If you’ve boarded pretty much any commercial aircraft in America or really in most parts of the world, you got to witness something special and might not have realized it. When the cabin door is closed and your aircraft is getting ready to depart, a truck hooks up to the front of the aircraft and pushes it back from the gate or parking stall. It’s a process so seamless that you probably don’t even think about it. These trucks are known as aircraft tugs, and they’re highly specialized vehicles that use clever engineering to make moving a plane around pretty carefree.

The business of moving an aircraft is a surprisingly large one. The smallest aircraft, like ultralights, light sport aircraft, and classics like the Cessna 150 could be moved on flat paved ground with little more than your own two hands and legs. However, as the Aircraft Owners and Pilots Association notes, airplanes can get deceptively heavy for a single person, and it can go downhill the second that you encounter a slope.

That’s where a tug comes in. The most basic aircraft tugs are little more than towbars with lawnmower engines that hook to the front or rear of a small plane. Some of these towbars are so basic that they’re powered by an electric drill that drives a wheel. Amazingly, a power drill-driven tug can move a 3,600-pound aircraft. An aircraft owner might even purchase a motorized tug that’s radio-controlled, turning the process of moving a plane into a giant RC car. Yes, it’s exactly as crazy as you’re thinking:

However, the extremely common way to move planes involves hopping into a tow vehicle, hooking up to a plane, and just towing it to where you need to put it. My local small public airport, Galt Airport (10C), uses a utility golf cart attached to a towbar to move planes around.

Realistically, just about any vehicle that can connect to the towbar can do this job. In the case of Galt Airport, the cart is most often used to move aircraft like the on-site flight school’s fleet of Cessna 172M Skyhawks around.

These are planes that, at their maximum gross weight, are only 2,300 pounds. The 172 also rolls on the ground on a trio of small, smooth tires, so there isn’t a ton of rolling resistance, either.

Where things get really crazy is when it comes time to move a much larger commercial aircraft, and that’s where the ridiculously awesome trucks come in.

The Art Of Reversing A Plane

Technically, turbine aircraft can have the ability to do what’s called a “powerback,” which means to use reverse thrust from the aircraft’s engines to pull out of the gate.

As an airline captain writing for USA Today reported, it was common for rear-engine airliners of the 1980s like the Boeing 727, McDonnell Douglas DC-9, McDonnell Douglas MD-80, and their derivatives to powerback from the gate. Doing so reduced the number of ground personnel and equipment at the gate. Check out this MD-80 powering back from a gate:

However, using the aircraft’s engines to reverse out of a gate has its drawbacks. Using the engines to reverse wastes fuel and exposes the engines to the risk of ingesting debris, causing potential foreign object damage. A powerback procedure is also quite loud, and since pilots don’t exactly have rearview mirrors, they would ideally want a spotter to make sure the plane doesn’t reverse into anything. As the Aviation Safety Reporting System notes, powerbacks also carried additional risk because jet blast is so strong that it could blow over trucks, break windows, injure people, and send unsecured baggage carts careening away.

A lot of the time, powerback procedures are prohibited, so in the vast majority of cases, a tug will move an aircraft if it needs to reverse. It is possible to see a pilot reverse a plane today (check the video below), but it’s not nearly as common as it used to be.

A Boeing 747-8 weighs 485,300 pounds when empty and has 16 large tires on its main gear. A narrowbody, like the Airbus A321neo, still weighs 109,700 pounds empty and rolls on six tires. However, towing these planes might not work as you think, and I have a perfect example of why.

Automakers love performing marketing stunts by making their trucks and SUVs tow a large airliner or a heavy train. Perhaps the most famous example of this is the stunt that Volkswagen pulled in 2006 by making a Volkswagen Touareg V10 TDI pull a Boeing 747. On the surface, this seemed impressive because the mid-size Touareg had pulled an aircraft that, as we established above, weighed a mind-boggling amount of pounds. Then there’s the visual of the comparatively tiny SUV pulling the massive plane.

That marketing stunt is part of why the Touareg V10 TDI became my dream car. But as an adult, I noticed something interesting about the stunt. According to VW, here’s how it achieved the famous tow:

The vehicle was a standard production Touareg fitted with a special towing adaptor to connect it with the aircraft towing link and loaded with 4.3 tonnes of metal ballast to bring its total weight to just over seven tonnes (7,030 kg) including the driver, an engineer from the technical department at the company’s headquarters in Germany.

The car’s engine, self-levelling air suspension, wheels, tyres and structure were all standard.

This was illuminating. This wasn’t a normal Volkswagen Touareg V10 TDI, but one that had an extra 4.3 metric tonnes of ballast added to it. Why did Volkswagen make it heavier?

The process of moving an aircraft doesn’t involve a vehicle that moves every single pound. The Touareg doesn’t need to tow over 400,000 pounds in order to move a Boeing 747, but only a fraction of the total weight. Weight, rolling resistance, slope, and surface conditions all play a role, with rolling resistance mattering more than just weight. In order to get the aircraft to move, the tow vehicle has to overcome the initial rolling resistance of the tires. Once you get the tires moving, the aircraft becomes easier to roll.

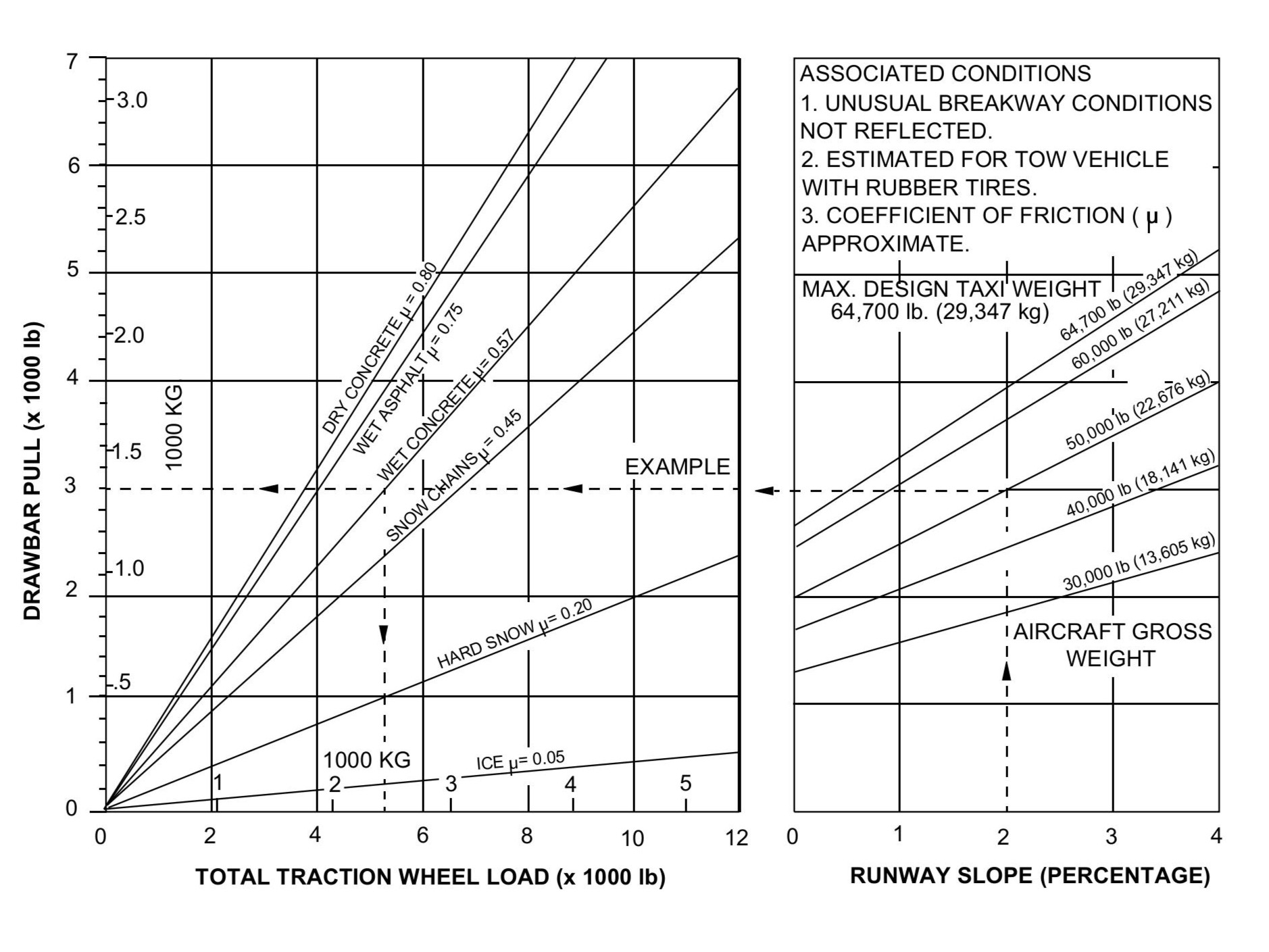

Aircraft manufacturers publish charts detailing how much force it would take to tow their planes under certain conditions. For example, here’s a chart from Bombardier Aerospace for the De Havilland Canada Dash 8-400, also known as the Q400.

Bombardier helpfully explains what you’re looking at:

At an aircraft gross weight of 50,000 lb (22,676 kg), an uphill slope of 2 % and with a wet concrete surface, the corresponding draw bar pull or push required is 3,000 lb (1,360 kg) and the total traction wheel load is 5,250 lb (2,381 kg).

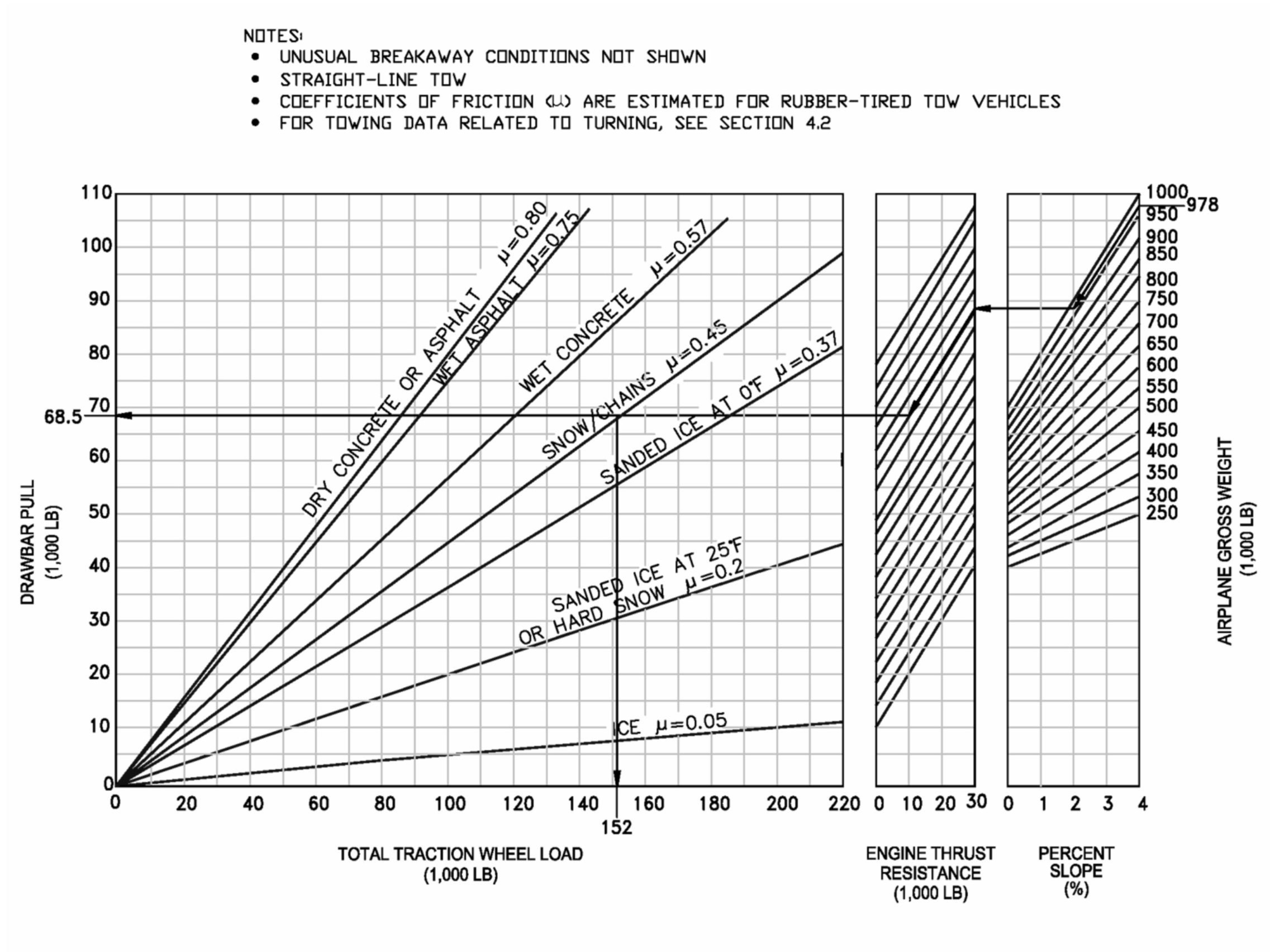

In other words, in the case of the Q400, the tow vehicle needs to exert only a few thousand pounds or so, not the full 50,000-pound weight of the aircraft. Here’s a similar chart for the Boeing 747-8.

The tow vehicle needs to be able to put that power to the ground. In the case of the Volkswagen Touareg V10 TDI, since it’s a passenger vehicle that wasn’t designed to tow widebody airliners, it’s light enough that it would spin its tires before putting down enough of a drawbar pull to move the Boeing 747. So, Volkswagen added enough ballast to keep the SUV’s tires planted.

This is why a few dozen people can move a large aircraft with a rope or why one man can move an entire school bus with only his teeth. These people aren’t moving all of the weight, but overcoming rolling resistance and our old friend, gravity.

So now that you have a good idea of how towing a plane works, let’s look at the specialized vehicles that are designed to tow aircraft.

Big Tow

As Simply Flying writes, some of the earliest aircraft tugs were just basic farm tractors. If you couldn’t move an aircraft by hand, you just hooked a tractor up to the aircraft and moved it. This made sense because early airfields were situated on farmland, where farmers were happy to lend their tractors to pioneering aviators.

As the Military Aviation Museum writes, the idea of using a specific vehicle to tow an aircraft really came into its own after the outbreak of World War II. During this time, aircraft production had skyrocketed and there became a need to move all of these planes around. Many of these aircraft were icons like the Douglas DC-3, which you weren’t going to move efficiently without some muscle. There were so many planes that the U.S. military grabbed just about all tow vehicles that it could get its hands on.

Some early aircraft tugs during the 1930s and 1940s were actually tugs designed to tow airline baggage carts and cargo trailers in warehouses. If these tugs were good enough to tow long carts of lumber, a plane shouldn’t have been a big deal, and so the vehicles found their way to airports. David Tracy had covered the history of the baggage tug in the past:

The company that first made those baggage tugs (or towing tractors, or simply “tugs”) is Clark, and like many vehicular outfits in the U.S., it started in Michigan:

From day one, Clark was an industrial machinery company, building the “world’s first internal combustion-powered industrial truck” known as the Tructractor. As you can see in the image above, it was a rear-engine, rear-wheel drive, rear-seat, front-bed flatbed truck.

And believe it or not, only ten years later came the first Clarktor, and it looked much like the luggage tug we all know and love. Yes, in 1927 — almost 100 years ago! Clark Material Handling Company, which now makes mostly Forklifts, describes the first Clarktor, writing:

The Clarktor tow tractor is introduced. The Clarktor was used to pull airplanes and warehouse trailer trains. It was equipped with an electric self-starter, the first industrial truck or tractor to have this feature as standard equipment. The Clarktor remained in production until 1987.

Clark tugs remain in use pretty much everywhere. You’ll find these at small public airports towing around small planes, you’ll find them putting in some work at EAA AirVenture Oshkosh, and you’ll even find aviation enthusiasts driving them around, treating them like heavy golf carts. These tugs join an armada of vehicles known as ground support equipment (GSE), and this category of equipment covers everything from air start units and boarding stairs to refuelers, water trucks, loaders, catering vehicles, de-icing vehicles, and a wide array of other airport vehicles.

David Tracy also explained why these old tugs were good at towing airplanes. Here’s what David said about the Clarktor CT-6 tug:

Also interesting is the answer to the question you were probably all wondering: “What exactly is it about these trucks that makes them good for towing?” The engines are definitely long-stroke, and therefore make good torque. But beyond that, it’s the gearing — and not in the transmission. Check this out:

The transmission’s first gear ratio is a fairly standard 3.7:1, but that rear axle ratio: Wow — 17.311 to 1!

A typical hard-core rock crawler will have maybe a 5.38:1 axle. To have three times that axle ratio is incredible. Combine that with a fluid coupling that reduces shock loads and presumably offers further torque multiplication, and you end up with a low-speed (up to about 15 mph) tugging beast!

Also notable is the tractor’s weight. Having all of that low gearing only goes so far. If the tractor weighs nothing, it’ll just spin its tires. The Clarktor CT-6, which is only 8’4″ inches long, or about six inches shorter than a Smart Fortwo, weighs a hefty 4,700 pounds.

Another early tug that was used in the 1940s was the Ford-Ferguson Moto-Tug, which the Military Aviation Museum says is loosely based on the Ford 9N agricultural tractor.

But what happens when you need to tow something larger? What if you want to push a Boeing 787 Dreamliner back from a gate? Now, we’re getting into tugs built just for the purpose of moving aircraft.

Purpose-Built Tugs

According to Simply Flying, one of the first companies to build tugs specifically for towing planes and baggage carts was French company TracMa. The TracMa looked like the Clark tugs that I mentioned above, but a crucial difference is that they were built specifically for airport use, rather than adapted to airport use. TracMas were known for their powerful diesel engines, but also for their four-wheel-drive systems, which aided in towing aircraft that were getting larger during the rise of commercial aviation.

The TracMa towed and pushed planes through the use of a towbar. One end of the bar connected to the tug, and the other end connected to the nosewheel of the towed aircraft. When the TracMa wasn’t towing planes, this same towbar setup allowed it to haul baggage. This is also exactly how many modern tugs work several decades later.

As Simply Flying notes, TracMa was so successful with its tractor that, at least in Europe, “TracMa” became synonymous with “tractor,” and several GSE were built on the TracMa platform. Tugs were also coming into their own here in America, too. American company Eagle Tugs launched an innovation in 1969 with its Bob Tail. Mercury Ground Support Equipment, a seller of the modern Eagle Tugs Bob Tail, describes its story:

In 1969, the genesis of today’s air cargo industry occurred. Eagle was there to answer the airlines call for an all-weather, high-speed cargo tractor which had not yet been invented. Eagle successfully engineered and developed the Ford F-350 Bob Tail for United Airlines at Detroit Metropolitan Airport. Within two decades, the Eagle Bob Tail had become the narrow and wide-body cargo towing standard used by all North American and British Airlines, and also military GSE. Eagle experienced reduced Bob Tail interest in the mid 1990’s as its customers tried industrial tractors, converted to high speed use, as Bobtail replacements. However, by 2003 the converted industrial tractors had demonstrated a track record of unreliability when compared to the Eagle Bob Tail. Examples of these problems include drive shaft, drive wheel, drive hub and braking issues.

One of the greatest innovations in aircraft tugs happened in 1980 when TracMa, in cooperation with Air France, introduced the first production tug that didn’t require a towbar.

How these tugs work is fascinating. Instead of linking to the aircraft through a towbar, a “towbarless” tug works by driving up to the aircraft and using a hydraulic system to lift the aircraft’s nose wheel up.

By eliminating the towbar, one of these tugs carries several advantages over a typical tug. For one, eliminating the towbar means one fewer pivot point. Instead of steering the aircraft through the towbar, the tug now steers with the aircraft. A towbarless tug has a smaller turn radius and is more stable. The tugs themselves can also be smaller because they don’t need to carry so much weight. Instead, a towbarless tug uses the aircraft itself to add weight. Towbarless tugs are also faster and seen as more efficient, too.

Now, you’re probably wondering how towbarless tugs drive, and I have you covered there, too. An increasing number of these tugs are all-electric. But for ones that do have internal combustion engines, they may use a torque converter automatic transmission or even a hydrostatic transmission that pumps fluid to hydraulic wheel motors. Some other designs are diesel-electric. Yep, these things have four-wheel-drive, too!

Here’s what these machines look like after they’ve gobbled up a plane:

Don’t miss this excellent video showing one of these tugs at work:

Tugs are often classed by the maximum takeoff weight of the aircraft they can tow. A small tug, which might not even have a cabin or a seat, may tow an aircraft with a max takeoff weight of 15,000 pounds. Think of small single-engine piston aircraft or mini jets. A medium tug gets you up to 100,000 pounds, or what a business jet, some small narrowbody airliners, or a turboprop might weigh. Then, you have the tractors designed to carry everything bigger than that.

I’ll give you another example here. The Tug Technologies Corporation, another popular producer of tugs, had the GT-110, which is old by today’s standards. This beast has a gross weight rating of up to 120,000 pounds and can pull 78,000 pounds on the drawbar. That’s why these tugs are so crazy huge. They’re dealing with mind-boggling amounts of weight here.

Yet, their power isn’t even that impressive. One common configuration of the Tug GT-110 has a Cummins QSB6.7 inline-six diesel, good for 275 HP and 728 lb-ft of torque. These are engines that Cummins normally sells for marine use, and are a relative of the B6.7 diesel truck engines. Yep, a common diesel pickup truck makes way more power than an aircraft tug. A more modern tug, like the TLD TMX-650, has weight limits above 150,000 pounds and can punch out 103,000 pounds on the drawbar.

But again, towing an aircraft isn’t so much about throwing horsepower at the situation, but effectively overcoming resistance.

For an example of what a “medium” towbarless tug looks like, you have the cute JETporter JP100s above. Don’t let the little size of this one fool you. It weighs 7,000 pounds and can tow an aircraft up to 100,000 pounds using a pair of 10 HP DC electric motors.

The art of moving a plane is almost as fascinating as the engineering put into the aircraft themselves. It’s fascinating that the aircraft tug gets so simple that you can buy one that’s basically just a power-drill-driven wheel. But then, they also get so complex that they have hydraulic transmissions and, when loaded, weigh tens of thousands of pounds more than the typical loaded semi-tractor.

But now you know why the trucks that push aircraft back from airport gates are so weird. They’re built to carry some ridiculous weight and weigh a lot themselves, so they can lay down some serious traction.

The crazy part is that the aircraft tug is only one of countless different ground support equipment that you might see in an airport. Large airports basically operate like their own little cities, and your next flight wouldn’t go nearly as smoothly if it weren’t for the army of airport workers and vehicles that, somehow, keep the world of aviation flying.

The other issue with powerback is that the engine ingests the hot exhaust gas increasing the turbine temperature.

When I worked for Garrett aircraft engines I worked in certification testing. One of those was the certification of thrust reversers for a new design engine. A long metal tube was attached to the inlet of the engine, so the thrust reversers could be deployed for long periods of time while keeping the engine from ingesting hot exhaust gas. Amazing to watch those clamshell doors being battered around while the engine was at high thrust settings to test the long term durability.

In the USAF we used Coleman MB4 tugs with 4 wheel steering. The mark of a good tug driver was the skill to back a fighter into a shelter in one shot. Newbies would weave all over, chasing the nose wheel.

Mercedes’s Friday deep dives are always a great way to end the week a little smarter about something you never knew you needed to know.

The Wheel Horse company, builder of garden tractors, turned their tractor platform into a towbarless tug by mounting the articulating tug assembly to the back of the tractor and connecting it to the steering mechanism. The front axle was removed and the operator sat backwards on a cushion atop the hood of the tractor, and the whole thing moved and operated in reverse compared to a “normal” tractor. It looked odd, but it was one of the smallest and least expensive towbarless tugs made at the time, which made it rather innovative.

Everything worked off of the tractors’ hydraulic pump which ran its hydrostatic drive.

https://www.youtube.com/watch?v=u_GgXYvgmbE&t=33s

Mercedes, I invite you to go down the rabbit hole of Wheel Horse. 🙂 They had a hand in originating the small garden tractor, and once they refined their design by the early 1970s, they pretty much built them the same way into the 1990s. Remarkably heavy-duty little machines, and engineered with a sort of straightforward simplicity that largely disappeared in other manufacturer’s offerings during their run.

They company also had an aviation connection beyond their tug design — the company’s business plane fleet and aviation involvement grew by buying Skystream, a local Cessna dealer, flight-training and aviation services company that also flew regional commuter routes from its hub in South Bend, Indiana. They went on to fly various early business jets and turboprops, including a number of Beechcraft 99s in a pink-striped livery. Somewhere I read that they actively recruited women as pilots, a very progressive effort in a very male-dominated industry at the time.

I remember the days when planes would still powerback from the gate with the reverse thrusters at certain airports. It was always fascinating to watch what would get kicked up and if nearby luggage carts would get blown away. The tugs are definitely safer all around, but they can’t match the surreal silliness of watching a luggage cart go rolling off on its own with ground crew chasing after it…

As for the tugs, gear reduction is a magnificent thing. I may be an electrical engineer by trade, but I have worked at enough industrial facilities to appreciate just how impressive torque multiplication can be. Very neat article.

The few times I’ve experienced a “power back” were really cool.

I imagine there’s also a certain number of times they can cycle the thrust reversers before they need to be serviced. Looks like a pretty high stress component.

I love that there is a place on the internet where I can read about tail lights and airline tug trucks.

Most impressive that they loaded the Touareg with 7 Tonnes and, with stock suspension kit, it still looks level & composed.

I doubt an F150s would look as good with an added 7t in it.

I doubt they chucked it in the cargo area and called it a day, the weight needs to be even distributed for traction as well as looking good for the commercial.

Probably had weights on the seats/in the footwells

And it still weighed less than an M5. Just kidding, I think…?

No love for the Jeep CJ-10A tug?

David must be supremely disappointed.

Mercedes! I am very disappointed in you- if you are going to be a proper pilot, you have to know the proper pilot terminology. Precisely no one in aviation refers to them as “towbarless tugs”. They are always called “nose pickers.”

Great article, Thanks, Will you be covering other airport vehicles in future ? Those fire engines they have look cool.

I second Mark’s motion for more GSE content! It’s actually a surprise that one of those bobtails hasn’t already ended up in your fleet, Mercedes. Also, those airstairs have been in a curiously large number of movie pursuit scenes!

Watch out for bridges and hop-ons. You’re going to get some hop-ons.

As a kid growing up on SAC bases in the late 60’s and early 70s, I recall the chunky MB-4 tugs and super-short wheelbase Ford trucks out on the flightlines handling the B52s and KC-135s.

Then there were the enormous (at least to my kid-scale mind) snowplows for northern-tier bases that would clear the runways, come and clear the streets in base housing till they’d get called back to clear the runways again, then come back and clear more streets…

The other cool “small things that move big things” are the mules at the Panama Canal which bring the ships thru the locks…

As a kid growing up on SAC bases in the late 60’s and early 70s, I recall the chunky MB-4 tugs and super-short wheelbase Ford trucks out on the flightlines handling the B52s and KC-135s.

Then there were the enormous (at least to my kid-scale mind) snowplows for northern-tier bases that would clear the runways, come and clear the streets in base housing till they’d get called back to clear the runways again, then come back and clear more streets…

The other cool “small things that move big things” are the mules at the Panama Canal which bring the ships thru the locks. In some ways they’re just as fun to watch as the experience of being aboard a ship which is rising/dropping.

Fun Fact. The “Mules” at the Panama Canal do not tow the ships through the locks. They are there to keep the ship centered between the locks walls as it motors through under its own power. A non trivial task as the ship rises or drops within the lock.

Under the heading of jobs I would not do, is being in the rowboat that carrys messenger lines from shore to the ship. The messenger lines are used to pull the cables from the mules to the ship.

Way back when, they thought planes would get even bigger and overestimated the size of a tug needed to move them.

Hough built some true beasts.

When I worked for Northwest, we still had some Hough T-300s and even a T-500 tug.

The T-500 was a 16v92 Detroit with an air starter. Most of the T-300s were 8v92s or 8v71s, but we had one that still had an old International V8. The T-500 was like 100,000 pounds and in high gear would reach truly terrifying speeds… like 7mph, which feels like a lot in something that heavy with no suspension.

So much fun to drive.

Bobtail truck airport tugs are in the special pantheon of “regular vehicles modified for special purposes that make them look silly”.

Float plane retrieval trucks are another. Not sure what else is out there.

One of the main reasons for the adoption of the hydraulic lift tug is that each aircraft type requires its own towbar if you’re going to use a traditional tug. At larger airports it was not uncommon to be delayed because the ground handlers had run out of 767 towbars or A32x towbars during busy periods for example. There are very few towbars that are common across aircraft types, even with the same manufacturer.

Hydraulic lift tugs get around that. If you want a bit of fun, Google how much just the towbars cost 🙂

Random trivia- when Denver opened their new airport in 1995, all that stuff at the old airport had to make the 20-mile drive to the new airport – https://www.upi.com/Archives/1995/02/27/New-Denver-airport-readied-for-takeoff/5613793861200/

I wonder if they used multiple routes so the specialized equipment wouldn’t slow down those two thousand rental cars from moving as fast as a 19-year-old day hire could flog a Chevy Corsica Or Similar before vanpooling back for another.

And, in the interest of absolutely nerd-sniping the shit out of someone here: https://www.allsurplus.com/en/asset/127/27056

The auction post reads, “Does not run, condition poor, ‘electrical wire fire.’” This has David Tracy + Notorious S.W.G. collaboration written all over it.

“I have 3 weeks to rewire a 100,000 lb non-running airport tug and drive it to my daughter’s daycare to use as a mobile bounce house!”

Can I pick it up w/ my F-150 and a Hertz rental car trailer?

There’s something genuinely heartwarming about how many absolutely niche videos exist on YouTube – it makes me feel good about humanity that someone was so interested in this that they filmed it and uploaded it, and that not just one person but thousands have done so. It speaks well of us that that’s true about just about any random thing at all that you can think of.

We can only hope that it all stays available.

During WWII thu US also used tracked tugs, which were closely related to bulldozers. I’ve see one in a museum in the PNW

Where? I need to see this.

I think it’s the,Erickson museum in Madras, since that’s the last one I visited

I seem to remember seeing remote-controlled towbarless tugs being used at Heathrow in 2019 for some pretty big aircraft. Anyone know if that has become more widespread?

As I recall, the APC in the movie Aliens was a modified tug. So, there’s that.

That’s the biggest reason I get excited whenever I see a GT-110 (thank you Mercedes for telling me what they’re actually called) working at the airport.

The combination of low slung and truck seems so futuristic, like this configuration will be important for manipulating tech we can’t even imagine yet. Or dealing with hostile lifeforms.

In GTA5, the airport pushback tractor is called the ‘Ripley’, as a little in-joke.