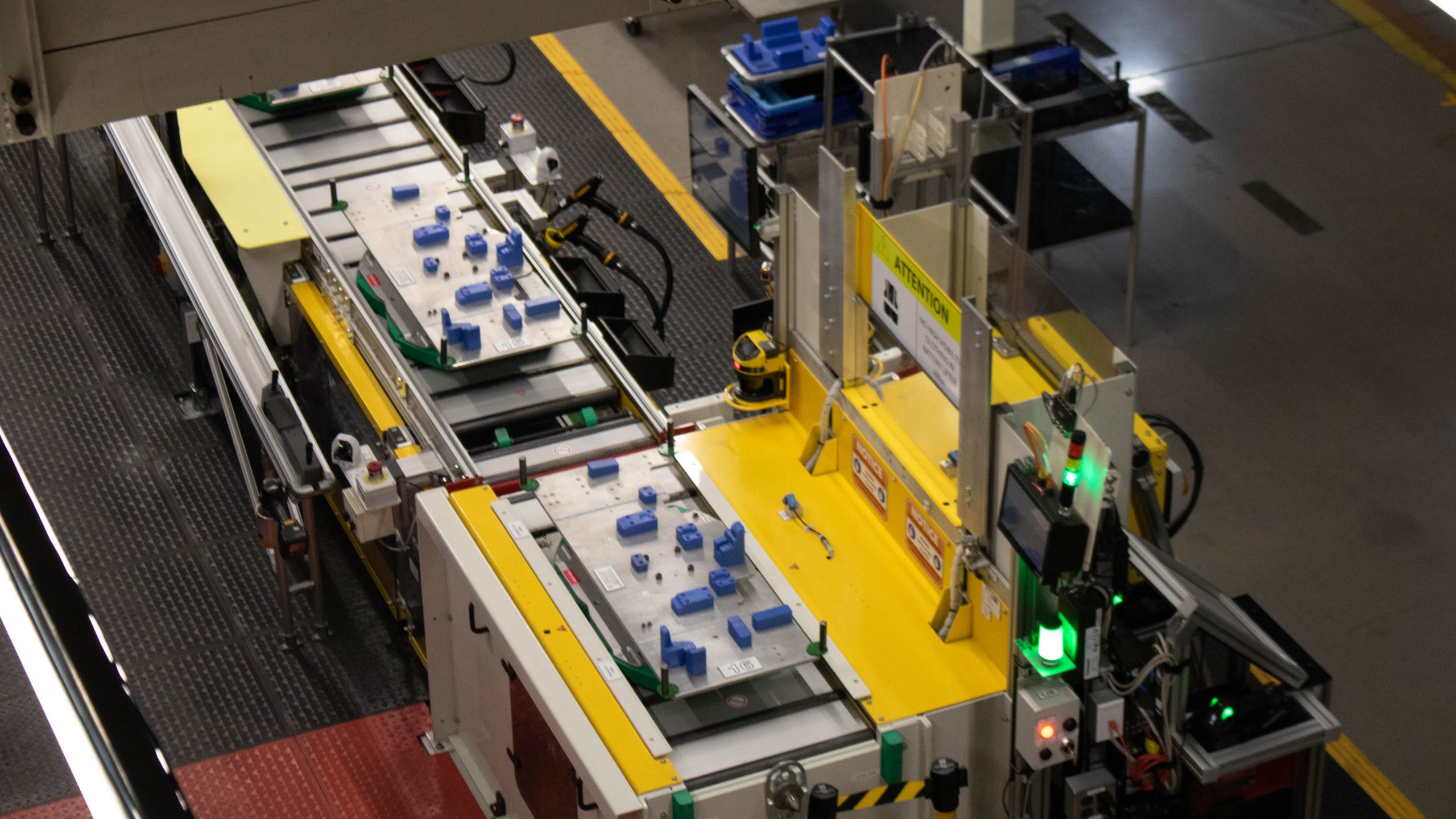

Perhaps the most surprising thing about the battery pack assembly line itself is how relatively small it is. In terms of total footprint, I’ve seen larger apartments, which says a lot about the efficiency of the line. Considering a new RAV4 rolls off the line at TMMC West every 58 seconds, the battery pack assembly line runs slightly faster just for the sake of margin, and it features some cool worker-led innovation. Obviously, you’re going to want to isolate battery terminals when building high-voltage packs, and custom tools to do just that were rapid-prototyped using 3D printing, then injection-molded for durability once an ideal fit was achieved. Speciality equipment like this makes building packs such a snap, Toyota even has time to take them for a ride.

See, between the battery pack assembly line and the vehicle assembly line sits a massive passageway for parts and people that simply can’t be interrupted by battery pack cross-traffic every minute or so. As a result, each battery pack rides an elevator up to a conveyor that runs well above the passageway on the ground floor below, ending at another elevator that lowers each battery pack to the vehicle assembly line level. Oh, and if you think that’s cool, wait until you hear about documentation.

It’s no secret that assembling a modern vehicle requires huge amounts of documentation to maintain quality. We’re talking petabytes of data from scans of spot weld accuracy and penetration to torque values of installed components to which batches of which parts from which suppliers made it into which vehicles. Not only does keep quality up, it can also make identifying and repairing problems easier after a car’s rolled off the assembly line.

Because Toyota collects so much data when building the new RAV4, each hybrid battery pack sports a QR code that leads to a database, telling a franchise dealer or third-party repairer when a particular pack was made, what sort of cells are inside, when the cells were made, and it sounds like Toyota’s even thinking of sharing torque values from the pack assembly process in this database.

Speaking of data, Toyota’s North American assembly plants now all feature vision-based artificial intelligence, not to replace trained safety and quality control professionals, but to augment them. The goal is to spot potential issues humans might miss, and then leave it up to humans to actually make improvements. For instance, cameras and image recognition are great for spotting quality control concerns that might not be visible at a glance, then humans assess what the computers have found, solve any problems on the spot, and implement new processes for improved quality control. It seems like a logical evolution of Jidoka, which Toyota describes as automation with a human touch, and so long as it continues with the mindset that a computer can never be held accountable or be responsible for decisions the same way a human can, it seems like a responsible way of using machine learning.

While we’re on the subject of automation, it’s worth noting that there are some tasks that would just be grunt work for humans. Manually installing a spare tire on a vehicle every minute or so is a real pain in the neck, so Toyota’s invested in developing a robot that automates the entire process, from placing the spare tire in its well to closing the hatch properly with different techniques depending on if a vehicle’s equipped with a manual or power liftgate. Once assembly’s done, it’s off to quality control where each new RAV4 gets checked over under the bright lights, put on a chassis dynamometer, and any last little issues can be corrected.

By trialling production of the new RAV4 while cranking out the old one, Toyota’s able to dramatically shorten the time required for a full changeover. In the case of TMMC West, it’ll happen mostly over the winter break, meaning the actual downtime involved is rather small. Shortly after the holidays, things will get busy again. After all, TMMC West is running full-tilt, and it’s expected to keep that pace when full-scale 2026 RAV4 production starts.

Top graphic image: Thomas Hundal

So if these were sent to the US, would they have a 25% tariff?

Reading about the assembly line improvements and innovations from Toyota make me even more hopeful for the future of companies that have Toyota as partners for building eVTOLs.

This is not a knock on you or the topic, but more of a general rant/vent, as the debate over the use of “all-new” has been going on for decades and definitely has PR/marketing speak to it (it gets thrown around in actual midcycle refreshes even).

But people latched on to this with the new Camry and suddenly Internet Commenters started saying “well actually it’s not a new generation just an update of the old one.” In fact that’s something that Toyota and every manufacturer has done for decades. Ground-up redesigns might be like every 2-3 generations of a model (obviously varies).

Toyota has done that a lot in the past. The tenth and eleventh gen Corolla was the same basic car.

We live in depressing times when a bland looking crossover becomes ” The best selling car”.

The best selling car has nearly always been a boring car. Camry and accord held the crown a long time, Taurus for a while, none of these are exciting cars. Fun stuff is not meant to sell in massive volumes because what I think is fun, and what you think is fun are different.

Most people have vanilla or chocolate pudding, not orange mint pistachio.

Keep making the old one, drop the price by 20% (since your tooling and R&D have been paid back already) and see if anyone gives a crap about the new mostly the same 60% different model?

Sorry to be pedantic, but 40% is not mostly the same. It’s mostly new, just not all new.

A few brands have done this successfully. Ram 1500 Classic and Malibu Classic are at the front of my mind here.

This only works if the new model is being manufactured on a new, separate production line or facility- Which usually occurs when the old product is so dated that the original line will require a total overhaul to meet current standards.

Manufacturing in parallel gives the brand the option to keep the old model going, but there are heavy downsides:

-Eventually the original tooling will begin to wear out- Does it make economic sense to repair or replace it for a dated product?

-Continuing to run the old tooling will eventually result in degradation of part quality- Which would be of concern to a manufacturer with a reputation like Toyota.

-Continuing to run the old production line often doesn’t actually result in savings or a cheaper product. Old lines are slower, less efficient, and rely on higher levels of expensive hand labour compared to the latest and greatest. (Which they must now compete with.) They may also depend on dated automation and machinery that become challenging to maintain.

-There are strong marketing downsides to selling an aging model indefinitely- A hit to the perceived quality and image of the brand, plus a reduction to the perceived $ value of the new model.

This is generally why this phenomenon only happens at lower quality/ discount manufacturers like Dodge, or for commercial vehicles like the Chevy Express which aren’t expected to maintain cutting edge fit and finish or the latest styling. Or, the tooling is sold overseas where labour is cheap, and the old model doesn’t undermine the brand on their home turf. (See Fiats > Ladas in Russia, Nissans and VWs in Latin America, etc)

Often, keeping old models in production is more about honouring labour agreements or keeping workers employed out of good will than any actual product-driven reason. (See Volvo 240)

None of this applies for a competitive, high quality, mass-market, consumer-facing brand like Toyota, who continually upgrade their facilities and manufacturing methodology to avoid obsolescence.

Yes, I can see a psychological downside where the where the old version is unconsciously bad because it’s inferior, and at the same time the new model is bad because it requires extra money. While the advantageous reverse of both could be picked up on, humans (as all animals) naturally look for trouble.

You hit the nail on the head, I was just listing examples where it has been done. I am very well versed on the manufacturing tooling process; I am a production Engineer for an OEM. I have worked on a couple of new model launches. My favorite part is when the pre-pro units are going through the factory in full spy shot camo before the public unveiling of the product.

I’m glad to hear I’m on the right track, as I am not very well versed at all- This is just overview I gleaned from an industrial design program I studied.

(Sorry if my comment came off as a rebuttal, I actually meant to reply to Kelly above)

My brother did some tool & die work for suppliers to the automotive industry, mainly dies for smaller stamped steel parts. I’ve heard some of his stories about how much maintenance & repair work go into the tooling for something as simple as a seat adjuster handle.

The amount of die work/re-work went into fixing quality issues on last launch project I was on would blow most minds. For example, To just fix a 3mm variance on fender to hood gap took 7 months of effort every weekend running trial parts.

That’s wild.

I think these new RAV4s have a better chance of reaching 300k miles than the newer Tundras (which are more complex). Cheaper to maintain and insure too.

There are a couple Tundra hybrids in my neighborhood and it messes with my head every time I hear a hybrid coming and turn to see a big ol truck.

A bit off topic but what is the correct pronunciation of RAV4?

I’ve heard it with a long a and a short a.

In other news back in the 60s GM built full size Chevy sedans (full frame) and Firebirds (unibody with front subframe) interchangeably on the same line at Lordstown. The sedans had six engine options and the Firebirds six engine options (none of which were common) while each had four transmission options.

In 1969, Chevy tried building Corvairs and Novas on the same assembly line. It went as well as you’d expect. The last of the Corvairs, November 1968 and onward were effectively hand-assembled in a separate area.

Probably still had a soda bottle shoved in a recess.

That is quite impressive. I would guess that the lines ran very slowly though, even for the time.

Lordstown rate when they were building B body /F body cars was 50 an hour. Fisher Body and GMAD were pretty capable outfits.

Is that the plant they had to send people out to the lot after the shift to make sure the right parts were on the right cars?

“put on a chassis dynamometer”

Wait…does that mean Toyota has the data somewhere of what HP numbers my RAV4 put down?? That’s awesome!

I’d be really curious to know the deviation from car to car. On the one hand, you’d expect them all to have identical performance (of the same configuration), but I bet it varies.

These days manufacturing consistency is pretty impressive. I think the variation is quite low.

I don’t disagree. It’s still interesting to think one RAV 4 is putting down 224.3 hp (or whatever) and the one behind it is making 223.9 and what variable(s) might account for the difference.

I highly doubt they do a pull for HP and TQ numbers and instead just make sure it functions properly in a short simulated “normal” drive cycle.

In Kentucky they (at least used to) have drivers grab the car (Camry, Avalon, or Venza) from the end of the line, do a quick brake check, and then they’d take it through a quick closed course on the way to the holding yard. When a vehicle is coming off each line (2 in Kentucky at the time) every minute that’s obviously quite the undertaking and requires a lot of people (and space).

Taking some time away from the process by doing a quick check on a rolling road makes a lot of sense.

You do both. There is a person that drives it off the line to the Dyno for a quick up to highway speeds test. then to the final quality gate. Then another person takes it on that quick drive loop.

Doesn’t surprise me in the slightest that they can pull this off. I remember visiting the NUMMI plant in Fremont for work in the mid 2000s and they were building Tacomas and Matrixes. Tacoma beds were assembled and painted in Mexico and shipped to Fremont to mate up with the rest that was built on site.

I was thoroughly amazed at their JIT operation even back then and that they somehow didnt wind up with white trucks with green beds on them.

I am amazed that the beds and cabs matched up as well as they did. I know that they had problems with the early 80’s pickups, as the truck and tailgates were painted/shipped separately and didn’t always match perfectly.

Those late 80’s and early 90’s pickups had their beds built and painted in CA while they mated up with their truck at the port of Tacoma. It used to be a regular sight to see pairs of trucks working up and down I5. They had a specially built trailer with racks that carried the beds sideways 4? or 5? high and always were in pairs. So yeah for many years the “final assembly point”, for chicken tax/quota purposes, was Tacoma WA. I personally believe that played a big part when they decided their compact “pickup” needed an actual name.

To be fair that was the loophole big enough to get a truck past the chicken tax so it wasn’t just Toyota that sent “incomplete vehicles” over that was just business as usual.

My 1996 Tacoma was built at the NUMMI plant. I had bought it new in TN and later moved to California. When I did I recall seeing those beds on trucks locally for awhile after I moved here. Almost 30 years later I still own it and its been the most reliable thing I’ve owned.

It is weird that when the incomplete vehicle loophole was closed that they still continued to build and paint the beds in a different country from the rest of the truck. I guess the trailers weren’t fully amortized? Old habits die hard?

This doesn’t mean every car company should try this… my 2022 Ford (special order) had mismatched tires (rims were fine) from the factory. No it wasn’t a swap at the dealer during PDI.

It’s a one-of-one!

I remember reading articles and press releases about Honda back in the 80’s, where they managed to start building the new Accord while the old Accord was still churning out the other end of the plant, with no plant shut-downs for “retooling.” Not really anything new.