There was once a glorious time in vehicular history when seemingly everyone was obsessed with gas turbines. These smooth engines promised lots of power in a smaller package when compared to piston engines, and were fitted into everything from cars to trains. One of the wildest proposed roadgoing applications for gas turbines came in the 1950s and 60s from General Motors. Back then, the General built a series of turbine-powered semi-truck concepts, and each a bit wilder than the last. One of them was this, the ridiculously powerful Bison, which looks like a stubby Moon rover.

The gas turbine is a wonder of engineering with some incredible history behind it. The earliest known design of a kind of gas turbine was made by Hero in the first century BC. Seriously, this idea goes way back! Leonardo da Vinci also sketched something called a smoke jack, which also works on the same basic principles as a gas turbine. As the Academic Press (via ScienceDirect) notes, the first patent for a gas turbine (Patent No. 1833) was granted to British inventor and engineer John Barber in 1791. It would take until about the 1930s for the design of the gas turbine to evolve into something similar to what we know it as today.

A modern turbine works by drawing air in through an inlet, where it goes into a compressor, which pressurizes the air using airfoil-shaped spinning blades. That pressurized air is joined by fuel and is ignited in the combustion chamber/burner. Then, the ignited, high-pressure, fast-flowing mixture enters the turbine, which has its own airfoil-shaped spinning blades. The mechanical work of the rotating turbine can be used to spin a propeller shaft, driveshaft or generator. The turbine is also connected to the shaft that drives the compressor. A turbofan engine is a type of turbine, and the long shaft containing the turbine and the compressor is capped off with a gigantic fan featuring titanium blades.

This is a very simplified explanation of how a gas turbine works, but what you need to know is that gas turbines have proven themselves to work really well for specific use cases. Of course, the turbofan is the king of commercial aviation, but gas turbines are also found in power generation and military vehicles.

The Theoretical Advantages Of Turbines

The gas turbine carries some important advantages, such as a high power-to-weight ratio compared to a reciprocating engine and a more compact size than would be necessary for a reciprocating engine to make the same power. Gas turbines can also run on a variety of fuels, and depending on the exact application, can make lower emissions than alternatives (though emissions would end up being one of their biggest issues). Modern gas turbines are also quite reliable and can score quite high efficiency.

Based on these potential advantages, it’s no wonder that gas turbines have been found in some fascinating applications. Car people will be quick to point out the Chrysler Turbine Cars of the 1960s. These cars offered lots of promise, as the turbines had fewer moving parts than typical piston engines, ran on a variety of fuels, and were planned to be fuel-efficient. Turbines promised a future without valves to check, no carburetor to adjust, and no dependence on gasoline or diesel. It was the perfect idea for the Jet Age.

The most bombastic application of turbine technology was the Union Pacific Gas Turbine-Electric Locomotives, which were some of the largest and most powerful locomotives to ever run the rails. They were also so loud that cities hated them, so hot that they cooked birds and melted overpasses, and had an insane thirst for fuel oil.

But these were hardly the only developments. Rover made the Jet I turbine-powered car in 1950, then there was also the M1 Abrams tank and even the Ford Big Red turbine-powered semi-truck of 1964. Dan Gurney briefly drove a turbine-powered racer, and there have been turbine-powered land speed cars. Heck, even Toyota made a working turbine car in the 1980s. For a handful of decades, it seemed as if automakers were almost as obsessed with turbines as they were with Wankel rotaries.

General Motors spent decades playing with gas turbines, and while the General can say it never cooked a flying bird with its creations, its gas turbine concepts were ambitious. Perhaps the craziest of all of them was when it considered changing the trucking industry with turbine power.

GM Plays With Turbines

General Motors first started exploring turbine power for road vehicles during the 1940s. It was during this time that Chrysler was also exploring its own turbine car program. This timing wasn’t a coincidence. As Hot Rod magazine writes, while there had been turbine developments before World War II, the technological advancements brought on by the war made turbine power more feasible. General Motors claims to have beaten Chrysler to the production of a turbine car prototype with the 1954 XP-21 Firebird 1, a car that GM says “first gas turbine automobile ever to be built and tested in the United States.”

This wasn’t a production vehicle, but a tester meant to evaluate if a turbine car could really work. From GM:

The idea for Firebird I originated with Harley J. Earl, the legendary GM Styling Vice President, who also designed the car’s aircraft-inspired fiberglass-reinforced plastic body. The engine, termed “Whirlfire Turbo-Power,” was developed under the direction of Charles L. McCuen, then general manager of GM Research Laboratories Division.

Unlike a jet airplane, which develops thrust through the action of exhaust gas through a tailcone, the Whirlfire Turbo-Power engine propelled the Firebird I through a power turbine acting on the rear wheels via a transmission. The engine was capable of 370 horsepower at a power turbine speed of 13,000 rpm.

Every surface of the vehicle was refined in the California Institute of Technology wind tunnel, one of the first examples of the application of aerodynamic theories to automobile vehicle design. The negative angle of attack of the wings and the 6-square-foot area of the tail fin were all optimized through this ground-breaking work.

The Firebird I looked like a jet aircraft with its wings chopped off. Next came the 1956 Firebird II, and it featured seating for four under a canopy, 200 HP, an independent suspension, and disc brakes on all four wheels. This was pretty advanced stuff for GM back in those days.

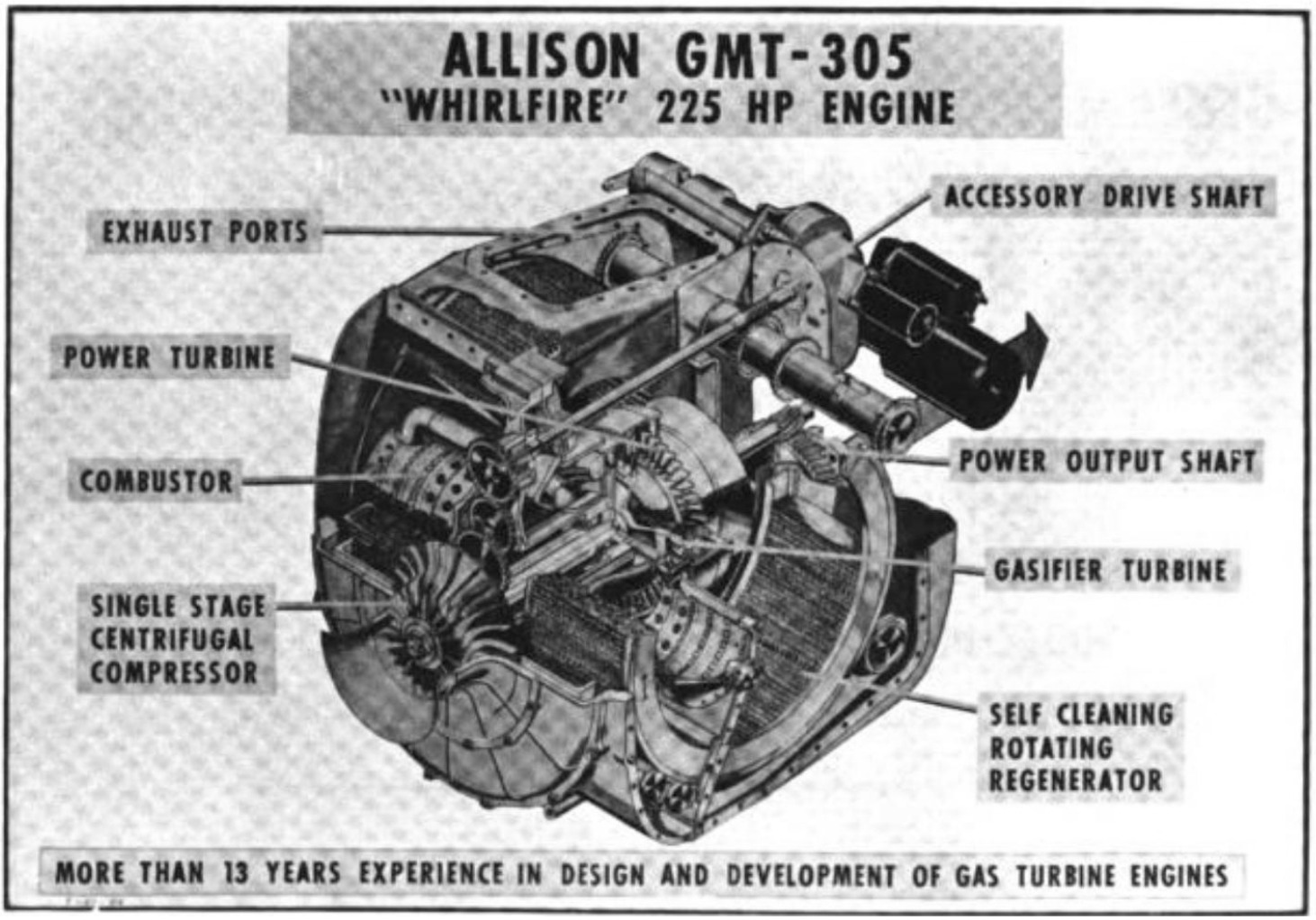

Finally, GM also produced the 1959 Firebird III, which looked like something that would be at home in an early Batman film. This one had a 225 HP Whirlfire GT-305 turbine and an additional 10 HP gasoline engine to run the vehicle’s accessories. This one was the craziest of the Firebirds — which had no relation to Pontiac — with anti-lock brakes, joystick steering, cruise control, air-conditioning, and even air drag brakes like a plane has. Supposedly, the car also had a sort of rudimentary version of today’s smart fobs with a key system that signaled to open the doors using sound waves.

GM would later create the Firebird IV for the 1964 New York World’s Fair, and it was marketed as a turbine car, but this concept wasn’t functional.

This was only the beginning. General Motors would also fit turbines into its Turbo-Cruiser I, II, and III prototype buses as well as the RTS-3T and RTX. The Turbo-Cruiser I bus was built in 1953 after GM purchased back a TDH 4512 from Detroit Transit and fitted with a turbine engine. Unfortunately, as Curbside Classic notes, cracks in GM’s turbine program were apparent early on. The GT 300 turbine that powered the Turbo-Cruiser I made twice the power of a GM 6-71 diesel, but also had twice the fuel consumption, was expensive to produce, and had unacceptable emissions. Sure, the engine was lighter and more powerful, but it just wasn’t practical.

GM’s Early Turbine Design

General Motors also messed around with planting turbines into semi-trucks. The promise for buses and cars also looked appealing for trucks. What if you had a small, lightweight engine that had fewer moving parts than a diesel and made more power to boot? Sounds like the future, right? That’s what GM thought, anyway.

In the 1950s, General Motors kicked off the development of turbine semi-trucks with the Turbo Titan I and then the Turbo Titan II. Like the Turbo-Cruiser buses, these two turbine trucks were based on existing GM truck models that originally shipped to customers with piston engines.

At the heart of all of GM’s turbine developments was the Whirlfire turbine. These engines were initially the work of GM Research, and in 1954, GM explained how the engines worked in the Firebird I:

Mechanically, this gas turbine car is the reverse of conventional automobiles. In the nose, ahead of the driver, is a 35-gallon glass fiber-plastic fuel tank. Behind the driver is an integrated power “package” with an engine consisting of two mechanically independent parts-the gasifier section and the power section. The gasifier section provides a source of compressed hot gas, and energy from this gas is delivered by the power section to the car’s rear wheels. Thus, the gasifier section replaces the engine and torque converter pump in a conventional automobile, while the power section replaces the torque converter turbine, transmission and rear axle gears.

The Whirlfire gasifier section closely resembles a complete small jet engine. The exhaust gas, instead of firing through a tailcone to propel the car, is funneled through a power turbine that is directly connected with the car’s rear wheels through a transmission. Backbone of the gasifier section is a so-called compressor rotor and a gasifier turbine wheel, both attached to the same shaft. Air enters the compressor where its pressure is raised to more than 3½ times atmospheric pressure, before it enters the engine’s two combustion chambers. Kerosene is burned in these chambers, raising the gas temperature to approximately 1500 degrees Fahrenheit.

The hot gas goes through the gasifier turbine which drives the compressor. The blast of hot gas from the gasifier turbine is funneled toward the second turbine, the power section turbine, which is connected with the car’s rear wheels via a two-speed transmission.

The GT-302 turbine that powered the Firebird I made 370 HP when the gasifier turbine was spinning at 26,000 RPM, and the power turbine was spinning at 13,000 RPM. The complete engine unit weighed 775 pounds.

These early turbines proved to be thirsty units, which you’d think wouldn’t be a great fit for a highway tractor. However, GM’s logic was that you could just run the turbine on the cheapest fuel you could find. GM would also compensate for the screaming high RPM these turbines ran at by gearing the output to deliver high torque down low, like you would get in a piston truck engine. In theory, the result was that a turbine truck could be affordable to run, very durable, and be literally turbine smooth.

George Jetson’s Semi-Truck

Visitors at the 1964 New York World’s Fair were treated to an overload of turbine goodness. Chrysler took people for rides in its Turbine Cars. Meanwhile, Ford brought its own turbine-powered semi-truck with the Big Red prototype. General Motors had some turbine fare to show off as well with the aforementioned 1964 Firebird IV. It also one-upped the Blue Oval with its own idea to revolutionize trucking. Meet the Bison.

The Bison was something otherworldly. As the Motor Cities National Heritage Area writes, the Bison was designed under the lead of Bill Mitchell, and it looked like no other truck that had been produced before or since.

The cab of the GM Bison was something special all on its own. There were no entry doors, and entry was achieved through opening the clamshell canopy, sliding two side panels, and then climbing in. Once in, the driver and their passenger would have a commanding view of the road ahead, but their seating position also wasn’t as towering high as the typical semi.

Inside the cab, the driver would command the truck using a yoke, and GM teased a future where the driver would be able to make phone calls right there from the center console. GM talked about how the truck would have a powerful HVAC system to overcome that expansive greenhouse, but curiously missing from the concept was any place for the trucker to sleep. If something like this were ever made real, the truck would have been a day cab rig.

While the futuristic and aerodynamic body was plenty weird, the real madness happened in the pods just behind the cab. General Motors claimed that the Bison could be powered by two, perhaps hypothetical, drivetrains. The official setup for the concept truck was power coming from a GT-309 turbine. By this time, GM’s turbine development had entered its fifth generation, and production had been transferred from GM Research to the Allison division.

The GT-309 was a development that started with the GT-302. In this guise, it made 280 HP and 875 lb-ft of torque. The turbine was tweaked for truck duty by gearing down the turbine shaft speed of 30,480 RPM to an output shaft speed of no more than 3600 RPM, perfect for hauling. Likewise, GM recognized one big problem with turbines, and it’s the fact that they cannot provide engine braking.

The GT-309 compensated for this with what GM called the Power Transfer. How this worked was that the system pulled excess power from the gasifier compressor and directed it to a clutch on the main rotor’s output shaft. This helped with acceleration and with fuel economy, but most importantly for GM, it also allowed for the turbine truck to have engine braking. GM claimed that the Power Transfer’s engine braking effect was up to three times of that provided by a piston engine, including the engine braking provided by a diesel’s exhaust brake.

Meanwhile, the GT-309 had an exhaust regenerator system that allegedly captured more than 90 percent of the recoverable energy from the turbine’s exhaust heat. This improved fuel economy, but also brought exhaust temperatures down from over 1,000 degrees to under 500 degrees. In theory, this would be a pretty big deal for the Bison since the trailer would hook up directly behind the turbines, and the exhaust blast was pretty close by.

Speaking of the trailer, GM correctly predicted a future where there would be standardized container freight pulled by semi-trucks, and the trailer hooked up to the Bison for photo opportunities reflected that. The trailer allowed for the insertion of a standardized eight-foot by eight-foot cargo container. These containers were stackable, adding up to lengths from 10 feet to 40 feet.

Even the maneuvering system was pretty weird. The GM Bison featured four-wheel-steering with four different modes. One mode permitted typical operation, where the front wheels turned with the truck. Another mode allowed for tight turning by turning the front and rear wheels opposite of each other, like a car with four-wheel-steering would have. A third steering method involved locking the trailer’s fifth wheel, keeping the trailer straight, and then turning all four wheels with each other, creating a straight truck. Finally, the last method for turning the wheels involved turning only the rear wheels, and this was meant to help with hitching onto the trailer.

For suspension, the truck used an air and oil setup that was bolstered with a pair of jacks between the rear axles and a sanding system for low-traction situations.

Getting back to the motive power, the GM Bison was also said to have a second turbine. However, no details were given about this engine other than an output of 720 HP. Supposedly, this second engine would spool up for accelerating, hill climbs, and for pulling really heavy loads. Given the lack of details about this engine, it’s entirely possible that it didn’t exist.

This theory is bolstered by another claim made by GM that the truck could also be a series hybrid. Apparently, the turbines would act like generators for electric motors attached to the truck and trailer, not unlike how a diesel-electric locomotive works, or how Union Pacific’s Gas Turbine-Electric Locomotive worked, for that matter.

What was clear, Hagerty writes, was that the Bison wasn’t a functional concept. It didn’t actually drive and had to be pushed to where GM took photos of it. That’s a bummer, but thankfully, General Motors wasn’t done with turbine experiments just yet. Only a year later, Chevrolet launched the Turbo-Titan III, a GT-309 turbine-powered semi-truck that was both functional and a lot more realistic than the Moon rover-like Bison.

A Turbine Titan

Chevy said that the Turbo-Titan III was created after the previous two prototypes had successfully racked up “many thousands” of highway miles in testing. Now, it was time for Chevy to show off something futuristic and glamorous. According to the truck’s marketing, Chevy started with the superstructure and frame of its existing cabover semi-tractor, then formed a body of fiberglass and steel on top of it. The snazzy bodywork featured stylish intakes for the turbine and lighting elements that retracted into the bodywork when not in use. On the back of the truck was a beautiful trailer made out of stainless steel.

The GT-309 turbine made a return in this truck, and it was still making 280 HP and 875 lb-ft of torque. GM described how it worked in this truck:

Gasifier section-This portion of the turbine engine is primarily a hot air producer, responsible for generating the enormous blast of hot high-velocity gases needed to drive a power turbine. Consisting of compressor, burner and gasifier turbine, it is comparable to an aircraft turbojet engine. When revved to about 15,000 rpm with fuel and ignition on, gasifier operation becomes self-sustaining.

Output section-Adjacent, but not connected, to the gasifier turbine, and taking the full blast of hot air from it, is the power turbine wheel, operating at speeds ranging from stall to about 35,000 rpm. A reduction gear train cuts this to the 4000-rpm output peaking speed, and multiplies the torque accordingly. Peak torque is developed when the power turbine is stalled–875 lbs.-ft. of it to get even heaviest loads moving.

Regenerator – The key to really efficient gas turbine operation is regeneration-the salvaging of heat energy from the exhaust gases and transferring it to the incoming air stream, to minimize the fuel required for heating the incoming air. Also, the regenerator effectively muffles turbine noise, making further silencing by muffler completely unnecessary.

Power transfer-Under most operating conditions, extra power is available from the gasifier turbine in excess of that required to run the compressor. The GT-309 design incorporates a power transfer system whereby a portion of the gasifier turbine output can be fed into the output gear train to supplement the power turbine. Performance and efficiency are thus improved without size or weight penalties; and with power transfer engaged during deceleration, engine braking is two to three times as effective as that of a piston engine.

Power was routed to the drive wheels through an Allison MT-40 six-speed automatic, but minus the torque converter that it would have in piston applications. This was because the output shaft wasn’t directly connected to the turbine. Thus, the turbine, which idled at 33,000 RPM and was reduced down to about 4,000 RPM, could act as a fluid coupling. The final drive was an Eaton-Hendrickson 34,000-pound dual-drive bogie with spiral-bevel-geared two-speed axles with ratios of 7.17:1 and 9.77:1. The tractor had a gross weight of 48,000 pounds, a combined weight of 76,800 pounds, and stopped using air brakes.

Most of that was pretty normal. Aside from the turbine, the only other weirdness came from the steering, which connected two rotary dials to GM Saginaw power steering units, and the pop-out cab windows. Aside from those, the Turbo-Titan III wasn’t nearly as bombastic as the Bison. Personally, I think it looked way cooler, too.

Beautiful Failures

Unfortunately, there is a reason that none of these turbine trucks never reached production, and it’s largely for the same reason why turbine trains and other land-based turbine vehicles failed. These manufacturers did build reliable and powerful turbines; they even figured out how to get engine braking to work in them, too. But the engineers never defeated the problem of turbines guzzling fuel.

GM said that the Turbo-Titan III consumed fuel at a rate of “0.45 lbs. per horsepower-hour.” Two GM engineers published a paper in SAE International, which stated that the Turbo-Titan III even got the same fuel economy as a diesel at exactly 65 mph. However, fuel economy dipped well into the single digits in any other situation. Sadly, GM also couldn’t figure out how to overcome the high cost of building a turbine engine, either. I didn’t even mention the high pollution of running these turbines, another problem that had fixes, but wasn’t entirely solved.

There was also the inherent throttle behavior of a turbine. These engines take seconds to respond to changes in throttle position. This is a pretty big deal in aviation when a pilot moves from a piston-powered aircraft, whose engines respond immediately to throttle inputs, to a turbine-powered aircraft. Now, imagine waiting seven seconds or so for a turbine to spool while you’re trying to merge onto a highway.

Ultimately, General Motors gave up on its turbine trucks. Instead, its turbine development shifted to buses, where GM would run into another dead end. Ford ran into the same dead ends, too, but the story of Ford’s turbine truck engines will be one for a different day.

It’s not known exactly what happened to GM’s turbine truck prototypes and concept, but it’s believed that none of them were saved from destruction.

What’s wild is that these trucks even existed in the first place. There was a time when the Big Three were all working on revolutionary turbine projects, just like when much of the world was obsessed with Wankel engines. Yet, like the rotary, the turbine had a lot of promise, but a few huge issues that the automakers couldn’t figure out. Still, it’s impressive just how far the Big Three came in spending decades and millions of dollars on trying to make turbines work. Perhaps there’s an alternate reality out there where diesel fell by the wayside and the world moves on turbines.

Top Image: GM

I think this is another case of why moving away from traditional ICE engines was so difficult. Things like turbines and Wankel engines had many drawbacks, but no more than when piston engines were invented. I imagine none of the drawbacks were that insurmountable either, but the sheer amount of development and adoption required to hone them into competitive power units was too much. This is why electric motive power will win, as it is used for countless other non-automotive uses, and it is far simpler than any ICE, meaning development is far swifter.

All that amazing tech and they used a floor mounted high beam switch…

Mercedes continues to amaze me with her deep dives into transport oddities. Great article! Could have been helped with captions on the photos as I can’t keep my Firebirds straight.

When I first moved to Christchurch NZ in the early oughts there was a free turbine-powered shuttle bus that went up and down the main city street. Can’t recall the brand (only the body maker, Designline) but I believe it was turbine/electric. Very distinctive turbine sound – not loud, but I didn’t care for it. I’m pretty glad turbines didn’t become a thing for wheeled transportation as I think a city full of spinning turbines would have been unbearable.

Oh look, it’s got its own Wikipedia page: https://en.m.wikipedia.org/wiki/The_Shuttle_(bus)

Crumple zone? You, dear driver, are the crumple zone!

Just lock your knees to offer some more cab rigidity.

The beloved VW Bus?

“…and then Mercedes purchased one to pull her RV.”

GM Allison installed gas turbines in conventional looking semi-tractors in the 1970’s. They where akin to turboprop engines, except for a large honeycomb heat exchanger to improve fuel efficiency. This effort appeared to have DOE funding, and the funding must have dried up.

These turbines probably consumed double digits MPG more than you think: 0.2 miles per gallon going up hills with a full load.

Yeah, I think think only load they could pull was their fuel tank :D.

But very cool looking anyho.